Leaderboard

Popular Content

Showing content with the highest reputation on 02/15/25 in all areas

-

7 points

-

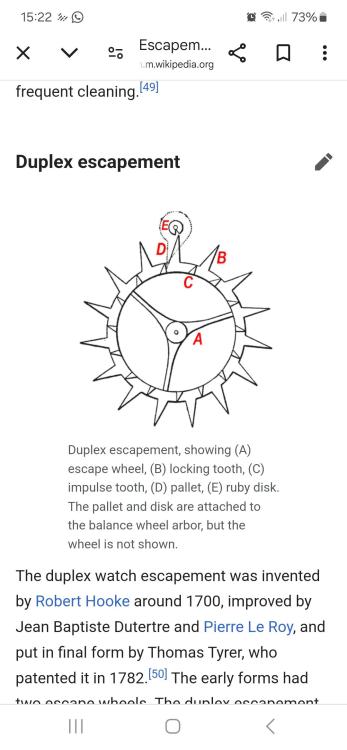

Hello again watchbangers! Here I am again with my newest project I had on my table with the appropriate walkthrough for anyone in the future! If you do not want to read everything, here is a link to the full Youtube Video: https://youtu.be/Fw2DmVTBdxQ Now it was only a matter of time until something really patina-ed would find itself to me and this was it! My very first pretty nicely patina-ed dial! I have had plenty of patina-ed watches before, with all kinds of horrible patina ( or damage), so I really grew fond of this “nice „ one while working it it! Ironically its a Dugena Tropica ( hehe) which is in rather good condition! From the outside the large issues were the extremely gunked up areas around the crystal as well as the battle scarred crown which would need a replacement! And the watch was ticking! Funnily enough, the case back revealed the habit of a previous owner wearing this watch on a nato strap for quite a while I think ( With the marbled pattern on the metal) ! Now opening the watch revealed many previous marking on the inside meaning that this watch was probably cared for well and a very pretty perlage finish ! The inside revealed a fairly simple movement with a pretty blued balance spring and nicely polished screw for the ratchet wheels ( even if they don’t look like that on the picture). There was a fair amount of dirt stuck to the case holder ring and in the thread of the case back, so I will clean that out with an ultrasonic before putting the serviced movement back into it! I released the movement from the case by unscrewing and taking out the movement clamps ( they where a real pain to work with) and plopped it out onto a cushion to take a look at the state of the dial. The dial had a nice hue to it with a few blobs of deeper colours scattered around the center. For some reason, there was a higher scale of “degradation” on the right side. Maybe there was more moisture there? Or more sunlight? If anyone maybe has a clue why this happened please comment! Otherwise its cool to realize that the hands used to be a bit too low on the dial as you can see the circular scrape marks of the hour hand which probably took away some of the patina! When I checked the hand height however, it seemed like someone fixed that issue already in the past! The indices as well as the hands looked sharp and I might just polish some grime of them with some pith wood later. Taking of the dial and the hands reveals a petty complicated dial side at first but after a closer look is basically an older version of the typical eta calendar system nowadays. So I start by taking of the hour wheel with the friction spring, the cover plate for the setting wheel and the wheel itself. As the cover plate was also keeping the date ring in place, I can now remove that aswell while also not forgetting the date lever and its spring. Thirdy I took off the date wheel which pushes the date ring one day further. Now I know that it works on a similar “spring” concept as I also removed a spring lodged underneath it but I somehow cant wrap my mind around the exact method yet. Then I removed the newly revealed cap jewel ( love those) for the escapement wheel. Then I took out the setting cover plate and then yoke, the clutches and the yoke spring. The setting lever was screwed in from the back side so I will just unscrew that later. Don’t forget that! With that done, we can switch to the back side of the movement and take off the balance wheel first to make sure that we don’t accidentally damage it when further working on the watch. That also revealed the caliber number which turned out to be the ETA 2408 movement. Then we take of the ratchet and winding wheel with the click and the click spring , which where lying in the milled groove beneath, which I found pretty neat, the click also had a cool curved shape which I like, you can see that in the video. Off goes the train wheel bridge revealing the simple gear train. Then I took out the gear train as far as I could, so the seconds-hand wheel, the third wheel and the escapement wheel. I took of the pallet fork and its bridge in the same step.. Then I turned my attention to the last two “wheels” and revealed them by taking of the barrel bridge. I removed the barrel and the minute driving wheel ( which basically hooks through the entire plate to the front side and drives the minute wheel.) With that the movement was basically disassembled and I had a quick peek at the shock systems. This watch interestingly had a screwed down Inca-Bloc on the main plate side, I wonder how that would work when adjusting end shakes? I took both jewel packages out for the cleaning Now after cleaning all the movement components in a 1:2 ( Cleaning / Rinse) cycle with Elma WF Pro and Elma Suprol in my trusty Glashütte cleaning machine I reassembled the watch by following the steps backwards and lubricating on the way! Here is list of which lubritation I used where: Moebius 9010: Escapement wheel, seconds hand wheel, jewel caps. Moebius HP 1300: Mainspring Arbor, Barrel pivots, minute wheel (both), minute driving wheel, Pivots for transmission and setting wheel and contact surface of the date lever. Moebius 9415: Pallet fork jewels Molykote DX: All strong friction points in the gear less works and on surfaces which showed high stages of wear. After the reassembling the watch and lubricating everything I slapped it onto the timegrapher. Of course I demagnetized it before. The dial up side had an alright rate and beat error however I am unhappy with the amplitude. As I didn’t have a spare mainspring, a new balance spring or the ability to manipulate the palettes, I just hoped that the amplitude would rise a bit after the watch had run in a bit and would maybe even gain a bit more through the tension of the case clamps. I also replaced the crystal with a one and cleaned up the grimed up case with some physical force and an ultra sonic bath. The final product was this beauty: This project was a fairly simple one! However pressing in a tension ring crystal was a first! It defintly felt weird pressing down on an acrylic crystal haha. Otherwise it is a bit frustrated not being able to physically influence the ampltiude other than by replacing parts. I will definetly be looking into getting a heating plate and some tools soon so that I man manipulate the escapement! Gotta get those degrees up! What I also found really cool is that I could see a previous version of the modern Eta date wheel! It was like a little time machine going back 40 years! Anyways.. I am rambeling on now so I will cut it short! I hope that this post helps anyone in the future and I am sorry for any misinformation! I am not a professional of any sorts and am just doing my best! If you guys have any thoughts, comments and complaints, please comment!3 points

-

3 points

-

A bit of info, and some other similar (mirror-image in some cases) examples: https://17jewels.info/movements/unknown/lepine-v/ https://watchparts24.de/Antique-movement-with-dial-14-defective-and-incomplete https://www.millsys-watch.co.uk/henry--cie-movement-3821-for-project-or-parts-4878-p.asp I get the impression these old "bar" style movement - and many old French mantel clock movements - were made from generic designs, with each individual maker using their own variations in details around the base design, as long as the end result fitted its case.3 points

-

That depends, doesn't it? If you are a highly skilled watchmaker with years of experience, then it's as easy as he makes it look. Like Fried manipulating a hairspring. If you are a rank amateur like most of us here, then your results may vary. To make a functioning winding stem though, given the right tools and enough patience, should be possible for even the most ungifted amongst us.2 points

-

one of the amusements with discussion groups and people from all over the planet would be words that can have entirely different meanings somewhere else. Where silly people who think just because they speak English that they will grasp English on some other location. So conceivably it is the same thing I'm attaching an image so you can see what it is. I just now checked to see what the actual ingredients are and all it says is denatured alcohol. One of the reasons I like the point out that it's the alcohol that dissolves shellac is often times people get excited about any form of alcohol in watch cleaving and have a meltdown. when I was cleaning watches at home I discovered that the L&R rinse was not drying and sometimes fluid left on the plates. Talking to a friend he told me he was using an alcohol rinse and that was solving the problem. I'm assuming what's happened to the cleaning products is with time they become more environmentally friendly in other words they do not evaporate extremely fast. so a trip to the hardware store and problem solved. But that was a long time ago and the last time this conversation about alcohol came up I think I looked and I don't think it's available anymore. If I remember right people doing woodworking were upset because the solvents they use for their woodworking products are getting hard to get probably for environmental reasons again. Then universally today isopropyl alcohol is what is recommended. For instance Elma recommends that in there cleaning machines as the final rinse. It's what we use at work in our exotic machine from Elma. As it's exactly what they recommended just make sure it's 99%. Then whatever alcohol you're using for your final rinse it just a final final rinsing of the rinse and your only in there for a few seconds probably like 15 seconds in other words it's not going to dissolve the shellac. If it does you have a problem with your shellac.2 points

-

Great, that confirms that the barrel is turning. But we need to see it from the other side to be able to see just what is happening. It's something in the train of wheels, so we need to see what the train is doing when the barrel slips.2 points

-

It's a 5 bar movement, probably made one the Swiss, France border. Unfortunately, it's probably impossible to identify. The only thing I can tell you, is it has a Geneva stop works.2 points

-

This one popped up in my feed last night (T&T&T Watch Repair) where he makes a winding stem on a lathe. I don't own a lathe but found it fascinating. Those of you who do have lathe experience, is it as easy as he makes it look? I'm going to guess not1 point

-

1 point

-

That's because it's plastic. Have you tried putting a plastic bag over your head and see how much it reduces your hearing.1 point

-

The other bit here is don’t jump to the conclusion that you are using a movement holder. You are not, you have shown here a movement held with a case vice. Tom1 point

-

Nop, the lid of the barrel is turning. To be sure, You need to see the teeth of the barrel if they are turning. Or put dot with marker on both the lid and barrel and see if their position one against the other will change.1 point

-

I don't think there are any that haven't been turning the air around here a deep azure. And we're not even a month in...1 point

-

You're supposed to put the movement directly onto the timegrapher.1 point

-

Why are you putting the watch in a holder on the timegrapher?1 point

-

1 point

-

My preferred material for fixing pallet stones now is UV cured resin. After adjusting and testing the locking depth of the stones, just apply 2 tiny drops of the resin and shine a UV light on it for 20 seconds and it sets rock hard. After that, the pallet fork can be washed in IPA to remove any traces of the uncured resin. If you want to remove the pallet stones, just soak it in acetone for a couple of minutes to soften the resin.1 point

-

That's the correct movement with the correct display but the top lcd line appears very feint. Good price though so I guess you'll just have to wait and see.1 point

-

I have come very close several times to click the buy button for one of these clones, l'm all up for cheaper versions that do the job, many of us have weishi's right, but then fear sets in. When I was at school (80s) we were made to use these cheap fountain pens to improve handwriting, these pens would decide to puke up their contents whenever they chose to, most kids bags and pencil cases had nasty ink stains, and that's where the fear is, a couple of pence worth of ink is nothing, the thought of getting to your workbench and seeing twenty quid worth of 9010 pooled on your mat, I would probably have to call in sick. gpraceman pay no attention to me, I'm just a miserable b*****d, and I probably will click that buy button. But I'm going to hide my 9010 just in case this happens and I get blamed with demands for my stash.1 point