Leaderboard

Popular Content

Showing content with the highest reputation on 02/20/25 in all areas

-

5 points

-

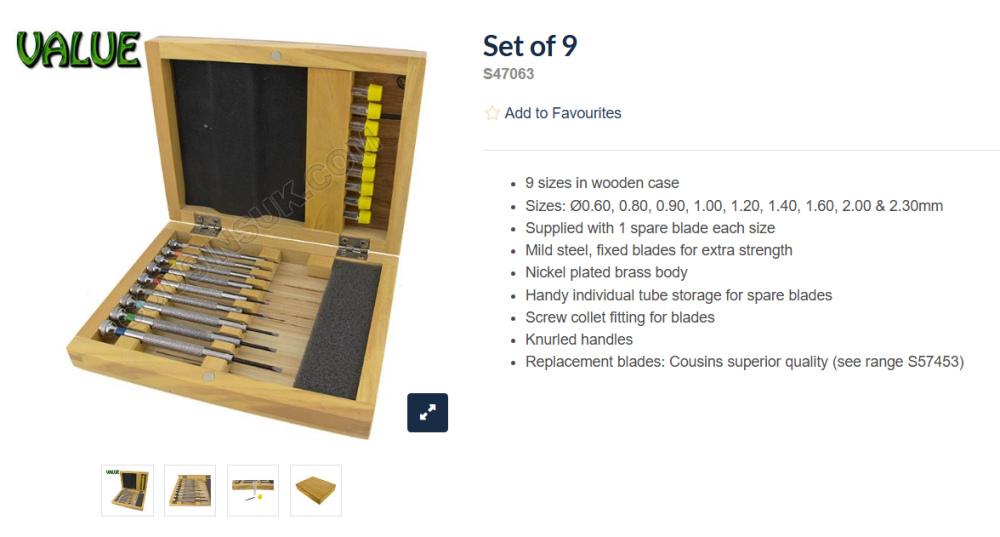

I have Bergeon screwdrivers and I'm not overly impressed. I think my less expensive A*F screwdrivers are easier to work with.4 points

-

Up to 1.6mm, I have Bergeon above Cousins, the difference? Not a lot.3 points

-

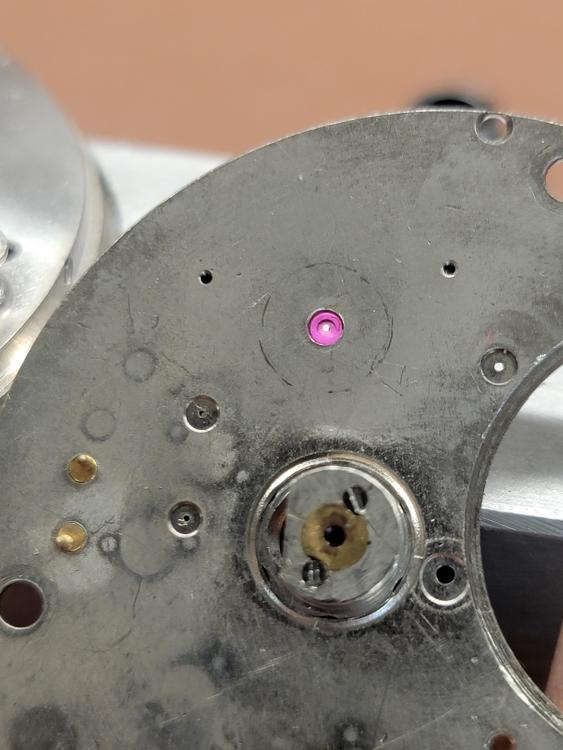

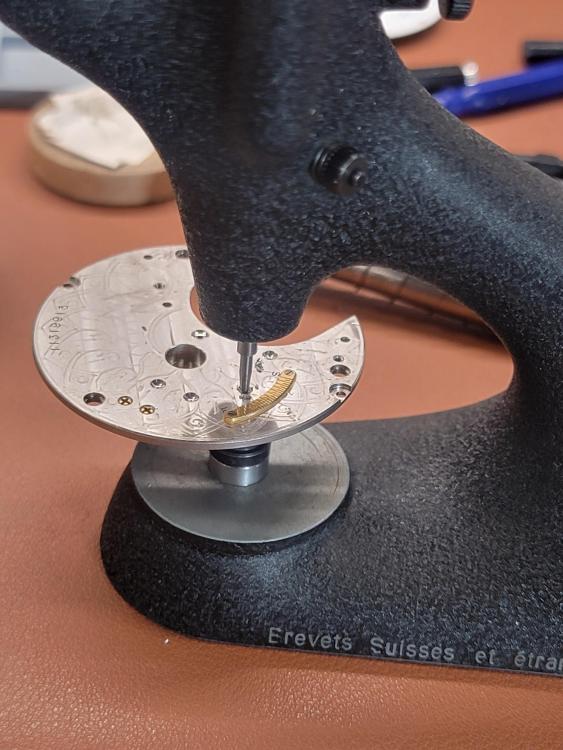

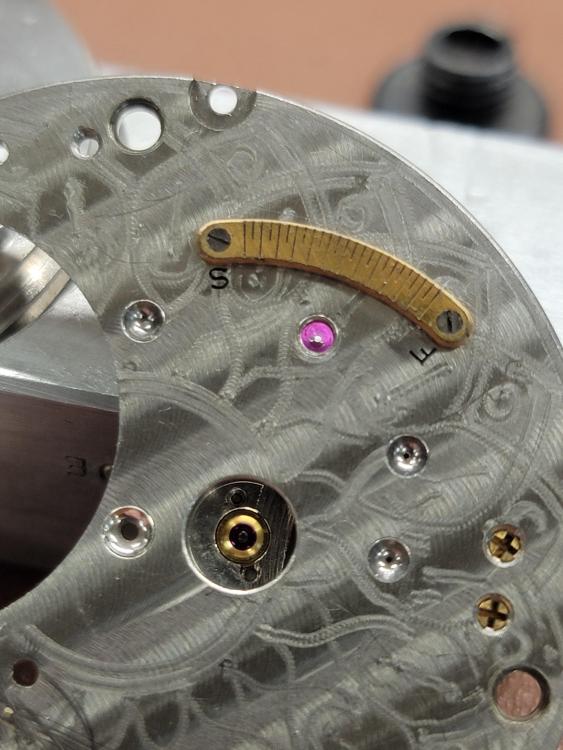

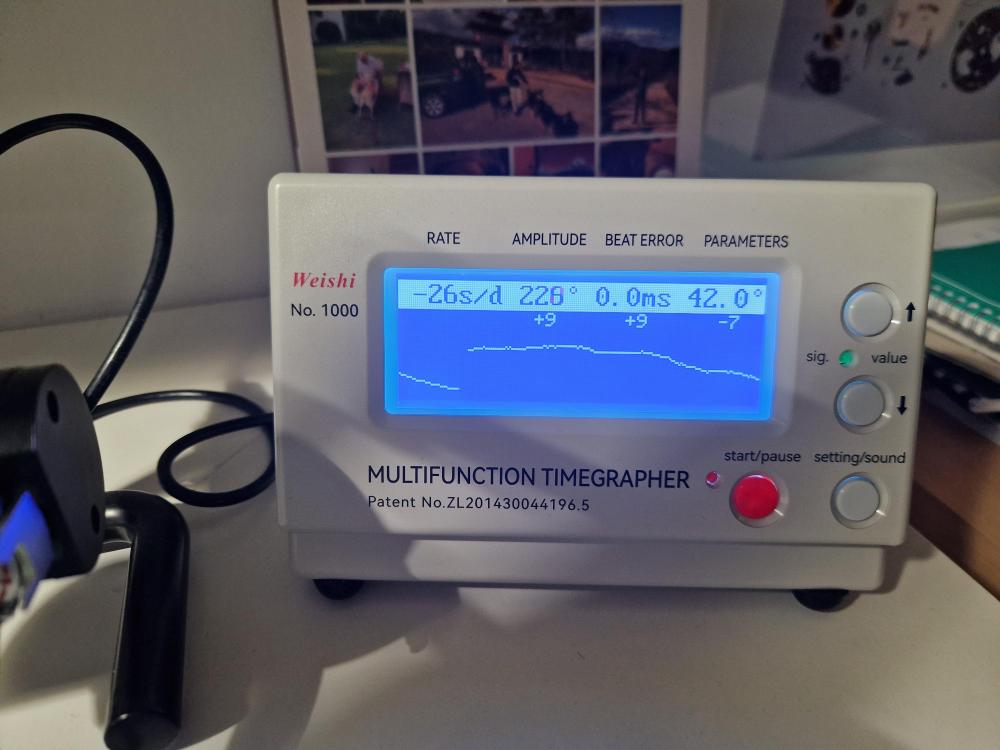

I'm super proud of myself today! Not meaning to show off, just wanting to share my joy: 1. First time replacing a balance staff -> success (and cleaned/restored my staking set in the progress) 2. First time refitting a pallet stone - > success (and build myself a little tool for it) Then came the confusion that started this thread... so thanks all for your guidance! Then... 3. Bending the old/correct hairspring into good shape in both dimensions (concentricity and flatness) -> success Next challenge was unexpected. Every once in a while, I was getting traces like this (especially in vertical positions): So back to fault finding.. Identified two things: i. centre wheel has quite a wobble, out of flat ii. a LOT of endshake on most train wheels, particularly the 4th wheel. On the latter, it actually resulted in the oil creeping from the jewel diwn the pivot to the pinion spokes. The pivot shoulder was so far from the jewel that there was no capillary action left to hold the oil (notably not even HP1300) So next corrections: 4. Managed to bend the centre wheel into a good flat shape (in situ) 5. Adjusted the train jewels with my Seitz press. Very little endshake now. In sum, pretty much every aspect of the train and escapement needed fixing. And I did it Now, I'm delighted with the results: Vertical direct comparison/improvement to the above: And dial up: This shitty, excuse me, Vostok has taught me a lot!!!3 points

-

Nice job, You do know you will now have to jewel all the rest as well.2 points

-

Yeah, I may have to give that method a try again as it's a bit of a pain when the movement doesn't have a quickset date.2 points

-

The hardest part in making a stem is making sure the winding pinion seat is square. I dont have a file rest, so locking the headstock and doing it free hand is a challenge. But they are not hard to make. Its a great skill to learn, for when you have a unique movement that has a broken stem, and want to get a job out the door instead of waiting a week or two.2 points

-

You certainly have a right to be! Congrats! I've been trying this many times but never really succeeded. For some reason, Archimedean spirals confuse my brain. I know they have an absolute centre, but I can't find it for some reason. The only time I truly succeeded in manipulating a hairspring was by @nickelsilver helping me out by drawing arrows in an image of where to push. I feel very envious that you are ahead of me! It seems you got it just right! In my experience, however, there's such a thing as too little end-shake especially when working on these Russian movements where the tolerances are pretty crude. It's a bit like shoes, just right is the best but if that's not possible it's better with a little too large than too small. Anyway, it sure looks like you nailed it! And should very much be so. I've probably had nearly a hundred Vostok movements on my TM, even brand-new movements, and have very rarely seen results like that. A bit of roller coaster is simply the norm for these movements. So again, congrats! Yes, they are great to learn with, but let's not forget these movements were never meant to be marvels of Swiss precision, but inexpensive and practical enough to be afforded by the masses. For this reason, and IMO it would be unfair to call them anything derogatory. A few decades ago these movements were manufactured by the many millions every year. It's a general misconception that the Russians are unable to produce quality in anything. The quality level is a very deliberate choice, and there are plenty of examples where Russian technology far exceeds Western technology.2 points

-

2 points

-

You guys are way over my pay grade. I am going to rest my mind for a while and then decide what to do. Cheers2 points

-

2 points

-

Lol or it has , to have, in its present perfect form within a negative sentence. I blame predictive text, it has no idea what I want to do. Come to think about it, neither do I . My daughter is way worse than me, chief officer of grammer policing in Yorkshire. Text messages stress her out, she corrects me to the point that I will only ring her now. " Dad what the hell is this you've just messaged me ? there are 12 tenses, please use them correctly or not at all. You're supposed to be learning English, I would ask for your money back ! " Anyone want a 31 yr old daughter ?2 points

-

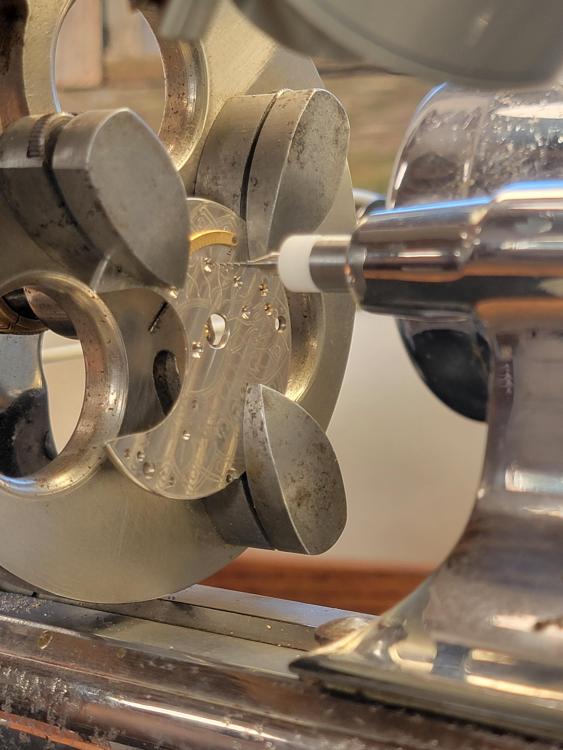

If there's a bushing, I would push it out, and make a bushing to take a jewel (hole probably doesn't correspond to standard jewel diameters). This maintains originality, and the bushing for the jewel can be made in "one shot" on the lathe ensuring concentricity. This technique also allows a relatively small range of jewels to accommodate a large number of repairs. I do this often for broken rubbed-in balance jewels, where suitable replacements can be hard to find. In some cases I make a bushing for a jewel that has the correct profile to "rub-in", but in some cases the only viable option is to open the hole in the place/cock larger than the original setting. Anytime a hole needs opening more than 0.10-0.20mm I go straight to the faceplate in the lathe. On something like this escape wheel pivot hole, you would have to go through multiple reamers to get to the jewel size, and in spite of their self-centering nature, they do drift. The faceplate allows things to stay in their original location. If there's a bushing that can be pushed out, and you have a jewel that's slightly larger than the hole, and you don't mind altering the piece, then you should be safe reaming to the jewel size.2 points

-

Makes sense from a production perspective: make 1 type of mainplate, suitable for both high grade (put in jewels) and low grade (put in metal bearing) movements.2 points

-

Press in the modern jewel. This some random 7 jewel Waltham, not priceless, and if the choice is between it running or not running, it should run. But did you try pressing out the entire bushing? Waltham made some of those friction fit and replaceable and they are possible to find NOS. I know this was the case with some 12 size grades, so it is worth looking into for 18 too. Then you would have a guilt-free repair.2 points

-

Alex Hamilton had an interesting idea, a piece of pegwood with some grease rubbed into it then ran the greased edge all around the inside of the ring.2 points

-

Took me a while to introduce, but here I am! I have been in love with watches for just a few years now, I don't have a great collection, I am not a great hobbyist regarding servicing and repairing, but one step at the time I hope top get always better and with more knowledge of this wonderful world! Thank you all for dedicating time reading this!1 point

-

1 point

-

1 point

-

1 point

-

Sounds like the problem you get with dirt in the move ment wandering around, dry or dirty movement. Service required.1 point

-

I think the idea is to rub the grease into the wood so that only a wet surface is visible but no actual grease. That was my understanding of it anyway.1 point

-

I did that on a handful of movements and, at least in my hands, I was getting too much grease on the teeth. I was probably charging the plastic stick I was using with too much grease, but I ended up going back to doing it manually as I feel I have more control.1 point

-

It still wont work because you need to be able to release the click.1 point

-

1 point

-

If youre comfortable modifying a jewel to add a chamfer, why dont you just get a jewel with the correct ID and then adjust the OD of the jewel? You will need a diamond wheel, and it should be done wet.1 point

-

Sorry, but no point to try to straighten all this teeth. Heating may help, but the teeth will be soft after heating. This is the first wheel after twin barrels, so the torque is big. The option is to source donor clock.1 point

-

1 point

-

Or just a square shaft that you can connect with an existing let-down tool. To be honest, I'd only bother if I was servicing ones of this type regularly. It's a simple enough task to do it manually as a one-off. As OH says, a piece of stiff wire would be enough. I do prefer to use the let-down tools rather than a winder; They have less tendency to whip your fingers off if you slip1 point

-

I don't know if it would work, I'm waiting for someone with more experience than me to give their opinion. If it would work, it's my gift to horology.1 point

-

1 point

-

It’s possibly a long term learning opportunity. Put it aside for now and research the techniques to replace a toot/block of teach and tackle it once you maybe have a go with some scrap stuff afterwards. Tom1 point

-

1 point

-

This continues to behave - fitted the correct dial spacer and movement holder today as well. I've actually ran it through every date without issue now, though am also checking it keeps running fine with normal use.1 point

-

Yea, I'm also watching in wonder. Good luck @Roll1ex! You have my admiration and I'm rooting for you. "Who doesn't dare, can't win"1 point

-

Make sure you Patent it !!!!!!! Some may bend without heat but you should have a feel for it once you start. If you do need heat then as @watchweasol said a small torch would be best. All my clock stuff is in storage at work along with my tubes but I'll dig something out tomorrow and post some photos. If nothing else you'll get practice if the next clock has the odd crooked tooth.1 point

-

ok, the cleaners used will vary but overall the method is to soak and rinse than follow with lubrication. For myself the method is much the same but can be adjusted depending on the condition of the movement. FOr example if someone used WD-40 or grease, I will soak in Goo-Gone. This is an all purpose glue\grease remover.1 point

-

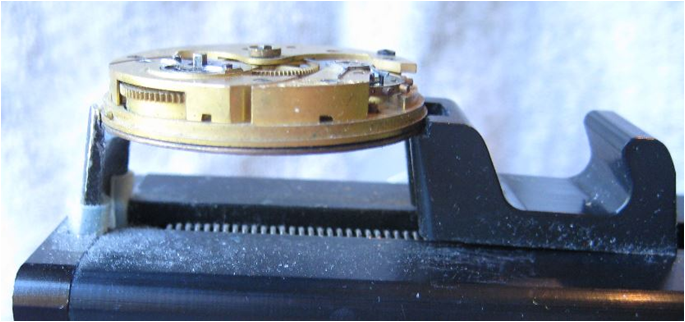

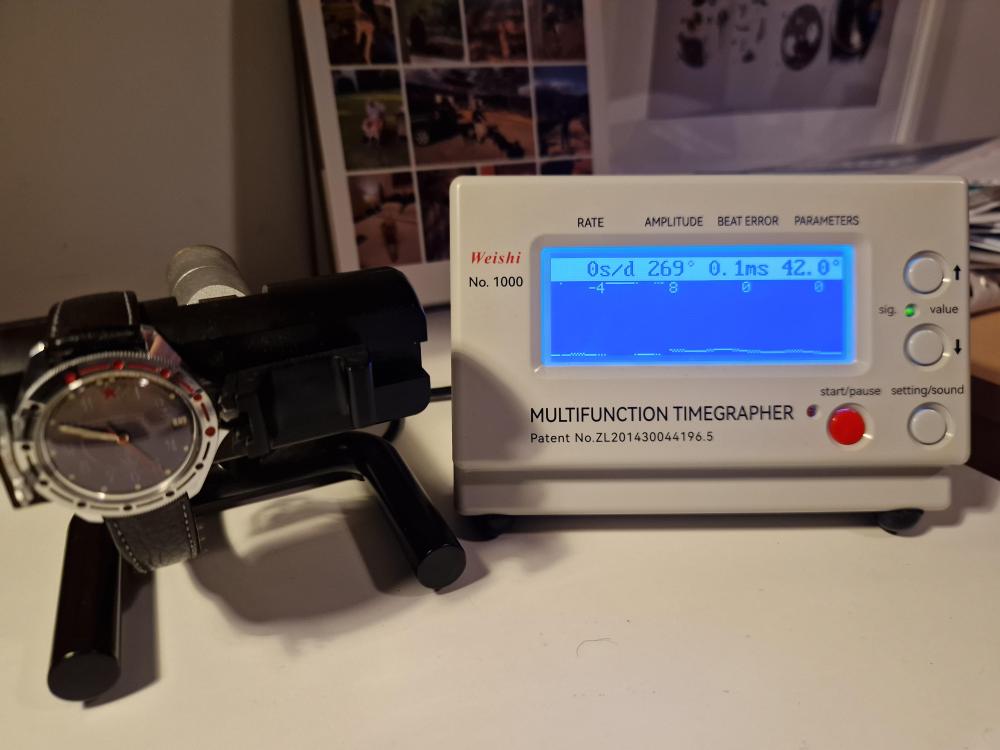

the timing machine microphone is specifically designed to hold the watch movement. Holding a watch in a movement holder sometimes works and sometimes does not work. this is because the signal which is not an audio signal yes it's an audio frequency but the signal is a vibration and that vibration has to cleanly make contact with the metal plate on the end of the microphone where the sensor is mounted. then this subject has come up quite a bit lately on the discussion group including a confusion of exactly how the holder is supposed to hold the watch so you would hold it like in the image below.1 point

-

Such a crazy experience trying to fix this watch. I ended up ordering several spare parts from used movements from different suppliers on eBay which turned out to be in not so great shape, now the watch is not performing good at all, readings on the timegrapher are all over the place. Ultimately I found an exact model on eBay and won the auction at a decent price (below 100euro). I also suspect the spring could be magnetized and that's why I cannot regulate it properly, even though I changed the balance wheel with a completely new one, but from a similar movement 46943 as I couldn't find any for my model. I am not there yet, but I won't give up either. Meanwhile I worked on several (non Japanese) watches and didn't had any major issues, this includes a "Precise" GUB Glashütte from around 1945-1946 that works absolutely perfect.1 point

-

1 point

-

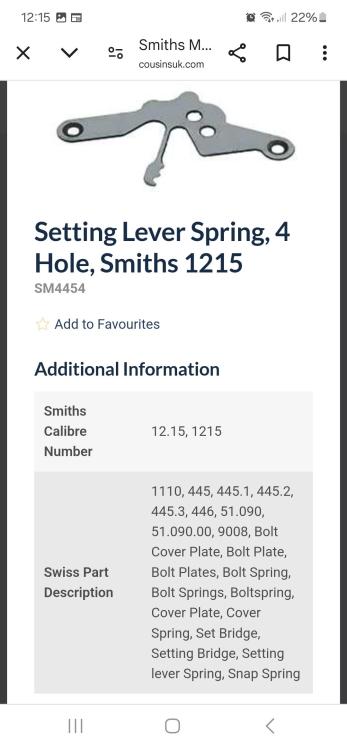

Hi @Teeroy, haha, yes, I think there's a "trick" that you're missing. I think you're trying to install the screw too early.. Finish the keyless works from the dial side first. Including the setting lever spring. The latter will hold down the setting lever sufficiently to then turn around the movement and put that screw in with no problems. But be very gentle with the first turns of the screw (almost no downward pressure) -- otherwise you may damage the setting lever spring.1 point

-

Balance wheels and hairsprings cannot be manufactured to <0.07% tolerance (=1min/day)! So the factory will measure hairspring (elastic moment) and balance wheels (moment of inertia) separate, sort them into classes and combine matching ones. @Knebo mixed parts from different classes and logically got a huge error. Frank1 point

-

1 point

-

Hi again here, Old thread, but if still interessed in repivoting wersus new staff turning, I can give my 5p here. This is not my routine way of balance staff turning, but I haven't made routine turning video, just this one I have. But it shows the technic I use when needed to work on T rest. The repivoting of balance staff is something I generally don't recommend as prefered way. You can see the balance in the video is useless and I used it just to show the process, as a friend asked me to. Repivoting takes about 10 minutes to me and saves dissassembling and reassembling of the balance. Staff turning usually takes 30 min. and then assembling, trueing, poising checks and so on may be another 30. The both ways usually will reqire regulation of the balance, but it strongly depends on what is expected as watch performance - is it needed to be chronometer-like adjusted or just good strong beat is enough. Another helpfull video shows how to take off the brokend old balance staff from the balance, when it is the riveted type. This all are simple phone recorded videos, so quality of the record is bad, but anyway, I hope, still can be helpfull1 point

-

Hi there seems to be no manual for the 3330 the closest I can ger is this one for the 3301. let me know if its ok . If not I shall continue the search. cheers Omega_Omega 3301 (1).pdf1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)

.thumb.jpg.19a9c4ff164d78d516aa9f05a063752b.jpg)