Leaderboard

Popular Content

Showing content with the highest reputation on 02/23/25 in all areas

-

3 points

-

I have a non-Vevor branded 3L. It's worked flawlessly for years. Doesn't get used on a daily basis by any means, but it's been through its paces all the same. Those shops often reduce quality over time as they find ways to save cost though... Hopefully the replacement does you well.3 points

-

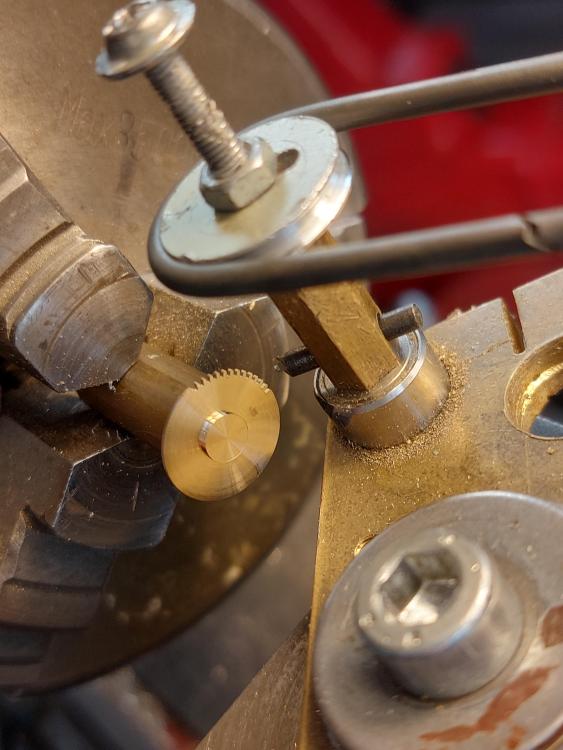

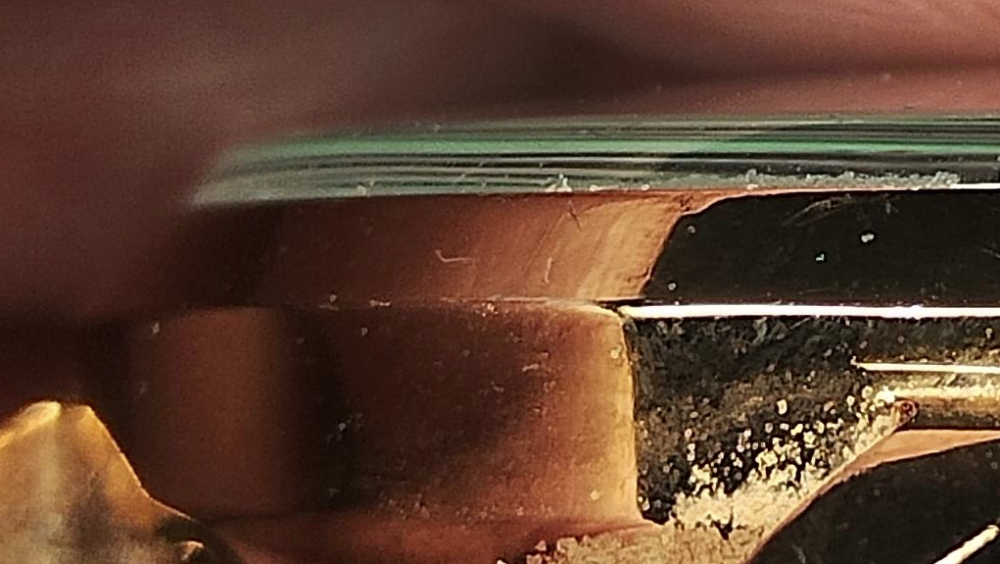

Project Update: Timesaver Lapping Compound is really amazing stuff. I was able to eliminate all the binding high spots on my spindle bearings. I started with the rear bearing which was the one that would lock up completely. It took 4 or 5 rounds of twisting that bearing with my fingers using the Timesaver compound to get it to where it would turn 360 smoothly, but it could still lock up when contacting the frame bearing 100% So for that I had to assemble it tightened down and lap it, which worked. No more binding of the rear bearing. When fully assembled and the locknut all the way in, I still had a high spot where the pulley would slow. I could not figure out where it was, so I did two rounds of disassembly and assembly of both front & rear bearing with Timesaver compound, gradually tightening the locknut until it was all the way in and I could spin the pulley all the way around without slowing. At that point I took it apart and cleaned it all up again, reassembled with oil and now it runs fully smooth with the locknut as far down as I can turn it. The Timesaver compound leaves a light gray, very uniform matte finish. This part started out with a polish but the fine matte turns so much more smoothly. You can see the finish on both the inner angle and the outer steep angle. It obviously does this to both mated parts of the bearing. I am beyond pleased with the result, and all I have left to do is mount my motor.2 points

-

The one in the unlined box is Steiner, and would be my first choice for sure. Replacement parts are available, and they are adjustable for alignment, unlike any other Jacot tools.2 points

-

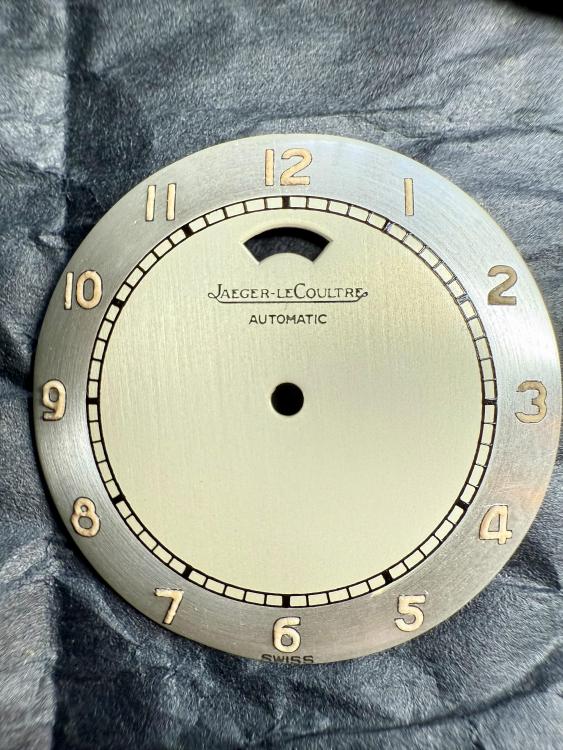

The idea of retaining the original dial and having a new dial made up....that sounds like a good option that allows for being able to wear an otherwise stored hidden away watch and a return to originality .2 points

-

Who are the tools' makers? If either is a Steiner, keep that one because it is possible to get replacement parts from Horia. Either of them looks like a fine tool though, and both have the hard-to-get big center wheel runners. Nice.2 points

-

So what mainspring did you use and how did you grease the barrel.2 points

-

Give it a full wind, then work backwards. Remove the second hand and check amplitude. Remove minute hand and check. Remove hour hand and check.... until you are down to bare bones or when amplitude goes back to 290-310.2 points

-

Sorry I am not able to participate al the time in the discussions. Here we see the things somehow are gone in a little wrong direction. The differences in amplitude in vertical are not connected to the hairspring. At least in You case. I tried to point to the reasons, but not enough clearly. The hairspring position between regulator pins will affect the timekeeping, but this is another thing. The amplitude differences reasons are in more friction related to a certain position. When balance is ABOVE the pallet fork, it is closer to it. Closer is hard to imagine, but it is in the limits of radial free plays of balance bearings and in quality movements very small is enough to cause the guard finger to rub in the safety roller for example. Wear of the pivots may cause such problem, as good as change of balance from another movement for example. So here I would try to check the clearance between guard finger and roller in both sides and if there is difference, I would try to equalize thus increasing the smaller one. In movements with banking pins, slightly opening the one where the clearance is small solves the problem. Of course, different reasons also exist for such behavior, but this is what I would try first as most probable.2 points

-

You've very welcome. I'm just going to say that the 'Rodico hack' gave me a bit of a bum steer, both the light and the rodico suggested a groove that I not think isn't actually there. The theory is fine, my practice may not have been Good luck with trying to replace your crystal, hope it works out for you.1 point

-

1 point

-

1 point

-

Did Fossil advise that thickness as that seems way too thick to me. Can you post a photo how the one you've got looks when in place.1 point

-

This is a regular problem - rebanking while fully wound and continuing winding by autowind. This is bigger than needed friction of the spring bridle on the barrel wall. What is the bridle shape? Is it well polished (sometimes it is not and friction is due some bad edge or burr)1 point

-

1 point

-

1 point

-

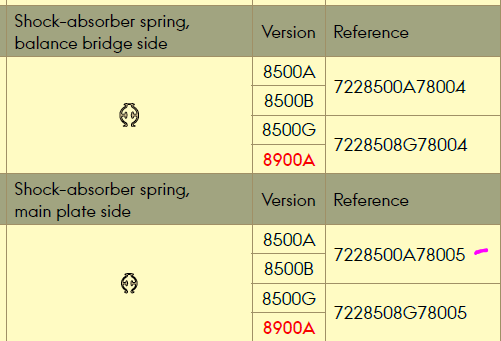

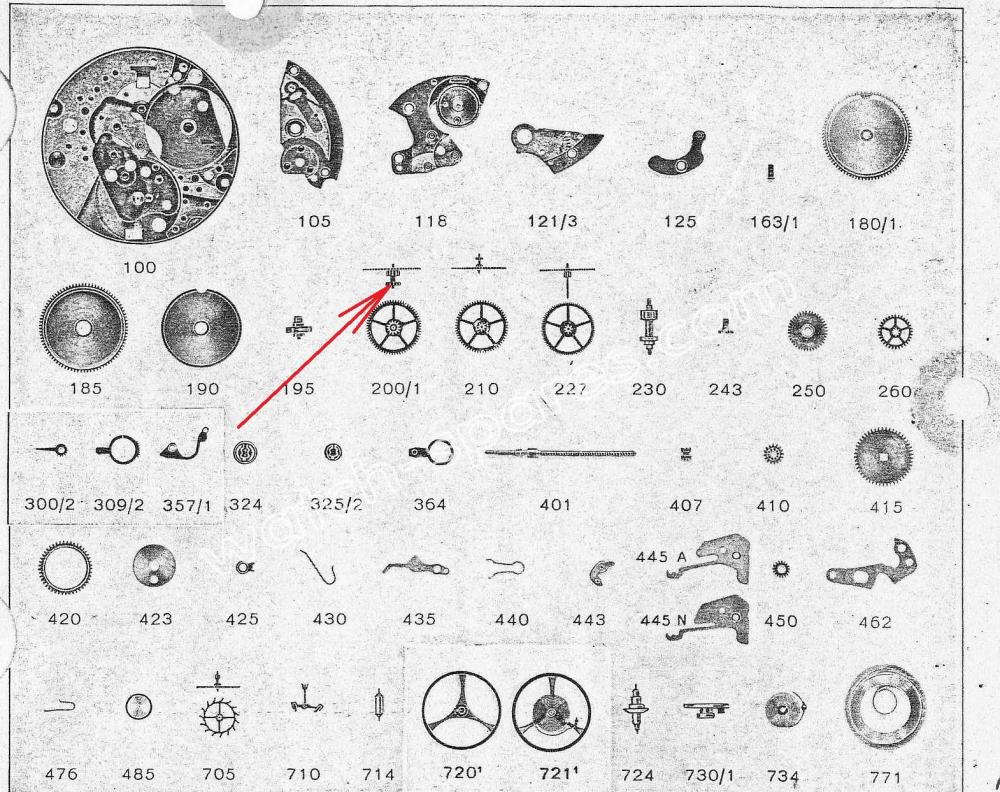

your watch has two springs like this, one for the balance one for the main plate. then the spring is listed as a replacement part here is the part number 7228500A78005. then if you go searching for the part number you basically find almost nothing except. If you look carefully at the number you see that the base caliber for the part is 8500 a. That technical sheet of parts list is out on the Internet or we can download it and I've attached it. Then did you get a nice picture it looks like this. Then just because this particular part interchanges with your watch doesn't mean that all the rest the parts will. 3559_Omega_8500-8501-8900-8901_E-1 cousins.pdf1 point

-

1 point

-

The second one looks like a screw starter. You wind it till the flat is inline with the prongs, put in the screw slot and release. The spring tension displacing the center section holds the screw making it easier to get it started in the thread without dropping it. Tom1 point

-

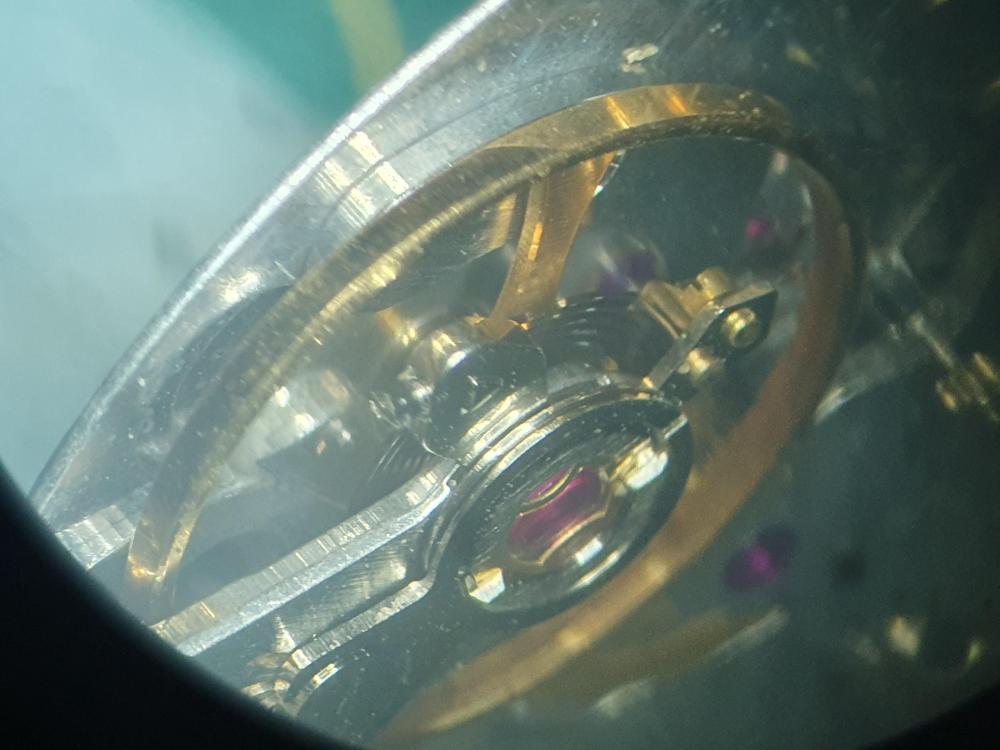

…found art so if it’s yours clearly quite valuable …no idea except perhaps with those jewels what look like the sneaky little date wheel jewel on a Rolex something calendar wheel related. Center pivot for an automatic weight through the rectangular hole, outer jewel to aid its rotation inner jewel for a date ring…1 point

-

Looks like it hinges between 10 & 11 with the clip between 4 & 5. Being Omega it will be restricted supply so best removing inside a plastic bag to reduce the potential of any flight.1 point

-

1 point

-

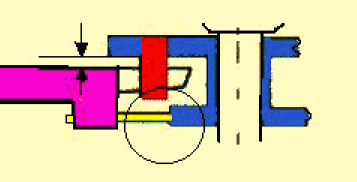

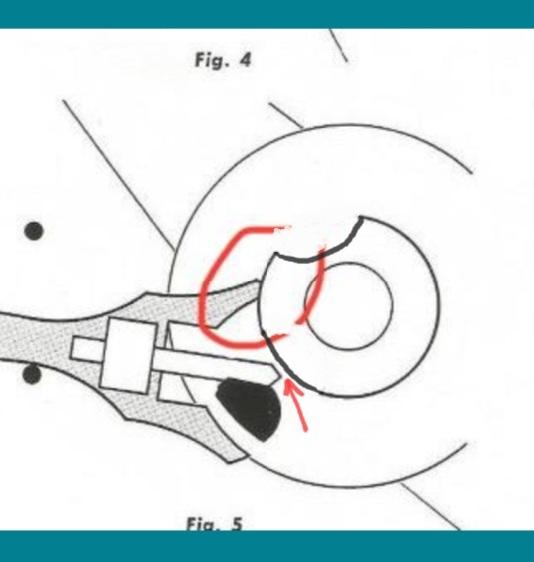

So I've done a little dodgy photo editing for you .....this is the clearance that we are looking for. Gaurd finger/roller safety . Nothing should rub on the roller, this would be friction...something that kills amplitude in this case. The fork horns and impulse clearance take over the safety when the finger passes through the cresent as in the top diagram. There is a lot more to it than this , but this is the rubbing that Nev was referring to. And no the gaurd finger shouldn't touch the impulse pin , the only parts that should touch it are the insides of the fork slot that give it a shove ( impulse )1 point

-

@Leonid I have edited your post and added a translation. Please post in English, there are many translation services free online. Tom1 point

-

Not tight on their arbors but maybe the hour hand tube rubbing on the dial hole.1 point

-

Not quite what I was describing, this is when the impulse pin and fork horns provide safety . In the bottom picture as the balance continues to rotate anticlockwise you'll notice that the gaurd finger ( the center pin of the fork ) takes over the safety of the escapement locking. The gaurd finger keeps the lever banked at its current position on the bottom banking pin shown. You are looking for clearance between the finger and small roller after the crescent has moved further around. No you dont need to do that , dial down on your bench you can move the balance wheel around and gently try the lever for the finger clearance. If the sideshakes of the lever and balance are excess then the finger and roller may contact easily.1 point

-

This is an interesting topic. @JohnR725 remarked correctly that resale value will dramatically go down then dials are refinished. I recently saw a 1940 Longines Flyback Chronograph in incredible condition. Could have been worth 50-70k. But the dial was repainted. Now the value is around 5k. Crazy. I'm also a big advocate of originality. Even if it includes a big of damage/deterioration. BUT, I nevertheless agree with @mzinski.. if you're afraid of the radium and you won't wear it... and you're not looking at selling... then do what you want with it! You'll honor the watch more if you wear than storing it away in a lead-box. BUT, this brings up a deeper question. What is "refinishing"?? There are different levels: 1. Keep everything original and just clean gently (my favourite) 2. Remove radium but leave everything else exactly how it was (I could live with that!) 3. Correct/add paint where it has faded in a manner that blends in with the original paint (I probably wouldn't, but maybe acceptable) 4. Repaint the whole dial .. 99. and then there is what I've so far seen from Kirk Rich. If you look at this video: .. you see how they remove EVERYTHING from the dial and "recreate" it from scratch. To me, this is absolutely unacceptable (unless the dial was completely gone... which it really wasn't in this case). Any collector will immediately see that it's redone (e.g. all the printing is a tad too thick; the edges of the pie pan have become rounded,...). I personally find it a crying shame. There's nothing original left in this dial (except the brass plate itself). That's just my opinion, though. I may be unfair to Kirk Rich, because maybe that's what the client wanted. And if, upon request, they just remove radium - and leave everything else untouched - great! They probably have the skills. But just make sure you know exactly what they're doing.1 point

-

Was the hour hand touching the dial? There should be a gap between the hour hand and the dial.1 point

-

1 point

-

keep the bottom one, it looks like it has the internal drive feature and an extra spindle more modern so might have had less use ,but rob the burnisher from the top one. no ! in fact keep both, watchmakers need at least two of everything..at least...so start looking for two more...at least.1 point

-

Even one or two evenings out per year is enough to exercise a fine restoration piece. Doesn't have to be a daily driver.1 point

-

1 point

-

As well as the case interfering with the results it could also be how the case is being held that's causing further problems.1 point

-

I concur with keeping the original dial and hands but respect you are concerned about the radium. Is this a cal 59? 700? If so there are replacement dials and hands around. Find something in poor condition to send to the restorer and keep these original since they are in excellent condition, not only because of value but because of the artifact value. You are not only the owner but a custodian of a piece of history, imo… …that said, I’ve used Kirk Rich they did excellent work… …feel free to note my hypocrisy . In the case of this watch the movement was in nearly flawless condition after service and I’m a fan of the idea of coherence, so now the dial matches the other elements…1 point

-

1 point

-

Yes it does thank you. So small winding of the watch causes it to rebank ? Can the watch also be hand wound, can you tell how close it is to being fully wound ? It's starting to sound like the bridle is not slipping soon enough, so the bigger question of why you are getting rebanking at low amplitudes is answered....you're not.1 point

-

Your timegrapher readings aren't inferring in any way that there is knocking (rebanking) is occurring, in fact, quite the opposite. I would trust your readings more than your ears. What are you hearing? And what is the trace on your timegrapher?1 point

-

1 point

-

A quick followup: A 30.0x29.3 i gasket 0.8mm high (Sternkreuz) and a 1.3mm 29.3 mineral glass (Cousins) Worked a treat.1 point

-

1 point

-

Apologies I thought it was more an open disussion for similar questions. That said thank you Rich, you helped the penny drop and thanks for the Sternkreuz catalouge suggestion, super helpful resource. I was indeed trying to fit a snap-in when I should have been using a top-glass. Snap-in's I've relised are held in place by the outer part of the glass, whereas the opposite is true for top glass which are effectively placed over part of the case. It's still not 100% clear for me if my watch needs a topglass or an armoured crystal. I'm eering towards topglass because although the metal ring does fit inside the inner diameter of the old crystal, it also slots around the dial like a chapter ring to hold the movement fast, and also the crown wouldn't almost certainly let water in, so we're not going for water-resistant. One can also purchase a topglass crystal with a specific inner and outer diameters, although in my case I need to go 1mm wider OD copared to the old crystal to get the right ID. With regards to the armoured glass, I understand now why you said buy it in 3 sizes to ensure you find the best fit as this inner diameter is not given in the catalouge. Again, thanks very much, very useful info. Nick1 point

-

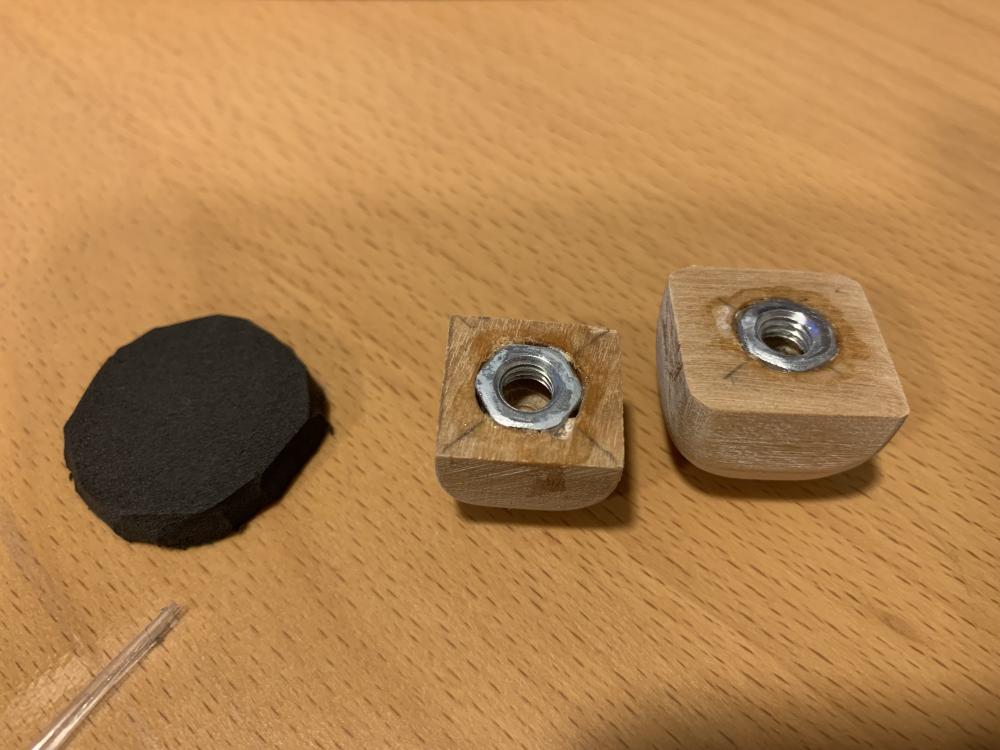

I actually did this a few days ago to put my 1st acrylic dome in. I have one of the cheap lever style chinese presses. I sanded down some scrap wood, put an M6 nut into the back and just used some super glue to hold it in. I put a small piece of foam over the dome when pushing on the crystal. Without the foam, I broke a crystal, but I chalked that up to also being too large and being the 1st time I have tried this, was using way too much pressure to make the larger size fit. The smaller size down is the one that ended up fitting.1 point

-

0 points

-

The tiny plastic ultrasonic cleaner I'd been using for years died on me last week so I decided to order one of the Vevor 3L machines from Amazon that are so common. It failed partway through its first cycle, the heating element was heated far above the temperature I had set, and the control panel went dark, though the power switch remained lit and the fuse is not blown. Boo. One star. I have this poor suffering Bulova 10BC movement that was in my previous little cleaner when it died, then went into this new cleaner when it died too. Between the two of them, it's had approximately one complete first cleaning cycle but no decent IPA rinse.0 points

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)

.thumb.jpg.19a9c4ff164d78d516aa9f05a063752b.jpg)