Leaderboard

Popular Content

Showing content with the highest reputation on 03/01/25 in all areas

-

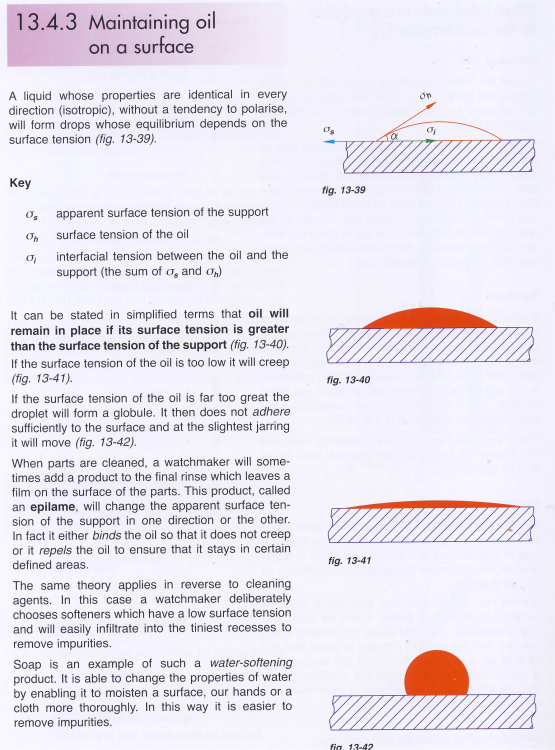

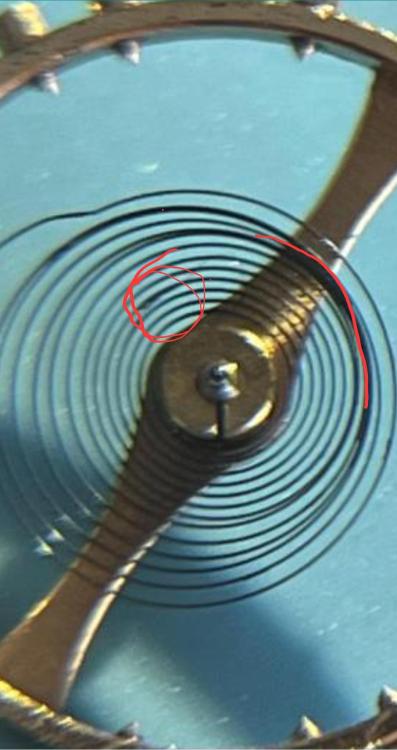

Stepping back and trying something simple that has not been suggested in this thread as far as I know (unless I missed that..): What did you do to clean the balance & mainspring? Looking at the photo, there seems to be a lot of dirt. Could it be coils are sticking together? Dunking it in some suitable cleaner (one-dip, haxane or other) and demagnetising the part might help. Nothing ventured..5 points

-

I tried UV nail laquer mixed with lume powder recently: it became terribly glossy, unnatural. I use lume powder of just right grain, tinted with artists color pigment, mixed with a sort of glue that I got from a lumeing company- no idea, what it is. Dried it looks exactly like original vintage lume, same grain. Just finished, min. hand original early 40s lume, hour hand was empty:4 points

-

Lume color and texture is a fully different talent…I have not acquired. I have one of those kits with three different texture powders and 8 color pigment powders. I think it was from Lobtime. I can achieve acceptable results with the tans and browns and non luminous green. Most other colors I usually end up buying the color/texture I want rather than try to mix it… Don’t get me started on ‘white’ … …I just did orange to cover major surgery on this chrono seconds hand. The original orange has a textured appearance that looks like cerakote. I added a bit of texture powder to testor paint and it passes the 30cm test, though a touch too clean…3 points

-

I think it's a throwing star for killing people who mod, redial or use a non genuine part.2 points

-

I think I have more chance of becoming Porky Pig then you getting that hairspring correct.2 points

-

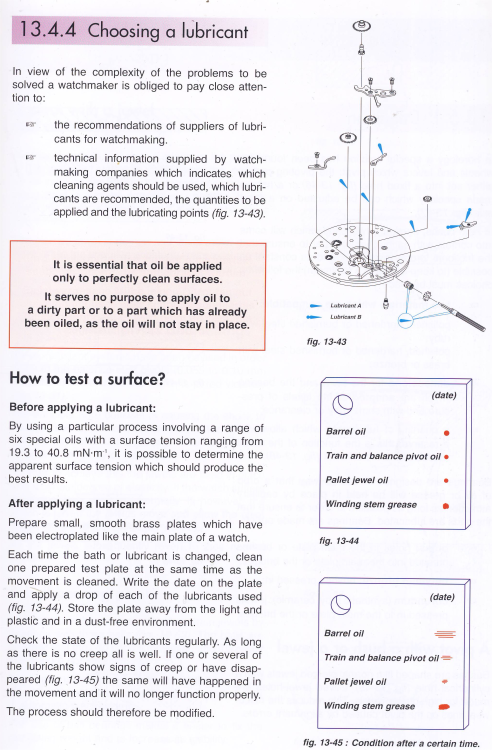

So the first pages into the Tribology book, brought up something that I hadn't thought about and without reading back through the thread I don't know if it was mentioned . Canthus listed properties of the 9010 , i can't see or rather don't know if there is an additive here to protect the oil from heat damage as would be the case in an engine. All friction is the resistance to motion, which is an energy dissipation, that results in the formation of heat at the point of contact. Its not measurable in a watch, by us, because of the size ,but that doesn't mean to say it doesn't exist. The fastest moving components of a watch are the lever and balance staff, the lever pivots are not oiled but the balance staff's oil has to cope with permanent friction from a constant load and velocity. I'm Fascinated to know what the temperature would be at the exact point of contact, especially at a molecular level and if it has a degeneration effect on the oil.2 points

-

I kind of found this tweezer holding position by accident, i was looking to increase the angle of the curve on the tweezers to make the tips more upright, which is really important when correcting a twist. Otherwise a compound bend is created ( a twist at an angle other than 90° ) A really good tip from when i was learning to understand how my bending actions affected a spring; was to use a big spring, even better practice with an old worn mainspring or the central portion of it, it's basically the same thing and will behave in the same way as a hairspring, you need a small one though, it takes a lot to bend a mainspring with tweezers.2 points

-

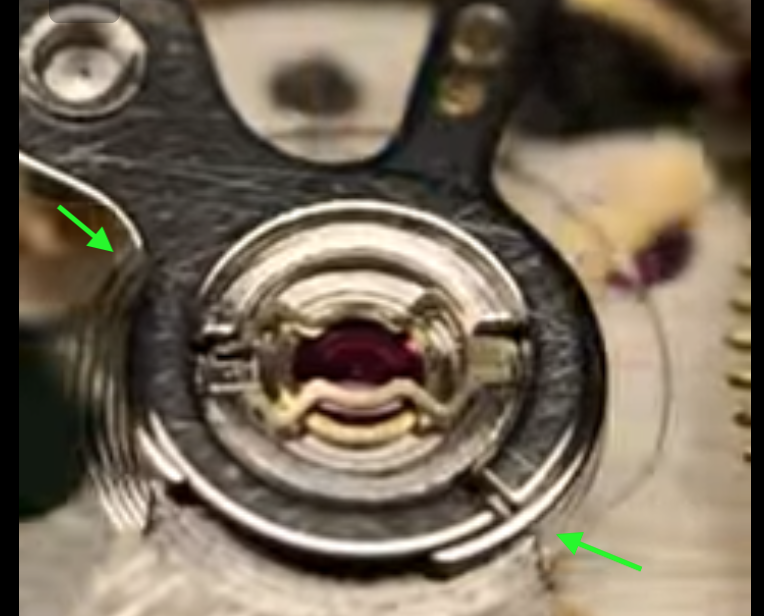

The membership option has been around for a long time. What annoys me is that already published and what used to be free videos have now been hidden on his new Netflix-style channel. Yes, he generally doesn't seem particularly concerned with the truth and has no hesitation in winging it when he's unsure how things work, like pushing out a jewel while banging the pusher into the decorated bridge!? Horrific if you ask me. I shouldn't complain too much, though, as I've picked up quite a bit of useful stuff on his channel, and I'm very grateful for that, so thank you, Kalle! He doesn't show it, but I'm pretty sure he banged the stake so hard into the balance arm that he didn't include it in the video. It's no wonder the balance wheel looks the way it does after the staff has been replaced.2 points

-

Yah, the stand- You’ll be back and forth all the time on sizes and a stand makes it so quick and easy to spot and pull. Keeps your work space tidy…2 points

-

It's definitely practice I'll give you that. Maybe try something a bit bigger so you can see the changes that you make easier. With a small spring like this it's very easy to get fuddled, until you understand how your intentional bends affect it . I like to well fed before I start playing around with a spring, heading towards low blood sugar becomes apparent at magnification. I always use 2 pair of curved tweezers for straightening out twists and vertical bends. I keep my hands low on the bench so that my wrists and forearms are flat down as well. The tweezers are slid between middle and wedding finger, i find this gives me the most stability with zero shake.2 points

-

Just looked at their vid "Balance staff repair- the easy way". Yikes. The balance arms are visibly more true before he removes the staff than after (punched out without any special tool like the K&D/Platax) , and he says it looks pretty good on the truing caliper, when it's off a mile. Yuk.2 points

-

Greetings! I've been interested in mechanical watches since 2000. I live in Seattle and I'm switching careers to become a watchmaker. I'm currently enrolled in the Norwest School of Horology. I don't know how active I'll be on this site, but y'all want an introduction so Hi There!1 point

-

If I were to do these mods on the Speedmaster, they are totally reversible. They are just pressed in case tubes that are threaded. Maybe people would be interested in it if someone took the jump and did it.1 point

-

One of the interesting properties of the watch would be the heat is being generated at a relatively confined space next to Sapphire. So is your heating up your oil and the entire droplet oil is absorbing the heat it's in good contact with Sapphire which is what the ruby colored jewel it really is an Sapphire is a very good conductor of heat. Maybe another reason why oil doesn't last forever at least on the balance jewels.1 point

-

Never needed anything like that when it came to repairing Jungings chiming/striking clocks. I think it has something to do with their watches.1 point

-

I am 1000% for modifications. I'm not a "mod" for modifications' sake kind of person by any means. I don't have to screw with something just for the sake of it. I upgraded and modified the movement for one of my dailies. Came with a basic 2824-2, and I put a top grade Sellita in it, and modified the movement to better suit the watch. The case/dial doesn't have a date function so it was removed from the movement (the manufacturer left the date function in the original movement), and requires extra long hand shafts (which makes the ghost date function somewhat more curious since they customized the movement to that degree but not the other...). Similarly, I had a Seiko 5 that I bought in college. Wasn't my first mechanical watch (that would be the accidental Nazi watch), but very close. It didn't survive a car accident (I obviously did, but only just). I replaced the movement, dial, and crystal (so case, hands, and band are all that's left of the original), and wear it every time I'm in the shop or working around the house. These modifications had a distinct purpose, and weren't just... I don't know, different hands for the sake of having something different... I don't know... Not a thought process my head really does. The first watch is probably worth a little, but I don't care. I probably increased it's value. The second was all around scrap. Regardless, neither of these will ever be sold. The first is going to my daughter when she goes to college probably. The second will meet its end on my wrist. Probably operating an air hammer, or welding, or slammed against a boulder, or who knows what. If you're modifying for yourself, do you. Right to repair is the same as right to modify in my mind. Best case scenario, you love it or it takes a $ watch and makes it a $$$ watch. Worst case scenario, you make others of the ilk more valuable by removing one from circulation. The way I see it, everyone wins.1 point

-

No, just filled. But you could add age signs like in the minute hand. I use a fine brush and my artists watercolors then on the dried lume. However very rarely, if justified, as it would be near to fake. Frank1 point

-

1 point

-

I mentioned Hooke before, it is thought (unproven) that he invented the hairspring, Breguet improved it.1 point

-

What do you refer to? Only the hour hand was restored, everything else is age.1 point

-

1 point

-

I can imagine, Nev is right - he is not in my country . But redistorting a funnel shaped hairspring is no fun at all, you cannot be sure that the coils will go back equally.1 point

-

1 point

-

Personally, whichever you choose ,I would go for the revolving stand. Much neater on your bench while working and easy to use. I'm sure it will come in a cardboard box that you can put it in or find a small box for it. You can buy a cheap wooden ( i prefer plastic for most storage, wood is hygroscopic ) case from lots of places to put the drivers in but a revolving stand would be an extra cousins order if you decide you want one.1 point

-

1 point

-

I used a far less precise method: colours from my daughter's paint set mixed in to my standard lume/humbrol lacquer mix! (My colour mixing/matching isn't too bad though - I was a printer earlier in my working life so have quite a bit of experience there.)1 point

-

I wouldn't think it makes that much difference between the two pushing points. The aim being looks to put pressure at that first bend where the terminal curve starts, as opposed to where the spring exits the stud. I'd have thought with the regulator being close to the stud...the spring will lean against the regulator pin for leverage and push the coils further out at around one oclock where the terminal curve finishes. I'm with the rebanking idea. If it were the coils touching I'd have thought that the effect would remain, for a while at least. If its rebanking then that is an impact, a more severe action that takes place and is quickly delt with until the amplitude catch back up. Interesting to discover which symptom the watch has, but whatever, the root cause appears to be too much amplitude. The cure would be to reduce it...oil the lever pivots, change the mainspring for a weaker one, flatten off the balance pivots which would better average out the positional amplitudes. A good habit to get into is measuring the mainspring for correctness when servicing it. Someone might have put a stronger spring in for some reason. Possibly a reason that you've fixed during a service or an adjustment that you've made. Handy to know whats in the barrel before diagnosing an issue. Similarly a doctor should want to know information about a patient's heart, have they got a pacemaker fitted ? before making comment on their blood pressure.1 point

-

I'm no expert, and the numbers do suggest re-banking, but it also looks to me that coils of the spring might still be touching when the amplitude is large. In the video, compare the coil spacing where it goes under the cock (at about 5 o'clock in the pic) with where they go under the stud carrier 180 degrees away.1 point

-

There is always more than one way to skin a cat and everyone have their own personal preference. There are 3 types of binder commonly used lume. 1. Solvent based varnish. This is the original old school way. Lume powder us mixed with a solvent based varnish and a solvent is added to achieve the desired consistency. Downside is there is a limited working time. And in git climates, this can be very frustrating, especially if you have a fan or AC blowing at you. And the room get filled with solvent vapors. 2. Water based glues. Craft glue like Elmer's, which turn translucent when dry can be used as a binder. Advantages are longer working times and low cost. Disadvantages are long drying times and some steel hands can rust while drying. 3. UV curing resins. This can be nail varnishes, UV glues, UV varnishes. Advantages are long working times, fast set. Disadvantages are steep learning curve and difficult to remove afer setting, I have been using the UV cured method for several years. The working consistency of the mix has to be very dry to avoid a glossy finish because there is no solvent or water to evaporare away. The thickness of the applied layer has to be thinner as there is minimal shrinkage after setting. There is no right method to anything in watchmaking, unlike what French chefs say. Experiment and see what works for you.1 point

-

1 point

-

" it could be worse " wow just...wow Kalle, I'm not sure how it could though, maybe if it were like the front wheel of an eight year old's push bike after he'd just rammed it up a six inch kerb. Really surprising this video, I'm no artist but my daughter's pet Husky could draw or a more balance staff looking balance staff than this. I stopped watching Chronoglide when it was FREE .1 point

-

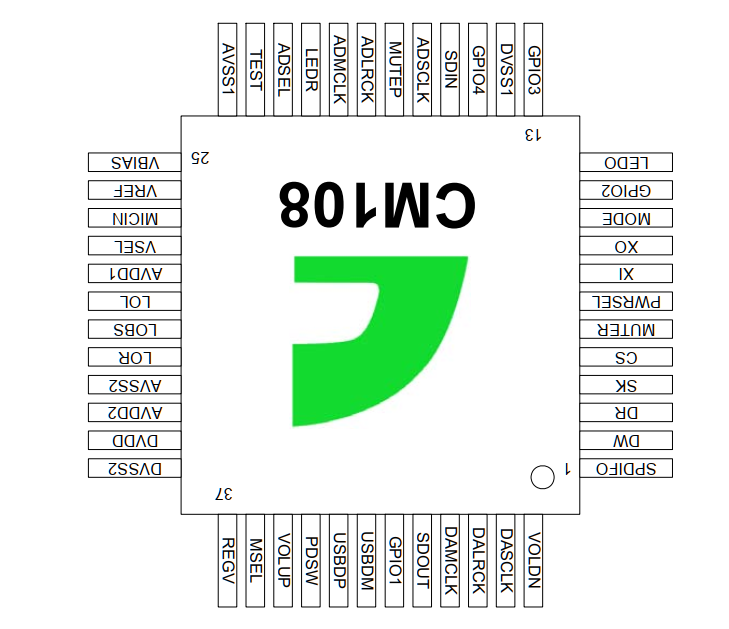

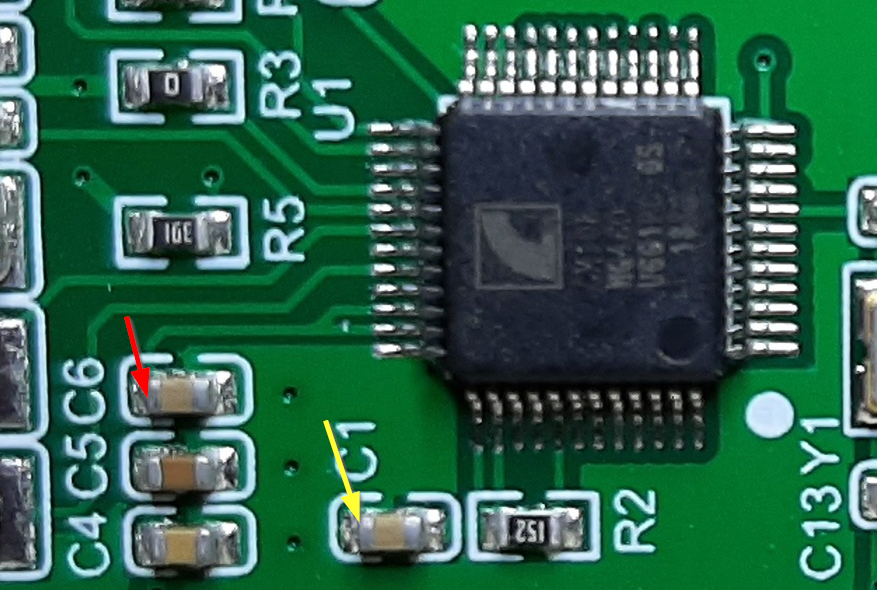

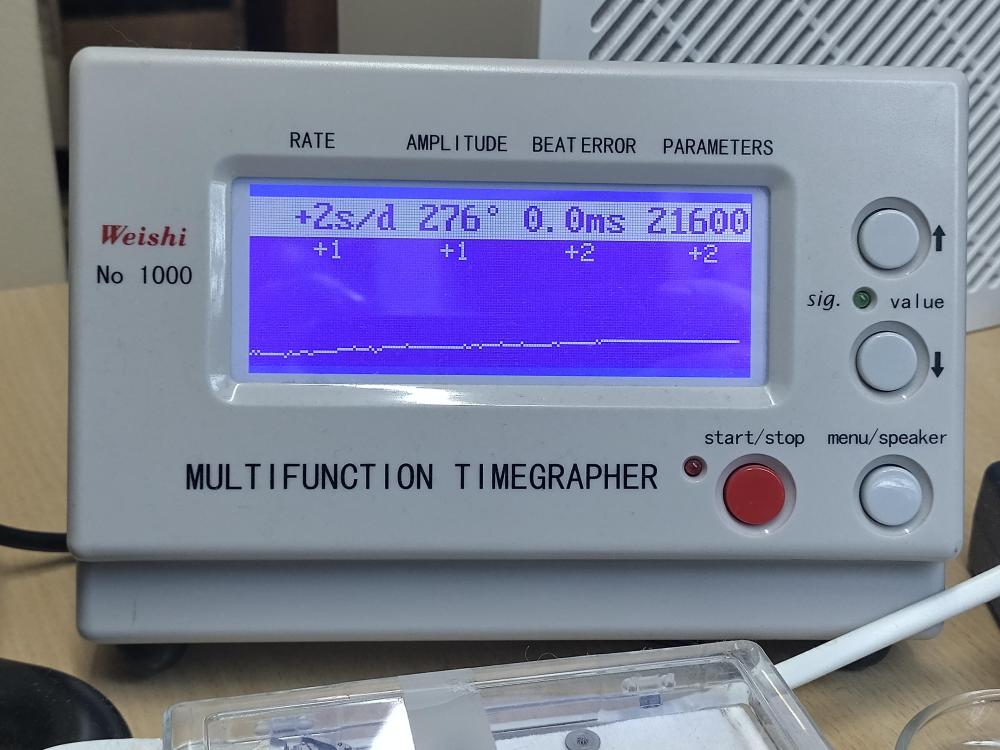

Still two more missing. But you can already see that something isn't right. Even the two horizontal positions are suspicious - the difference in amplitude between dial up and down is too much. In the two vertical ones, which amplitude seems ok, the traces are messy. I've recently had similar traces when a wheel was out of round (more precisely: not flat) and endshake was way too large on some train wheels. Could be other things. But definitely not in good shape.1 point

-

What does the timing machine say? In both horizontal positions, and 4 vertical? The fact that it's stopping the watch is saying, "I need a service". Lots of sellers do "servicing" , with the quotes being very important.1 point

-

1 point

-

I'm still convinced you're dealing with re-banking. The 325° amplitude you mentioned, is that with the lift angle set to 42 or 46° ? The difference in setting should easily add 25° of amplitude. I'm not sure how pronounced the galloping sound is if the rebanking is marginal (i.e. just "blocking" only the last hypothetical 5° of an oscillation)1 point

-

That must be the video where I got my judgement about that person (Neverenoughwatches knows … ). Frank1 point

-

I was at Costco yesterday. Haven't noticed the jarred peaches you're talking about, but I did see some rice pudding in little glass jars that had my attention. Slightly larger than the baby food jars, and twice as tall. They had pressed on foil instead of lids though, so I wouldn't be able to keep the cleaning solution in them. I passed. The only jarred peaches I've seen (and have in the pantry) are in a giant jar a good 10" high and at least 6" diameter. It's only watchmaking application would be to store the stripped plates of the many movements I've ruined! Ooh... Good point. I don't think any have made it through the dishwasher since my realization 24 hours ago, but I'll be sure to verify that. I did load a 12 pack into the pantry last night, so I'll have plenty one way or the other. Thanks! #2 has been WAY easier than #1. None of the health issues and no pandemic to make them worse/more stressful. Just a happy squeally baby boy! Yesterday he hit a milestone in that is officially fully mobile. He can make himself be anywhere in the house at will (below knee height). He finally figured out all the transitions between laying down, sitting, crawling, standing, and walking (along the furniture). We thought we were baby proofed, but it seems that's a moving goal post with a 5yo sister and all her leavings to chase. Nothing is safe!1 point

-

That is great to know! I am glad the tool is complete! Thank you all for helping because I had no clue what I had bought. I knew the tool looked nice, but I did know if everything was like it is supposed to, but now I have peace of mind keeping that one.1 point

-

1 point

-

1 point

-

When you finally purchase you watch timing machine you might find the following vid interesting. How to determine what the watch you are working on lift angle is using a timing machine.1 point

.thumb.jpg.19a9c4ff164d78d516aa9f05a063752b.jpg)

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)