Leaderboard

Popular Content

Showing content with the highest reputation on 02/11/25 in all areas

-

3 points

-

Not used my set that much, but didn't notice any damage, although to be honest I probably didn't look. Will check them for hardness tomorrow and report back.2 points

-

I would love for small scale metal fabrication to reach the level of ease of 3D printing. I just had to pay $20 to get a setting lever shipped from the Netherlands on Ebay, I could remodel that part in Fusion 360 in an hour but have no way to actually make the thing.2 points

-

Oh you probably don't really need to do the barrel with air. Only if you have just reduced the size of the barrel arbor hole. The other wheels should spin with air, the barrel may not easily and in any case the barrel arbor does not move in its pivot holes while the train is unwinding. The barrel rotates around the arbor. The barrel arbor only turns while winding.2 points

-

Hi Joe and thanks for the welcome back ! Hopefully Mark can sort me out. Ive missed being in the asylum with all the other inmates. Thank you again Joe.2 points

-

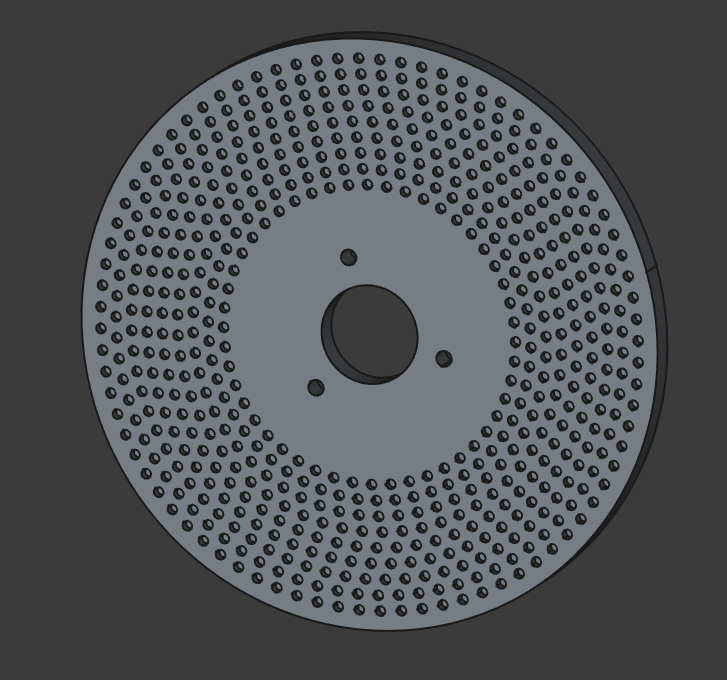

Wow my formatting was no good on the last post. Anyways, here is the latest build. A dividing plate for my lathe. I will print this part shortly, but I need to verify some measurements on my lathe before I do. My CAD software did not love me when I was doing this. Its a fairly easy part to design, just using polar patterns. So far I have settled on the following indexes: 80, 78, 75, 70, 65, 60, 56, 54, & 48. Trying to capture the largest amount of divisions I could. But I can always print another one.2 points

-

Here's the "coffee station" as promised. It elevates it off my drafting table so i don't get any more back and neck issues, and I've attached some flexible LED lights to each side, when the overhead just isn't shining in the right spot. Sorry about all the ancillary clutter but we are getting new carpeting in the upstairs bedrooms and the Mrs has moved all the furniture and knick-knacks into my workspace.2 points

-

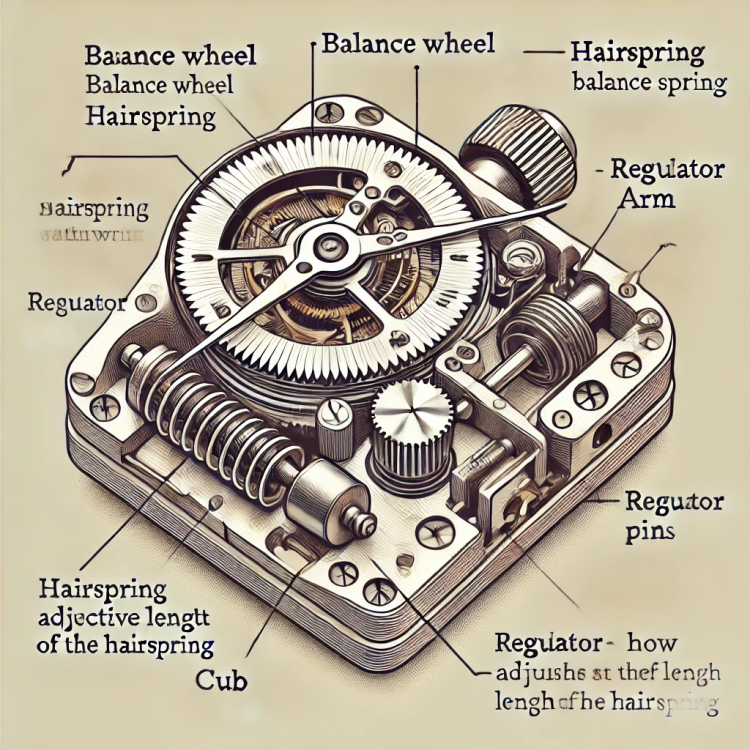

As here the conversation is about matching hairsprings/balances in russian watches, I have some information that will help to understand what is happening. The supplier of material for hairsprings is only one for USSR/Russia watch factories and they are not able to reproduce it with small enough tolerances. The batches of coils with the profiled wire (may be it is called ribbon or tape?) every time have slightly different thickness and other parameters. The hairsprings always are produced from the wire with same shape - length, diameter, number of coils and angle between beginning/end. Thus, when the wire parameters change with the next batch, the 'strength' of the new hairsprings changes too. To solve this problem, the balance wheels are turned with different moment of inertia to meat the different hairsprings strength for every new batch. Further, within every batch, the hairspring manufactured are tested and separated to 20 groups of strength, the balances again separated in 20 groups of moment of inertia and every group of hairsprings is matched to related group of balances. As the balance wheels are easier to manufacture with desired and predictable parameters, and the hairsprings is harder to make with desired strength, they first make the hairsprings with whatever strength will be and then make balance wheels to match the hairsprings.2 points

-

I agree: perhaps 100º amplitude, but a lot less than 180º. That's definitely not overbanking or rebanking and not likely to be an issue with lubrication. Next steps: Determine whether the train runs freely. Let down the mainspring, then remove the balance and pallet and give the barrel a nudge and check that all the train wheels spin. Assuming they do, pay attention not to how well the wheels spin, but to how they stop. The escape wheel should slow steadily and gradually. If it comes to an abrupt stop there is something wrong on the train, such as one or more pivots lacking end shake. If you're not sure, film it and have the experts here cast their eyes over it. Determine whether the balance oscillates freely. Reinstall the pallet cock (but not the pallet fork itself) and the balance, screwing both down securely. Noting the "at rest" position of the spokes on the balance, use an oiler, or an artist's paintbrush, or a toothpick (or some combination of those ... I tend to use a paintbrush in one hand and a toothpick in the other) carefully turn the balance 180º. When you release, count the full oscillations (where a full oscillation is two beats, one clockwise swing and one anticlockwise swing) until the balance comes to a full stop. If you get much less than 100 full oscillations there is an issue with the balance or its pivots. Take lots of pictures including clear views of the hairspring from the side and top. (NB: For an 18000bph watch like the Zaria 2009, 100 full oscillations is 40s of balance movement.) My best guess based on your video is an issue with the balance. I wouldn't be surprised if you only got 20 oscillations out of it before it stopped. But that's really only a hunch and could be totally wrong.2 points

-

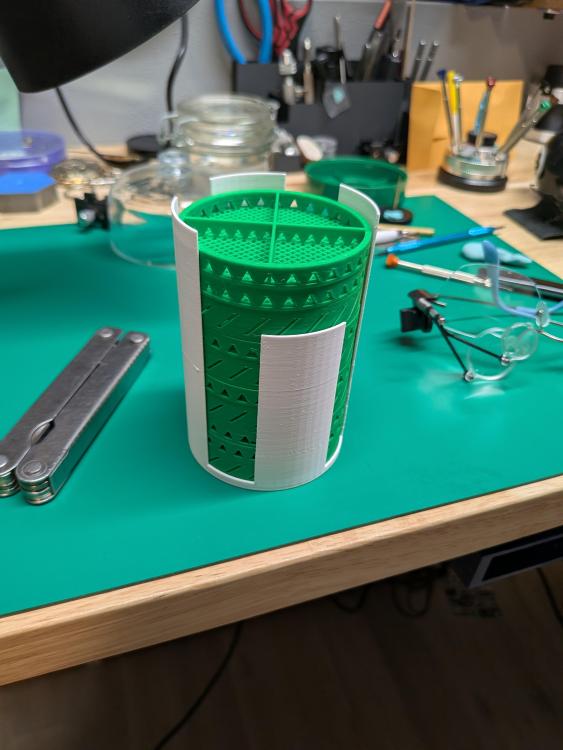

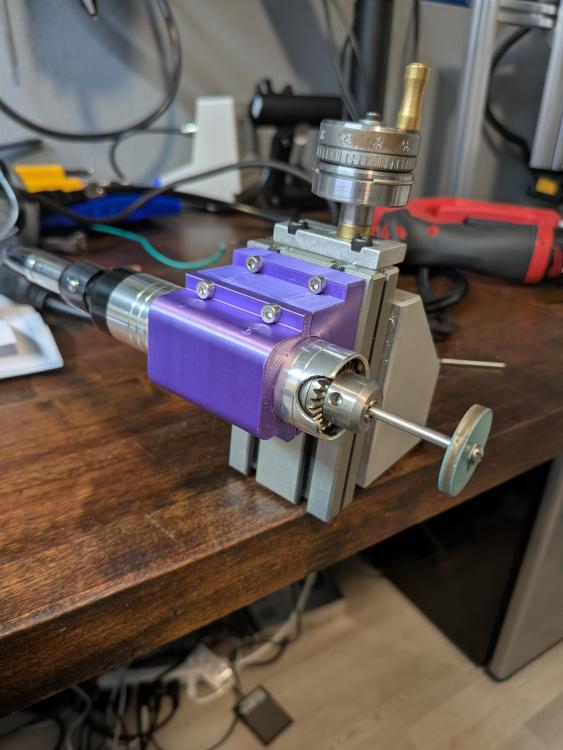

I figured I should actually post my tool builds here. I like making tools almost as much as I like watchmaking. I'll post new tools I make below and label them. First up, my cleaning machine. You can see my other post on it. Next up. Some parts I make for the cleaning machine. Baskets and such. Then I made a toolpost grinder setup for my flex tool. This will be used for precision grinding, and also for wheel and pinion cutting. Then we have the lapping table for the lathe. The is a simple build. Next is a 2 axis polishing vise. I'll add more later on1 point

-

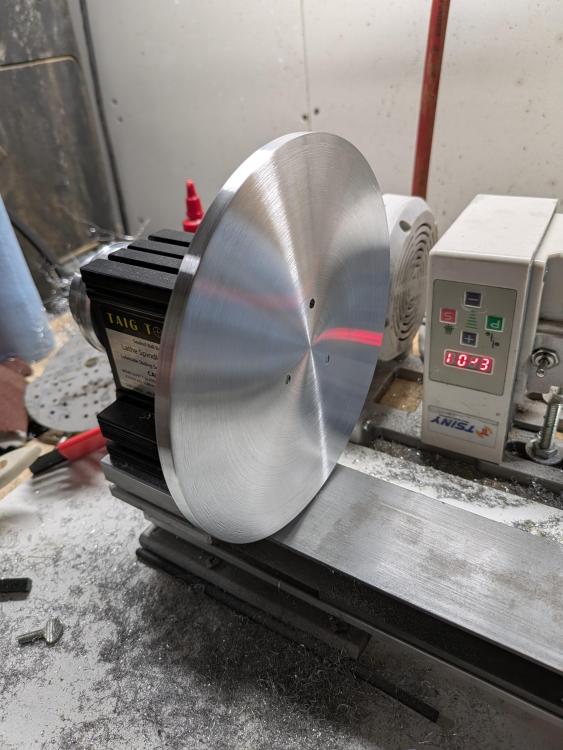

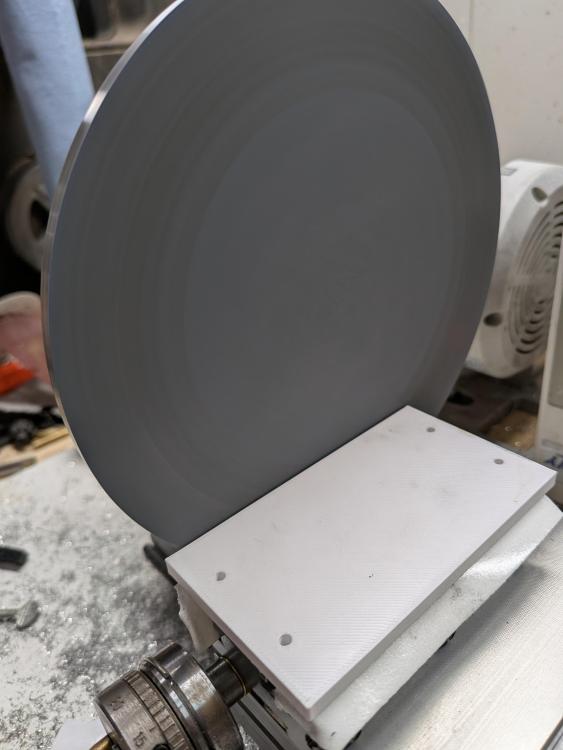

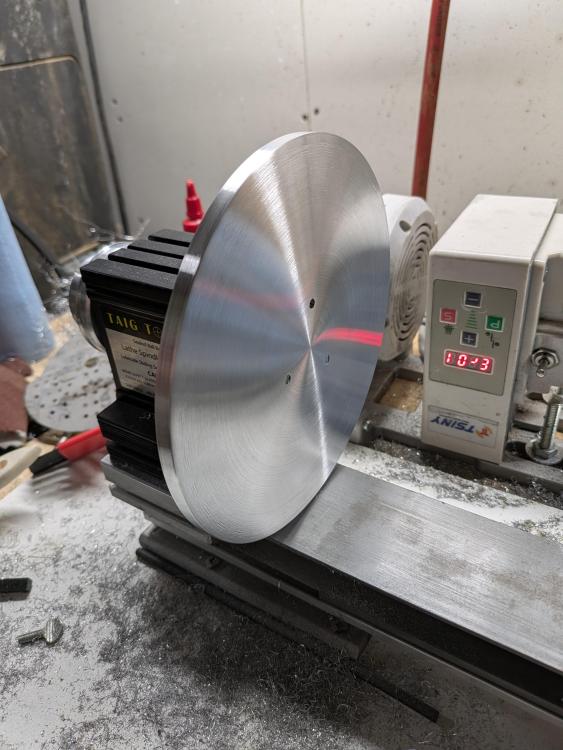

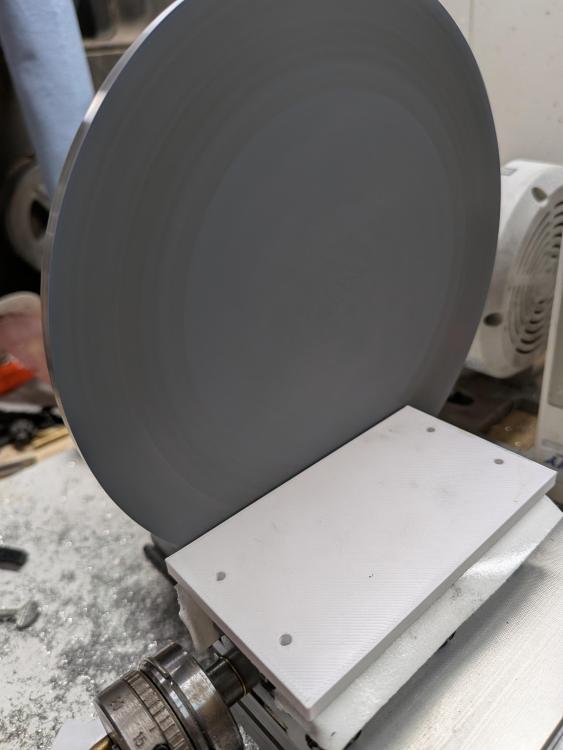

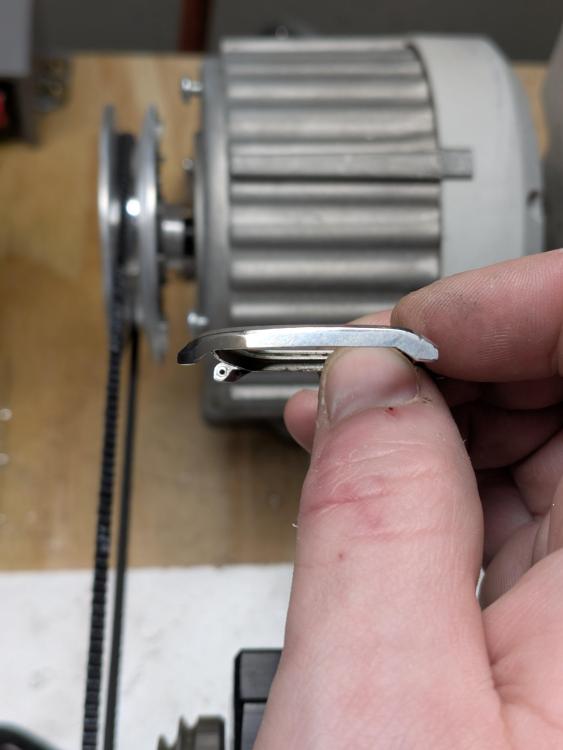

Hello all. As stated in other topics, I'm working on a lapping table setup, as I do a fair amount of restorations, and things are needing to get more precise. With my recent addition of an impulse micro welder, lapping is necessary. To start off, I have a few lathes, and the one I'll be using is my Taig Micro Lathe. I purchased it unassembled, as I wanted to modify it readily. I use a sewing machine motor to drive it, and it has a lot of adjustment on speed. In order to do this, you need this tailstock riser to use on the headstock, and this spindle mount to attach your Lapping Plate to. I ordered some 6 inch aluminum disks that are 1/4 in thick. After finding the center, I placed the spindle mount on the center, then drilled and tapped the holes. Then I used a vertical belt sander to reduce the OD of the disc enough to mount the piece on the lathe so it spins freely. Then I faced the part as best as I could(cross slide only has so much travel) and finished it off with 240 grit sandpaper. I attached some 2k grit sandpaper for now, but will be replacing it with lapping film. As for the table, I'm 90% done with the build, and should have it done this week. I'll add that to my post. The white plate below is just the base and is not centered on the headstock axis. The lapping vise as seen in some European restoration videos is extremely expensive. I have designed and made a fixed polishing device, similar to the one by horotec. I have designed and am prototyping a 2 axis vise for rotational bevels. My last design is going to be the 3 axis vise, but I'll get to that one later. Attached are some photos of the lapping plate for the lathe.1 point

-

1 point

-

1 point

-

No, superglue stands a chance of melting the watch and lens. You want to use G-S Hypo Cement or Jewellers Cement. Edit Should have added the irrespective of what was their before and depending on the size you could look at fitting an I-Ring & Crystal.1 point

-

1 point

-

Certainly not GUSTAV BECKER. 4 8 The effective pendulum length is 4 pouces and 8 lignes; a pouce is an old French inch, and is 27.07 mm or 1.066", and a ligne is a twelfth of that, 2.256 mm or 0.88". So your pendulum should be approx. 126 mm long1 point

-

We need a better photo of the movement, there will be a button to press.1 point

-

Hello guys, it took some time te work again on the watches. I promised to let you know what I found out. There was too much sideshake on the escapewheel (not jewelled). I found a donor plate and now it works fine.1 point

-

You're welcome. I try to keep the habit of testing every wheel independently after initial cleaning but before any complete assembly, just so I can address any issues found without having to take everything apart. That is the best time to discover there's still rust in a pinion or a wheel will have issues with endshake. (though it is still necessary to test end shake when the whole train is assembled)1 point

-

Wow! OK, that's certainly something to aim for. Thank you for taking the time for posting all that. Very good of you. There have been a couple of posts, including yours obviously, that have taken information that I've seen before, but put it very clearly and concisely. It's been very useful.1 point

-

For this test of the whole train, the barrel is installed with ratchet and click, all wheels are installed, but the pallet fork is not installed. Apply a little wind to the mainspring and the whole train should spin until the wind runs out. Ideally then, the escape wheel should rebound back the other direction briefly. That is a sign that the mainspring can unwind all the way without any train friction binding it. If as it unwinds, you get no recoil and the escape wheel stops abruptly, there is friction in the train. Then, install each wheel one by one, alone, and test its spin with a puff of air. The escape wheel should spin like a top, uninhibited. And up the train, each larger wheel will spin a little less but they should all be set in motion by a puff of air. If one is binding, check its pivots and reclean them. If all of them spin freely independently but the train still doesn't spin freely together, then install the wheels in meshed pairs to check the wheel and pinion interaction - a puff of air should still be able to get two wheels spinning. One dirty or rusty pinion leaf can easily slow or stop the whole train.1 point

-

@RickTock Are your punches also soft steel? I'm curious to find if some production batches have corners cut, or some sellers unload the faulty QC-failures as I have seen with other tools. But I am no longer tempted to ever buy one of these sets.1 point

-

1 point

-

1 point

-

Nice work but for future reference I just twist press fit a new pivot in the heat from silver soldering would have annealed the arbor & of course the blue steel wouldn’t be hard either just my suggestion.1 point

-

Hello Dave and welcome to the forum. No need to blow the budget on tools have a look at Cousins uk online catalogue, they have budget tools which for the price are adequate for starting up. If you decide to go deeper into it then splash out abit to the next level. Avoid buying kits as they have many tools you will never use or want.purchase the basics, screwdrivers and tweezers these items get the best you can afford then build up from there.1 point

-

^ this I hate a cluttered working environment. I always try to put everything away at the end of a work session unless I'm actively adjusting something that's on test. Tidy desk, tidy mind. As mentioned above, looking for a lost part is 100 times easier with a clear desk. I also have a laminate floor, which helps. Looks like enough lume there to paint a battleship Thor1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement. If there is anything we can help you with don’t be afraid to ask. Nice clear photos can help a lot.1 point

-

1 point

-

Well, the logical thinking is that this is not related to cleaning issues as the movement will not get cleaner in CL position than in CR. When there is significant amplitude difference in vertical positions, first thing one has to check is in which position the problem is, but position of the crown is not important here. The important is 'balance above the pallet fork', 'balance under the pallet fork'...1 point

-

Thinking of small CNC milling machine for instance. Here's something that's interesting 3-D printed components and a conversion of a small inexpensive milling machine.1 point

-

For shallow drawers, I use several office document drawers. I have an extremely shallow one, which is good for keeping small tools in a single layer. Then I have a medium depth one, which is good for bigger tools and bottles of small parts. The problem with having too many drawers is I can't remember where I put my stuff. I should really get a label maker and start labeling the drawers. For stuff that I use once in a blue moon, I stash them in plastic boxes and store them away in my cupboards. To help me remember where I stashed them, I downloaded an inventory app that has a database that keeps photos of the item, the storage area and storage bin where it's located. It's really useful. But only if I remember to key in the data.1 point

-

I expect they're bent up so should be able to bend them back with a pair of small pliers.1 point

-

If you're looking for a 1332/1337 Circuit Module then I think you'll struggle.1 point

-

One day I was curious and looked up something and found a really interesting website out there. Can't quite remember how they did this but basically they were looking at how people died. So for instance there appears to be a perception by the rest of the world that the USA is a wild West everybody carries guns and we have shootouts on our streets on a continuous basis. Or basically the number one way of being killed in this country would be with a gun. So the website basically looked at how people died and made an interesting conclusion. So the simplistic was it's easy to point a finger at somebody died from a gun. Is not so easy to look at non-natural deaths that are achieving the exact same desire of terminating somebody else. West I think going so far as to suggest that non-natural Deaths might actually occur at a higher rate then if you had access to guns. Or basically a lot harder to track. The problem with politicians are they are not very bright and they always take the easy way to do things. So guns are bad if they go away bad things will not occur. Versus some way of spotting when individual or individuals are plotting to do bad things. Often times after bad things occurred and things are being investigated there were indications sometimes that something bad was going to occur and nobody was paying attention. But these solution is to make the bad gun Galway and the problem solved. Or basically politicians will do what they do best which is to make life unpleasant for the rest of us and no We are not going to feel more safe with what they're doing typically.1 point

-

1 point

-

1 point

-

I'm in two minds about AI's abilities to write code. It tends, currently to write code that is the programming equivalent of that bizarre "curb pins" watch drawing. What it boils down to is the inescapable fact that AI has no ability to comprehend the real world. It is debatable whether it ever will. Don't get me wrong, ChatGPT and its pals write code. They can write it in pretty much any language, and they can write it quickly. However they need a lot of prompting to make the code actually functional. In that respect they are both good and bad at the same time. If you need a framework written quickly for a well defined problem, then AI can, to some extent, do that. You still need to go through the iterative process of refining the code to make it actually work. In other words the AI doesn't (yet?) have the ability to do this, so it is still down to the porridge between your ears to get things to function, and probably always will be. Will I be out of a job any day soon, as a result of advance in AI? Probably not. Will over reliance on AI be the cause of problems in the future? Probably. Will AI, on balance, be a benefit or a hindrance to us? I suggest AI is a tool. It is not the only tool in the toolbox, and it is a relatively narrow use tool. Whether it is a net benefit to the human race, all rather depends on what we choose to do with it. It isn't going to do anything we humans don't ask it to do, so if we use it intelligently then it will benefit us. Given the state of the world today, I would say the chances of us using it intelligently are probably about 50-50. In other words, don't give up the day job just yet. Robbie the robot is not about to give us all a life of infinite leisure any day soon.1 point

-

I had the same question myself and then I found a watch that had a sort of skeletonized barrel - From this I observed that when an automatic spring goes beyond a certain point that the bridle slips in a smooth controlled type way until the tension is low enough and the friction holds the spring again. From this I assume that the breaking grease is there to both prevent wear on the barrel wall and to smooth the transition into the slipping state1 point

-

I remember back in 1987 when I first started to learn programming. A friend of mine told me not to put too much time and effort into it as something called AI (Artificial Intelligence) soon, within a year or two would be doing all the programming and I'd be out of work. I've been making a living as a programmer and teaching programming ever since. Now we're clearly in the hype era of AI. I'm old enough to have experienced many hypes and they never delivered what they promised, but I guess this time will be the exception, or!? The "hypes" change our lives, but never as predicted and as fast as expected.1 point

-

If the barrel is really moving, then the rivetting of the center pinion to center wheel has given up (could be the third wheel/pinion, but would be strange). Usually this is a dramatic thing and you can't wind any real tension on the spring without the pinion slipping in the wheel, so a little odd in your case. Basically, the barrel can only move as much as the escapement allows it to move; if it moves more, then something is slipping in the gear train.1 point

-

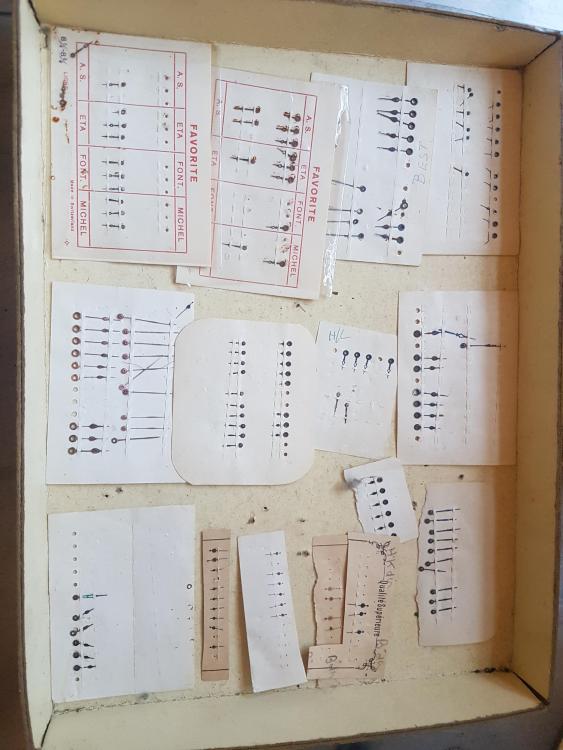

Local auction had a box of random watchmakers tat. Nothing amazing, but I spotted a few bits in the box, so I bought it. Just had a dig through to assess what's there. First off, some watches. I ignored these. Some limit, a sekonda quartz, and a rotary quartz. I may or may not see if these work. I know nothing about them but I know if they weren't tat, they wouldn't be in the box. Next layer of items were some empty tins, a glass globe (this might actually be handy!) And a tray of glass watch crystals. It's slim chance I'll have the right size if I need them, but I play with early 20th century watches, so glass is nice rather than plastic. Next grouping is all the little boxes. The watch pins will be handy, as will the dial washers and the screws. An entire tub of setting lever screws there. There is some other bits and bobs too. Don't know how the enamel is ment to be used. No idea what clock bouchons are, or what the cylinder pivots are. Bottom of the box has this assortment of hands. I need some sub seconds hands. I bought a new selection, but I think there might be something better in here. That brings us to the small selection of tools. A broken something, adjustable winder maybe? Not sure if both bits belong together, but it's broken, and not all there whatever it is. A glass pippette maybe? An old oil pot, ill mix lume in this rather than using a teaspoon. There is a packet with a load of broaches though. I figured these would be handy. Not sure if cutting, smoothing or both. Might be handy for the seconds hands! There are also some small drill bits, and a nice surprise, a tin of taps! I need a 0.8, hopefully there will be one in there. Then some pocket watch and clock bits. The dials are nice. One is a chronograph, the other says chronometer. The movements are incomplete, but I think that's the one for the chronograph. Looks way more complicated than what im used to, even with a load of bits missing. Has depose stamped on it. And lastly, the other thing that made me tempted to buy the box. A zenith trench watch movement. I think the black dial might go with this. Not sure about the case parts though. Few bits missing on the movement but some of them might be in here somewhere. I love black dial trench watches so as soon as I saw this, along with the broaches and hands, I figured I'd buy the lot. all in all, worth the £26 I think. I expected more radium, but luckily only 1 hand and the dial.1 point

-

If the drawers are to stay ,then think about layering them up. Battern up the sides of them inside, and lay sheets of stiff cardboard or plywood/mdf depending on their size, across the batterns. Making trays that you can lift out - finger holes in the sides of the trays- will make them easy to remove. Layer your tools in the drawers according to usage, most used in the top trays. Second hand office equipment ...steel pullout drawers make for. great storage . I like to keep stuff on my bench down to a minimum, just the tools required to do the work plus a little extra of what I think I might need. Finding lost parts is much easier when there is no clutter, that's less important now, but it became a habit from when I started. A clear bench is also easier and quicker to wipe down, dust can be a real problem in some environments. If you are new to the hobby, then every new tool that you buy, you'll want to proudly display on your bench. That will soon change when it becomes overloaded . Your working style will evolve over time. So basically when you first start...everything will be out on your bench, and when you've learnt that isn't good...you'll put it all away in drawers .1 point

-

1 point

-

I'm sure I've seen those screws before. I think they were in a Mumbia special that had been recently "serviced". They too were bit of a multiple choice question when it came to how to undo them.1 point

-

1 point

-

No, I did not change the mainspring. Pretty sure I have one though. 3-4 years ago I was into these Walthams. So I acquired dials, hairsprings, staffs, and a mainspring or two. Then I moved on to Elgins. Until this batch showed up, I had moved on.1 point

-

If I watch the video you posted at 0.25x speed on YouTube, unless it is dropping frames in a perfect visual trick, it looks like the amplitude is only 90 to me. It seems to male one half turn in total while 180 would be a half turn on each swing. Do you have free train movement without the balance and fork installed? A little wind should run the train all the way down with a little bit of recoil. And without the fork installed, does the balance oscillate freely for at least 40sec with a puff of air, or turn it 180 and let go. It should oscillate close to 100 times.1 point

-

Here's a link to the PDF for the book. You can either download sections or the entire book I would go for the entire book if you can because it's more complete than the sections. Then as a whole bunch of other interesting stuff here to download also https://www.mybulova.com/vintage-bulova-catalogs Here's an interesting book and an interesting website. You can look at the book online but it also downloaded in a variety of your favorite format. This is an interesting book as it's basically a training manual of how to service A variety of watches tools troubleshooting. https://archive.org/details/TM9-15751 point

.thumb.jpg.307163a16053c9b0265ac99bf2ab69b9.jpg)