Leaderboard

Popular Content

Showing content with the highest reputation on 02/21/25 in all areas

-

4 points

-

The hairspring is matched to the wheel and staff assembly, but it is variations in the wheel portion of the assembly which significantly affect the moment of inertia. The MoI is proportional to mass and to the square of the radius around which the mass is rotating. That means dimensional differences between staffs have hardly any effect, but the tiniest differences between the mass and dimensions of wheels, especially at the rim, puts them outside the range of any individual spring.3 points

-

I think so, a balance staff's mass is compact and close to the axis of rotation so would have far less impact on rate than any change to the wheel's wide distribution of mass. A change of balance staff would result in no mass change, except in maybe density, quality of material which would be extremely negligible. Hairsprings are not vibrated to a wheel after a staff change so that proves that idea.3 points

-

It looks like it is a very old and incomplete truing caliper, used to find out if a wheel is bent out of round. The little nubs in the jaws would be used to hold wheel pivots. And that protruding post on the lower arm opposite the screw I would guess originally held another metal blade used for comparison against the wheel's rim. The size of it and being sprung closed makes me wonder if it was meant for clocks rather than watches. If that was its purpose, it is probably no longer useful since it is missing a part and is in terrible condition. Tools that do this can be bought for very little. It is also possible this is for something else entirely, and not a wheel truing caliper. Here's a common style, picture randomly lifted from ebay. That black metal part on the post is what I think is missing from yours.3 points

-

3 points

-

That's because we don't hear much about it in mainstream media (if ever?!), but some examples are: Aerospace and Space Technology Military Technology Nuclear and Submarine Technology Electronic Warfare and Cyber Capabilities Anyway, my point was simply that the goal of the Soviet/Russian watch industry was to produce affordable yet reliable watches for the masses, whereas the Swiss watch industry focused on serving a free market.3 points

-

Does it do this at less than full wind? I wonder if what you're seeing is similar to what happens if you crank a manual movement all the way to the end of the mainspring where it may have crazy amplitude for the first 5-10 minutes while the ratchet eases up on the barrel arbor. On an automatic at full wind that could mean your mainspring isn't slipping like it is supposed to.2 points

-

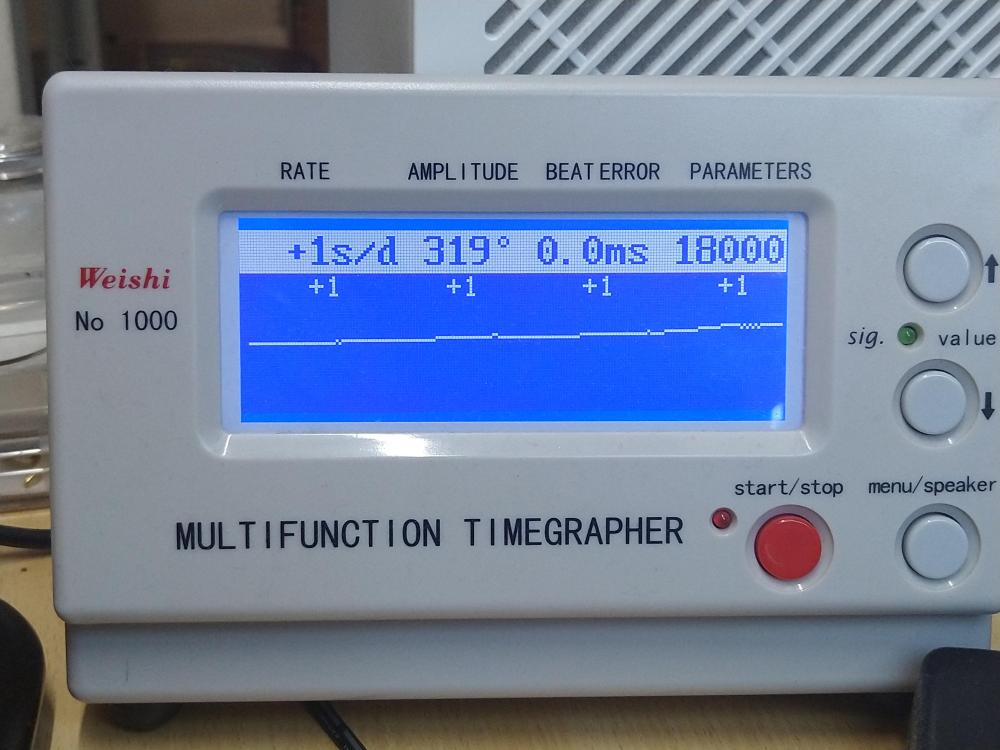

How can these two statements be true? Either you have too much amplitude and it's rebanking, or the amplitude is OK and there is another problem. Do you have a timegrapher pic of the 'rebanking'2 points

-

It depends where in the world you are and how much you're willing to pay for a new spring but this is probably the next best thing. https://www.dynagem.co.uk/products/tools-gr4112x.2 points

-

From one of your earlier photos, the roller jewel is situated 90° to the balance arms (usually it's either 90 or in line with the balance arms). To situate the hairspring close to correct from where you will need to further adjust it, place the balance wheel without spring into the movement and align the impulse jewel with the center of the banking pins. Then lay the hairspring on top of the balance cock so that the stud is over its hole and the collet is over the jewel. note this position in relation to the balance rim and then you can install the spring close to where it needs to be. But as @nevenbekriev is implying about your NOS hairspring, it probably is not going to work for you. The balance wheel and hairspring left the factory as a married pair and if you try to install a different hairspring to that balance wheel it will probably not come anywhere close to running at the correct rate afterward. It could be out by several minutes per hour even if it is a hairspring from the exact same grade and made in the same production run. The balance wheel and hairspring ("balance complete") must be kept as a matched pair.2 points

-

When I was in school we had to put in a jewel on a 7j movment using the faceplate and slide rest to open the hole. For those who were ahead they could jewel more of the movement, all the way up to fully jeweled. It was interesting to see that those movements that got further jeweling pretty much all ran worse than unjeweled, which was 100% due to not getting the part correctly centered before boring the hole. Drifting the hole location just a few hundredths of a mm can have a dramatic effect, even causing the watch to simply not work (depends a lot on where in the train the defect is introduced- between 4th and escape wheel will be worse than center to 3rd wheel).2 points

-

Rolex, Omega et al used ebouches at some stage, and then improved them. I really don't see the difference or why everything has the be authentic. To me an improvement is an improvement. Of course some movements are of historical importance but otherwise? One of the most famous clocks in the world, the Westminster clock isn't authentic, it was automated about 100 years ago.2 points

-

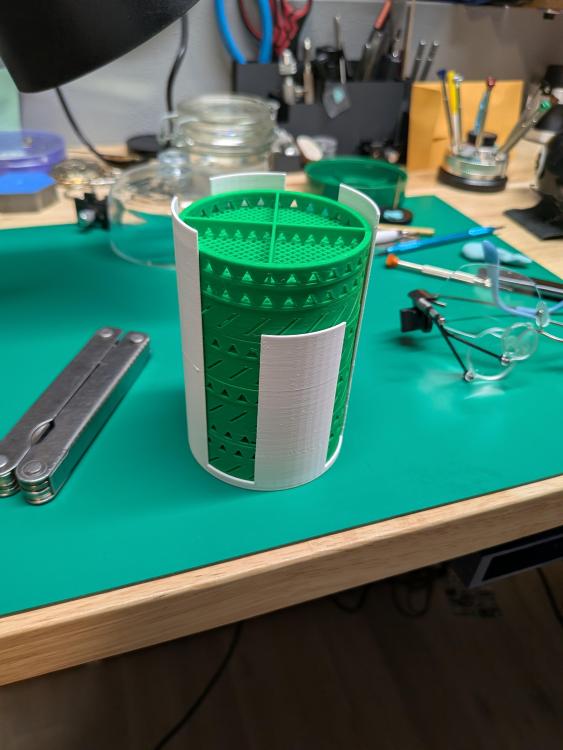

Hello everyone. As promised, I am showing off my diy cleaning machine. This was built with NEMA 23 stepper motors, controllers, a power supply, and an Arduino nano. I will list the parts used below when I'm at my computer. The frame is made from 3030 extruded aluminum, which I had made by Misumo online. The cleaning basket was purchased in eBay. Some miscellaneous parts needed are an 8mm shaft, some couplers, buttons, and wire. The codes I wrote for it can be completely adjusted and changed however it is needed. I have since adjusted the speed the linear shaft moves up and down. In the future, I plan to add another stepper motor to include a turntable at the base, with 4 jars, so the entire cleaning process is one process. Right now I still need to get jars that fit, and to build a fan for a drying cycle. Please post any questions you might have, and if you're interested in the code used to build your own.1 point

-

Strange that the values aren't as high as you think as lift angle should be 50 Deg. What have you done to the movement.1 point

-

Yes that can happen. There are size differences between the various manufacturers. Sometimes a roller table will be loose on (for instance) a dgn staff, but will be a perfect fit for a ronda staff. It's good practise to always measure the critical dimensions before fitting it to the wheel. (ask me how I know..)1 point

-

Sorry. At rest = watch left in one position for 30-60 seconds to stablize and continues to be in that single position The initial read out is a programmed test with 30 seconds pause between positions for stabilization than 60 seconds of timegrapher reading to determine average performance. The subsequent photos demonstrate watch in dial up position, stabilized. Then watch moved (rotated), set back on to timegrapher, and the following ~60 seconds of amplitude jump, rebanking, and settling back down to 270 amplitude. Make more sense?1 point

-

Yes, go soft on it. Test. Redo. Smll increments until you get there.1 point

-

1 point

-

Hi @graemeW, Check out this video from 15min onwards. Cheers1 point

-

Setting the roller higher will upset the fork interactions with it.1 point

-

I thought the same after reading what appears to be contradictory information. But the OP does say when the watch is on his winder ' it gains so much time so quickly ' .1 point

-

Your timegrapher readings aren't inferring in any way that there is knocking (rebanking) is occurring, in fact, quite the opposite. I would trust your readings more than your ears. What are you hearing? And what is the trace on your timegrapher?1 point

-

Is this for the same Heuer and what are the case details. Edit Just done a little more digging on Dynagem and would be cautious before ordering anything. Dynagem Limited was dissolved in 2015 Dynagem Ltd was dissolved in 20211 point

-

1 point

-

Vintage tools are cool but sometimes they need to be just for display. If you want something functional don't buy them, if you want something cool on your bench, go for it.1 point

-

You can get 19/64" or 7.6mm here in the UK and they also have them at our local fixings supplier. https://www.amazon.co.uk/Aexit-Silver-Stainless-Hexagon-243M312/dp/B07M848GKW1 point

-

In theory I guess the balance staff is accountable as it forms a portion of the mass along with balance wheel that the hairspring is matched to. But the staff has to conform to lots of other things in the movement that are more important than just the addition of its mass. Thats why there are tens of thousands of different sizes and shapes. But the matching would be done with the hairspring and the balance as one piece. I wouldnt expect the moment of inertia to change much with the addition of the staff, but the hairspring has to fit somewhere and the staff provides a seat and a pivot to allow oscillation when vibrating the hairspring. Maybe thats different in a factory setting ?1 point

-

HWGIKE#44 Zaira 1509B swiss lever, full service. So the last time I tried to service her sister I was brutal and destroyed her mainspring. This time I was gentle, but made two little mistakes, once I put the MS barrel together without the arbor and then slightly damaged the barrel when I removed the lid, and then I put the dial the other way around.... realized it when the hole for the stem was at 9 o'clock. This is a lovely little Russian movement with excellent performance. Lovely design and it was great to work on it, it must be a reliable company for many decades.1 point

-

1 point

-

The screw is holding the boot and allows it to turn, so really just keeps the hairspring from escaping the pins. The important thing is that the hairspring is concentric and flat - all the coils are evenly spaced - they should be so without any interference from the pins. So the hairspring should sit directly between the pins with minimal gap either side, just allowing enough for rate regulation. Any more than a minimal gap then the hairspring's active point can back up to the stud when amplitude starts to drop - weaker oscillations unable to bounce the hairspring between the pin's larger gap - having the effect of the rate dropping rapidly. So if the hairspring is resting on one pin, how much energy is required for it to reach the other pin at a distance. I would want to free the hairspring from between the regulation pins, check that the coils are concentric, adjust the hairspring at the stud to make them so , then tighten the pins back up with the hairspring resting in the center of a very small gap between the pins.1 point

-

For anyone not sure about buying a watch from ALDI , My mother bought an Ascott watch from Aldi in 2013 and 12 yrs later after 2 batteries it is still going strong . It looks good ,the leather strap is showing signs of wear but overall it has been great . She has washed the dishes with it on for years so it is actually water resistant . Works out at around £1.50 per year for a good looking watch . I am not a watch snob so I buy what I like and not what fashion or collectibility dictates . My son is a watch snob ,he collects and displays . I enjoy my watches and am never afraid of getting them damaged as they are cheap.1 point

-

Goo gone is like kerosene with lemon oil. A good soak in kerosene work just as well. I just did a ladies timex with a nightmare of a winding/setting spring that goes under the rocking bar holding the winding/setting pinions. It not like the usual Timex movements with a fixed spring on the other side of the mainplate.1 point

-

That's not an easy fix Rich, the train and escapement are plate bearings. I think closing the lever bearings might be a bad move, they have a deep narrow sink as do all the train bearings. Fitting friction jewels might be possible but again a big ask in something this basic. I thought about shaving the gaurd pin down so it has a little more clearance but still holds the escape teeth lock.1 point

-

Up to 1.6mm, I have Bergeon above Cousins, the difference? Not a lot.1 point

-

You certainly have a right to be! Congrats! I've been trying this many times but never really succeeded. For some reason, Archimedean spirals confuse my brain. I know they have an absolute centre, but I can't find it for some reason. The only time I truly succeeded in manipulating a hairspring was by @nickelsilver helping me out by drawing arrows in an image of where to push. I feel very envious that you are ahead of me! It seems you got it just right! In my experience, however, there's such a thing as too little end-shake especially when working on these Russian movements where the tolerances are pretty crude. It's a bit like shoes, just right is the best but if that's not possible it's better with a little too large than too small. Anyway, it sure looks like you nailed it! And should very much be so. I've probably had nearly a hundred Vostok movements on my TM, even brand-new movements, and have very rarely seen results like that. A bit of roller coaster is simply the norm for these movements. So again, congrats! Yes, they are great to learn with, but let's not forget these movements were never meant to be marvels of Swiss precision, but inexpensive and practical enough to be afforded by the masses. For this reason, and IMO it would be unfair to call them anything derogatory. A few decades ago these movements were manufactured by the many millions every year. It's a general misconception that the Russians are unable to produce quality in anything. The quality level is a very deliberate choice, and there are plenty of examples where Russian technology far exceeds Western technology.1 point

-

Lol or it has , to have, in its present perfect form within a negative sentence. I blame predictive text, it has no idea what I want to do. Come to think about it, neither do I . My daughter is way worse than me, chief officer of grammer policing in Yorkshire. Text messages stress her out, she corrects me to the point that I will only ring her now. " Dad what the hell is this you've just messaged me ? there are 12 tenses, please use them correctly or not at all. You're supposed to be learning English, I would ask for your money back ! " Anyone want a 31 yr old daughter ?1 point

-

If there's a bushing, I would push it out, and make a bushing to take a jewel (hole probably doesn't correspond to standard jewel diameters). This maintains originality, and the bushing for the jewel can be made in "one shot" on the lathe ensuring concentricity. This technique also allows a relatively small range of jewels to accommodate a large number of repairs. I do this often for broken rubbed-in balance jewels, where suitable replacements can be hard to find. In some cases I make a bushing for a jewel that has the correct profile to "rub-in", but in some cases the only viable option is to open the hole in the place/cock larger than the original setting. Anytime a hole needs opening more than 0.10-0.20mm I go straight to the faceplate in the lathe. On something like this escape wheel pivot hole, you would have to go through multiple reamers to get to the jewel size, and in spite of their self-centering nature, they do drift. The faceplate allows things to stay in their original location. If there's a bushing that can be pushed out, and you have a jewel that's slightly larger than the hole, and you don't mind altering the piece, then you should be safe reaming to the jewel size.1 point

-

Thats is the correct click, the cousins photo is poor, the minute wheel bridge also has a broken jumper spring.1 point

-

Ok, good. I'm keen to see @nevenbekriev's reply to this to learn the significance and what to do to address it.1 point

-

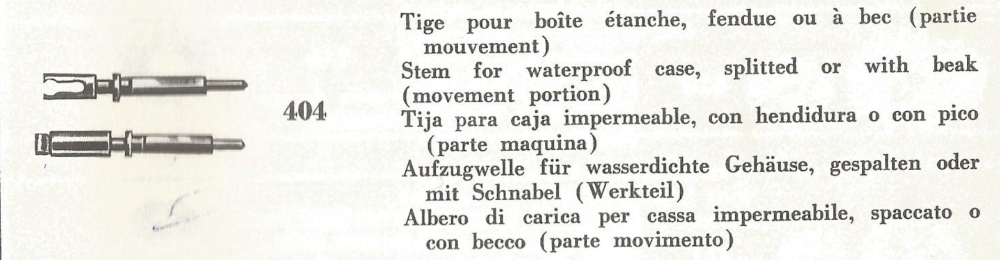

Ah! Thanks guys! It is indeed a front loader as the back does not come off. It makes sense that I would need the split stem! Also, thanks for the unsolicited advice also. No, will not make this my first job. I have some other beaters that will get that honor.1 point

-

Welcome! The stem is partly determined by the movement and partly by the case. If the case does not have a removable back then it may be a front loader needing a split stem. I have no experience with them; I only know they exist and come in two pieces, a movement portion and a crown portion. Otherwise you'll generally need a single stem. There may be different variants of a single stem to fit different crowns. I'm not sure. Now a word of unsolicited advice: don't make your father's 1951 watch the first one you work on. My father's watch was the second mechanical watch I worked on, and I lost a part and broke a part. Fortunately it was only about 20 years old and parts were available and relatively inexpensive. Yours is over 70 years old and if parts will be harder to get. If you care about the watch, work on half a dozen or so that you don't care about first. Maybe buy another 10BUC movement on ebay and practice disassembling, cleaning, reassembling and lubricating it a couple of times. You'll make all kinds of mistakes that will teach you valuable lessons that you will want to learn before you do anything with your father's watch. Also, if there's any lume left on the hands, it's likely to be radioactive. Take precautions not to ingest or inhale it.1 point

-

Thank you. Again. Excellent presentation from @Jon I now know how to do it, whether I can justify getting a staking set however is another matter - seems to me a rather lavish outlay to repair a part I can get from Cousins for £5. So second question - should I invest in a staking set or just keep on replacing bits as I go?1 point

-

yes that is very clearly a riveted staff or staff that supposed to be riveted in. friction fit staffs have a very different look to them. Typically they friction fit into a steel hull but permanently mounted on the balance arms. Typically the hub is blue in color to alert the watchmaker that they're not supposed to drive that out with the staff.1 point

-

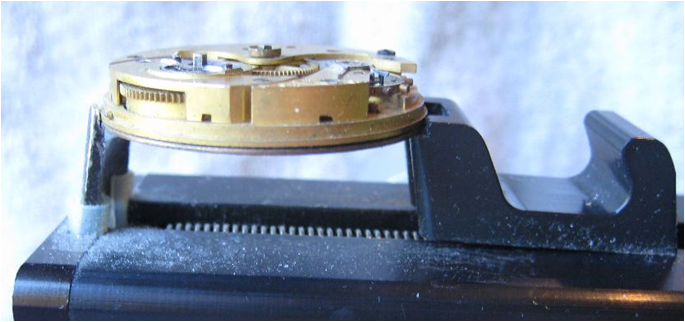

I'm always suspicious of pin lever watches and timing machines at least for amplitude. This is why there are times where you'd need to visually look at the amplitude and see if it agrees with the timing machine. then the mainspring should be fine. then the various positions on the timing machine do look interesting don't they? then I see the hands and dial on the watch? Usually for timing when the watches running that's when you usually want to have it on the timing machines of case there's a problem you have to start removing things. So basically if it had a calendar you wouldn't have the calendar on you typically don't have the automatic on just the basic running watch on the timing machine. then there is a another problem possibly? The microphone of the timing machine was designed to hold a watch. He was specifically designed this way because it needs to pick up the vibration which happens to be in the audio frequency but it needs a vibration of the watch cleanly clearly sent to the outer metal plate where the sensor is mounted underneath. So occasionally watches held in movement holders or even fully cased up watches will not look as nice because the movement holder of the watch case etc. is interfering with a clear signal. Oh and of course having a dial on the watch on the timing machine is a bit of a problem as you can risk damaging the dial. Another reason the time the watch before the hands and dial are on. here's an example of how the microphone is supposed to hold the watch and yes this isn't a wristwatch it's a 10 size Elgin watch but the principles the same. this is the way you want to hold your watch so the sensor that's down underneath gets the best and cleanest signal.1 point

-

Have your tried to put the screw in the setting lever outside the movement? Just the two parts. To test that they fit into each other at all. This also makes me wonder. Does the shaft of your setting lever fit snuggly in its hole in the mainplate? It should. If not, maybe you really have the wrong piece.1 point

-

For holding the lever in place on an English lever, 3/4 plate movement, a clip is made from an old mainspring. Maybe this idea would work here.1 point

-

Another small update. All these loose basket parts were annoying. So I designed and printed this holder. Having a printer is too much fun! On a side note, I had some case parts in one of these baskets going through the ultrasonic after polishing. I had it heated to 40C and totally forgot about them for about 2 hours. As expected, the parts basket melted a bit and is discolored. These are printed in just PLA, so I didn't expect them to be resilient. I will probably end up printing them in ABS in the future, but for now, they work just fine.1 point

-

Omega used to etch a little Ω on the inside of the crystal. I'm not sure if they still do that either. But, let's entertain a purely hyperbolic and ridiculous scenario. Everyone knows the Omega Moon watch, but did you know that Neil Armstrong never took his watch out of the lunar landing module? And that it was Buzz Aldrin's watch that was the first to be on wrist on the moon? And, that was disappeared enroute to the Smithsonian and has never been recovered? So let's say I found it at a pawn shop in Newark, NJ right next to Jimmy Hoffa's gold Rolex Datejust. My story goes that Omega provided two Speedmasters -- one for Neil and one for Buzz (for the sake of the story, Mike Collins, the command module pilot, wore a Timex). During testing the crystal got scratched on Buzz's watch and NASA had it replaced with a new one ... possibly from Omega, but as a Govt. agency they probably went with the lowest bidder. So the whole moon thing happens and parades and history and medals and game shows and cereal boxes, etc. Now I've got the first Speedy that landed on the moon and there is a big, golf-ball sized dent in the crystal from Neil Armstrong's lunar tee-off. Should I try and retrieve the original scratched crystal from NASA? Keep the damaged crystal that was actually on the lunar surface? Or should I just get a new crystal so the watch can once again be used as a watch? The watch is more valuable: A.) With all original parts, regardless of condition. B.) In the condition it was in at time of historical achievement? 3.) In optimal working condition regardless of the parts? Now take out all the historical hyperbole and think about it as you just bought a Speedmaster in 1965 for $185 U.S. (yes, that what they sold for in 1965) and change B. to "The condition it was in after you fell in the pool on your honeymoon after too many Pina Coladas." Does it change the answers? Should it change the answers? Are you fond of rhetorical questions? What is the airspeed of a coconut-laden swallow?1 point

-

I would replace the crystal personally. You could retain the original crystal just in case a collector offers big money if it is all original. When I have replaced crystal and even original worn marked straps I bag them up to go to the owner with the repaired watch. Tom1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)