Leaderboard

Popular Content

Showing content with the highest reputation on 02/24/25 in all areas

-

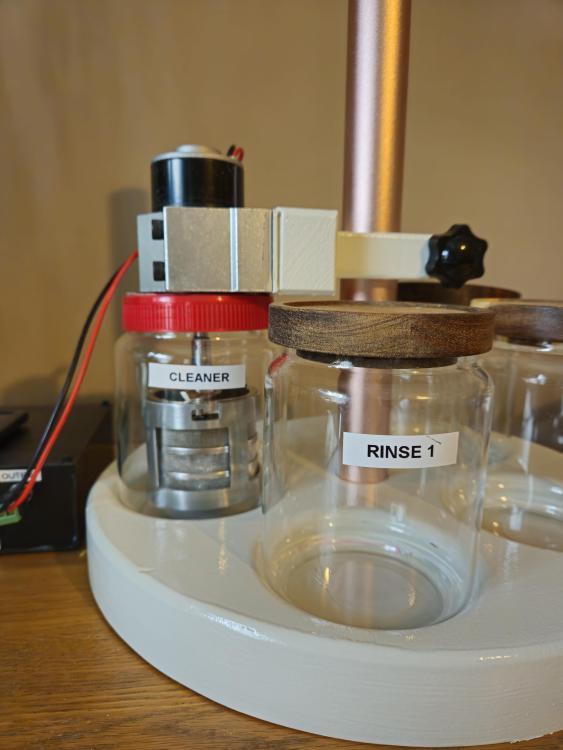

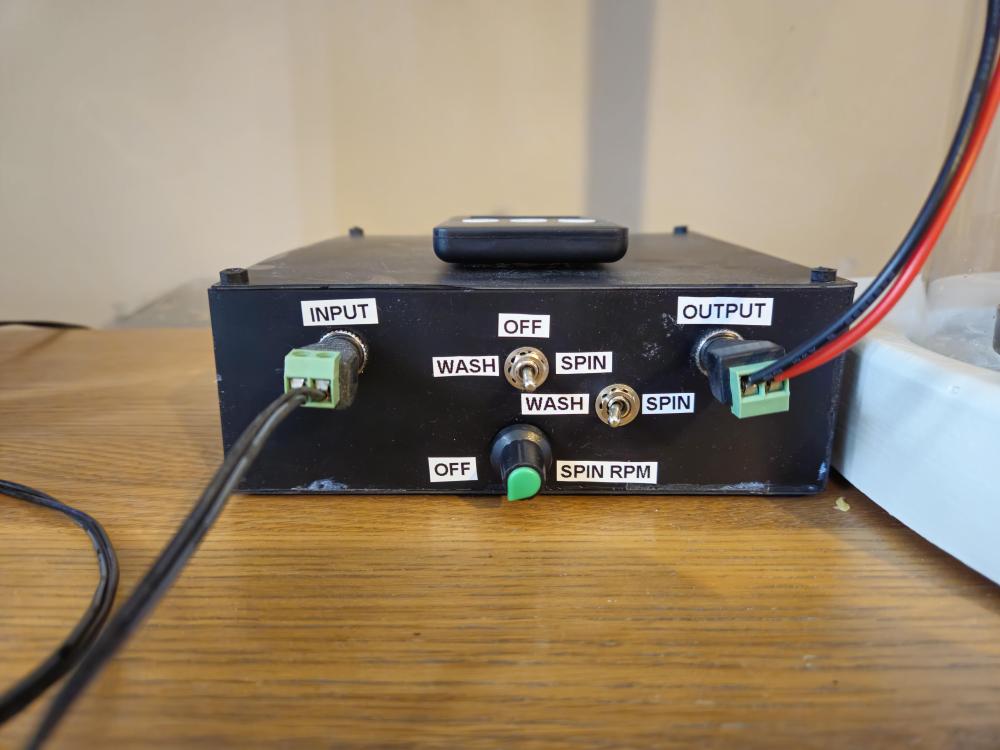

Hi all Following on from my DIY Dial Feet welder reciently posted, I decided the next thing it would be helpfull to make would be a Watch Parts Cleaner, so below is my version. Basket was from an American seller on ebay and its all controlled by an Arduino for the wash cycle and a speed controller for the spin function. Base is a laminate of two sheets of 3/4 ply wood and the colomn is from a defunct vacuum cleaner. Timer is a basic digital kitchen timer stck to the top of the control box. Here is a short video showing how it functions7 points

-

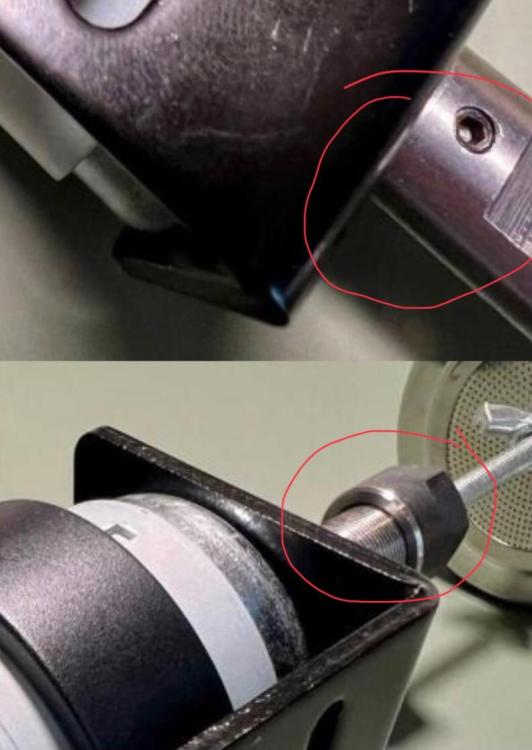

Project Update: Timesaver Lapping Compound is really amazing stuff. I was able to eliminate all the binding high spots on my spindle bearings. I started with the rear bearing which was the one that would lock up completely. It took 4 or 5 rounds of twisting that bearing with my fingers using the Timesaver compound to get it to where it would turn 360 smoothly, but it could still lock up when contacting the frame bearing 100% So for that I had to assemble it tightened down and lap it, which worked. No more binding of the rear bearing. When fully assembled and the locknut all the way in, I still had a high spot where the pulley would slow. I could not figure out where it was, so I did two rounds of disassembly and assembly of both front & rear bearing with Timesaver compound, gradually tightening the locknut until it was all the way in and I could spin the pulley all the way around without slowing. At that point I took it apart and cleaned it all up again, reassembled with oil and now it runs fully smooth with the locknut as far down as I can turn it. The Timesaver compound leaves a light gray, very uniform matte finish. This part started out with a polish but the fine matte turns so much more smoothly. You can see the finish on both the inner angle and the outer steep angle. It obviously does this to both mated parts of the bearing. I am beyond pleased with the result, and all I have left to do is mount my motor.5 points

-

I got told the cure for boredom is curiosity and there's no cure for curiosity, hence the start of watch repair.4 points

-

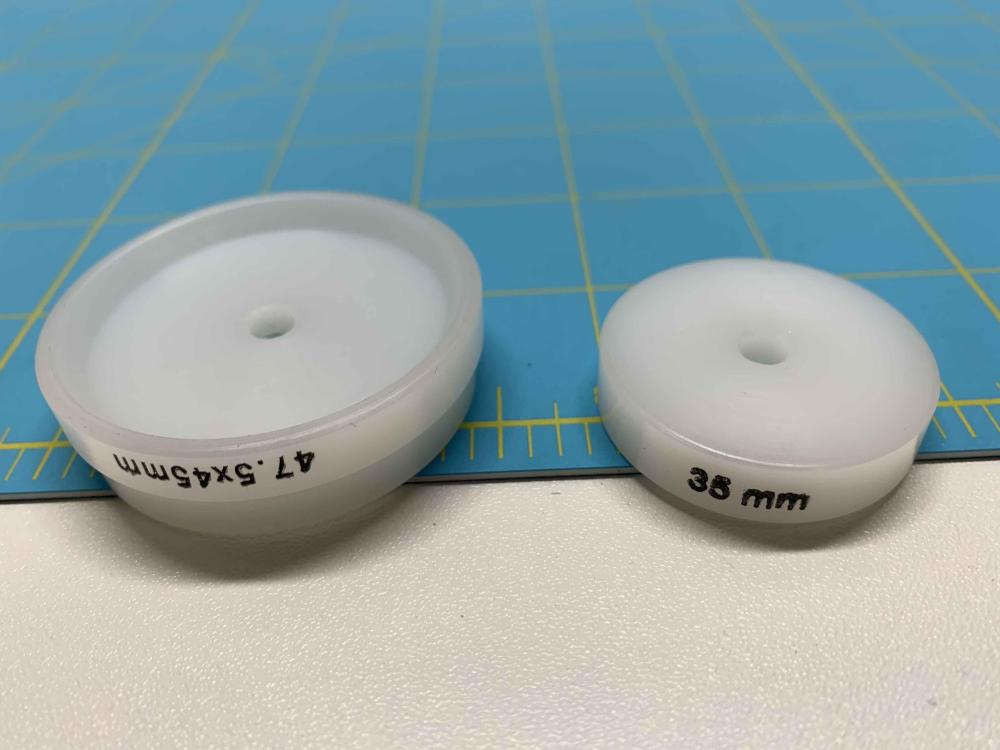

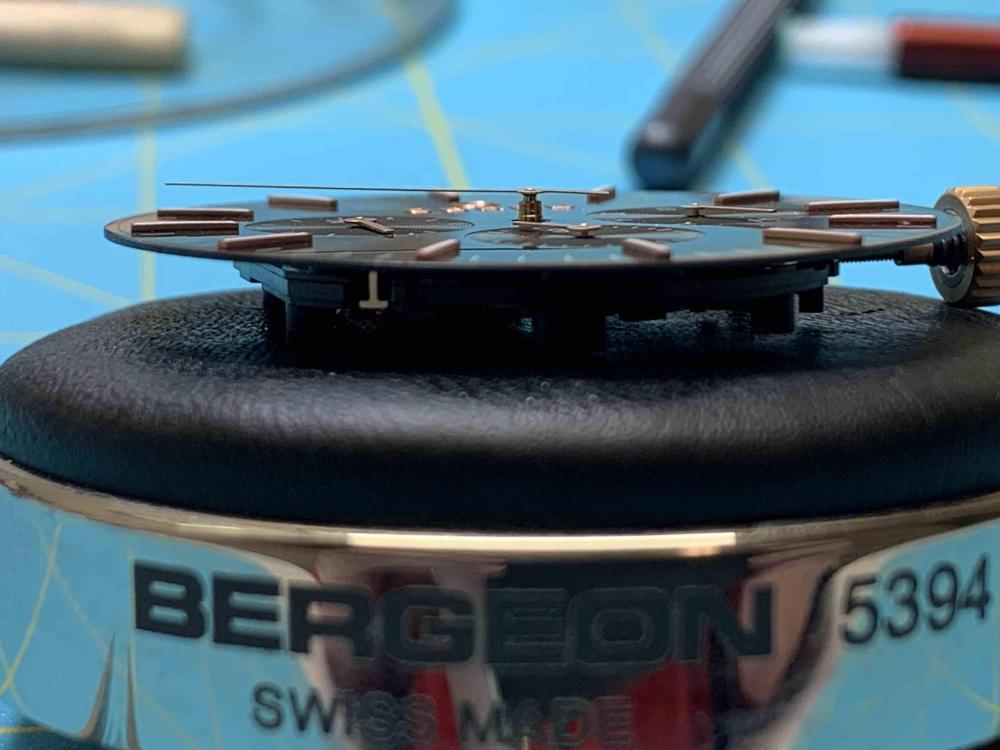

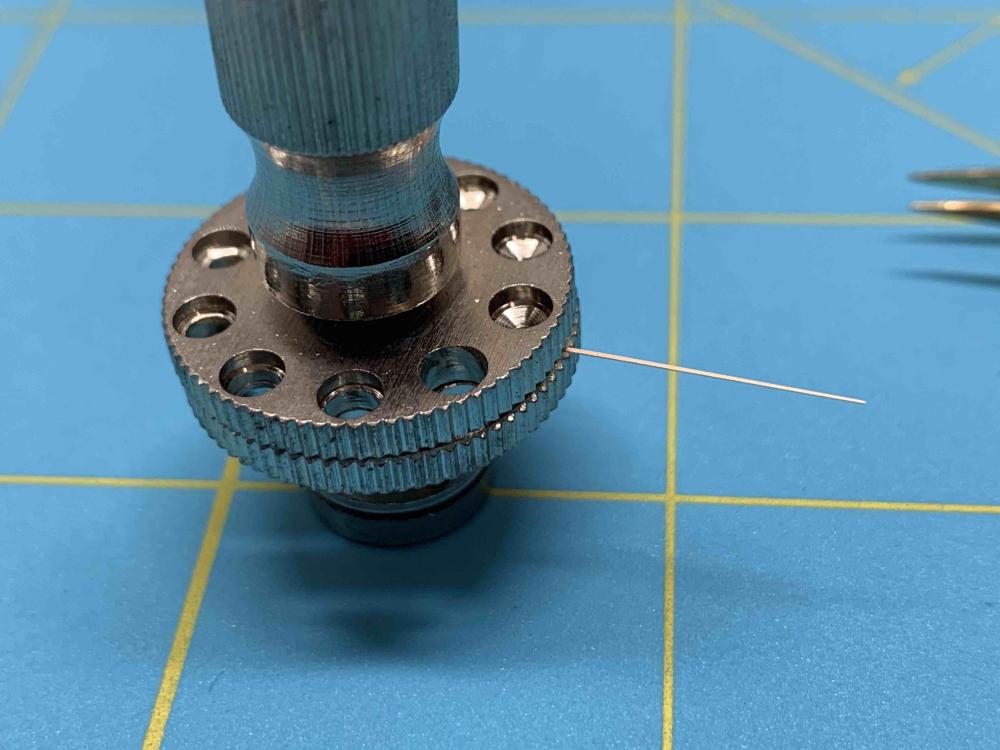

After using my old Bergeon auto oilers I thought I’d upgrade to a new/spare set. So a quick hunt on Ali and I bought a single auto oiler £16 to see the quality. Well it’s perfect and measured against a gen Bergeon it’s exact, even the Bergeon needles fit and visa versa. So I plumbed to by a whole set including base, £72 including postage and under two weeks to arrive. there are many on Ali, I just went with most sold with highest reviews.4 points

-

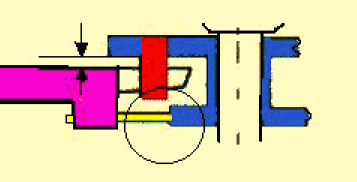

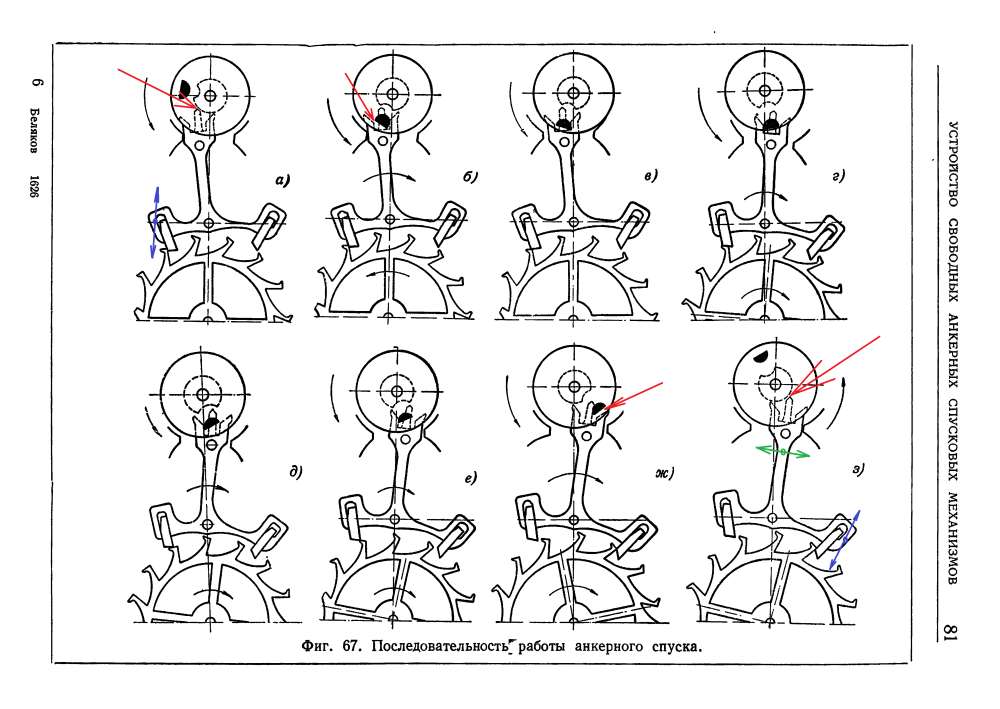

Here I have better drawing to show what checks is needed to do. The red arrows show where the clearance or free play must be present. If You look at downside right part, the green arrows show how the fork must be free to make some movement between banking and the roller. This movement, thou small, must exist enough to ensure no friction allowing balance to rotate free outside limits of lift angle. As the fork is hard to be accessed due presence of the balance wheel and hairspring, much easier is to reach the part with the stone, so the blue arrows show where it is convenient to check for presence of the free play. This is not obligatory, but more convenient to remove all other parts from the movement for the checks. The balance should be turned to different positions in both directions and hold there while the free play checked.4 points

-

3 points

-

3 points

-

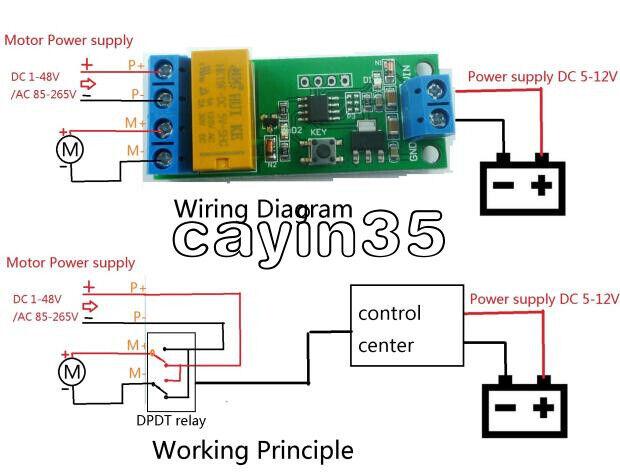

It's good to see so many homebrew cleaning machines being made, if you want to add an inexpensive auto forward reverse control module to your cleaner these are available off ebay and ali for around £4. I added one of these to mine set at 10 seconds forward and reverse, they are easy to program once set there's no need to touch it again.3 points

-

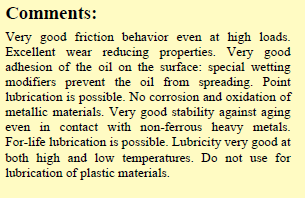

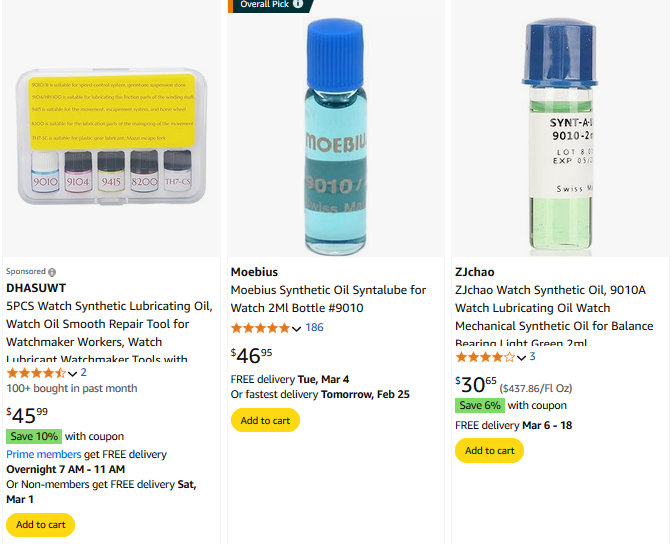

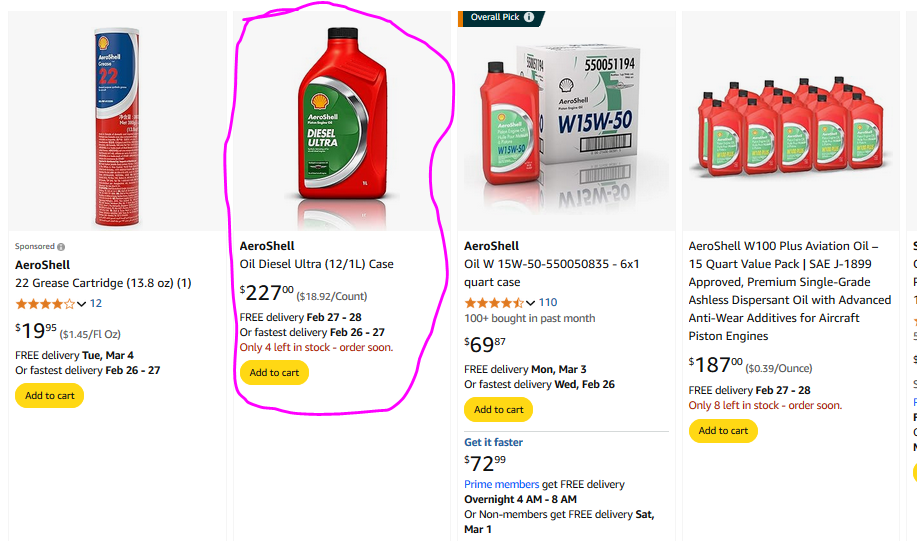

I'm confused as to why? Do you think that it doesn't do a good job, are they selling us a dud? Too expensive? As you say, it's the de-facto standard in the industry, and has been for years, so If it doesn't work well as a lubricant, doesn't last as long as advertised, or causes damage etc, why haven't we seen it? In which case someone else would have produced a better product and taken the market. You may have found a cheaper alternative where the available parameters match, but oil formulation is complex, you may be missing some crucial components. I remember the days when car oil changes could be 3-5000 miles. Modern oils have extended that to 20,000 miles+. Looking at the viscosity and specs doesn't explain how that is achieved. It may be that you are right, and they are just packaging 'standard' oil and selling it at vastly increased prices, but as 2ml of 9010 costs about £20, and it lasts me for many years, I think I'll stick with it. BTW I do use Molykote DX as a cheaper grease alternative Anyone know a triboligist?3 points

-

Yes, I've used this product on 2 lathes after @nickelsilver's advice. Works great. The matte finish will possibly help keeping the oil in place as well..3 points

-

Sorry Rich, I have missed this thread . Pin lever escapement is a special one. It is simple, but often simple things has more complex action and action explanation than the complicated ones. I need some photos or at least to know if there are banking pins or no. The movement of the pallet fork after unlocking can be separated to two parts: First part is obligatory movement, caused by pushing one of the pins by impulse plane of one of the EW tooth. Then the next, second part of the movement is 'run to the banking', which is generally caused by the 'draw'. As we have discussed before, the draw is like attraction the fork to the banking pins if like they are magnets. The draw is good thing, but it's presence in pin pallet movement is much more problematic to ensure due friction and the design and it is much more reliable on one of the sides than on the other. Small wear of the teeth where the pin drops on rest plane will kill the draw. Do You have reliable draw on both sides? But I know the answer... Now about depth adjustment and the things the depth affects... Increasing the depth will increase the limits of the obligatory movement of the fork. This is good, as if You increase this limits, then probably the guard finger will stay more away from the safety roller, in both sides. So, even if there is no reliable draw, this can solve the problem. BUT, in movements where no banking pins, increasing the depth will decrease 'run to the banking' and the limits of the entire movement of the pallet fork (just like closing the banking pins in regular movement), thus bringing closer the guard finger to the roller. If the distance the guard finger stays to/from the roller is different on both sides, it is simply corrected by bending the fork. Generally, adjustment of worn pin pallet escapement is question of compromise between all the needed conditions to ensure normal work. But it is not good idea to shorten the guard finger. The worn bearing holes of the pallet fork and escape wheel make the compromise hard, sometimes impossible, so it is good idea to restore the holes, may by closing by punching and then broaching or by rebushing. In worst cases, EW teeth reshaping helps. But this are cheap movements, so one usually will do it only for fun...3 points

-

I have two of these, the red and the black one and not had any issues using them, I did though a misshap damage the needle on the black one and just replaced it with a Bargeon needle, as it was actually cheaper than getting the Chinese needle shipped over. Never thought I would ever write that.2 points

-

Hey everyone, I have seen loads of fantastic projects online and here on the forum for cool DIY watch cleaning machines. The one thing that has put me off though is the complexity of these, they use arduino and Raspberry pi boards and code that I dont have the patients to learn. I am aslo a firm believer in the KISS approach (Keep It Simple Stupid) :-). So, With an entire world of electronics boards on Aliexpress I thought that there has to be one that will do everything I need and that wont bankrupt me. I also don’t want any code to deal with, this board can run in both directions (just haven't figured out a simple solution for that yet). It only spins in one direction for now, but that is ok for my applications. So, the attached video is my prototype of a small form watch cleaner. Mostly a proof of concept to make sure the main components play nice together. I also had a very firm gaol, to make it as cheap as possible. I want to keep it sub €200. Below are the electronics I used and I also had some Aluminium extrusion laying around around and some mechanical pasts for the slide etc. But these are problem about €30 - €50 in total. The basket I got from EBay but is far to small for the final version (always read the fine print). What do you think of my first attempt? I have no interest in trying to build a product and instead would rather collaborate with any electronic engineers out there on you to simply allow this board to alternate direction. Electronics The board was €18 - https://nl.aliexpress.com/item/1005002120012963.html?spm=a2g0o.order_list.order_list_main.458.4fad79d2RNQWU6&gatewayAdapt=glo2nld Motor was €16 - https://nl.aliexpress.com/item/1005002820843944.html?spm=a2g0o.order_list.order_list_main.26.4fad79d2RNQWU6&gatewayAdapt=glo2nld My channel on YT https://youtube.com/@watch-this-official?si=yGn8AoiWxRdbFvG_2 points

-

OK so it's a case (no pun intended) of Pleonasm which I'm sure @Neverenoughwatches knows all about.2 points

-

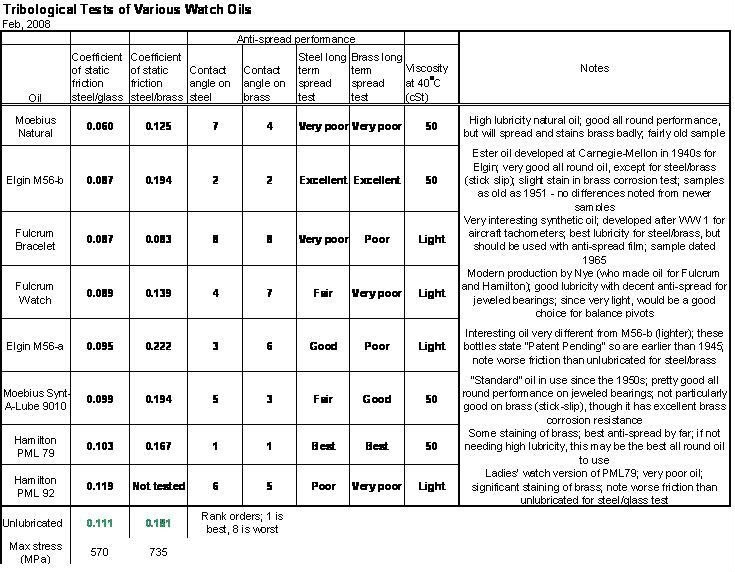

The problem with recommending your own products would be who exactly are these people that are not recommending their products? Then yes there are other companies that manufacture horological lubrication. Problem is lubrication recommendations typically come from tech sheets. Tech sheets typically come from companies big enough to supply spare parts and allow you to service their watches. So basically the most commonplace that you would find specifications would be like citizen and Seiko at one time both specified their own oils. The Swiss typically only like to embrace Swiss products which would be basically one company. Of this hasn't always been true for the Swiss in the past there were other recommendations including the US products. What the problem is a lot of the US companies don't seem to be making lubrication anymore for instance a very highly recommended lubrication is Elgin oil made by the Elgin watch company it's actually superior to the Swiss. Not only is superior but when it was being made it was actually being shipped to Switzerland. this is because Elgin made synthetic watch oil before the Swiss did. But Elgin doesn't seem to be making a horological products right now it seems to be? But don't worry a product is highly regarded as this has been synthesized and I'm attaching the PDF of specifications. As far as I know the German company which is still manufacturing horological products although the last time I looked at the website really sucked for promoting those products. Now the problem with this oil was the last time of the only time I saw it for sale in the US it was at least $100 for little tiny bottle. It's hard enough to convince people by a little tiny bottle at the price we pay now and then paying two or three times that well that's going to be a problem. So basically this is really simple for instance I don't have any 9010 on my bench. That's because I embrace 9020 as I think it's a superior lubrication with no loss of amplitude typically. Or that German company a lot of people use their products so yes there are replacements. Then thinking about replacements? Okay now we have a problem not enough specifications here. So basically we get a viscosity which is extremely unhelpful and some other spec which I suppose is nice but where your other specifications? Let me give you an example of specifications that you're missing because viscosity sucks his specification sort of. I found this on another discussion group a long time ago Okay so what do we have well the natural oil would be I believe 8000. It's a very popular oil because it's really cheap. Unfortunately it's also a natural product so it as poor characteristics. So when you look at the chart you see a talk about friction then they have contact angle which I think is extremely important number as I believe it relates to how an oil or lubrication spreads. Then long term spread test which is really one of the most important things. Horological lubrication has to stay in place long term in other words if you're servicing a watch like a modern automatic watch it needs to stay in place at least five years preferably longer. So conceivably could have the right viscosity and maybe a superior lubricant but if it spreads and is gone fast it's worthless. Oh and then there's the other little problem before we finish the chart. If you have a modern synthetic oil that's absolutely perfect but it spreads superfast how exactly do you know that? In the early days of natural lubricants they had an outstanding property when they went bad of typically getting sticky and stopping the watch. Synthetic lubricants have a habit of spreading with time no longer doing their job and customers who don't want to get their watch fixed and soon especially metal on metal the watch will disintegrate. Very common with early automatic watches that had a lot of metal on metal bearings. He often see this and discussion groups for people are bragging about not paying the greedy watchmaker they've run the Rolex for 30 years unfortunately the guy get a heckuva sticker shock when they get that watch fixed and they discover it's disintegrated all because the lubrication is no longer where it's supposed to be. Plus thrown in that the gaskets after 30 years have disintegrated and moisture got in and is now grinding what's left of the pivots okay now next oil is the Elgin 56 – B notice the very low contact angles notice excellent for long-term spreading and this is the Elgin oil that was synthesized by the Germans. Which reminds me if you look at the PDF attached We get a viscosity of 125 slightly thinner than 9010 personally be happy if it was slightly thicker than 9010 as I still perceive viscosity as even though I know it's really contact angle. Then notice the comments all just paste here how does your lubrication compared to this? Now back to the chart down below notice the all favorite 9010 is listed. Also noticed that it really isn't a spectacular lubrication at all. Plus the Hamilton PML oil that looks really promising. Then it's a shame the 9020 isn't listed I suspect it was listed it would actually look quite good because from personal experience it doesn't spread as fast as 9010. Then to avoid up problem which is quoted below you're not allowed to promote your own product so I assume you do not actually manufacture this or sell it. It's an aviation product where exactly what I purchased this anyway? Plus the unfortunate problem of really validate in the horological lubrication you would have to have tested it for quite a number of years. So short-term it might look outstanding but what does it look like at least five years from now? I think if you read the fine print mentioning money is not a problem. the fine print basically says you're not supposed to profit in a monetary way off of the discussion group. Which of course does bring up a problem of anyone on the group who is repairing or generating any money from the knowledge they learned on the group is profiting in a monetary way. But the real interpretation is you're not allowed to sell a product on this discussion group. Typically in a horological discussion group expressly for relatively new people or any of us there is quite a sticker shock at the price of a little tiny bottle of oil. For instance let's go to Amazon and let me look for 9010 and let's get an image. First we end up with a confusion of two versions of 9010 at differing prices and differing Reviews? Okay reading the fine print of the third oil it appears to be at least in the way the bottles labeled identical to the Swiss version of it sizes Swiss version I assume it's the same thing is just being sold at a cheaper price but I do have to wonder if it's a clone or a counterfeit product? Okay but back to the discussion the middle oil that looks right and it costs $46.95 for 2 mL. The problem is people don't really look at the cost properly. For instance yes I used to use 9010 and how long did my bottle last before I replaced it? Many years ago I replaced all my horological lubrication's because somebody at a meeting suggested that they should be replaced from time to time. I then decided that I really don't have to replace my oil unless there's indication of a problem because typically now I only do personal watches. But back to the original question how long did the first bottle last we lubricating a watch you're not using very much at all so it seems like a really tiny bottle really isn't considering the quantity you use is extremely tiny. I don't know if anyone's ever figured out how many watches a lubricated but the cost per watch basis it's not very much at all. But typically that's not the way people look at they look at it and say oh my goodness if I was to change the oil in my car it would cost $1 trillion I am obviously getting ripped off that would be the biggest problem. Oh and then there is my other amusement with pricing look at the far left hand product look at all the oil you're getting you getting everything to service your watch. Then yes I've seen these kits show up on eBay so somebody is broken apart the bottles they probably bought 20 mL bottles which are cheaper than the 2 mL bottles at a cost per milliliter not for the bottle of course then they repackaged in little tiny bottles and on the surface it looks like it's a good price but if you were to figure out what it cost per milliliter at least the last time I checked the price sucks. So basically it looks on the surface to be a good price could you get a whole bunch of oil you just not getting very much of it. Possibly good if you only one oil one watch you're not really sure if you want to get seriously in the watch repair. Now we run into a problem? Suppose somebody agrees with you and would like to purchase some they can't purchase it from you because that would conflict with the rules the messageboard. So going the Amazon seeing as how I can buy watch oil we did run into a minor problem of typical Amazon for confusion like far left-hand side grease is not what it is so it looks like it's it's the middle product and We run into a tiny problem. Apparently have to buy an entire case and okay I guess on a cost basis it would be better it's an initial a higher investment but I would get equivalent of 4 1/2 bottles of 9010. On the other hand since I don't use 9010 it's not a problem which means I'm not going by the replacement either as a be a waste of my money. But it's going to be a really hard sell on the group if people Purchase the replacements conveniently and cheaply. Then just as a reminder for those enterprising souls you can't purchase this and repackage it and sell it on the group. But maybe you could sell it on eBay looks like a good moneymaking opportunity here. Elgin Watch Oil TS5500EN.pdf2 points

-

https://www.ebay.co.uk/itm/193754159385 I got mine off ebay from a chinese seller as the item/seller had good reviews, delivery about a week. If you add an on/off switch to turn turn the 12v supply voltage on to power the module, this will be for the wash / rinse cycles 10 secs forward 10 secs reverse, turn the power switch off, the voltage from the motor controller will still flow through the relay to power the motor in one direction only forwards so can be used for the spin cylce to remove excess fluids. ali also have them even cheaper. https://www.aliexpress.com/item/33047036994.html?spm=a2g0o.imagesearchproductlist.main.5.494dxFmGxFmGJy&algo_pvid=0f312fc7-e51e-40cf-825c-1c6d3e0cc96d&algo_exp_id=0f312fc7-e51e-40cf-825c-1c6d3e0cc96d&pdp_ext_f={"order"%3A"37"}&pdp_npi=4%40dis!GBP!3.01!0.80!!!3.70!0.98!%40211b441e17404265287781362ecf32!67373171443!sea!UK!0!ABX&curPageLogUid=bpHiOVAN3bbn&utparam-url=scene%3Aimage_search|query_from%3Apc_web_image_search2 points

-

Haha I admit It did cross my mind " that wobble is so bad it must have been intentionally added " Aww darn...I could have made mine so much more rustic looking and cheaper. We need Link please Valley2 points

-

Is it genuine Swiss Bergeon imported air ? how much to filI up my air puffers ?2 points

-

2 points

-

Depends whereabouts and to what applications certain aviation oil is used. A big difference between the inner workings of a watch and the majority of other machinery is that there are parts in there that shouldn't have oil on them. Typical machinery, like say an engine of some description needs oil to reach everywhere, and where it doesn't need oil... those parts would be sealed off and isolated. In a watch all of the parts are exposed to each other at very close proximity,without the correct type of oil that can stay in place , it can spread from one area to another quickly. Thick oil stays put, thin oil will wander without an additive to keep it in place. Micro machinery is another ball game, I expect there might be some small stuff in aviation just the same, but does that also require a special expensive oil. High pressure oil.....contact surfaces in a watch are much smaller than typical machinery. Would forces be comparable taking that into account ?2 points

-

Catchy thread title, Håkan While I am by no means a hairspring master like Neven, I don't see anything wrong with your hairspring. The terminal coil does seem to be closer (or even touching) the outer regulating pin, though. Hence, Neven's suggestion, no ? But I would not expect it to be the source of the behaviour you show on the TG. Before bending anything, maybe check two things: 1. Verify amplitude visually with super slow-mo video when the strange behaviour is occurring. Maybe the lift angle is somehow wrong (I can see that you put the usual 42° that it should be, but maybe it has been altered be a previous watch destroyer). I would still see rebanking as the No1 suspect. Everything seems to point there. 2. How did you clean the hairspring? Any chance that the coils are sticking a bit when they touch at high amplitude? I've seen the coils come extremely close in my recent Vostok, but it didn't impact the rate/timegrapher readings. I've also had cases (particularly with Russian watches) where old/contaminated degreaser led to sticky coils.1 point

-

1 point

-

1 point

-

1 point

-

The 3 sided punch method didn't work. The roller table bas a small bevel around the hole. I tried to distort it with the punch but there was no way I was going to be able to move enough metal. I ended up using the eyelash trick which seems to have worked well.1 point

-

1 point

-

Balance issues and the related escapement problems can be many. It's an area of watch repair that is the least understood, so you're not alone. There are many books written about just the escapement. Thing is you are trying to repair watches that are old , worn and probably had many hands working on them , many unexperienced and untrained hands. The situation of - buy an old watch, try to fix it, cant fix it, break it a little bit more, move it along - . A watch that you are working on might have had this happen to it a lot of times. I enjoy that challenging side of repair, but not everyone does, you try you fail, but you try again and eventually you land a success. That success rate grows until it outweighs the fails, you just have to keep going and if you enjoy that journey of learning then the fails really do not matter. If it was easy then it wouldn't be worth doing because you wouldn't be learning anything. Consider the proverb of " The idle mind "... some say watchmaking is for the insane...pah that's rubbish, working in my watchroom is where my sanity returns......did I just make the suggestion that I could be a sane person ?1 point

-

Photos and details of the old movement along with the stem are needed to help further.1 point

-

The wobbel is not on purpose, in the final version it will be more controlled. Hopefully.1 point

-

The cost saved for your own use will never be worth the effort to find out. Unless you intend to buy 50 gal oil drums to decanter into 2ml vials and flock it to us peasant hobbyists1 point

-

I wanted to see how fast and cheap I could throw one together, including the coffee brewer basket holder, I managed it in just over 2 hours. It does have a 12 volt motor programmer not shown here, I think that was 16 quid, the dearest bit. Most folk try everything to get the wobble out, I spend time putting one in . Agitation is the name of the game lol.1 point

-

I buy generic over the counter medication, the active ingredients are exactly the same at a fraction of the cost of branded items. Does the same apply to lubricants, are they exactly the same or as close as to not make a difference? The only way to know for sure is through experimentation. I have to agree with @mikepilk, 9010 is expensive but will last many years.1 point

-

1 point

-

1 point

-

1 point

-

This is a regular problem - rebanking while fully wound and continuing winding by autowind. This is bigger than needed friction of the spring bridle on the barrel wall. What is the bridle shape? Is it well polished (sometimes it is not and friction is due some bad edge or burr)1 point

-

1 point

-

yup! Got in touch with Fossil, they said it was a 39mm glass, so I ordered one (even though I'd measured it at nearer 39.5mm - but hey, they know best, I've never fitted one before). Glass plops straight in and is loose enough enough that you can wobble it and hear it tapping the sides of the case as it moves... It's just a few quid for another, but with the postage on top, that's a tenner down the bog1 point

-

I doubt that you can get the inside of the hole as smooth as the factory can. But please try it and let us know the progress.1 point

-

OK, the original spring is bent only where it goes in the collet. Source some needle where the collet can be put on for easier manipulation and bend the spring back. First thing to achieve is to bring it in plane which is perpendicular to the needle. Then we will need pictures from above to see if it needs correction of spacing and centering. Yes, of course, the new spring can be accommodated by changing of the moment of inertia by adding or removing mass, but it is much easier to repair the existing spring. Even If it break where it goes in the collet, it can be reattached (repined), and this can be compensated by adding some mass to the screws.1 point

-

That is fixable, and worth an attempt. It really only is the one bend by the collet. And if you wait a little bit, the wizard nevenbekriev will turn up and tell you exactly where to grab and which direction to push or twist in order to fix it. For me, a relative novice, I would flip that spring over and gently push on the collet to get it closer to flat, then see what the distance between those two coils looks like. You have already come so far on this watch and made so many advanced repairs - you can pull this off. Yes indeed. So as long as the roller jewel lands centered between the banking pins, it will be very nearly perfectly in beat. Without the pallet fork installed, sight with your eye a straight line from the escape wheel jewel, through the pallet fork hole jewel to the balance staff. The roller jewel should be dead center between the pins then. Some people prefer aligning the jewel with the balance arm because it makes it easier to see that line from above, but I still find it harder to view the jewel through the pins that way so I prefer the roller being perpendicular to the balance arms myself.1 point

-

Funny I was just restoring a nice jewelled nibbed one of these 2 days ago. It is a truing poising tool , depending what the nibs are. I have a couple of traditional non jewelled ones as well. Ok for poising but there are better more accurate tools. The TruPoise bench tool works on the same principle of supporting the pivot ends. Clean it up, restore the nibs and try it out on an old balance . Looks rusty and the register arm is missing, if you haven't bought it I'd give it a miss. These calipers are much better for truing, poising one end and the other end for truing that have cone shaped nibs to support the balance pivots while truing.1 point

-

It looks like it is a very old and incomplete truing caliper, used to find out if a wheel is bent out of round. The little nubs in the jaws would be used to hold wheel pivots. And that protruding post on the lower arm opposite the screw I would guess originally held another metal blade used for comparison against the wheel's rim. The size of it and being sprung closed makes me wonder if it was meant for clocks rather than watches. If that was its purpose, it is probably no longer useful since it is missing a part and is in terrible condition. Tools that do this can be bought for very little. It is also possible this is for something else entirely, and not a wheel truing caliper. Here's a common style, picture randomly lifted from ebay. That black metal part on the post is what I think is missing from yours.1 point

-

You shouldn't use LR batteries for watches as they are alkaline batteries and have a tendency to leak. You should use SR batteries instead, which are silver oxide.1 point

-

LR626 & 377 are the same battery. As you can see from the back these are sealed movements so not a lot can be done if the problem is with the gear train. What test equipment have you got and can you post a video to show what's happening.1 point

-

Just bought this great old tool (lathe?)and now finally will be able to make the bezel I have needed for about a year now for my big old 65mm pocket watch. Just love these old tools. No idea how old it is but it must be 100 years or more. Tomorrow I’ll show you a nice old set of pliers - with teeth! For making the right size hole in pocket watch hands.(round or square). I finally found a great old watch maker 4th generation who is teaching me all sorts of tricks including using my lathe to drill out and re pin balance staffs. My next visit we’re going to make one from scratch. At last somebody to lead me!He also let me have a few of his grandfathers tools this one , the pliers and a great full set of Lorch 8mm collets for my star. More to come when I get home cheers Jules P.S hope IBIS doesn’t mind me setting up and checking my tools on their work desk in the room…1 point

-

1 point

-

Filing this story under Watch Case Issues, but only because there's no section on the forum for really bad judgment... A friend of mine calls me the other day and says "Can you get the back off of my watch? It needs a new battery and I just scratched it trying to get the back off." I tell him no problem, bring it over. The case back is a press-fit and pops right off for me. I even have the battery he needs. So far so good. I make sure the case and case back are spotless, and clean and lube the case back gasket. I'm feeling very good about things at this point after investing about 5 minutes and enjoying some banter with my friend. Then I try to pop the case back on. Nope. No way with my all my strength is this thing popping back in place. No problem I tell my friend, happens all the time. That's why I have a little hand press for case backs and crystals. Heck, I've even installed a case back on one of my old grumpy watches using the bench vise in the garage once... So I choose a flat die for the case back and a concave die that will touch only the watch case and not the crystal. So far so good. Get everything lined up and give it a squeeze. Nothing. Take a deep breath and squeeze harder. Still nothing. Recheck everything is aligned the way I like and try again with all my strength. Nothing. Grumble. My friend (who has bigger hands than I do) offers to give it a try. I give him the press with the watch in place all lined up and tell him to give it a go. He does and we hear a satisfying little 'pop,' which I assume is the case back snapping into place. Great! He hands the whole thing back to me and I extract the watch from between the dies. Oops... Looks like the die on the dial side flexed so much that the centre pin the die sits on breached the crystal. Adding insult to injury, the case back still had not seated. Good grief! But it was worse than just the broken crystal (and my damaged ego). Two of the hands were bent and some glass must have worked its way into the movement which was now seized. Deep breath. Sent my friend home with no watch. Lucky for me the movement was relatively easy to get and not very expensive. Same with the crystal. Hands came back to shape well enough, and things went together well. The movement front-loads on this watch, so the first thing I did during reassembly was press the case back in place. Then the movement went in, crown installed and finally the crystal. I guess it all ended well because I had the watch back together, running well and in my friend's hands a week later. And at least he scratched it first! What a crazy ride.1 point

-

1 point

-

If I'm not mistaken that's for an air line to a compressor. High volume shops will skip the pump handle and hook right into their compressed air which is inevitably there already. Looks like a push-release fitting, on these the line (hard plastic) pushes in and is sealed. To remove you push and hold in the bit visible in the photo, the line comes right out. If you don't press that in the line is next to impossible to remove and and you get what's seen in the photo.1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)