Leaderboard

Popular Content

Showing content with the highest reputation on 02/28/25 in all areas

-

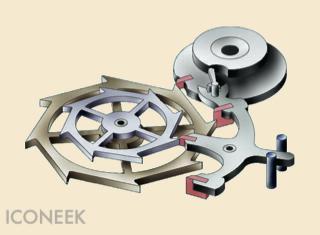

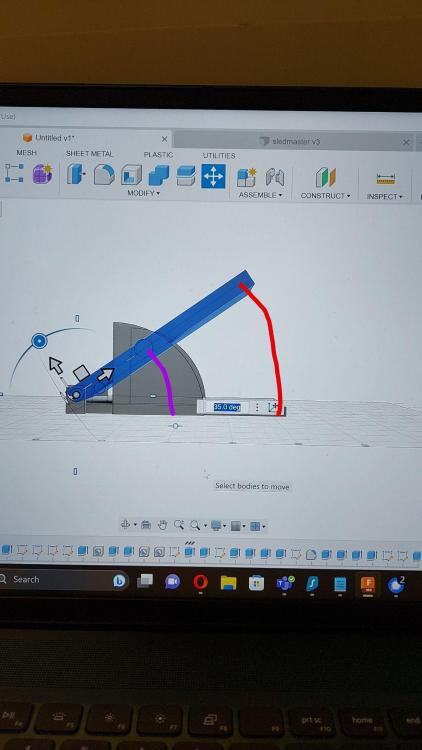

A couple of things here which cost me most of yesterday to learn and may help others as more of these movements age and start to need servicing. There is a lot of Valjoux 7750 here so some parts will be obtainable but please be aware that any damage could be a real headache. Worst case you may have to resort to buying a used replacement movement which are available at around £1000. If you are doing the job for a friend - are you happy to give them back a good looking paperweight ? The CoAxial Escapement parts are Omega only and thus unobtainable to watchmakers outside their AD network. Still willing to take the risk ? I did and got away with it but the stress levels took the fun away so I will hesitate to do another. The main challenge is assembling the balance safely and doing a professional job of the precise lubrication required. Have a read of Omega's Working Instructions No 40 - it's on Cousins site but and Omega search will not find it. Search under "Working". You will need a good Stereo Microscope and a very experienced oiling technique. Mr Daniels and Omega had a struggle over many years to get this escapement developed enough to suit mass production. It's more complicated and less tolerant to imprecise clearances and wear rates when running at 28,800 were an issue. Hopefully all resolved on the latest variations but only time will tell. The main advantage of not needing oil was certainly lost early on in the expensive battle. So still feeling lucky punk ? The struggle to get things reliable has left a development trail of three main types : The far right Starfish style is the latest. Mark has an excellent video assembling a 2500 Omega which has that variation. The 3330 has the middle one - early 3 level and seems to need a different installation approach. Whereas Mark comes in from the left and then turns clockwise - the 3330 seems to favour the opposite : Comme ca : You have to understand with this design the roller assembly is upside down and also has its own vulnerable pallet jewel: Winding the balance cock in anticlockwise keeps that tiny jewel out of harms way whilst you fiddle the roller jewel into the fork. You have to get the balance arbor sat in the baselate pivot jewel and the fork around the roller jewel before you swing the cock into place otherwise it is very easy to get things in a jam. Easing up the wheel in order to get a fit often works with a conventional escapement but this is upside down. Check things are in place under the microscope before applying any power. Now this is hard enough but when tried with any power wound on it proved impossible. With this version of the CoAxial the fork will sit stubbornly in one set position - it will not flick obligingly between the banking stops. At this point you will start to imagine you have broken the movement. Did I mention stressful ? Do not despair - this appears to be normal. LET DOWN THE POWER before assembly. The fork now swings freely and it will go together. Check things are in place and apply some power. The design seems to rely on inertia to get things pulsing both ways. And another possible snafu : The pallet fork bridge is retained in precise position by the two ears shown above. Mine were so tight that they needed a crow bar to release. When trying to assemble this meant the bridge was sitting with one ear in and one ear out which was sufficient to prevent the two pivots from dropping into place. I had to just stone away a tiny amount of metal to get a good push fit without any slop. Dangerous work. Neither was I impressed with the amount of play on the pallet fork pivots once assembled - nothing worn just not as tight as it should be. To be fair to the the good people at Omega it runs very consistently - almost no positional variation - just like a decent Rolex. Hope this diatribe will amuse the experienced and alert the nervous. Neil.3 points

-

In my opinion, they dont have the market appeal, because they are focused on watchmaking. That said, they make the absolute highest quality of watch within their price range, of any brand. The finishing level is Patek quality. The robustness of german engineering, and the looks of A. Lange. The pano line is stunning. The finishing is superb. And at a price point that can be had for $4-$5k used. The SeaQ Panorama is on my wishlist for a watch to hand down for generations. My 1016 explorer is probably worth in reality $1k, but the marketing and hype pushes the value through the roof. But Glaschutte Original watches are absolutely worth their value, and used they are severely undervalued.3 points

-

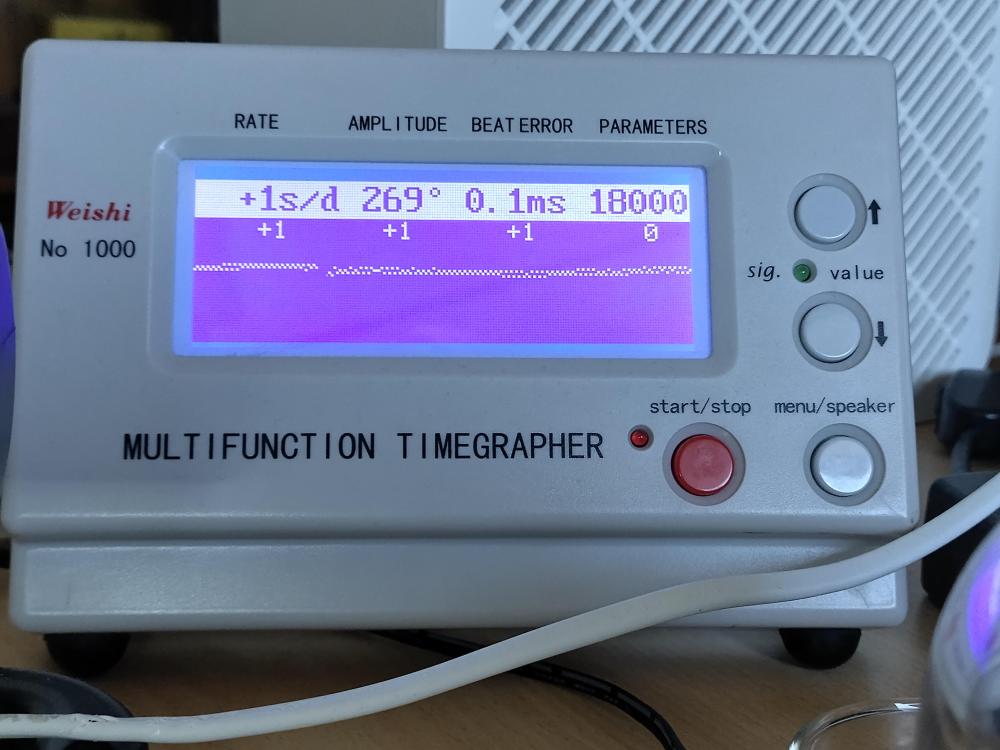

Still two more missing. But you can already see that something isn't right. Even the two horizontal positions are suspicious - the difference in amplitude between dial up and down is too much. In the two vertical ones, which amplitude seems ok, the traces are messy. I've recently had similar traces when a wheel was out of round (more precisely: not flat) and endshake was way too large on some train wheels. Could be other things. But definitely not in good shape.3 points

-

We have a thread where hairspring tweezers were discussed. I cannot imagine doing hairspring adjustments without curve tweezers, but I often see „adjusted“ hairsprings in fora with a series of small kinks instead of a curve. You should practice your skills with an intact hairspring, best of an alarm clock, make determined distortions and try to remove again. And make yourself familiar with the few rules for such adjustments. Frank3 points

-

The secret to good hand stability is wrist and finger support. Bean bags, sand bags, wooden blocks can be used for supports. Another secret is using very light touch tweezers. A heavy tweezer will fatigue the fine muscle fibres in the hand and cause tremors. Caffeine also causes tremors. The blood pressure medicine, Atenolol, has a side effect of making the hands more stable. That's why it is banned from competitive shooting. I'm not suggesting that you go out and get a prescription of Atenolol when doing hairspring work. Except when I need to twist the hairspring, I only use one tweezer in the left hand and a bent needle in right. Grip the hairspring a little behind where you want to place a bend and use the needle to stroke and shape the bend. To prevent tremors, I work on a slab of glass. I grip the hairspring with the tweezers and rest the tip of the tweezers on the glass. The needle tool also rests on the glass. I'm sure everyone have their own way to do hairspring work. This is only a suggestion. Try them out and see what works for you.3 points

-

I think you have done very well! It looks good just like this, in my view. Maybe consider painting the numerals in a colour like they were before (the burnt radium colour). That would restore the nice contrast it had. Probably not very easy, but with enough patience...2 points

-

" it could be worse " wow just...wow Kalle, I'm not sure how it could though, maybe if it were like the front wheel of an eight year old's push bike after he'd just rammed it up a six inch kerb. Really surprising this video, I'm no artist but my daughter's pet Husky could draw or a more balance staff looking balance staff than this. I stopped watching Chronoglide when it was FREE .2 points

-

Yes, but I think it's missing the rubber drive wheel. Which is of no consequence as the thing it drives is also missing (and the rest of the dead center turning stuff). Maybe there's another box of stuff within arm's reach of this machine, with all the missing bits? It's funny how many bare-bones machines are around (this one isn't bare-bones, just missing critical stuff); I guess it explains some of the random accessories that come up for sale. I have a friend in the U.S. who collects Swiss precision machine tools. He bought a Sip jig boring machine (this thing occupies the floor space of a king size bed) that was missing all its tooling, which is fairly specific to Sip. Some time later, 2-3 years (more?), at an auction there were the typical beautiful wooded boxes Sip put their tooling in, and it turns out some numbers matched up and they went to his machine. Crazy luck. Similarly, I bought a Swiss 102 lathe (Habegger, same design as Schaublin), it is a screwcutting lathe but it was missing all its change gears. I figured they were the same as Schaublin but they had a very different bore. A year or two later I was fishing around in the upper floor of a machine dealer, and found a set of change gears, which were actually the set for my machine. Like, the actual missing set (I know because there were a few on the headstock of my machine, and those were the ones missing from this set). Crazy again. I hate when machines get separated from their tooling.2 points

-

That must be the video where I got my judgement about that person (Neverenoughwatches knows … ). Frank2 points

-

One of the primary selling points of the F1 was that it was able to do normal lathe work with a slide rest/ T-rest, and also was highly adapted for doing fine work between centers. Originally it came with a normal (not collet holding) tailstock, and another offset tailstock that took special runners for dead center work. There was also a sensitive clutch system that ran off the headstock to power the dead center work. Apart from that it's just a normal lathe with plain conical bearings (not ball-bearings)*. The clamping system for things attached to the bed like the slide and T-rest is less than optimal in my opinion. Complete sets tend to go for a premium, like several thousand+. As this one seems to be missing the tailstock, runners, and drive cone for the headstock for dead center work, I would treat it as a normal lathe with slide rest and a decent set of collets- and the very useful collet holding tailstock. I'd say still in the 1500- 2000 buck territory, perhaps more due to the F1 "coolness"factor. *There's nothing at all wrong with plain bearings. They do need a little more care keeping them oiled and adjusted. Just it seems many assume the F1 has ball bearings due to its closed headstock design.2 points

-

I didn't know where to put this, so Ill put it here. I have a number of vintage dive watches that I've been collecting, and once I get more time to pursue personal projects, I'd like make some changes to these watches. These are swiss movements with stainless steel cases, and screw down case backs. I have thought about adding screw down crowns to them, but wondered if its taboo to make these kinds of changes. I have no problem doing it to these older dive watches, as I have no sentimental attachment to them, and will re-sell them when they are completed. But I am also toying with the idea of adding a screw-down crown and screw-down pushers to my Speedmaster. I don't have a rare Speedmaster, just a 3510.50 model that I restored that had a lot of water damage. What are your guy's thoughts on these changes? I dont plan on selling the Speedmaster, and the case back isn't exactly waterproof, but the idea that its only o-rings preventing water intrusion, has made me think more into it.1 point

-

Going back to your first comment. What screwdrivers are you using and what's the problem? You may want to look at this post.1 point

-

Hi everyone! I’ve been a long time reader and watch collector, and just recently have become fascinated with watchmaking and watch servicing. I’ve taken some “horologerie” classes at HSNY, bought a bunch of tools, oils and greases, and a dozen or so broken pocket watches of the Bay, from Elgin 12s 7j learners, to Railroad Grade Hamilton 992Bs and have metaphorically jumped into the ultrasonic deep end. I have been trying to keep my head above water, but have some questions YouTube just can’t seem to answer and wanted to reach out for some help! Thank you! I attached a pic of my latest and greatest tool acquisition! K&D 18-R Inverto Staking set… Looking forward, —phillip1 point

-

My guess (educated or not) is a rogue particle, lint, swarf etc. It's moving around the movement, occasionally jamming it up, a small wind dislodges it.1 point

-

What does the timing machine say? In both horizontal positions, and 4 vertical? The fact that it's stopping the watch is saying, "I need a service". Lots of sellers do "servicing" , with the quotes being very important.1 point

-

Hi there... sorry I didn't get a notification that you replied to my post! Thanks for the advice really helpful and I did get the watch going using an EW from my stash of scrap movements... But....and a big but....the EW had too much end shake and as you said the EW teeth just didn't like it when I inverted the watch. It was a good little 'learning piece' and I appreciate your help. Cheers Al Yep....and in the drawer of doom it went1 point

-

Hi there! Good to have another American pocket watch enthusiast around. One thing certain youtube guys get really really wrong is the recommendation to buy ebay pocket watches as learners. They are usually broken in a dozen ways that take a lot of experience and tools to overcome. But you already acquired the most important one in that fine K&D 18R. I look forward to seeing those watches come together.1 point

-

Don’t know about the lathe nicklesilver is your man for that as I have had nothing to do with Boley but looks to have a fairly comprehensive set of accessories and that is always a bonus , the Multifix motor will run on 220v or 110v but I can’t remember if I had to switch my one or straight of the bat, as for price it’s worth what anyone is prepared to pay for it but I have seen them advertised for £2000 plus what that converts to in your currency I don’t know but if you buy it do it on the assumption that it will need a strip & rebuild.1 point

-

I was at Costco yesterday. Haven't noticed the jarred peaches you're talking about, but I did see some rice pudding in little glass jars that had my attention. Slightly larger than the baby food jars, and twice as tall. They had pressed on foil instead of lids though, so I wouldn't be able to keep the cleaning solution in them. I passed. The only jarred peaches I've seen (and have in the pantry) are in a giant jar a good 10" high and at least 6" diameter. It's only watchmaking application would be to store the stripped plates of the many movements I've ruined! Ooh... Good point. I don't think any have made it through the dishwasher since my realization 24 hours ago, but I'll be sure to verify that. I did load a 12 pack into the pantry last night, so I'll have plenty one way or the other. Thanks! #2 has been WAY easier than #1. None of the health issues and no pandemic to make them worse/more stressful. Just a happy squeally baby boy! Yesterday he hit a milestone in that is officially fully mobile. He can make himself be anywhere in the house at will (below knee height). He finally figured out all the transitions between laying down, sitting, crawling, standing, and walking (along the furniture). We thought we were baby proofed, but it seems that's a moving goal post with a 5yo sister and all her leavings to chase. Nothing is safe!1 point

-

Update: having this HS to practice on has taught me: 1. that after working for about an hour, I suffer from the equivalent of the golfer's 'Yips', those involuntary twitches which cause one to miss the 'target': in the present case that being a smooth 'bend' in the HS. Taking breaks is therefore important & doing so is also a reminder/opportunity to re-dress the tweezers which is, this practice has reminded me, time well spent 2. that I lack the degree of wrist articulation required to make vertical adjustments effectively. What I intend to do now is to spend a little time in each session at the bench doing a little tweaking of this sacrificial HS in the hope of improving my technique as well as 'keeping my hand in' for when I have to work on a salvageable HS. I've often wondered about making some die-jawed tweezers to facilitate HS work & I now think such a tool could ameliorate the problems caused by the 'Yips' so I hope to find time to explore that possibility.1 point

-

You shouldn't be using any Alkaline Batteries on watches due to leakage potential.1 point

-

1 point

-

That one is a cause for envy! The largest beds in my Steiner set are in a runner ranging from 38 to 76, and more often than one might think, it is too small for some centre wheels. Getting a larger runner from Horia is very expensive. For even more info about this, check out this post, also by @nickelsilver!'1 point

-

We need a sideways view of the balance wheel with the bridge in the watch to see how bad they hairspring really is. Because the way it is out of the watch there is no way the balance wheels going to move. Then not the best picture of your pallet fork here. I enhanced it a little bit so we can see things better it looks like the pallet stone is out by a heck of a lot and that would definitely be an issue. It be nice of you get a better picture of both sides so we can see how deep the pallet stones are in.1 point

-

Sounds good- would definitely keep the Steiner then. You have a very nice tool there.1 point

-

I'm assuming that you have all technical documentation? Just in case I have PDFs attached that you may find helpful. In other words there is the service guide their something for checking the escapement and the instructions on lubrication cover the lubrication of the escapement which is critical. Lubrication isn't actually for lubrication my understanding is for a shock impact then if I was changing the pallet fork and probably change the escape wheel at the same time Then is also the problem of Omega possibly upgrading things. But oftentimes upgrading is requiring several parts to be changed at the same time so they all work together. But we don't have new enough documentation for that so would be speculation on my part if I was replacing the pallet fork I would also replace the escape wheel at the same time. Also based on someone I know sent their coaxial in for servicing and the service center replaced both components. Of course they have an infinite supply of components to replace things with. 8649_WI_54_E.CHECKING THE CO-AXIAL ESCAPEMENT FUNCTIONSpdf cousins.pdf 4435_Omega 2500A,2500B,2500C,2500D cousins.pdf 8645_WI_40_rules for lubrication cousins.pdf1 point

-

1 point

-

The hairspring is badly deformed. I mean in a manner that is beyond repair, sorry. We need to see it on the balance without the cock, but no much hope.1 point

-

I might have a solution to the solution creep issue: ONLY put clean tap water in the US, and put the various solutions in small jars with lids on them. Seal up the jars and empty/clean/dry the US at the end of every day (it's just water). I've never experienced/noticed any creep, but anything that did happen to get out would immediately be diluted beyond notice. I have one of the SS Chinese 3L models. I use it for things other than watches too, so I got the big one. Helps also that I can get three of my little solution jars in there at the same time, which is nice for my cleaning process (I keep parts separated by system through the process to make it easier to get things back together). The big guy also has multiple transducers, none of which have detached on me so far after 5 years or so of casual use. At this point in my watchmaking hobby, there are a number of tools I'd really like to invest in/upgrade. The only upgrade I can think of that I have any desire to do on the cleaning side is figure out a way to make the US quieter/less obnoxious. Another upgrade occurred to me while I was sitting here typing this: I have an 8 month old baby (in a few days), and if those tiny baby food jars will fit a typical main plate through the opening, they'd be even better for cleaning than the small mason jars I've been using... I can fit three mason jars in the US, which is 3/4 of my cleaning process. I could probably fit five or six of the little baby food jars in there though, and that may allow me to really speed up that aspect of the service process! Every time I put one in the recycle bucket it pings my "this seems useful" sense, but then immediately also triggers the hoarder alarm. Now I have a good excuse to set a few aside without feeling like I'm just adding to my clutter!1 point

-

Excellent information, my friend! I am very new when it comes to Jacot tools and I would have never known this u less you had told me. I will double check the runners numbering to see if there anything missing. Thank you for sharing the video Watchie. I will for sure keep the Steiner. I just have to make sure everything is correct. Which I think it is for what Nickel silver was teaching me on his reply. I think there must just be a runner that he mentioned that I may not have which is the one that goes from 4 to 10 1/2. But the other ones seem to match the one I have.1 point

-

Steiner did make "old style" Jacot tools before moving to their unique design. The trademark is still a rooster, but flanked by the initials C and S. They are fine tools and unlike most competitors already featured replaceable beds and lanterns. I do strongly prefer the more modern ones, as they provide means to fine tune the alignment of the pulley side (headstock) to the runner side. An old Steiner The old Logo The adjustment mechanism on the modern Steiner1 point

-

HWGIKE#45 Rotary Peseux 330 full service, acceptable performance. When I took the caseback off the hairsping fell out, I immediately knew that this is the project I want. 8 hours later at 5 o'clock in the morning i was totally and utterly defeated... my mind kept me going, but at the end both my body and soul was squeezed and i slowly sunk into the swamp of tiredness making one mistake after another. When the HS fell out I checked if I have complete balances for Peseux 330 and I noted that i got two... that time I did not know that both of them were faulty... of course it was not an option to place one of them into the watch... i had to go on the hard way... I almost made it work and the HS was almost flat and sort of concentric but it was not good enough.... When the HS was totally destroyed I tried my complete balances but both and then a third one I also found were faulty. Then I tried to marriage the HS from one of my faulty complete balances with the original balance wheel, but the wheel where I borrowed the HS from was not the same type as the original wheel so the HS was not compatible with it and I ended up like @Knebo with his Vostok: ... so I bought a donor from eBay and replaced the complete balance. The case and the crown are very very worn, when I took it apart I decided not to restore it so it would change its appearance, somebody got it in 1968 and it was a lifetime companion, I changed its glass though. Marden Fruit Show still exist, going to reach out to them to see if they want this watch, I am happy to hand it over, it has no real economical value anyway.1 point

-

That is a little narrow. I bought a 1.3L where the basket is about 12cm x 13cm. It's 60W at 40kHZ and cleans well. I use 400ml beakers - one sits nicely in the middle.1 point

-

Not repair per se, brand new channel from Finland looks like it could be interesting. Tom1 point

-

I feel that's what happened in the video, i thought he whaled down on it tbh. The vid was edited directly afterwards . You recommended glueing to me Nev and shellac worked just fine. I got curious about this idea, my original thought was that it would push the roller off-centre, which it would, but how much ? I pulled a couple of beard whiskers ...I won't be doing that again anytime soon . A beard whisker measures around 12 hdths, with a medium compression that finishes around 4-5 hdths, thats quite a big deal in the way of safety clearances if a roller is thrown off-center by that much. An eyelash is less of an intrusion in the roller hole, diameter at a mid thickness of it is around 4 hdths and compressed around 2 hdths, with the thinnest part compressing to 1 hdth. So if that grips the roller and all is needed is an extra 100th then it probably isn't going effect the escapement much. But it is organic material and may compress and wear over time, something more solid might be better like Mike's tin foil...or maybe just glue it in place.1 point

-

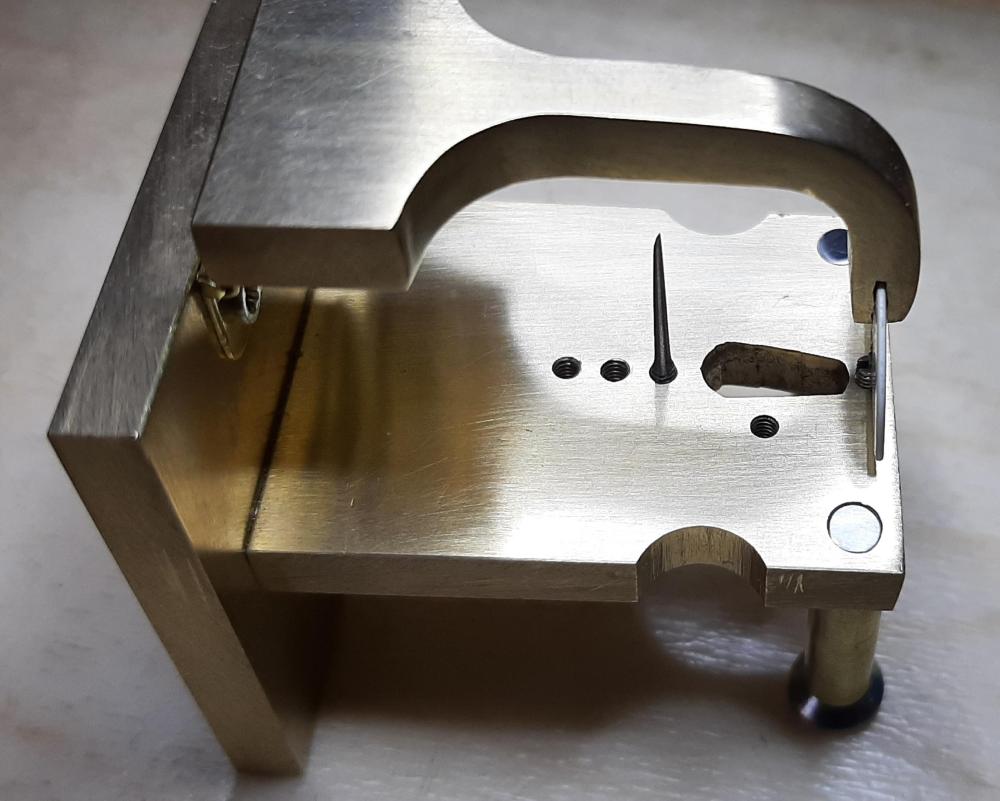

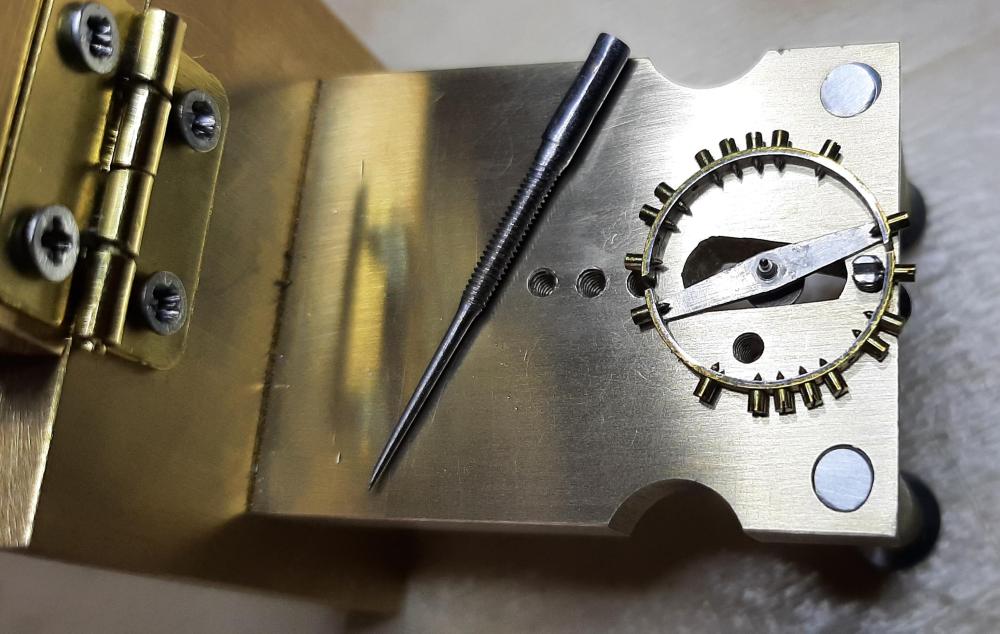

I've come to the same conclusion. After breaking ANOTHER pivot whilst trying to hold a balance+cock to adjust a timing screw, I decided all watch fettling was on hold until I made one of these thingies. I've wanted one since this post started years ago, but wasn't sure I had the tools to make one. I still don't have a workshop or any workshop power tools, but the good news is I managed to lash this one together with just the following : Vice, hacksaw, files, cordless drill (), M2 tap and die, M4 tap. Oh, and a blowtorch for bending the brass. So I bought some 5mm brass bar and started hacking. Without workshop power tools I had to improvise the hinge (I just bought a small brass hinge) and the front legs (just M4 screws). I couldn't have done it without @nickelsilver's plan and pictures. Thanks It's not perfect, but I just tried it on a balance to change a timing screw, and it works. It's great. I recommend everyone should have one. So buy some brass and start hacking. I can provide guidance if anyone needs it (but my metal working skills are pretty limited).1 point

-

1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)