Leaderboard

Popular Content

Showing content with the highest reputation on 02/26/25 in all areas

-

Haha. Haven't we all spent $1000 on a jewelling set just to replace a broken jewel on a $20 Russian watch?7 points

-

Keep in mind that viscosity is one of many factors in what makes an oil suitable for a given application. If you look through the many, many oils offered by the various companies, you will find many that share the same viscosity but are applicable in specific situations. A good example: Mobil made (makes) an oil called Vactra #2. It became the standard for slideway lubrication on machine tools, and was heavily used in the printing industry (think newspapers). This is an ISO #68 oil, with tackifier (Peritack), which helps it stay on vertical surfaces without running away. In the 80s, to comply with EPA regulations, Mobil took the tackifier out. Rather, they took it out 100% in California, and 1/2% was removed per year elsewhere. Turns out the printing industry was a larger market for it than the machine tool industry, and the printing equipment really needed the tackifer. Confronted with many angry customers on the west coast after equipement failure, Mobil created a new oil, or more accurately, re-introduced the old Vactra formula as Vacuoline. By this time the big users, who simply specified "Vactra 2" in service manuals before, now simply stated the actual performance requirements of the oil. There were always other makers making Vactra 2 equivalents. It all gets more confusing as machine tools moved from dovetail ways to box ways, and CNC equipment with water-based coolants became commonplace. Turns out the new non-tackifier Vactra works best with those; the tackifier could cause problems in automated lube systems and also contaminate the coolant. So in some cases Vactra 2 is the best thing. On an older manual machine tool, you would want Vacuoline. Of course these are all ISO #68 viscosity oils. I have machines that specify Kluber Isotel LDS 15 grease for the spindle bearings. This stuff is just as expensive as you might think if you've priced Kluber P125 braking grease for watches. With replacement bearings going for 400+ (in some cases ++++) bucks a pop, I never minded shelling out for the Kluber. Likewise, working on watches for money, where I guarantee my work, I use industry standard lubricants, that are within their expiration dates (pretty much ). Edit- Digging back in to the Mobil story (was going from 20 year memory), turns out Vacuoline has existed since at least the '50s. It was the same as Vactra (before it changed), but with an added additive package, I guess for even more special situations. Still ISO #68. At least Vacuoline 1409 is, there's 1405 at #32, and 1419 at #220 as well.5 points

-

This isn't my area so I asked someone who's area it is/was; previous R&D specialist of head or R&D for Shell. He's a bit vague, but he's one of the leading people in the world in his field I explained the topic. His responses were brief: "Oil is oil, or is it?" -> "Oil is not oil. Some oils migrate, evaporate, oxidise, leave residue. Others do not" The presumption can be made here that he is aware that viscosity and other attributes can match When I said that Moebius oils are expensive and people are looking for alternatives -> "Bad plan" Take what you will from it. It's not my field and I'm not going to badger him further, but I am going to accept what he says.4 points

-

Sitting back enjoying the discussion !!!! FYI the above additives are surfactant low temp flow improver anti-oxidants rust (corrosion) inhibitor anti wear additive Dye for a nice colour! Enjoy. Forgot to add that this has an PAO (polyalphaolefin) base oil. This is a synthesised oil manufactured from selected mineral oil hydrocarbons. Oil is oil. Lubricants can be anything that works for the reduction of friction. Even water!!3 points

-

From memory the thread diameter of Lorch collets is an issue in drawbars meant for WW and what I would call "Swiss" (Schaublin) standards. Dell's chart above is correct for Schaublin, at OD 6.82mm (.268") and P of 0.625 . I have a G. Boley here that measures OD 6.82mm P 0.625, and a Leinen that's OD 6.85mm (.269") P 0.635 or 40tpi. A Levin that's OD 6.89mm (.271"), P 0.635 or 40tpi. Finally a Wolf Jahn that's OD 6.85mm , P 0.625. All fit my Leinen drawbars fine, and the 40tpi stuff also fits my Swiss drawbars (various machines). Nothing I have comes close to 0.275", which I suspect if probably accurate for Lorch. The chart is definitely off on Levin, and "Boley for later WW lathes" as well. So yes, the 0.01mm difference in pitch doesn't seem to be an issue over the 8-ish threads that engage with the drawbar. But the Lorch thead seems to be somewhere between 0.10mm to 0.20mm oversize compared to average- probably why I don't have any in my sets of collets. It's been a long time since I had a Webster Whitcomb, but I have a pretty clear memory that Schaublin collets fit fine.3 points

-

3 points

-

Blocking people is a win-win scenario. The two people that do not seem to be whatever don't have to work together. Where here for fun learning if it's not fun then solve the problem which blacklisting would achieve. Then you can celebrate because if I was going to block you you would've been number one. Do you remember what happened as a newbie when you join the discussion group? Strangely enough I do and Mark terminated the discussion before well unpleasant conversations would've pursued. Yet you're still here and I'm still here as we each came to recognize the contributions of each other. Now for everyone else reading this I believe this is a discussion on let me check the title? Okay I don't really like the title but the subject of the discussion is a horological lubrication and apparently I'm doing something that I despise which is hijacking the discussion to become something else. So hijacking of discussion is over everyone else go back to?3 points

-

Welcome to the forum. The normal place to start would be to see what movement it is but in this case I think I don't think it would help. Can you start by measuring the square where the minute hand sits. https://www.cousinsuk.com/product/hands-pocket-pairs-by-size2 points

-

Who am I to question Dr Rogers but here goes. The article was written in 2019, we should have a follow up by now. How can testing only take 22 months? The usual service interval is around 5 years and if it never needs servicing the the test period is forever. Forever is impossible but how's it running after 10, 15, 20 years etc. Expense? If this is successful, how much would it cost compared to an equivalent without the new technology2 points

-

What is interesting here you were not expecting this? There are other discussion groups out there and in one particular group in the past it wasn't actually written anyplace but basically horological lubrication was a forbidden subject for the most part. Simplistically because the people on that group can be extremely opinionated or at least they were in the past. So if a lubrication question was raised people would run for cover hide in their bunkers hide under tables and hope it would go away. So it basically is a well-known fact that if you have a discussion on horological lubrication you going to have problems. Oh here's something interesting on lubrication in horology. Maybe It's a direction we should be going in after all if Roger thinks it's good it should be good enough for the rest of us? https://www.rwsmithwatches.com/journal/roger-announces-nano-science-research-collaboration/2 points

-

Lacking a tech sheet saying otherwise I'd definitely lubricate these, D5, 9020, HP1000 or 1300, for sure. I'd epilame them too but don't think it's critical. Edit- I'd oil the Breguet teeth too.2 points

-

Double check that it's centered in the regulating pins when you're happy with the overall centering. This can be adjusted at the stud without affecting the overall centering.2 points

-

It will have the same effect. First apply some pressure and see what happens. This will be elastic and will return back if the force is small enough. Thus You will be able to see what the effect will be if pressing more to achieve non elastic deforming.2 points

-

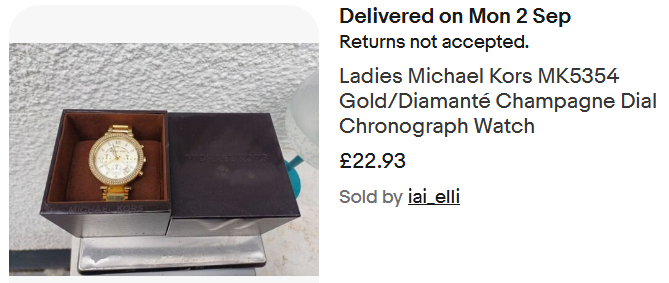

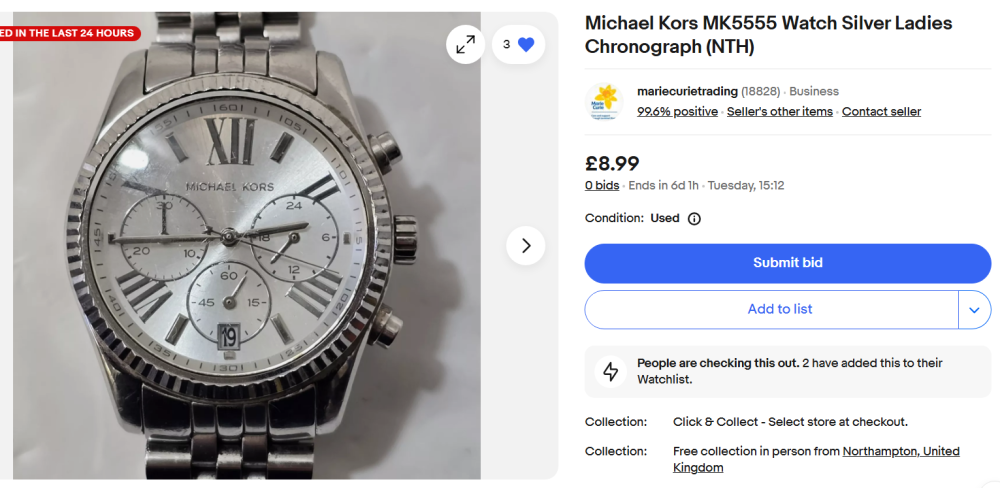

The photo I posted is a Ladies MK Chrono Boxed I recently purchased for just over £20.00 And here's what looks like a silver version of the OPs on eBay at the moment c/w strap. Your $200 to $250 prices listed maybe new but looking at second hand prices what they're asking bears no resemblance to what they're actually worth.2 points

-

I assume you mean adjusting the microstella screws. Very likely not. More likely your movement will need a full overhaul. When was it last serviced? Demagnetizing might help if it is otherwise in good condition. Low amplitude and hight rate (as in your case) would indicate it has been magnetized.2 points

-

If money has been plowed into research and development and you've turned out a good product , it's logical that you dont want anyone to copy it. What metals are we talking about ? In a watch a lot of it is brass and nickel plated metal. Some cleaners can be corrosive and as Tom mentions engine oils might have cleaning ingredients. This all depends what the shell oil components we are talking about. That's why you're re having such a hard time with getting us on board with this. Without hard evidence of one product being better than another, it's not going to happen. Stick to what is known that works is the best policy.2 points

-

I think that the industry essentially has ended up predominantly using moebius oils as that tends to be what the manufacturer seems to be specifying for servicing their products. This has likely ended up that because an independent service wants to maintain the manufacturer accreditation, which is good for business, they will tend to stock only the moebius oils. Why find something else, even if it would be a cost saving, if you have to keep using Swiss unicorn tears to earn a living anyway. I see it that as amateur watch repair/serviceing hobbyists we could use lard and be happy, however we ask the professionals we are lucky enough to bump into along the way what oils they use to get a recommendation as what is the best to use. In Europe and America I think this generally is moebius, if we had a sizeable contingent of Japanese watchmakers here maybe they would recommend seiko or citizen oils. India would likely be anchor oils, though everything I have seen about these oils say that they are very inconsistent in properties and consistency. It would be very interesting if we could get information as to Chinese manufacturers recommendations, especially Sea-Gull as the largest movement manufacturer on the planet. @Swefiddler as you have probably gathered by now watch lubricants are an “interesting “ topic. Around here at least the conversation tends more towards learning and understanding rather than the more “tribal” exchanges I have seen on other forums/groups. The part where I said about possible effects to metal was specifically about plating/gilding of movement parts. This can be very delicate especially in vintage/antique watches and there are numerous anecdotes around the internet of various “harmless” cleaners/chemicals causing damage. Just something else to consider. Tom2 points

-

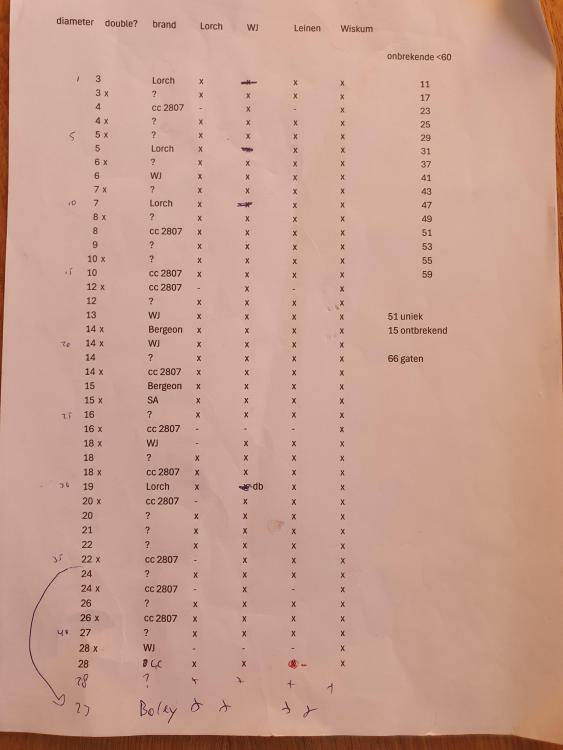

I have 8mm collets made by several manufacturers and did a check which collets fits which lathe (I have a Lorch, Wolf Jahn, Boley-Leinen and Wiskum lathes). I found that the Crawford (marked cc), Wolf Jahn, Bergeon, SA, and the collets with no makers mark fit almost all my lathes. However, the Lorch collets don't fit the spindle of my WW-style Wolf Jahn lathe (which is very simular to yours I believe). For some reason they won't go all the way in and they also bind up in the drawbar. Is it possible for you to try if they fit? If not, and If the price is ok, you could obviously just buy them and part with them if needed.2 points

-

The cheap 4 in 1 quartz watch testers incorporate a moving magnetic field , maybe just a spinning magnet that might impose itself on the movement's rotor? It can free up a sticky movement . I cant say I like the idea of pushing delicate wheels and pivots through gummed up friction. I would think only a temporary measure. I changed the movement on one that I paid a quid for, that and a new glass came to 12 quid. Was an easy fix and the chrono hands came off with no problems.2 points

-

I have never seen published manufacturer data about the sizes of soviet watches and clocks main springs. OP has the spring measured. I can try to measure one later too.2 points

-

Hi Rich, this is not rare thing for pin lever to have no draw and guard finger to touch the roller but to work well enough. The roller... It is usualiy part of the staff and is polished, also with small diameter. And, adding some small quantity of oil there also helps. But what is the condition of the staff pivots tips? I mean, the free oscillations test count DU and DD? As this is the main reason in such movement for bad amplitude.2 points

-

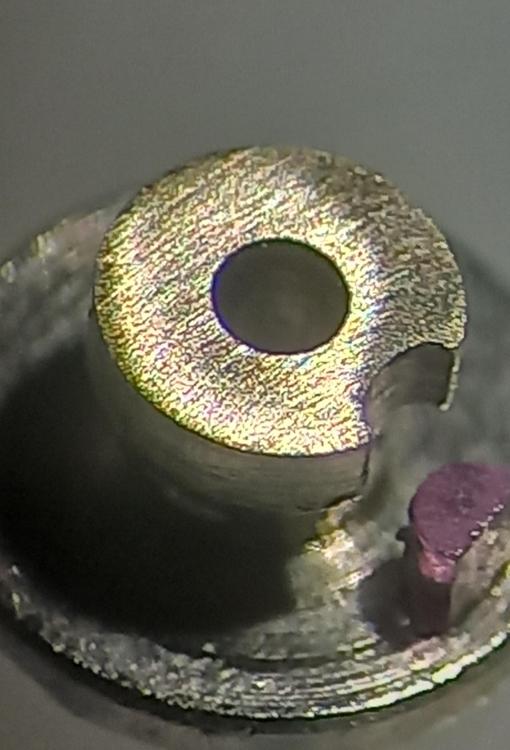

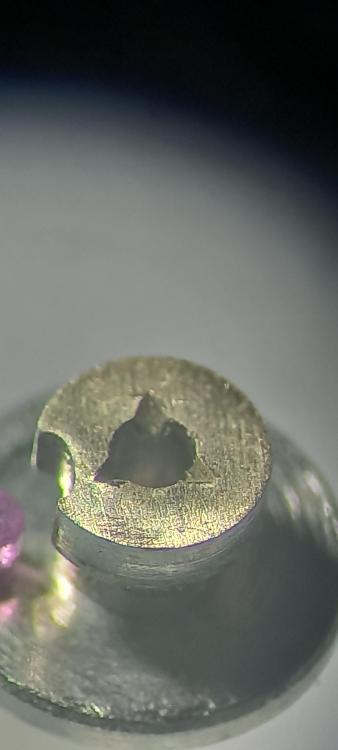

Not sure if I'm thrilled or not that I have one now Not just one but four, the first was way big, found three much smaller ones in another set. Finding a support for the experimental roller is proving more difficult. So sometimes you have to see things to believe them. With a trial roller of 1.5mm thickness and the smallest indenture punch I have this is what happened. The pictures are in order sequence of events and self explanatory, note that I polished the roller before hand so the result would be clear . Bearing in mind even though I'm a rough arsed joiner when it comes to watch repair I am super focused, very mindful of what I'm doing and extremely delicate when I need to be. The guy in the video definitely messed up as my hammer taps were barely perceptible compared to his. As you can see I did not support the roller in any way but destruction would be just around the corner. The punch I used, had never been, so it was sharp, if anyone tries this method of tightening a roller I suggest that their punch is also sharp. Unfortunately I couldn't test it for a fitting as the roller was recently orphaned by yours truly in another experiment that involved slicing its home in half ( lathe staff removal ).2 points

-

Finally, I had time to do the research I wanted to do before ordering my ultrasonic cleaner, and now it's done. I went for a small device (0.7 litres) that should work with the cleaning basket from my Elma watch cleaning machine. I would have preferred to get Elma's ultrasonic cleaner, but the price, £423 including tax and shipping, feels unjustifiable for me as an enthusiast. The machine I ordered cost me £64 including tax, shipping, and a 3-year extended warranty, which I paid an extra £6.4 for. I chose this particular ultrasonic cleaner because of the serious and detailed presentation on the website and the site's German (which often indicates quality). After completing the purchase, the feeling was confirmed in the email they sent, which not only congratulated me on my purchase but also included detailed purchase information on delivery time, warranty, and right of withdrawal, as well as the manual for the ultrasonic cleaner in several languages, including English. I love the German precision! Now, it remains to be seen if the machine meets my expectations, but I’ll get back to that. Here is the link to the page for anyone interested: https://www.expondo.de/ulsonix-ultraschallreiniger-0-7-liter-basic-100500332 points

-

1 point

-

Welcome to the forum. It needs to be completely disassembled, cleaned and all pivots and teeth checked. What tools and experience have you got? Before you do anything else with the movement you need to make sure the mainspring has been let down safely.1 point

-

@Neverenoughwatches the polished surfaces bit is not universal. If you take two or more guage blocks and slide them together they will stick. This is used to stack them additively to use them as a precision measurement device. Much more accurate than any micrometer. where you have two smooth surfaces friction is high, same as with two rough surfaces for opposite reasons. What you want is dissimilar materials both highly polished then at a surface molecular level friction is reduced. Tom1 point

-

Probably good news. I found one selling for parts, that looks promising. It is the exact same model. The case looks way better than mine, the crystal appears to be in a good condition, and it has the movement spacer that nine doesn't have. The movement is broken and it has no crown, but I don't need that. It should arrive in 7-10 days.1 point

-

I suppose it depends upon what you're using the oil for? For instance in a watch or clock it be nice if it would stay wherever it's put it but In a engine we tend to like it to flow around a lot so maybe that would not be a good thing?1 point

-

I had the same size, which was really handy to be close on my bench. The main idea was to float small containers with hairsprings etc in them, aiming for near direct cavitation action. It did brake though after a couple of weeks. I was sort of glad this happened as the pro to a bigger one is making a lid to hold the containers. My small one was also quite weak in power having only one central transducer. The big one has at least two. The small one didn't fit reasonable size glass jars, i think steel is better anyway.1 point

-

1 point

-

If it works it works , why change something that works for something that is unknown to ( in that application ). Timed experiments for ourselves if thats what we want to do, proving good result is something else. There was something like this way way back. A new to the hobby guy decided to use regular engine oil and vaseline for grease in a movement. I remember it was a Cauny watch, he managed to make it work initially, after a week he disappeared and never came back lol. Its a long time experiment if anyone wants to take it on, wear the same watch on a regular basis and meet back here in 5 years time. If the results were positive would we listen ? Probably not, hard to believe something that appears on the surface to be ridiculous.1 point

-

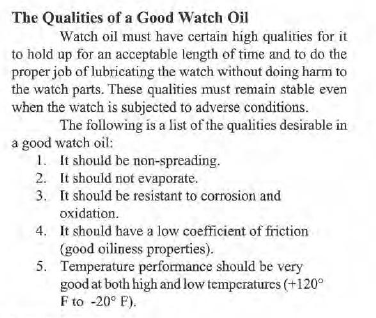

To help with some understanding here I'm attaching a PDF. The PDF is an entire article with page 5 talking about watch oil. Then I'm snipping out an image of the qualities of a good watch oil. Perhaps this might help in our discussion of what we trying to achieve here. 2000-02-web horological times watch oil reference.pdf1 point

-

Celebrate for what it's worth? I shouldn't be seeing this at all yet here you still are to me. I think when I was in the middle of blocking I popped out to look at something and when I came back it hadn't finalized or something so in which case you're not blocked. But it still brings up a problem of wonderful you know the drill but I don't know what the problem is with my answers and as I don't know the problem to be honest I don't feel like wasting my time doing an answer which is why it actually made me very happy to block you so I wouldn't have to waste my time and effort. Which is quite amusing because for anyone who knows me they would know that horological lubrication is one of my obsessions which is why I have so much material. Then as others have pointed out I have dyslexia. Mainly affecting writing so I use dictation software. The problem with dictation software is it's not perfect. It can be hard the read and recognizing that I can spend a lot of time on a simple answer really doing it until it looks perfect. Then I post a message and notice goofy wording complements mostly of the dictation software occasionally because I didn't quite pronounce something right. So yes it is a problem. So celebrate I haven't blocked you apparently1 point

-

Since it’s been concluded this is the work of the devil dare I suggest making the indent in the opposite end of the roller…1 point

-

Hmm... one of us must be reading the wrong post. OP didn't say second hand twitched or ran with a tap. He said he could change the movement if need be.1 point

-

Original OPs reply said the seconds hand twitched and then ran with a tap. Also the question becomes is the watch worth the price of a new movement and what experience and tools have they got for swapping the chronograph hands in particular.1 point

-

1 point

-

Thanks for the interest! Here's the position after phase 1: the HS seems to be shellacted into the stud & I didn't want to get into removing & re-attaching it; also I couldn't move the boot on the regulator to release the HS. Hence the arrangement at the outer end of the HS shown in the photo which gets these parts out of the way. After trying to undo the tangle around the collet for an hour or so I decided the only option would be undo the whole HS from the outer end & I'm now at the last stage of that having worked back to the final few coils around the collet.....1 point

-

Sorry, I meant to mention that, but I was on lunch and had to log back into work. 1200 and 2000 grit held on a staking block. The needle kept at a very shallow angle on the paper, gently rotating the oiler unit while moving back and fort across the paper. Cleaning (because it get's pretty dirty) in rodico to see the progress. It may not be necessary, it may be the holes in the jewels I've been working on are for fragile pivots. I believe some balance pivots are stronger than others, but whether an actual Bergeon auto-oiler fits all, and whether the needle on the one from Ali is slightly thicker, I don't know. If I was a betting man I'd suspect the Bergeon needle is a stronger material and consequently thinner but1 point

-

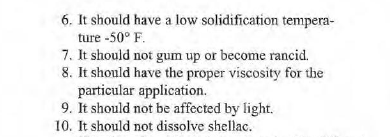

At high amplitude the coils are clearly touching near the end of the terminal curve, which would explain your timegrapher plot. You can see the much narrower gap where I've put the arrows compared to the bottom of the spring. Pressing where Nev suggests should open the gap. If not, just tweak it until the gap looks even.1 point

-

1 point

-

Hi Rich - I used the green 111/Fine, which is labeled for steel, cast iron, hard bronze. Mixed with basic 3 in 1 oil. I paid about $25 delivered for a little 3oz sample tub from a US tool supplier and have enough left to lap every other vintage watchmaker's lathe out in the world.1 point

-

I filed a square notch in a pair of plastic tweezers. I found it best to rotate 45deg from how it's shown in this picture then you can easily rotate 90deg at a time for the adjustment.1 point

-

Since the weather has been freezing my outdoor time has been limited. What better way to pass the time than to work on a few projects. Here are three I completed in the last few days. left to right - a 1942 Kelton ( owned by US Time \ aka Timex) it features the model 20 movement and a non-radiolite dial. In the middle is the 1960 US Time '100' Wafer Thin that features the then newly introduced model 23 movement and split case. On the right is the 1967 Timex 'Marlin' currently nick named the "Dot - Dash'. It features the model 24 movement and is a grail watch for many Timex collectors. The SSQ is used to help me check the time keeping. No need for fancy time graph machines or devices. My philosophy is to wear a vintage watch as a reminder that time is best spent doing what one enjoys!1 point

-

I do agree! Breguet, free-sprung, and the microstella screws on the inside of the balance rim seem to be the trick! I'd love to have a Rolex someday, perhaps an Explorer, but the prices are still crazy, at least for me. Regarding regulation, I contacted the owner of the Rolex this thread originally discussed. I set the owner's watch to the second on November 10th last year, and when I asked how it was running, she said she hadn’t felt the need to adjust the time yet. When I asked how much it was gaining or losing, she told me it was less than four minutes fast. That's about 2.7 seconds plus on average per day. Pretty sweet!1 point

-

About the bimorph sensor, my opinion, is that I had more expectations about it than it actually has. I have experimented with piezoelectric discs and apart from the commercial microphones of the timegrapher machines, they are the ones that give the best results. I only have one that he gave me @24h. And I have treated it very carefully so as not to ruin it. I replaced the glass of the commercial microphone of the machine in the photographs, but taking into account that I run a very high risk of ruining it, which I do not want. When doing the test I obtained very low results, without modifying anything in the application chain. It may be that you need to repeat the experiment. Above my skeleton watch with the bimorph sensor in Elma Mic. Above my skeleton watch with the Elma professional Vintage microphone. Above adapting a piezoelectric disc cut to the Elma microphone. I have no results but I remember that it was larger than the bimorph, but smaller than the Elma microphone. Above the cut disk and the original crystal of Elma. It is possible that I did not perform the tests to high standards.1 point

-

Was thinking we recently talked about the green sensor? Then I remembered we did we discussed the mounting it's critical how it's mounted otherwise it doesn't work very well. The reason we know about the existence of the sensor is it's used with some software found at the first and second link below. I had the opportunity to dissect their clip on microphone discovered the sensor and tracked it down. Also we know from other sources that this is the sensor they use in all their devices. In addition to using it with their clip on sensor if you send an existing timing machine microphone it's upgraded with one of these sensors and their circuitry. Original people using the sensor and their software https://www.etimer.net/ http://www.delphelectronics.co.uk/products.html The next to links or where it can be purchased from either the UK which I interpret to be the primary distributor which ships just about everywhere in the planet except the US. The next link is the US distributor. Even if it shows zero quantity in stock I is went ahead and ordered it and they came a few weeks later so that didn't seem to be an issue of having it in stock or not. Then yes you do have to purchase five of them even if it has a individual price. https://export.rsdelivers.com/product/rs-pro/bm15015-06hc/rs-pro-vibration-sensor-15c-55c-dimensions-15-x/0285784 https://www.alliedelec.com/product/rs-pro-by-allied/285784/70637796/?keyword=70637796 Then my best guess is there the original distributor of the sensor. I can't tell if they're the original manufacturer or basically the sole distributor but in a case I do believe there the source.Which probably suggests we could ask them questions and probably purchase thousands of them. https://lprs.co.uk/products/sensors/vibration-sensors.html RS PRO Vibration Sensor.pdf1 point

-

As far as I can tell everything covering a rather sizable time span they're basically all the same thing. They all physically look the same square with the leads attached. They all seem to have an aversion to moisture. Evolution of the sensors? Conveniently unhelpful for us I disassembled the microphone and the base which has the model number is now somewhere else. Reasonably sure this is a Vibrograph It's an interesting design plastic case italicized on the inside for shielding. The sensor assembly is mounted the black plastic piece that just slides in. The protruding probes as I'll call them go through soft basically like grommets. Then their motion Limited by the black plastic say they can't go very far and then the grommets they go through limit their motion also. Both sensors are identical they appear to be epoxy glued to the probe and they do not connect or the glue is. Otherwise it makes the wiring extremely confusing. You'll notice each one of the probes has been soldered and that goes to one of the terminals so that's the ground that also goes to one side of one of the sensors. Then both sensors are basically connected in series which I find is interesting Then I assume that all that circuitry was there because their coils on the other side because I assume this would do tuning fork watches. But it took the circuit board out there are no coils that circuitry is just for the pickup. It appears to have quite a few little tiny transistors which is what happens when you don't have an op amp.1 point

-

1 point

-

Here is an example of a recording with a piezo disk and a transistor. There is no preamp circuit (although actually the transistor + resistor is). It is sufficient for most of the watches that you will examine. And also the screenshot of wos. Note that none of the preamp has been added.20 seg. Transistor Clean.wav1 point

.thumb.jpg.073f338e6e0d8fb8186f15cc462a9323.jpg)

.thumb.jpg.90abbbef3d064b40a6a727019d5828dc.jpg)