Leaderboard

Popular Content

Showing content with the highest reputation on 02/18/25 in all areas

-

Me neither, i have a bergeon set that has been built up through joblot purchases over a few years, but I honestly can't say that they make me perform better than my first cheap set.3 points

-

3 points

-

I wonder how the next watchmaker wanting to adjust or change the jewel, will judge that ? Cursing? Frank3 points

-

Shellac comes from beetle secretions so is organic and will vary. Flakes are the best for us and have a longer shelf life. Test before use by melting a spot away onto a metal plate and examine the hardness the next day. The colour is mainly due to wax content - more wax - darker colour and it takes longer to harden off. This is great for French Polishing where you need some lubrication as the finish is rubbed onto to the wood. We need the harder De-Waxed blonde style which is also great for grain filling open pored woods before top coating. Worth doing for the lovely smell. Picture here of the last project from a previous mad hobby. 64 coats of shellac. Love the idea of using UV cement - will steal that trick. Modern guitars are finished in a UV curing polyurethane paint - takes 30 seconds so very useful.3 points

-

It was arguably the first spreadsheet. We used it back in 1980 to develop a business plan for a small semiconductor company that later became Crystal Semiconductor. We ran it on an Apple II. It is in the public domain now. In fact I have it on my pc and can run it under DOSBOX. Only run it for nostalgia reasons...lol. Lotus 123 was the later heavyweight and sued everyone else out of business. Goes to show that having lots of money and more lawyers beats first-to-market. Well...until microsoft!! Here in Texas, we have "constitutional carry." Before the legislature passed that, I became licensed to carry. Don't Mess with Texas!2 points

-

One big lesson to learn in watch repair is.... patience. I guess, "lesson learnt" ..and one of the most difficult things in watch repair is fault finding. Anyway... the behaviour of your barrel lid is definitely quite unusual. I never had this problem. 1. There's definitely too much grease now, as you can see it squeezing out between the barrel and the lid. No grease should be in the "step" of the barrel where the lid goes. 2. Are you sure that the lid is fully pressed into the "step" of the barrel -- all around? Photos from the side of the barrel would help. 3. Are you sure that the mainspring is correct and not too high (which could prevent the lid from being fully pressed down)? The fact that you found this mainspring in the watch doesn't guarantee that it's correct (a previous watch-destroyer may have put a wrong one). 4. "I was just putting four dots of (around 1mm diameter) of braking grease on the barrel walls" --> this sounds about right to me. I do like to spread out those dots to a thin line, though. It helps prevent that you effectively push down the dots (to the barrel floor) when installing the mainspring.2 points

-

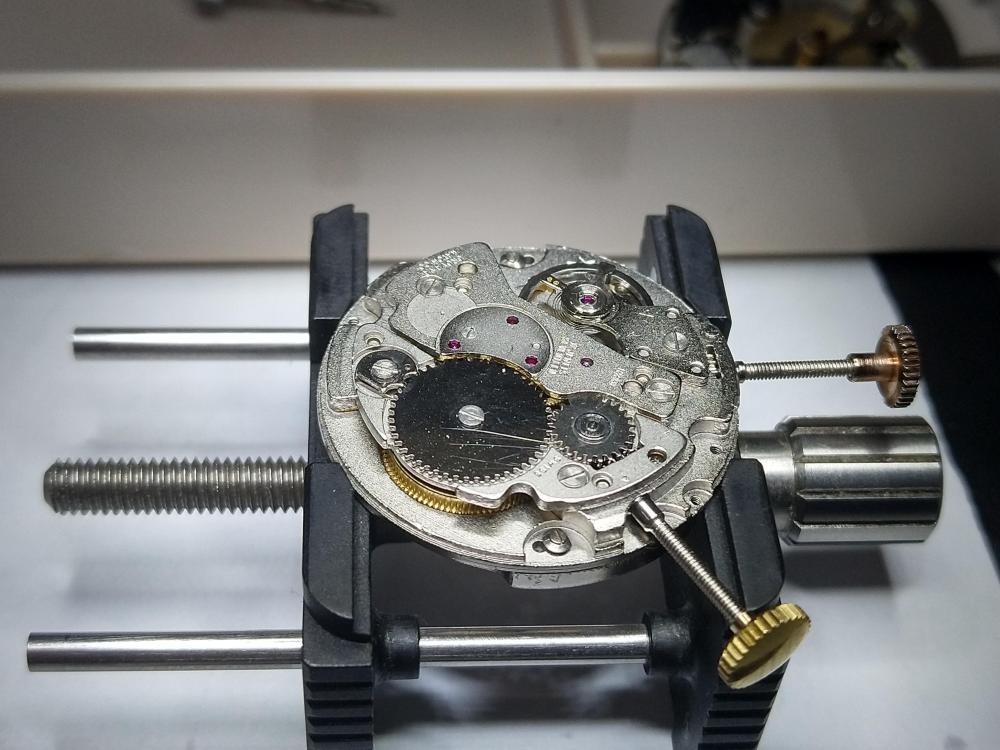

Thanks for your kind words, Ross! Much appreciated and it's great to see you around again! I'm afraid not and even if I had, I would happily share it with you for free. Some time ago I made a compilation of my walkthroughs here on WRT and you'll find it by clicking here. I have the unedited pictures for other calibres (listed below) that I plan to create walkthroughs for but we'll see when and if I get around to it. If I do I'll let you know. AS 1203, ETA 1080, 2763, Omega 601, Peseux 7040, Raketa 2609.HA, 2623.H, Rolex 3135, Seiko 7s36B, Sellita SW 200-1, Unitas 6498, Vostok 2414, 2416B I couldn't agree more but I'm afraid my only contribution was the picture. The explanation was made by @Klassiker2 points

-

1 point

-

typically on American pocket watches up until sometime I guess in the 50s you'll find serial numbers are all the plates. So even the pallet fork bridge underneath should have at least the last digit or two of the serial number even typically the balance wheel have the serial number scribed on to it as all these components were made and assembled together. But people sometimes do get creative. I was helping a friend once and he had an 18 size Hamilton I believe there is some issues which I didn't initially see. Then later I noticed that the balance wheel just didn't look right with the way it was? Then looking carefully I noticed it had an entirely different balance bridge. This required purchasing of a new orate used movement and better condition because this wasn't a conveniently fixable problem. I never did get to hear the history of the watch how it came to be this way the person does doing this for just wanted the problem to go away. So yes people can be creative and start swapping things around usually though when you have discoloration on plates and things it's because somebody probably left it too long in the cleaning machine or something similar or equivalent. one of the things you do if you're looking for watch shows is go to the national Association of watch and clock collectors website. See if you're lucky enough to have a chapter in your state or maybe a neighboring state. chapters will typically be having a meeting is a regular basis where a lot of times it's chapter meeting to buy and sell stuff. Then a lot of times the chapters will come together and have regional meetings. You can also look on their event page and see if there's any regional meetings coming up that you'd like to go to as now their typically open to the public.1 point

-

Welcome to the forum. You're best trying to get something that's at least working so when you've dissembled, clean, lubricate and reassemble you know it should still be working.1 point

-

1 point

-

Hello and welcome from Leeds, England. We can advise you on tools but we will advise not to start on anything sentimental. We all, or most break things to start with.1 point

-

1 point

-

Another Luthier. Another poorly paid activity with loads of expensive tools. The fiddle was for my grandson and shellac gives a lovely lustre and is easily repaired. UV cement should be ok to dissolve once you’ve figured out what you’re dealing with. Warning sticker? The UV paint on modern guitars is dreadful to remove - nothing legal dissolves it.1 point

-

Great job fellow midwesterner! I also had issues with a Hamilton PW that had its balance staffs changed to a different size. After ordering 2, I just ended up making one. But the hands looks great1 point

-

Sorry, I meant pallet fork and balance - specifically the shellac'ed parts. I always see people mention one dip and similarly "do not want in the house" level cleaners. but given all the smell I've resorted to running these two through my regular cleaning sequence (with a small exception - I make sure they don't stay in the IPA rinses too long, just pop it in, shake the part a bit, move to the next jar), and it looks all fine to me? Same for the cap jewels, a polish on watch paper seems to do more than any specific solvents (so while less obvious, I'm going to assume that pegging its holed partner is just as effective).1 point

-

1 point

-

Fellow luthier here (also been a long time). Shellac/French polish is my favorite finish. I even finish the handles on all of my tools with it (chisels need to be redone from time to time for obvious reasons). I actually prefer the garnet variety though. Adds a natural depth of color that is really difficult to beat, especially on walnut. I only break out the blonde for very special woods that don't benefit from the beautiful deep red color.1 point

-

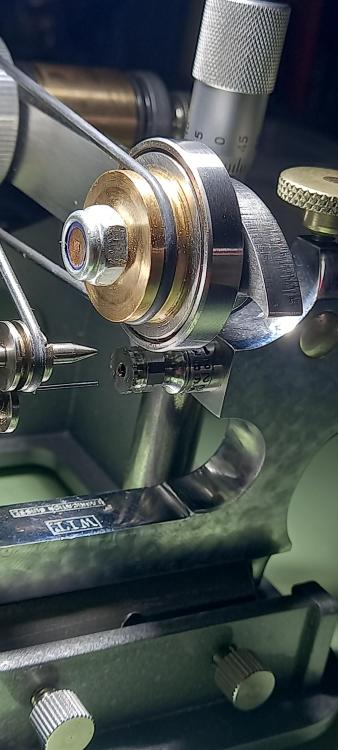

Finally got around to an inspection of the pivot polisher. Same wobble in the burnishing roller, not as bad as in the video. Doesn't seem to have any play in the bearing, more to do with the machining of the roller itself. But there is a major fault with the design of the roller burnishing faces, one edge is square for cylindrical pivots and the other edge has a chamfer for conical . Problem is the roller can't be reversed as bearing mount in the roller is too big and hits the wheel thats being worked .1 point

-

Why, almost everyone else does? The common practice with shock protected balances is to have the balance mounted on the mainplate with jewels removed and put through the cleaning machine. I use ultrasonic with Elma cleaner/rinse +30s IPA. I must have cleaned about 150 and never had a problem. If the balance does not have shock protection, I put it separately in a small brass pot (small enough so that it cannot bounce around too much).1 point

-

okay I'm having a confusion here? So I'm assuming the two parts would be the balance wheel of the pallet fork? Then as I quoted above and you get it may be can explain to me why don't you want to run those components through an ultrasonic?1 point

-

I dont count this one as there was an RL1223 not long time ago. This one was on my desk for years eating dust. Performance is ok, not impressive though. Passed its first test today, as it woke me up in the morning exactly when I needed it. Almost an identical is waiting for me to finish, cleaning machine finished its job early this morning.... went to bed after 4am.1 point

-

It depends what your intentions are going forward with watch repair whether or not you'd get the use from a staking set. In this case I'd just go for the replacement, put the other to one side and if you get a staking set down the line it gives you something to practice on.1 point

-

I think ideally you should just get a new one if you could. One of the problems I have in watch repair is if I solve a problem I move on. In other words I vaguely recall may be perhaps with a staking set but I can't quite remember. I remember having to do a couple of different similar watches and I don't remember which one that I tightened up and I'm still guessing I did it with staking set but just don't remember in yours does not look quite right.1 point

-

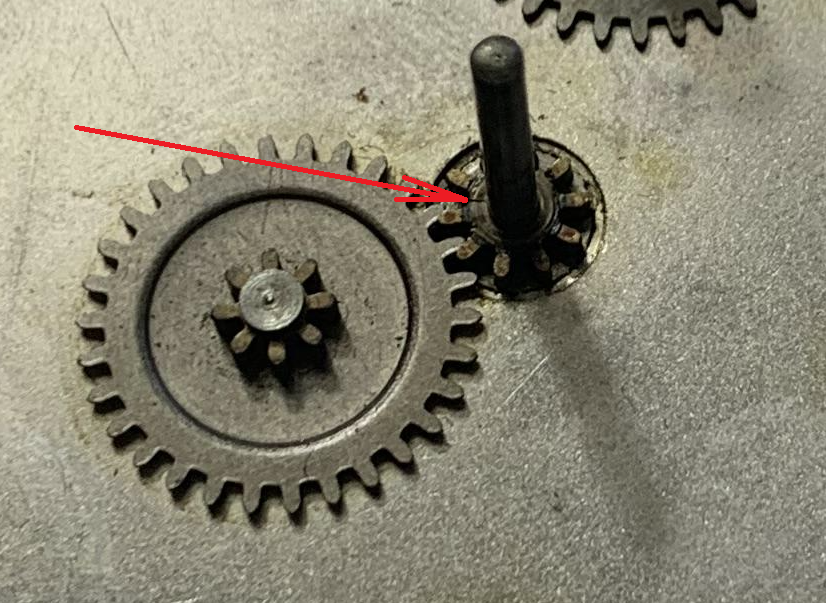

might be able to solder repair that pinion, but it will need removing.1 point

-

As you'll need to remove the barrel and clean I suggest as @Knebo has mentioned you check it's the correct size spring for the movement.1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement. If there is anything we can help you with don’t be afraid to ask. Nice clear photos can help a lot.1 point

-

1 point

-

I found it. It's an Elgin 495 from the 1940s. And while I remember thinking the movement was very worn, I didn't have the experience to know what I was seeing.It was absoolutely butchered, both the front and back of the balance cock were dug up with tool. I pressed the divots with my tweezer back to smooth them, put a paper shim in back and the huge end shake went away. The balance is still bent to hell so this is a project for later. It's nice what some experience accumulated can add.1 point

-

I have four sets of the Cheap supermarket calipers, 3 from Aldi and one from Lidl. Of the four only one eats batteries, with the display blinking after a couple months, although they still read fine for months with the display blinking, which it's battery needs replacing warning. The other three have never had their batteries changed and they are well over a year old now, and the Lidl one mentions on the box that it had battery saving built in. So they are not all battery eaters, in my case it's only the oldest set.1 point

-

Hello and welcome to the forum, you have already found the rabbit hole journey has a price tag, enjoy it1 point

-

1 point

-

1 point

-

No, I dont recall Clipper. Anything like Visicalc? He he. My first program was in Fortran on an IBM360. Input was punch cards and the output was a line printer. When running an application (like the Berkely SPICE simulator, you had to request someone at the compute center to load the tape). Things are different now. No necessarily better.1 point

-

1 point

-

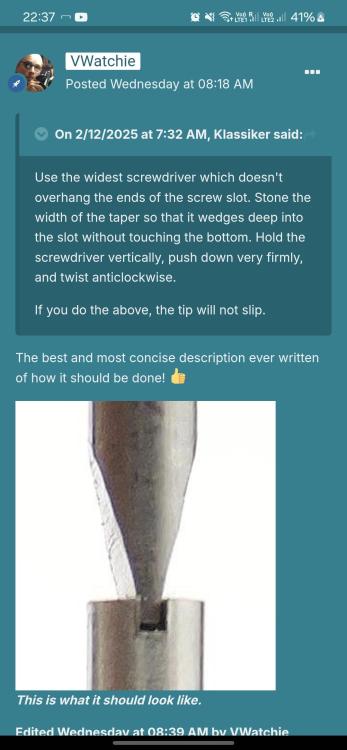

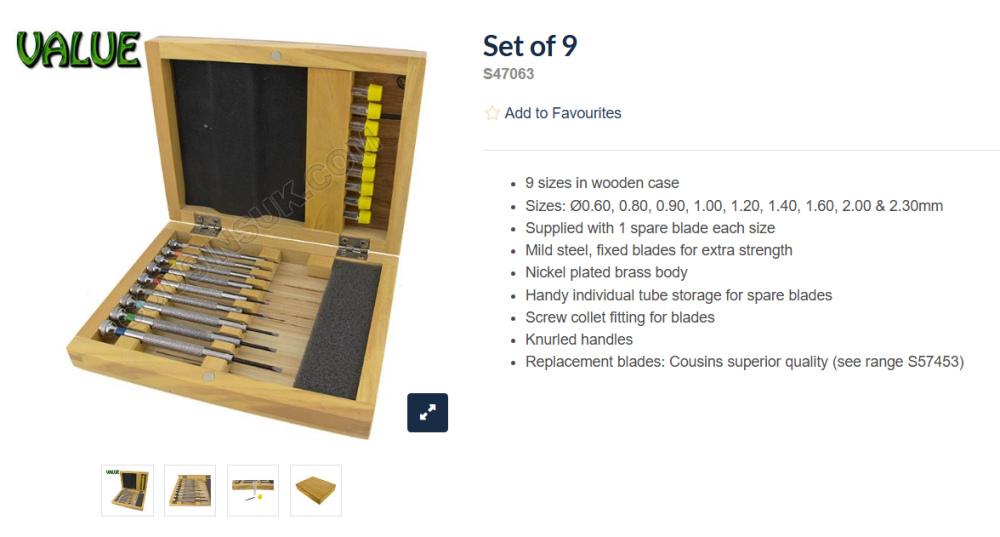

This can't be emphasised enough. Over time, you may even build up a collection of several sets, with two or three screwdrivers of any given nominal size, but dressed differently. I don't really care about the quality of the body. It's nice to have the best, and they'll last forever, but my best set are Beco Technic budget quality, and work absolutely fine. You'll want to be able to fit replacement blades later, ideally Bergeon or Horotec, so make sure they will fit. When working on watches, I use 0.5mm more often than expected, and never anything above 1.8mm. If I was starting again from scratch, and buying from that shop, I would probably get one or even two of this set: https://www.watch-tools.de/tools/screwdriver/7-s1-watchmaker-screvdriver-kt-quality.php1 point

-

Hi again. A little history on the watch I want to ultimately work on. It is a Hampden Watch Company, Model 4, William McKinley, 17 jewel. It belonged to my paternal Grandfather, a great man to me as I was growing up. I looked up the serial number, and learned the watch was made in 1915, which means my Grandfather would have gotten it when he was 17 or 18. I don’t know if he purchased it himself or received it as a gift. At this time, the watch doesn’t work, I think it’s a broken mainspring. When I opened it recently, I got the balance running for a short time. When it was running, it appeared to keep time well, but since it was only running for about 1 1/2 minutes, I didn’t have time to check it accurately. I don’t yet know what size mainspring to get, I think there are four sizes for Hampdens of the period. So I’ll have to measure it once I open it and begin the repair. In the meantime, I’ve been watching a bunch of videos, mostly Wristwatch Repair, and Watch Repairs Tutorials on YT. Fortunately, mechanical things come extremely easy to me (I took my bicycle apart, including the rear hub, and put it back together when I was 10. I’ve had automobile engines torn apart and put together again, without ever going to an auto mechanics school. My brain may work a little differently, as I can easily learn by watching a video, or watching somebody else doing a job before I get “hands on”. Still, I’ve gotten a Seagull ST36 to do some practicing on before I tackle the Hampden. The ST36 is the closest I’ve been able to find to the Hampden, the watch works appear the be similar, also the off center second hand appears to be similar. I’ve also gotten a bunch of tools in preparation. Hopefully I’ve made a good choice with them. (I was thinking of getting a kit from Sutcliff Hansen, but decided to search for my own through Amazon.). Most of what I got appears to be what Sutcliff Hansen offers, and I got a huge discount by opening a Prime account at the same time. Anyway, if you’d like, I’ll keep you posted, and post a video of my Grandfathers watch running once I fix it.1 point

-

Yes indeed. I was also once fooled by this "Bullongè" brand. Sounds nice and Swiss/French, but is a cheap Indian or Chinese make. Now... screwdrivers are one of the two most used tools (next to tweezers). It's worth investing a bit in them. BUT... even the best screwdrivers don't do the job automatically. You need some practice in applying the right pressure and holding them steady. Absolutely essential is to dress the screwdrivers to the right size for the screw slots - this applies to the cheap and the most expensive screwdrivers! It is NOT enough to match the screwdriver to the length of the slot (the obvious one). You also have to adjust the thickness! This video is helpful: @VWatchie and @Klassiker also posted this in another thread to illustrate the point I am trying to make:1 point

-

There are no German made watchmaker screw drivers today. Just the seller is German.1 point

-

1 point

-

Nop, the lid of the barrel is turning. To be sure, You need to see the teeth of the barrel if they are turning. Or put dot with marker on both the lid and barrel and see if their position one against the other will change.1 point

-

If the barrel is really moving, then the rivetting of the center pinion to center wheel has given up (could be the third wheel/pinion, but would be strange). Usually this is a dramatic thing and you can't wind any real tension on the spring without the pinion slipping in the wheel, so a little odd in your case. Basically, the barrel can only move as much as the escapement allows it to move; if it moves more, then something is slipping in the gear train.1 point

-

1 point

-

OK then, I hope these links work. The videos are only visible through these links and they're not public.1 point

-

Not an expert by any means, the way I see it static poising will show you how well you have restaffed the wheel, not so much how it will work. Dynamic poising though for me is more about how to get the best out of the watch once it’s working to its best mechanical level. Tom1 point

-

Baumgartner 866 Barrel friction fitted wheel .pdf Here is the last instalment of the BFG 866 lessons I wrote. This lesson shows how to remove the friction fitted minute wheel from the barrel cover, clean, lubricate and adjust the friction setting, so when in 'hand-setting' mode, the hands set correctly without being too sloppy or too tight when turning the crown. Some overlook removing this friction fitted wheel, but as you will see, there is a lot of old grease that doesn't help when left to congeal. Enjoy...1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)