Leaderboard

Popular Content

Showing content with the highest reputation on 02/10/25 in all areas

-

As here the conversation is about matching hairsprings/balances in russian watches, I have some information that will help to understand what is happening. The supplier of material for hairsprings is only one for USSR/Russia watch factories and they are not able to reproduce it with small enough tolerances. The batches of coils with the profiled wire (may be it is called ribbon or tape?) every time have slightly different thickness and other parameters. The hairsprings always are produced from the wire with same shape - length, diameter, number of coils and angle between beginning/end. Thus, when the wire parameters change with the next batch, the 'strength' of the new hairsprings changes too. To solve this problem, the balance wheels are turned with different moment of inertia to meat the different hairsprings strength for every new batch. Further, within every batch, the hairspring manufactured are tested and separated to 20 groups of strength, the balances again separated in 20 groups of moment of inertia and every group of hairsprings is matched to related group of balances. As the balance wheels are easier to manufacture with desired and predictable parameters, and the hairsprings is harder to make with desired strength, they first make the hairsprings with whatever strength will be and then make balance wheels to match the hairsprings.5 points

-

4 points

-

If the barrel is really moving, then the rivetting of the center pinion to center wheel has given up (could be the third wheel/pinion, but would be strange). Usually this is a dramatic thing and you can't wind any real tension on the spring without the pinion slipping in the wheel, so a little odd in your case. Basically, the barrel can only move as much as the escapement allows it to move; if it moves more, then something is slipping in the gear train.4 points

-

Like most other technologies. We had a mass school shooting in Sweden the other day and now our politicians are seriously discussing restrictions for licensed hunters to own hunting weapons. The shooter happened to have licenses for hunting weapons. Like with all other technologies it seems the problem is always with the technology in itself. I guess I must be stupid as I always thought it was the use of the technology that was the problem. But what do I know. I’m not a politician. In this context I saw a pretty interesting sign. It read: ”If guns kill people, pencils misspell words, cars drive drunk, and spoons make people fat”.3 points

-

Interesting insight to the manufacturing process. 1min / day would be ok. I'm seeing over 40min / day. That would be an explanation. I don't know exactly, but the two movements may be a decade apart. ANYWAY, I'll find out: 1. I'll put in a balance complete from another 2414 that I have. If that solves it, we know for sure. 2. I also still have the matching hairspring to this balance wheel. It needs quite a bit of bending back into shape. Well, more practice to be gained!3 points

-

2 points

-

2 points

-

First thing would be to check the hands against the lens. Is there no holding ring for the movement?2 points

-

From a personal perspective I am retired like many here, to be fair though I started off in electronics and moved into IT where I spent most of my working life. I think that a lot of us are intrigued by how things work which is what tends to bring us into watchmaking. That curiosity often leads us down a path of figuring out how to use and learn about some pretty arcane tools and subsequently how to achieve a repair by improvisation and making tools and parts. I have been lucky enough to be recently gifted a 3d printer and have ideas of where I can make tools, machines and work holding jigs to achieve some of my watchmaker ambitions. I am also working towards getting a small CNC desktop machine if my pension can manage. Something that I find really exciting is electrical discharge machining (EDM) is entering the diy enthusiast phase much as 3d printing did several years ago. It would be absolutely fascinating as an amateur watchmaker to combine traditional lathe work, CNC, 3d printing and EDM in a home workshop, the possibilities are staggering in my opinion. Tom2 points

-

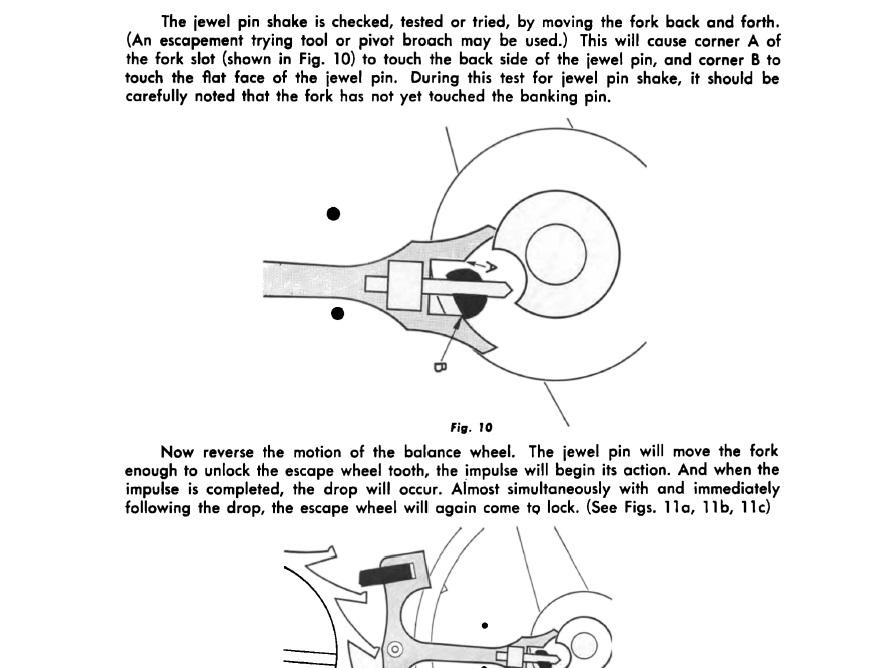

That's right. You might see in old texts mention of "corner test"; this is checking safe lock at the moment of drop lock (and that the roller is free to continue its course), but the roller jewel is still pretty much "in" the fork slot. It's also something to check, but doing the fork horn test covers it in 99.999% of cases. The fork horn clearance should be slightly larger than the guard pin clearance, so if it's good the other is too (but you still have to check to be sure guard pin clearance is smaller). I think the most comprehensive escapement set-up description I've done is here: This is a nice description of the "corner test" from the Joseph Bulova School of Watchmaking course, page 250 Here's an image showing the guard pin taking over the safety action. It's a smaller clearance for two reasons: the guard pin has less contact (friction) than the fork horns, and, depending on the horn shape, if the guard pin clearance is larger than the horn clearance, the roller jewel can hit the outside of the horn, possibly stopping the watch.2 points

-

You're welcome. PS: as you can see, it's always helpful to post information on the watch and movement in the initial post. I could have given you the right answer immediately.2 points

-

2 points

-

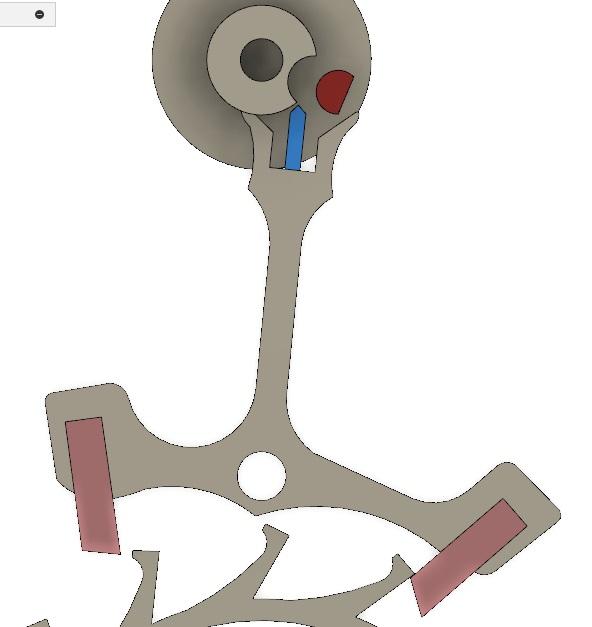

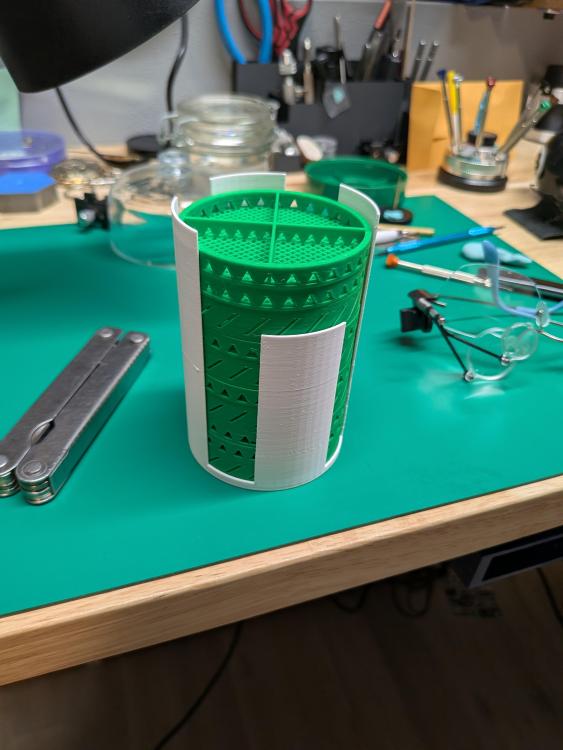

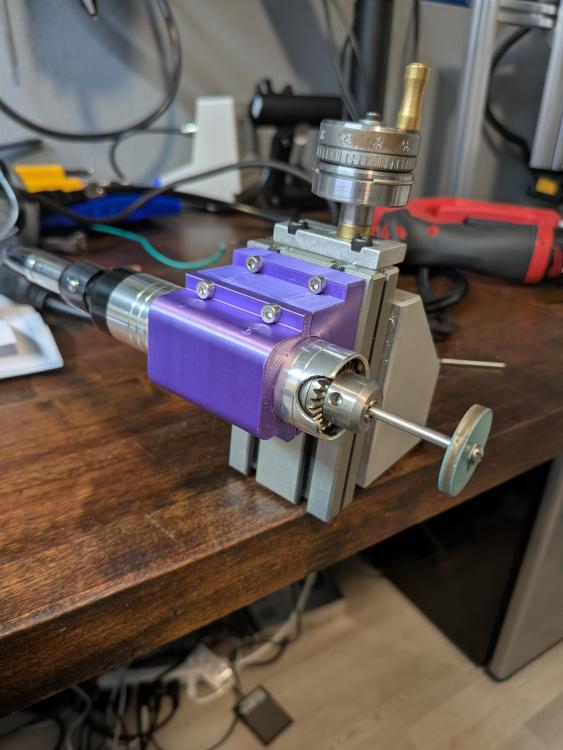

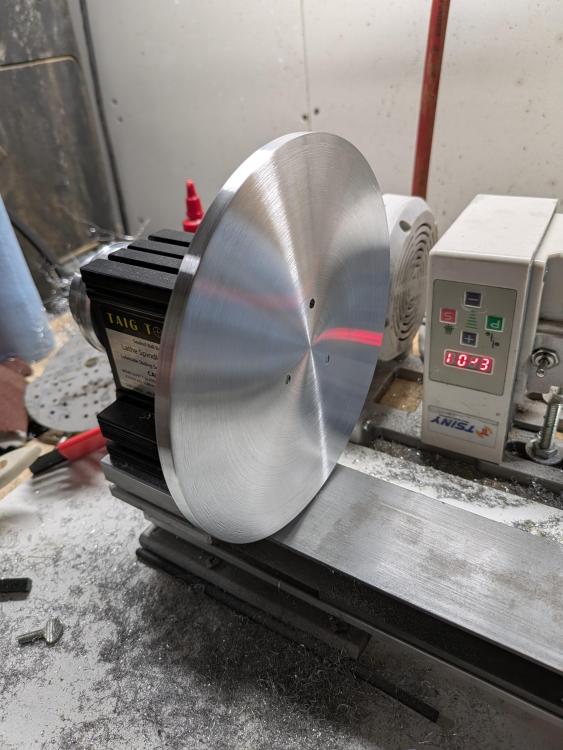

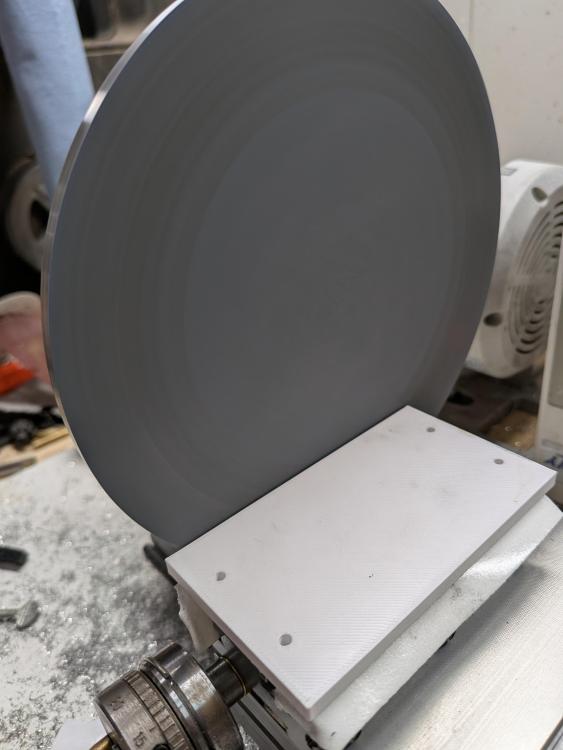

I figured I should actually post my tool builds here. I like making tools almost as much as I like watchmaking. I'll post new tools I make below and label them. First up, my cleaning machine. You can see my other post on it. Next up. Some parts I make for the cleaning machine. Baskets and such. Then I made a toolpost grinder setup for my flex tool. This will be used for precision grinding, and also for wheel and pinion cutting. Then we have the lapping table for the lathe. The is a simple build. Next is a 2 axis polishing vise. I'll add more later on1 point

-

1 point

-

Yes I believe there is quite a movement of all sorts of nifty DIY EDM. Then of course we throw in all the nifty other stuff we have? Typically we would think of things like why are EDM and somewhere I've seen where someone had a C NCE wire version that they had made. On the other hand you may be able to do something really clever like almost making a EDM milling machine. In other words you could have the cutter slowly moving downwards so it's nice and fresh but not have to have a spool of wire. Which might make things easier to make perhaps. Then of course the really nice thing with EDM is the metal can be at the proper hardness. Which works out really nicely when you're making really delicate Springs as you wouldn't have to harden afterwards. You may be able to get away with something with less power perhaps. I recently saw or someone send me an advertisement for a I reasonably sure it wasn't 50 W and it was cutting into metal. So conceivably you'd have to make lots and lots of passes. I don't think for the dial printing that the cuts have to be very deep. Plus if you were going to settle for something other than steel it probably use other materials that might cut easier perhaps. On the other hand think of all the fun you could do with 50 W as you can do a heck of a lot of metal cutting. Oh and there's other fun things you can do with your fiber laser like suppose you need a square hole in a mainspring? Yes a case I need a square hole in something and where I work we do have a 50 W fiber laser. Along with a CO2 laser and a diamond tip engraving machine which also has a rotary cutter that they typically almost never use.1 point

-

One day I was curious and looked up something and found a really interesting website out there. Can't quite remember how they did this but basically they were looking at how people died. So for instance there appears to be a perception by the rest of the world that the USA is a wild West everybody carries guns and we have shootouts on our streets on a continuous basis. Or basically the number one way of being killed in this country would be with a gun. So the website basically looked at how people died and made an interesting conclusion. So the simplistic was it's easy to point a finger at somebody died from a gun. Is not so easy to look at non-natural deaths that are achieving the exact same desire of terminating somebody else. West I think going so far as to suggest that non-natural Deaths might actually occur at a higher rate then if you had access to guns. Or basically a lot harder to track. The problem with politicians are they are not very bright and they always take the easy way to do things. So guns are bad if they go away bad things will not occur. Versus some way of spotting when individual or individuals are plotting to do bad things. Often times after bad things occurred and things are being investigated there were indications sometimes that something bad was going to occur and nobody was paying attention. But these solution is to make the bad gun Galway and the problem solved. Or basically politicians will do what they do best which is to make life unpleasant for the rest of us and no We are not going to feel more safe with what they're doing typically.1 point

-

Technically kills no-one, we do. We've been doing it since we appeared as as species and unfortunately will will carry on as long as we exist.1 point

-

1 point

-

1 point

-

That is not the makers name but the shops name that sold it. If I can see the back plate it might have something also can I see the platform as well.1 point

-

Landeron 48. Missing intermediate chrono wheel and it's cock, also the eccentric for depthing the wheel. Ups, the cock is here but not in place.1 point

-

1 point

-

1 point

-

Not so fast. While @Knebo is most likely correct, I would point out that this only secures the movement to the movement ring. There are a few more considerations. How is the ring secured to the case? Sometimes there are case clamps that secure the ring to the case so that these shouldered screws are enough to hold the movement to the ring. Sometimes there is a plastic case ring that holds the ring to the case when the case back is tightened down. Sometimes there is a long case clamp that goes across the ring to the case itself. Like this Longines ... If there is no plastic retaining ring or case clamps for the movement ring, then the stem is the only thing holding the movement and dial in the proper position. If you assemble the watch without the case clamps and you pull out the stem and can make the movement and dial move by wiggling the crown, then I'd say the clamps would be a good idea, although it's odd to see shouldered screws used with case clamps. It's usually one or the other. The other thing to consider, especially with a 2824 or SW200 is the height of the screw head and clamp thickness. If the clamp is too thick and the head is too tall, it could easily interfere with the rotor.1 point

-

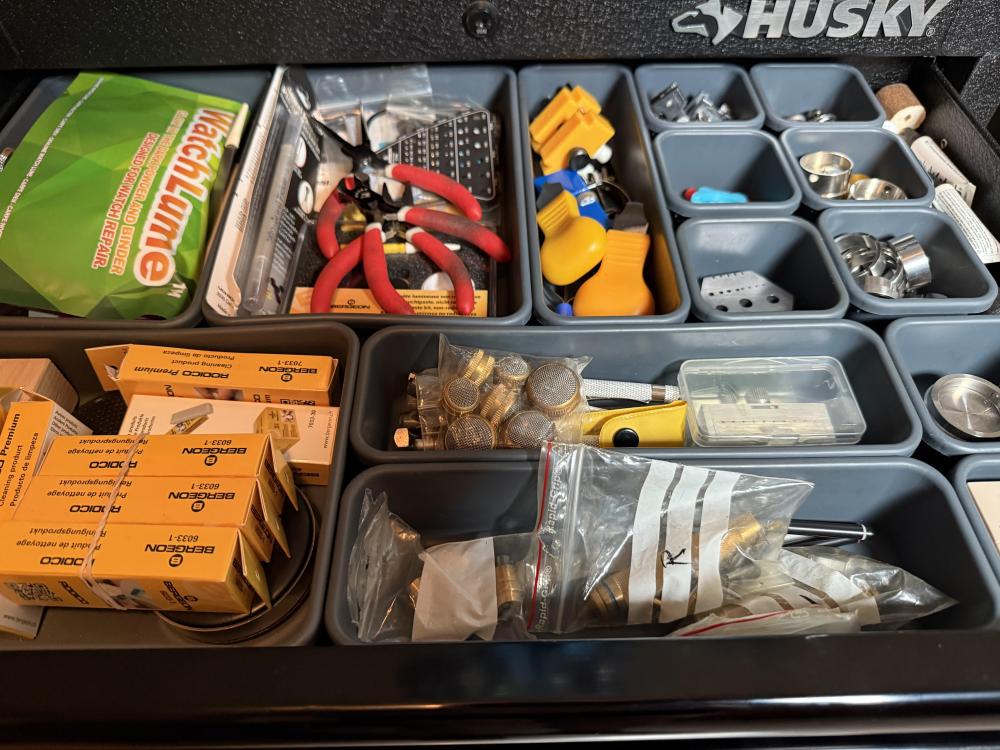

I found a bargain on a small roll around tool box that was short enough to slide underneath my work bench (to my left). While not perfect, I found these simple drawer organizers on Amazon. I still need to rearrange a few things, but it has made these large drawers quite handy to store small tools and other items. https://www.amazon.com/dp/B0BLC4SW8J/ref=dp_iou_view_item?ie=UTF8&th=11 point

-

Something has to be getting added friction somehow from the caseback then. The cock that overlaps the balance perhaps? Tom1 point

-

For small parts and bits and pieces I use artist pastel boxes. You can find them on almost any art supply site or, depending on how much you want to contribute to Bezos' newest yacht, that South American river store. I have also taken a platform for a coffee maker and put a pad on top, a 3-D printed screwdriver holder on the left (I'm left-handed) and my oil cups on the right. I use the k-cup drawers for frequently used tools and oils. It's a very nice work platform. I'll take some pictures of the actual setup when I get home from work ... assuming I remember, which has become more of a challenge lately.1 point

-

For small items, you want shallow trays, reaching onto deep trays is a pain.1 point

-

If you have access to a 3d printer have a look at the gridfinity system for drawer organisation. Tom1 point

-

No Andy, there is a diy movement for EDM cutting and boring. I can imagine where someone has the, I think best fit book where the keyless works parts are life size being able to digitise those and cut from the appropriate thickness spring steel. Another place it would potentially be useful is shaping HSS cutters for the lathe at small scales. I am not sure the cutter wire will be small enough to make watch wheels and pinions for a while but clocks it should be there now. i also should have added a fibre laser in the 50 watt range to my dream list for various things but definitely making dials and also cliches for pad printing. a man’s gotta dream, especially where tools/toys are concerned. Tom1 point

-

1 point

-

I'm in two minds about AI's abilities to write code. It tends, currently to write code that is the programming equivalent of that bizarre "curb pins" watch drawing. What it boils down to is the inescapable fact that AI has no ability to comprehend the real world. It is debatable whether it ever will. Don't get me wrong, ChatGPT and its pals write code. They can write it in pretty much any language, and they can write it quickly. However they need a lot of prompting to make the code actually functional. In that respect they are both good and bad at the same time. If you need a framework written quickly for a well defined problem, then AI can, to some extent, do that. You still need to go through the iterative process of refining the code to make it actually work. In other words the AI doesn't (yet?) have the ability to do this, so it is still down to the porridge between your ears to get things to function, and probably always will be. Will I be out of a job any day soon, as a result of advance in AI? Probably not. Will over reliance on AI be the cause of problems in the future? Probably. Will AI, on balance, be a benefit or a hindrance to us? I suggest AI is a tool. It is not the only tool in the toolbox, and it is a relatively narrow use tool. Whether it is a net benefit to the human race, all rather depends on what we choose to do with it. It isn't going to do anything we humans don't ask it to do, so if we use it intelligently then it will benefit us. Given the state of the world today, I would say the chances of us using it intelligently are probably about 50-50. In other words, don't give up the day job just yet. Robbie the robot is not about to give us all a life of infinite leisure any day soon.1 point

-

I remember back in 1987 when I first started to learn programming. A friend of mine told me not to put too much time and effort into it as something called AI (Artificial Intelligence) soon, within a year or two would be doing all the programming and I'd be out of work. I've been making a living as a programmer and teaching programming ever since. Now we're clearly in the hype era of AI. I'm old enough to have experienced many hypes and they never delivered what they promised, but I guess this time will be the exception, or!? The "hypes" change our lives, but never as predicted and as fast as expected.1 point

-

1 point

-

I can't picture how the barrel could move with the ratchet wheel unless it is becoming disengaged from the centre wheel. The movement of the barrel is regulated by the train and escapement so while everything is meshing properly it cannot move independently of them. So I would be looking at the barrel end shake and side shake to see if it is possible for the barrel teeth to disengage the centre wheel arbor.1 point

-

you're right, providing more context upfront would have helped me respond you more accurate. i appreciate your insight and will keep it in mind for future conversation. thanks again1 point

-

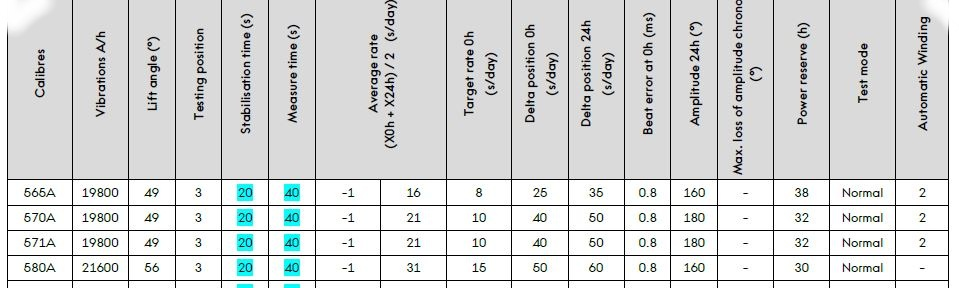

One other thing is when you're learning is not all tweezers are made the same. I think sometimes people struggle with parts flying away with tweezers that are Not really appropriate for watch repair. Why are the results disappointing to you? Oh wait I didn't read the entire quote your hoping for better amplitude okay how much better? One of the problems when measuring things would be what exactly are you supposed to be getting and when exactly should you be getting whatever it is you're supposed to be getting. In other words you're giving us the numbers after a few hours which is not entirely helpful other then yes you do of a problem. Then yes this definitely looks bad it would be really nice to have a picture of the timing machine what does the timing machine look like when it's doing this. Then a procedure would be nice like for instance Omega recommends winding the watch up and waiting a minimum of 30 minutes all the way up to 90 minutes would be considered fully wound up. Then amplitude for the group is well the group will be upset with you. But Omega only cares about the amplitude 24 hours later Which technically translates to 23 1/2 hours up to 25 hours. So in the vertical positions at 24 hours according to specification down below 160° is the minimum which you failed and the timekeeping has to be within specifications. Then yes Omega really does have 160° I know the groups going to fall over and have a heart attack when they see that. Typically watches that do not have longer running times like vintage watches are actually rated the going to lower amplitudes. Sub this watch was supposed to run 48 hours then the amplitude would be much closer to 200° or higher.1 point

-

Thanks for the nice introduction. We look forward to seeing those watches/movements and giving you our best advice. Cheers1 point

-

Not quite sure what you mean as that looks like the clamp under the screw?1 point

-

Looking at the case there's no bezel so it could just push out from the back once the movement has been removed but the correct way is with a crystal lift. I think you'll be lucky to find a #37. Here's one seller I've got marked for Timex, they've not got a #37 but do have some of the PA if you find one of these is correct. Edit Here's the 104 Service Manual showing cleaning procedure as mentioned in the 108 Manual. Lighter fluid can be used as an alternative to watch cleaning fluid and then IPA as a rinse. Model 104 Service Manual.pdf1 point

-

1 point

-

1 point

-

You also made a career of ingesting novel ideas, so taking up new tech in retirement is hardly a surprise. You're hardly the norm.1 point

-

Balance wheels and hairsprings cannot be manufactured to <0.07% tolerance (=1min/day)! So the factory will measure hairspring (elastic moment) and balance wheels (moment of inertia) separate, sort them into classes and combine matching ones. @Knebo mixed parts from different classes and logically got a huge error. Frank1 point

-

Organize? What's that? My bench is "organized" by chronological stratas. If I can remember roughly when I last used a particular tool, I dig down to where the stuff in that layer corresponds to that timeline. I hate it when someone cleans up my stuff. Then I can't find my stuff anymore.1 point

-

Ambitious project, @neevo! Good luck! Yes, just clean as best you can. Ultrasonic is good. Only lubricate with V105, NOT epilame. Rolex reversers need epilame (and no V105), but not these Omega ones. Frankly, I've had lots of bad experiences with several of the generic springs for the 55x Omega series (never had a 56x). I had problems with way-too-large centre coils and springs not actually fitting directly from their ring (i.e. 0.1mm too large..). All solvable issues, but frustrating when you expect plug-and-play. If you have a mainspring winder, reuse the one you have. It looks good. If you don't have a mainspring winder, I suggest buying 2-3 of these springs and see which one works best.1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)