Leaderboard

Popular Content

Showing content with the highest reputation on 02/14/25 in all areas

-

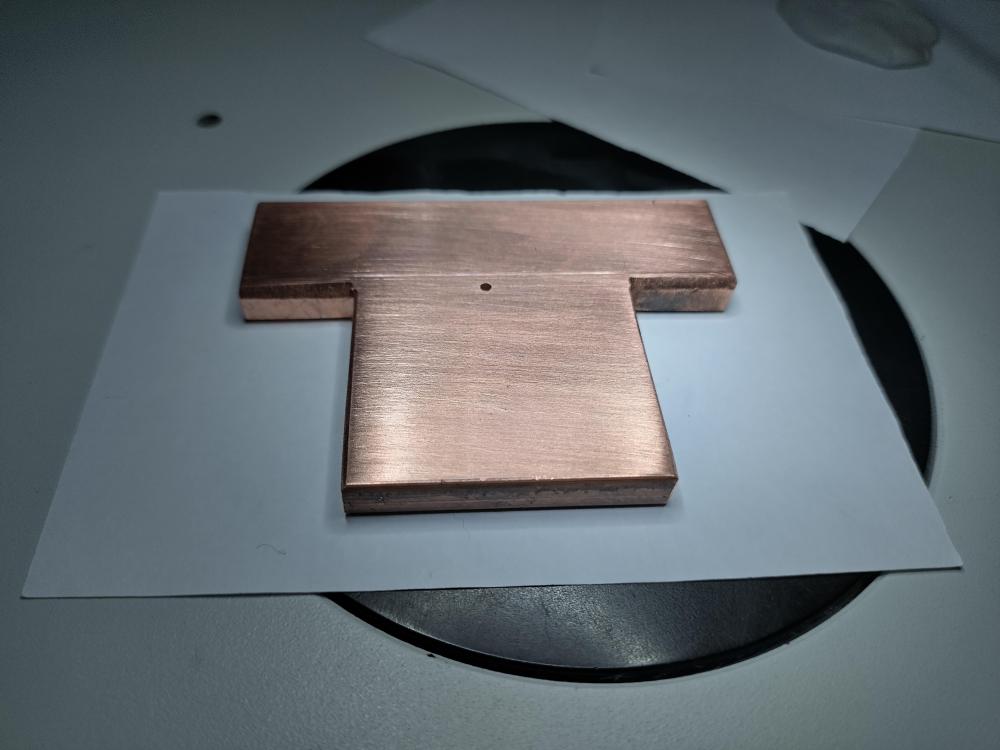

That‘s what I thought about too. But then I found that it is cheaper to just get a vintage staking set with punches. In the meantime, I have won a vintage staking set on eBay for €91,-. It is a bit stained and is not complete but has about 100 punches in good condition. With a punch diameter of 4.7mm I can buy a new Bergeon punch from Cousins or Boley if it is needed.5 points

-

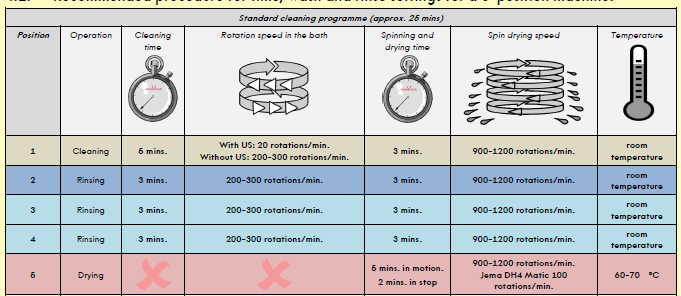

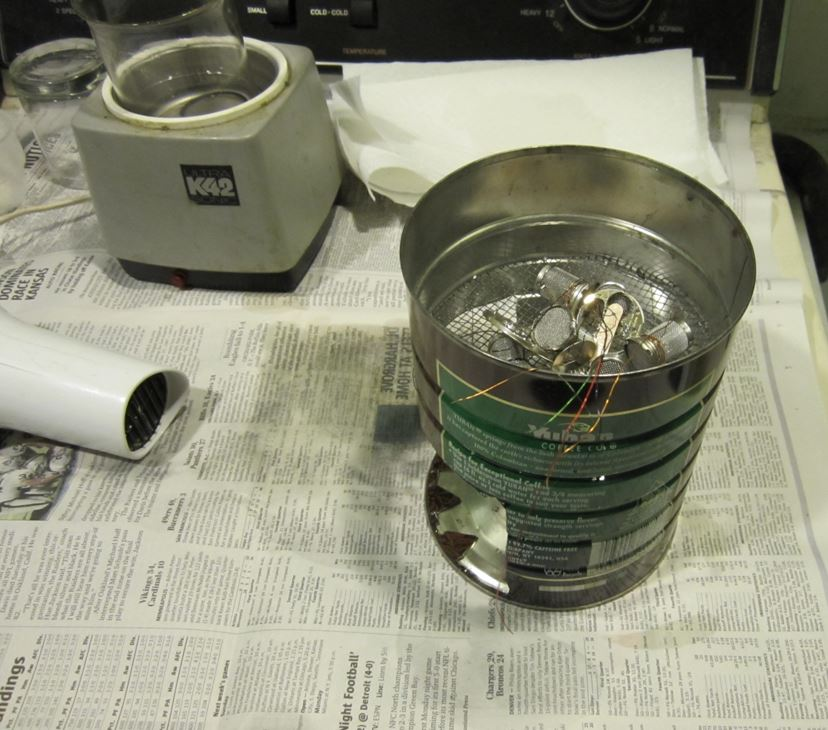

sometimes I think the fantasy versus reality catches up to people. For instance you watch the wristwatch revival channel and it's so easy and quick. then you discover that cleaning doesn't repair everything and more tools are required more skills and it's expensive when you break things. one of the things you have to be very careful of his products designed to make things bright and shiny. The watch cleaning products work extremely well and do make things nice and bright and shiny. But if you leave them in the solution to the long and they go beyond bright and shiny they will start to make things frosty especially brass. this is because the right and shiny aspect does not have some sort of time limit and it will start to etch things. The solution will turn blue green color and that really isn't what you want to do it all. Worst-case in another discussion group somebody went on vacation with their watch in the cleaning machine I assume the machine was off and when they came back they were now in need of a new movement. So that would be a worst-case scenario of. So basically are time-limited on bright and shiny. I was thinking what you need to look at is how professional watchmaker's clean their watches? In other words typically they put all the parts in the cleaning baskets and put it in the machine a push the button and walk away. here's a things like balance wheels pallet forks you win just toss them in with all the plates and stuff they would either go in a smaller basket in the machine or smaller section where there less likely to bump in the things. The greatest danger to a pallet fork is the person trying to put it back into the watch. here's a recommendation on cleaning. Notice it includes both ultrasonic and non-ultrasonic at least for the first cycle. So with ultrasonic the machines spin slower. Then notice how fast it's going when it's spinning off. I wonder how fast you can hand cranked the machine? then this thing is really have to spin no. Why are there so many procedures because everyone has a different point of view everyone has exposure to different stuff etc. So when I was cleaning watches at home here's what I did. This is a modern watch with a modern balance wheel where it's easier to leave the balance wheel attached to the bridge. Which means I took the balance jewels out and there in one of the baskets usually I put the jewels found on the dial side in with the dial side components and the jewels from the other side in the components on that side to keep them separate. Then the balance bridge is screwed back on the plate and the balance wheel is safely protected oh and yes the pallet fork is in one of the little baskets somewhere then the next image usually gets people scolding me. Typically with ultrasonic machines are not supposed to play stuff directly into the tank there should be a little but the spacing between whatever and the bottom of the tank especially with bigger machines as I believe this or variety reasons like cooling but this machine was purchased at a drugstore a very long time ago and is being used exactly as it was described. In other words small quantity of water surrounds the beaker in the ultrasonic take in the beaker is placed directly in the tank. so basically a very inexpensive purchase lasted of extremely long time. So is using one cleaning and technically three rinses you just don't see the third one as I usually tossed it afterwards. Parts large strong on the wires tiny parts into the baskets whole thing went into the beaker. Clean for about four minutes came out I placed it on paper towel to wick off the cleaning fluid while I changed the solutions. and I believe some more in this discussion you might have commented that you want to purchase an ultrasonic machine a lot of the machines will have holders for beakers or even jars or stainless steel containers or whatever. oh the final rinse that we don't see was alcohol. Then don't worry it wasn't isopropyl alcohol it was alcohol that's actually designed to dissolve shellac. Well it's used for a variety of purposes but one of the purposes is to dissolve shellac. But I was just using it as a final final rinse as the regular rinse had a habit of not evaporating as it's now more environmentally friendly that doesn't like to evaporate. So basically just a quick rinse in alcohol to rinse off the rinse so that everything would dry properly. Then originally I had a different hair dryer for drying it didn't blow as aggressively as the current one and didn't get as hot. So before I just place the baskets the parts in their path of the hairdryer on the newspapers and that was the drawing simple. Because the new hairdryer is way more aggressive much hotter and much much faster air blowing I got creative and made by coffee candleholder for the baskets. They usually one is drawing a place a piece of sheet metal on top with just a little opening so get nice and toasty warm up there. So all kinds of different methods because people have access to different things and have different ideas.4 points

-

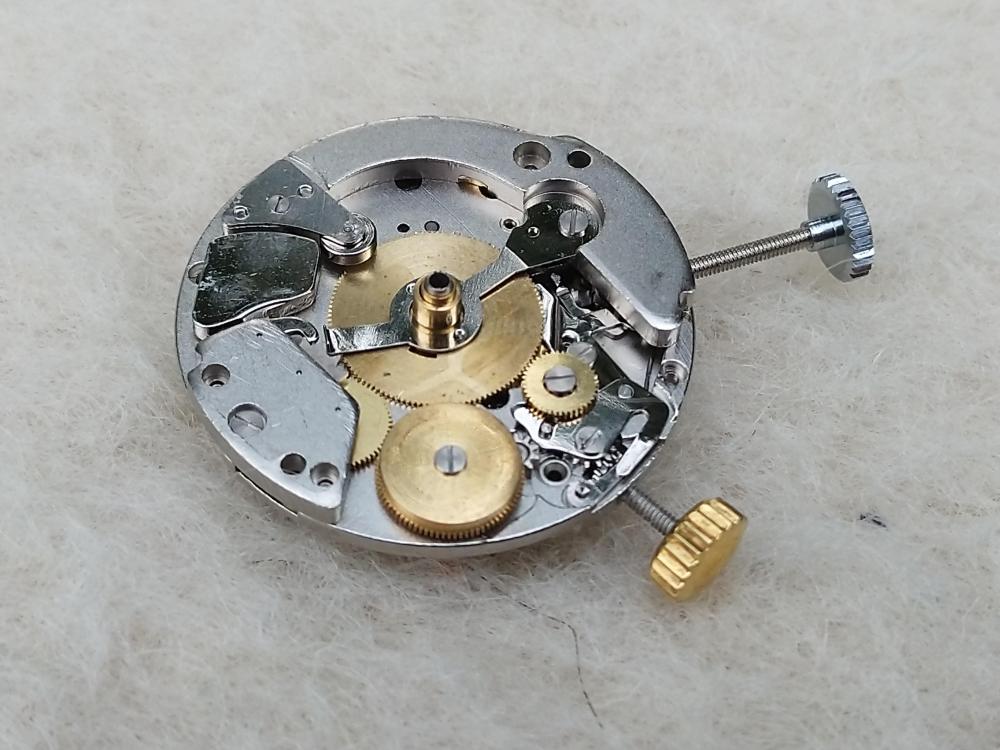

Ok. After many months following this initial post I believe I found the issues that were causing the problem. I found that I had indeed installed a balance jewel upside down along with the winding intermediate wheel. After resolving these issues the watch is running for almost 9 months really well without stopping for no reason.3 points

-

3 points

-

I think it was HectorLooi that posted some information at the time that we were discussing what materials to use for cleaning jars in an ultrasonic machine. It was decided that steel jars transmit the cavitation bubbles better than glass or plastic, which was considered the worst as it absorbs their energy. So I've tried a few different cleaning solutions, mostly non-proprietary watch stuff. There is a thread I made last year experimenting , actually I might have tagged it onto someone else's thread, I can't remember. Just mirror residue and evaporation rates. Elma pro ammoniated, paraffin, ligher fuel , Ipa, meths, and I think break cleaner was in there as well. Elma and paraffin have a very slow evaporation rate, probably days. Both have wetting properties and are far reaching, paraffin being very much so, if you're looking for a deep cleaning solution then paraffin soaks well and finds every nook, cranny and crevice. When I use paraffin which is usually if I hand or US pre clean then i place the parts on absorbant tissue afterwards to soak up the excess then spin them off and use IPA or break cleaner to rinse them off after that a rotary wash with elma and ipa for rinsing . I don't use a US that much, really just if any wheels and pinion leaves are really gunked up, which is when I hang them on the little wire tree. I kind of base how i will clean by how dirty and gunked up the movement is. If it's bad the procedure will follow : soak in paraffin for a couple of hours, peg out plate and bridges and hand clean what I can with a small brush to remove the bulk. Then onto the USM, some parts that can be hung go on the tree like wheels etc, others that can't go in a slow rotating mesh basket, all in paraffin, the USM loosens the crap up . Then put them in a rotary basket, spin them in paraffin, spin off the excess, then in elma then 3 rinses in IPA. That's like the full valet, if the movement is really dirty. The parts that don't get that treatment are the balance complete and the pallet fork, which I really like to clean by hand. Screws and springs I also won't put in a machine, too easily lost, these are easily cleaned by swishing them in a jar of whatever you fancy . If I get a really stubborn sticky hairspring, that will be removed for cleaning separately, brreak fluid is good for that or tetrachloroethylene. Thats one way to get rid of the mother in-law, at 85 yrs old mine is heart attack territory.........I could accidentally have an envelope with certain contents fall out of my jacket pocket onto her dining room table...accidentally....3 points

-

You can get 5mm tube with 0.2mm wall and maybe drill that to 4.7mm Think you'd be better drilling it out to 6mm, insert a 6mm tube with 1mm wall. then drill that to the 4.7mm3 points

-

Yes @SwissSeiko, most of us here are just hobbyist and some horological products are simply too expensive. For example, cleaning fluids. I think even you find L&R cleaning fluids expensive. But I haven't found anything that shines up parts like #111. So I just bite the bullet and fork up the $$$. Here in Singapore, a bottle of #111 is $180SGD. ($134USD) The Rinse #3 is the same price. Oils like 2ml of Moebius 9010 is around $45SGD. Imagine if you had to fill your car engine with 5 quarts of 9010! I have been using odorless kerosene to preclean my parts before putting them into the #111. The kerosene does such a fantastic job that I may use that in place of the Rinse #3. But I can't do without the #111, but now its role is just a brightening agent. So my cleaning regimen will be kerosene, #111, kerosene and IPA. I see how that works out. I might even re-distill my used IPA to save even more.2 points

-

What works for you, is good enough for me. You and I have great interactions on here, and you've taught me some things! I guess I should approach things with the thought process that most of the users on here are probably doing this as a hobby. I find myself reading some posts and thinking, that's definitely not how I would do it. But I do this for a living, I have overhead costs, bills to pay, taxes, tooling costs ect., and to many on here, it's probably just fine to do it as is necessary to work. So I'm probably a little overzealous when it comes to finishing. You should know, we(for sure at least me) appreciate you. If someone chimes in on my posts, it's usually you, and you're a good chap!2 points

-

This is such a blessing @Knebo! I was asked to worked on the same Watch model and I was thinking of declining it but then I saw this extensive walkthrough. So happy that you shared this.2 points

-

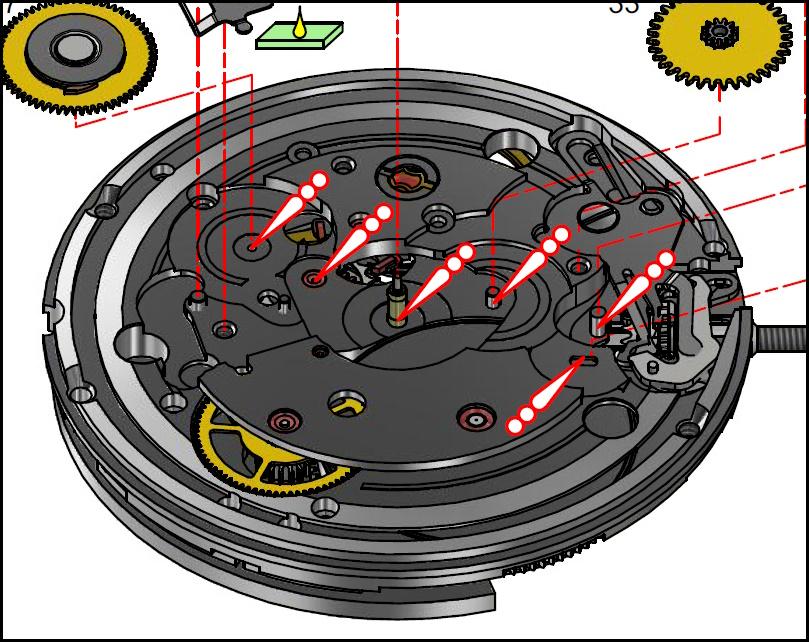

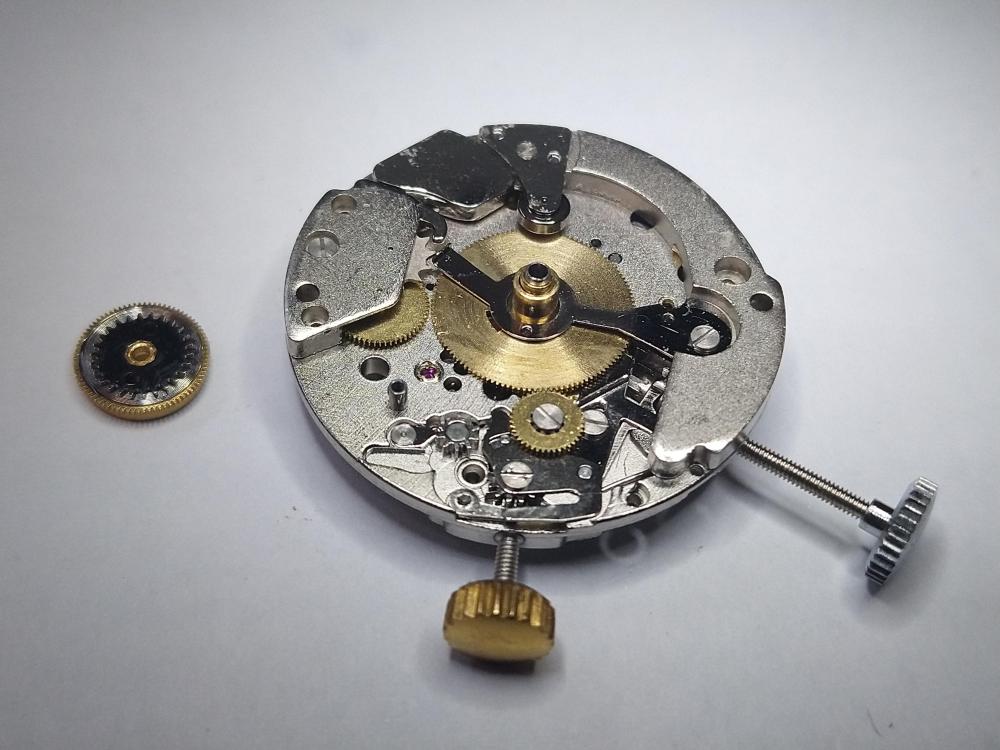

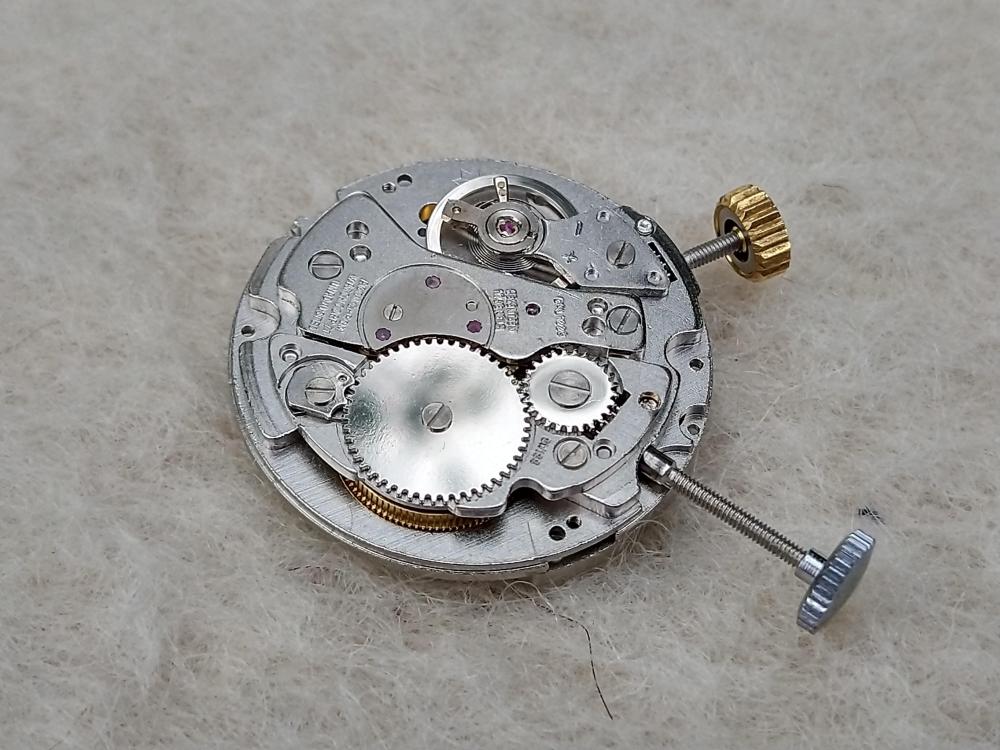

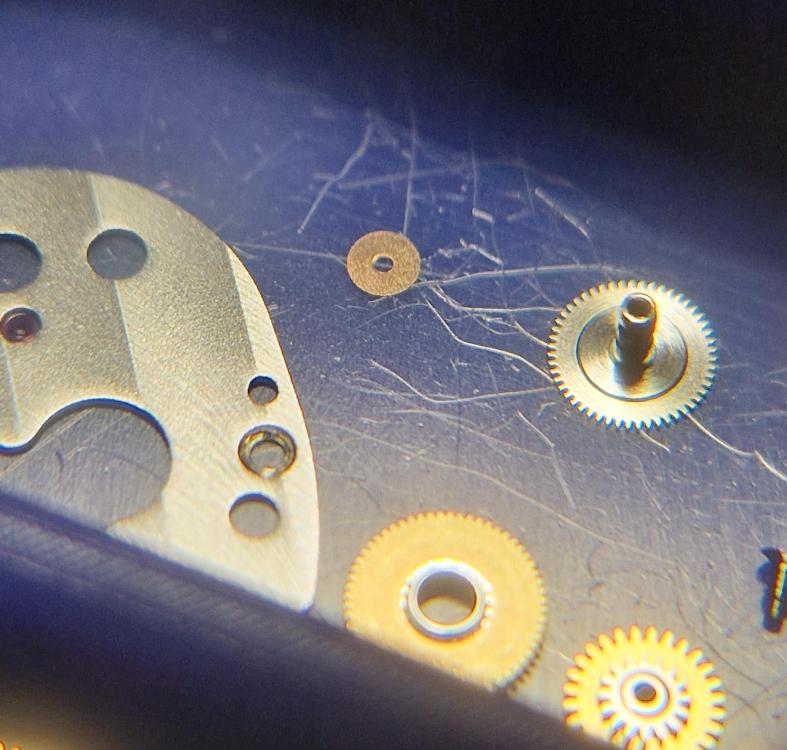

I recently serviced my first Sellita movement, the SW 200-1 calibre. It was my very first Sellita movement, so it was a bit more exciting, especially since I could compare it with my experience of servicing and repairing several ETA movements, including the famous 2824-2. The first time I heard about this movement, it was described—and still is—as an ETA clone. The impression I got back then was that the SW 200-1 was a fairly decent and relatively inexpensive copy, though it didn’t quite reach the same level of quality as the original. After servicing it, however, I’m pleased to say that my overall impression is that Sellita's movement is at least as good and, in some aspects, even better than ETA’s. When I disassembled the movement, the only unexpected thing was that the cap jewels and pallet stones were somewhat overoiled. Whether Sellita or someone else was responsible for this, I don’t know. Regardless, the movement performed well, but after seven years of 24/7 use by the previous owner, it was time for a service. One thing I really appreciate about the Sellita SW 200-1 is how easy it is to pull the crown to its second position to set the date. There’s absolutely no risk of accidentally pulling the crown too far out. This, I believe, is an improvement introduced by Sellita. My memory of the corresponding function in ETA's movements is that it’s far too easy to overshoot, inadvertently stopping the watch when you only intend to set the date. In fact, it works about as well as on the Rolex calibre 3135, which is perfect in this regard. ETA’s 2824-2 has 25 jewels, while Sellita’s SW 200-1 has 26 jewels. I’ve long been curious whether this difference was simply a way for Sellita to outdo ETA in the jewel-counting competition. To my delight, this turned out not to be the case. The extra jewel is placed exactly where, in my opinion, it does the best: as a bearing for the barrel arbor on the barrel bridge. Very nice! It’s also my impression that the click spring is stronger in Sellita’s movements, to the point where it became a bit fiddly to fit the click itself. I think there’s a good reason for this. When the cogs of the winding pinion and sliding pinion begin to wear (which only happens when you manually wind the watch), the pressure from the click on the crown wheel (which can move sideways away from the ratchet wheel) needs to be high enough to prevent the teeth of the crown wheel from slipping over those of the ratchet wheel. This could result in the ratchet wheel losing grip on the mainspring (not good!). This issue only manifests when you wind the watch manually. I’ve written about this issue in this thread/post. In short, I believe Sellita has solved this problem by making the click spring stiffer. Another sign of good manufacturing precision is the wonderful feeling when setting the time. The play you almost always feel in the crown of ETA movements is almost completely eliminated. It’s not at all stiff, just very precise. What unfortunately doesn’t impress me is Sellita’s assembly instructions. However, the documentation, unlike ETA’s, includes several exploded diagrams with part measurements. Personally, I don’t find this particularly useful, although it’s a nice touch. As for the assembly instructions themselves, there’s certainly room for improvement. The documentation is not particularly easy to understand and contain a few outright mistakes, such as showing that the escape wheel bearing on the main plate should first be oiled with 9010 and then with HP-1300. ETA isn’t entirely free from this issue, but their documentation is significantly more useful. And, of course, there’s nothing stopping you from using ETA’s documentation, as both movements are built in exactly the same way. This is something I actually recommend if you’re not experienced enough to not need the documentation. All in all, I would recommend the Sellita SW 200-1 over the ETA 2824-2. Not least because spare parts are readily available for independent watchmakers, meaning owners of watches with Sellita movements can generally expect faster and cheaper service and repairs. This also means they’re not dependent on the Swatch Group, which owns ETA, as well as brands like Hamilton, Tissot, Omega, Longines, Rado, Certina, Mido, and others, and doesn’t sell parts to independent watchmakers. In this respect, it’s better to choose a watch that houses a Sellita movement from brands like Oris, Baume & Mercier, Maurice Lacroix, Christopher Ward, or Stowa, to name a few. Additionally, ETA has started using plastic in some of its movements, which, for me at least, is a red flag and something I struggle to associate with high-quality Swiss movements. Thankfully, as far as I know, Sellita's movements are entirely free of plastic. Thanks for reading!1 point

-

I think you might be referring to what we in the UK call meths or methylated sprirts John. The violet coloured stuff that french polishers use to dissolve shellac for wood finishes. Here in the Uk it's mostly comprised of ethanol with a low percentage of methanol. This is one that I compared to some other solvents, it had the fastest evaporation rate with the least residue left behind.1 point

-

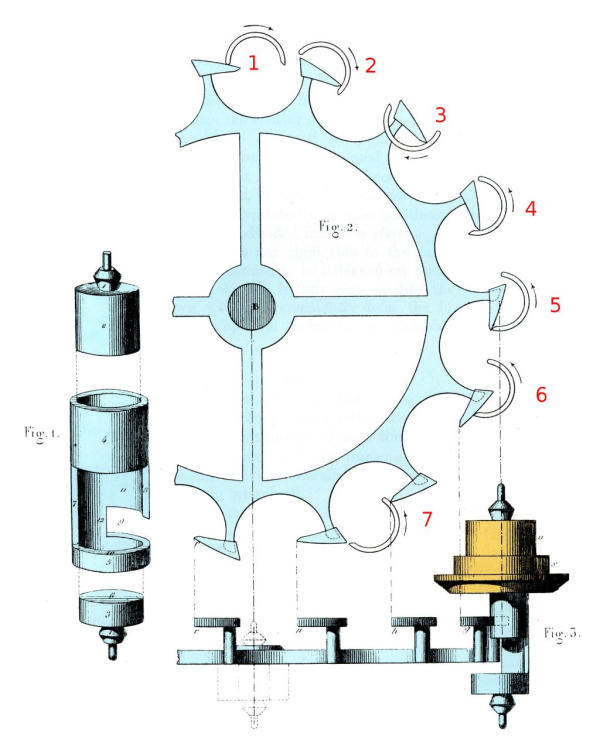

It's a 5 bar movement, probably made one the Swiss, France border. Unfortunately, it's probably impossible to identify. The only thing I can tell you, is it has a Geneva stop works.1 point

-

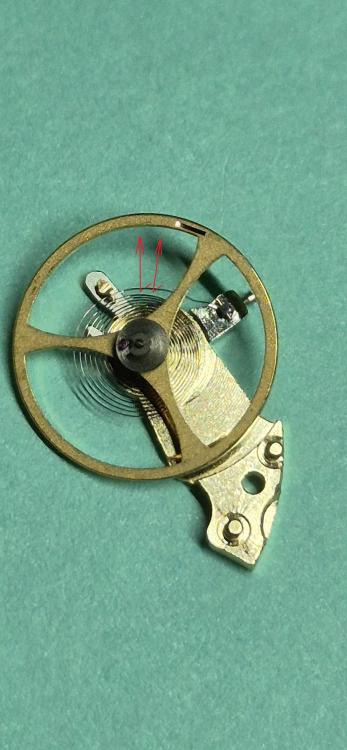

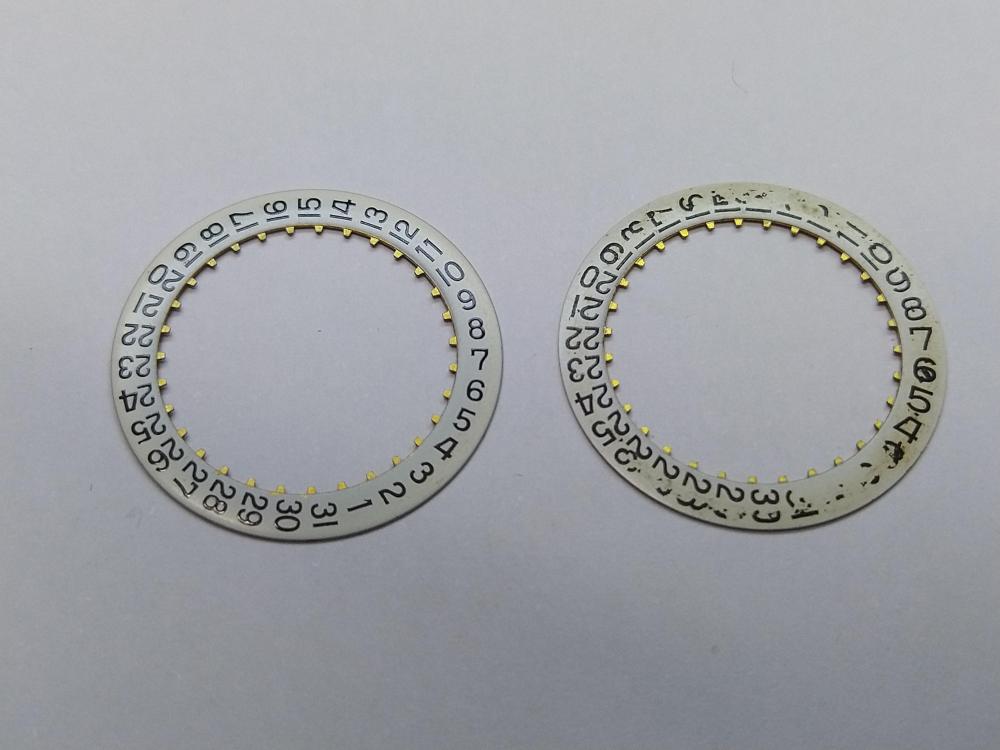

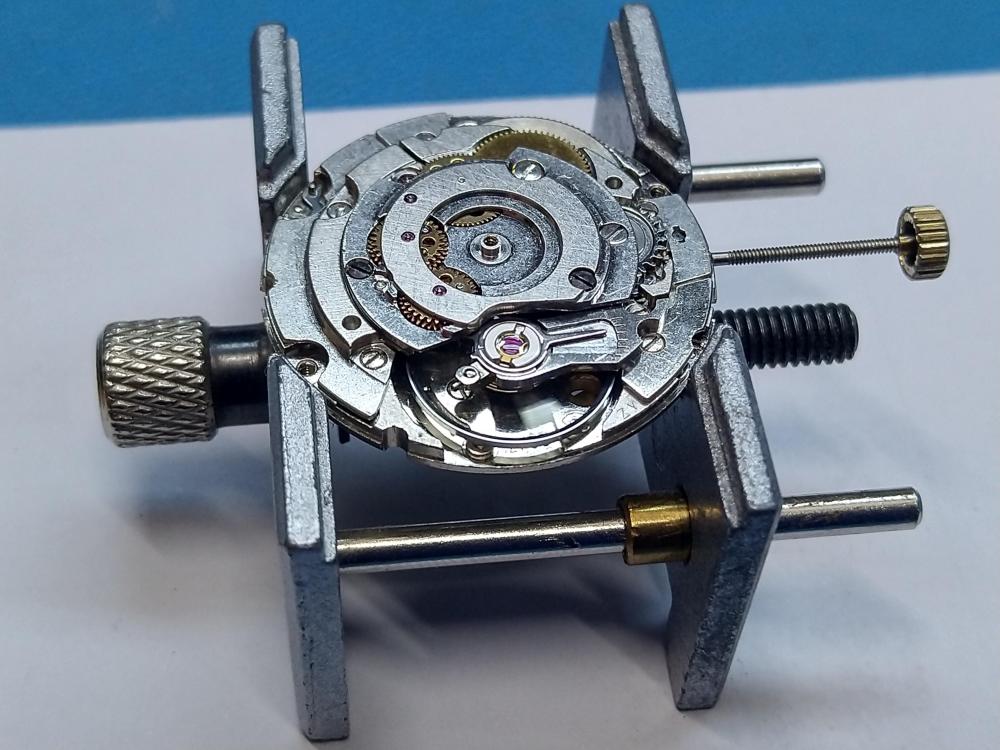

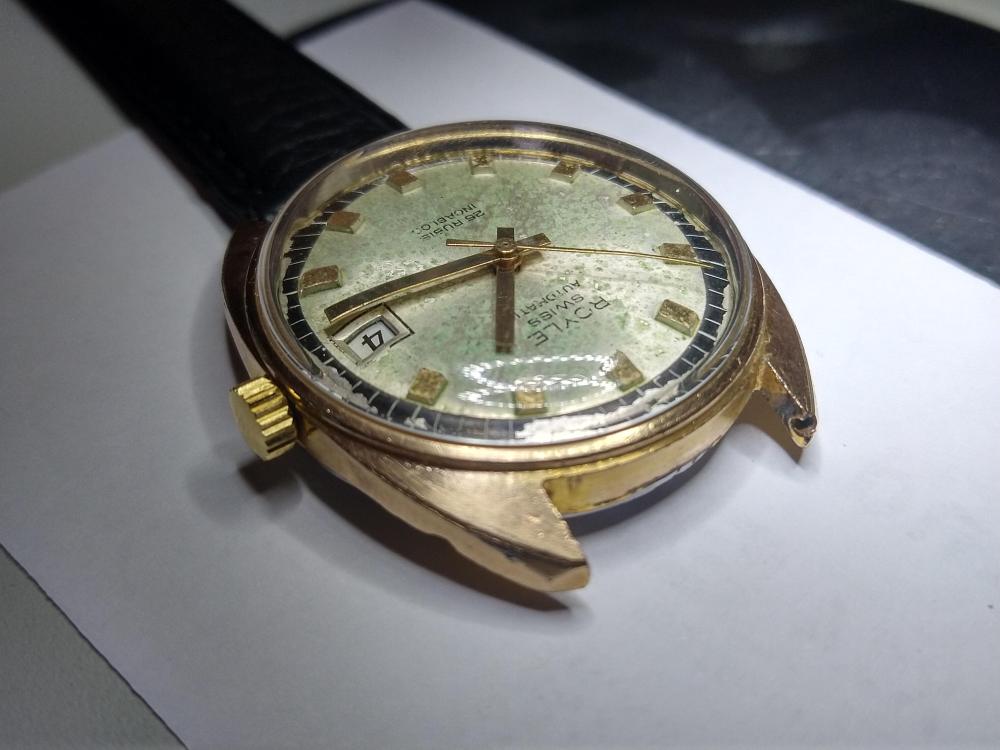

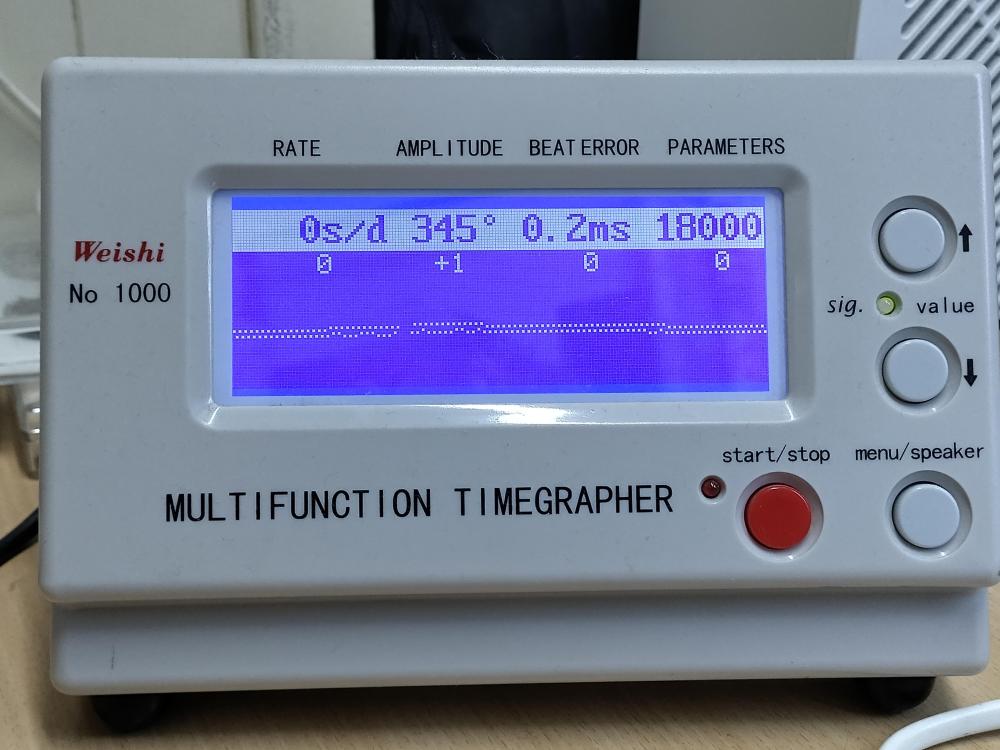

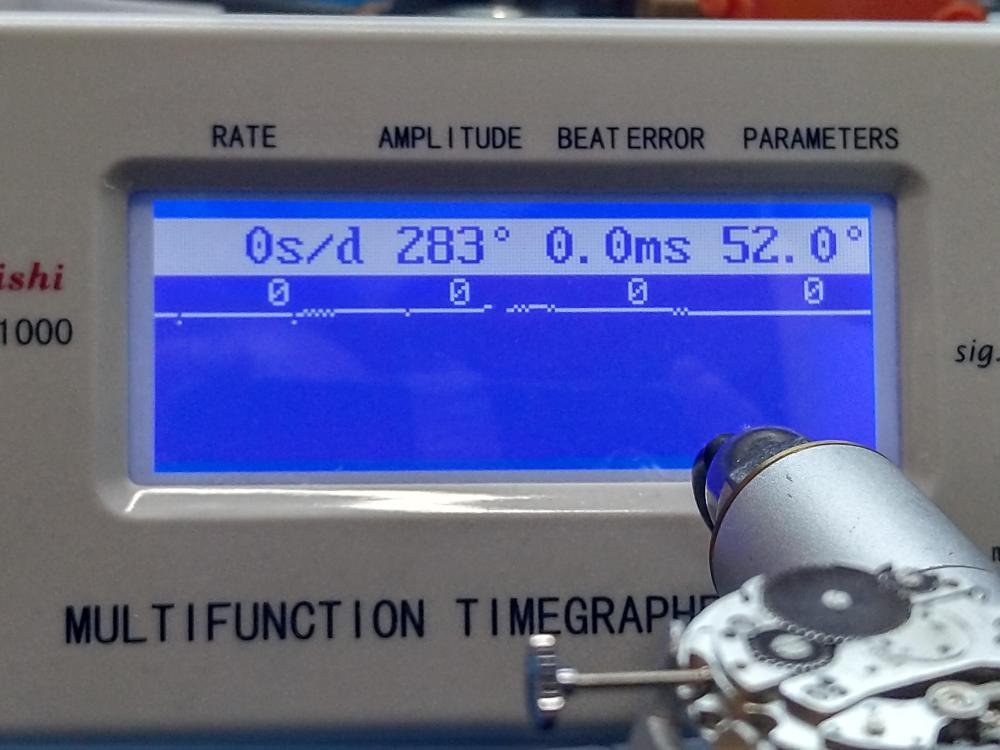

HWGIKE#40 ETA 2783 Full service, very nice performance. Moisture damaged, moisture went in along the stem ruining the stem itself, the dial and the calendar ring. I bought a new calendar ring from the US, a new stem locally from eBay and a new glass from cousins for it. You might question this as why would u spend money on a watch with a broken dial and with one case lug damaged. I thought i would be able to fix the lug somehow, but i failed to find a professional method what could be done at home. HWGIKE#41 Swiss chronograph pocket watch. I have been slowed down for the last 2 weeks or so because i was finishing the flooring in the attic. This is where I store most of my watchmakers related cartoon boxes and it became so chaotic that I had no choice, but to finish the complete flooring and to build shelves not just for watch parts but for everything. I still managed to find some time... with very little sleep...to do watchmaking. Here I have my first chrono pocket watch which was a real watchmaker job. Had to replace one rub in jewel cap for the balance, i had to re apply shellac juice for the pallets (had to quickly build a pallet warmer, going to finish it later, but for the job it was ok, i was holding it with a pair of pliers), the yoke spring is not original and had to work on its shape a bit aaaand... it has a Breguet overcoil hairspring where someone before me shortened the HS by pushing it out a bit and not cutting it... i had to bring it back from there keeping the beat error low and the amplitude high. I am very very satisfied with the end result. My memory is pretty bad nowadays, i cased this a week ago, had no time to take pictures since ... not like we had any sunshine for natural light since last Friday... however I believe no major mistakes were made. At the end I pushed the minute counter hand too hard and it stopped the whole movement... it took me a while to realize that. HWGIKE#42 Rondal RL 1223 alarm Full service where i first experienced knocking or galloping. I have a number of RL1223 movement in my drawer, but none of them are a runner as they were stored in a purpose made foam container, the foam disintegrated over the years and the little particles went everywhere. So I cleaned this one and dial down it produced a strange not always present noise I could hear from where I was sitting during the day, I was working while the watch was on the mic stand. First I did not understand whats going on so I checked the HS, checked the balance staff pivots, checked the bottom jewel and re-cleaned it, washed the pallets once more and so on so on again and again... then I narrowed it down to the balance and then i narrowed it down to the amplitude. Ohh.. it has to do more than 360 degrees.... the pic of the graph on the timegrapher was taken when the watch was only half wound, but when it was wound fully that was the time when the issue came back every time... so I set the test period to the lowest possible 2 seconds and i slowly started to wind the watch keeping an eye on the amplitude...i could go as high as 335 degree, but then that was it.... not good enough so I made a video and played it back slowly... Yipee, more than 360 degree the impulse jewel is hitting the pallets. Luckily it only happens dial down and when fully wound. The graph what I saw during knocking was like this: https://adjustingvintagewatches.com/amplitude-attacks-dealing-knocking/?fbclid=IwY2xjawIchUJleHRuA2FlbQIxMAABHZ28piDWfDu6lWbErREkucg2HEysYVmu9fjW3OpbZMaHqbFRK_sL3CgscA_aem_FfQZh_rjoNq4egAfp3sq1A1 point

-

Mine is an original, and the setting lever is different to the -2 I'd better not comment on that ..... unless you want to possibly learn some new swear words1 point

-

That kind of shellac is more for mounting jewels to dop sticks for shaping and polishing. The shellac for mounting pallets jewels are in flakes. https://www.cousinsuk.com/product/shellac-flakes You can either break off small pieces and place them on the pallet jewels and warm it over a flame or melt a small piece on your pallet warmer and dip the end of a toothpick into it and draw out a whisker of shellac. The whisker can be dabbed onto the heated jewels like solder wire. I find that the clear shellac has a sharper, more defined melting point. The opaque, cloudy type contain oils and waxes which affects the melting point and hardness.1 point

-

Shellac is kind of soft. Some more than others, some is really brittle, some melts at a lower temp, some a higher temp. We had stuff in school that was called shellac but was a muddy light brown color; worked great but didn't look "normal". I think it was more like sealing wax. My last employer had a bunch of really old flake shellac that was great, and normal looking too . As shellac gets older, it's "meltability" often goes down; this stuff was like 40 years old and fine. I wouldn't worry about it.1 point

-

Make sure you lubricated the teeth and the indexing spring once you get the new one.1 point

-

There used to be assortments of cylinders and plugs (they're called "tampons"). I suppose back in the day, with time not being important, one could sort through and find something that might work, but the fit of the tampon to the cylinder is such a precision fit, that I imagine one would always have to do some lathe work to get it right. I have always simply turned up a new plug, or drilled the tampon/plug in the cylinder and fitted a new pivot, which avoids having to get the right fit on the tampon and risk cracking the cylinder.1 point

-

1 point

-

1 point

-

Like so many things about watch repair Bill, your methods will evolve and improve as you hone them towards great efficiency. Having a good starting point though will save you a lot of time and some money. Weighing up how much time or money you want to invest initially ( I love using nice working gear, but more so for me making something " cheap and dirty " thrills me ) depends on how quickly and how much you become passionate about the hobby. I don't think the staying rate is high tbh, we see a lot of folk come and go here, it takes a certain type of person to remain interested. If pockets aren't deep or we dont want to dip into them then we have to get creative, thats a part of the hobby that is just as enjoyable as the watch restoration.1 point

-

1 point

-

Thanks I appreciate those comments ,very kind of you,the same goes for me, I admire your ability and passion for something you love doing, reminds me of myself years ago.1 point

-

Well it's passed the first test... good start! I've ordered the correct dial ring and movement holder since the dial doesn't sit flush against the case on one side. (I'll need to find that spring that clips into it - any ideas for a cheap source?) I'll continue to run/monitor and will fit those when they arrive. More hopeful that between cleaning, bending and refitting things I might be in luck...1 point

-

Yeah, that's the guy. I told him it's cheaper if I just send the pictures to my mother-in-law directly.1 point

-

Yeah you might be right. At the moment it sounds like it’s worth a try. As @Neverenoughwatches talks about inventing your own ways of doing things; I’m already thinking about ways to try and motorise the hand powered machine! That's really interesting, thanks. I did look at the ultrasonic route and will defo be giving it a try in due course. I've not seen anyone using steel cups in their ultrasonic tanks during my journey down this rabbit-hole; it sounds like a great idea though. Can I ask what cleaning solutions/rinses you use in the ultrasonic?1 point

-

There are so many threads here regarding cleaning machines, modern , traditional and homemade. They all basically do the same thing, some a little better than others, some in a much more convenient labour saving way. Personally I like the homemade route, up to something like 6 off to date. Designs can be as simple or as complicated as you like, what they all have in common is...having your wallet's best interests in mind. Surprisingly enough starting at around 20 quid, rarely reaching to a 100 for a simple device. Breaking down the actual process of how to clean effectively will help with the design ideas ( rotary ) not just for the driver but also for the baskets used and the containers specifics. Agitation is a big consideration - clothes in a washing machine don't just go around and around - the brain soon starts to throw out ideas of how to create fluid turbulence, such as the jar and basket shapes, wave breakers, basket impellers, basket speeds, alternating directions. Use one or two at least or all of them as needed. Using an ultrasonic machine requires less thought as to how you are going to get the most from it. My plan was to reduce the barriers between the cleaning cavitations and the parts to be cleaned, to an almost direct action. I managed to get that down to just one barrier. Making a lid to hold the cleaning containers keeps them off the bottom of the tank, this mean the tank holds the water and nothing else, thats one barrier removed , the tank's basket. The cavitations can then act directly on the containers. The next barriers that are normally present in most folks cleaning operation would be the parts baskets and the holder for them. I removed both of those, this is made possible by hanging parts from a small wire made part tree, that is then dangled into the cleaning fluid and slowly rotated to ensure the parts pick up small zones of cavitations. Its not quite as convenient as popping the parts into baskets but it is something I've got used to doing. I will say with only the one barrier present ( I use thin walled stainless steel cups that transmit the cavitations amazing well ) the cleaning action is insane and you do need to be a bit careful with what parts you clean this way and keep the operation short, 2 mins max, because the parts are getting practically the full force of the cavitations produced. If your machine is already powerful then you might want to add more barriers or use thick wall jars instead of steel cups. An alternative I might use is to float a small steel cup in the container and put the parts and cleaner in that second cup or rotate a small open basket in the cleaning cups. There are so many options to choose and try out, but definitely make a lid to hold your containers over the water tank. We all have ideas and we're all willing to help explain and show how we do things, your budget can be absolutely anything you like. Yeah you do that , it might jog my memory, better still have her ring my missus. Is he asking for money or else he'll plaster them all over Facebook, cis thats gonna be kind of embarrassing for you isn't it, especially if your mother in-law sees them.1 point

-

1 point

-

1 point

-

Yep. You can easily machine lots of materials dry if you stay within certain parameters, but machining the same material using the same tools in a high speed production environment (think cnc) you will definately want to use coolant (it's not called lubrication in machine shops).1 point

-

You do know cylinders come in three parts each end called a plug and the centerpiece. With the right cylinder stake you can tap the end plugs out.1 point

-

As I lost trust to this new balance, decided to take a different route. Removed roller jewel from new roller, made liquid shellac, installed new jewel into old roller with liquid shellac, heated by touching soldering iron to other side of roller. Works just fine, no rate or regulation problems.1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)

.thumb.jpg.19a9c4ff164d78d516aa9f05a063752b.jpg)