Leaderboard

Popular Content

Showing content with the highest reputation on 03/02/25 in all areas

-

4 points

-

The amplitude looks to be about 320 degr. If You need to know if it is rebanking, then force it by adding torque winding by the crown and holding after the full wind, if the amplitude can rise more than what it is on the video, then still not rebanking.3 points

-

It took me months to figure this out for myself after being led astray by probably that same video. $250 is in my opinion a great price for this set. Even if it is missing something here or there, it is really well kitted out. It includes the balance staff removal tool and what looks like its punch near the back left, and includes just about every stump I can imagine. I see a centering punch (the one with the knurled knob on the back end) but it would be nice to get a view if it has a good point and isn't broken. Even if it is, you can get a replacement from Cousins for about $15. The condition of the punches from these photos look a little rusty but not terrible. They should clean up just fine with some steel wool and WD40, same with the die plate. It's several hours of work but worth it in the end. I think this is a good buy. A kit this complete would go for $350 on ebay.2 points

-

Reading the thread, I found this: Don‘t know which yokel recommended this in his video (though have a suspicion). You will destroy the vertical fit of the arbor this way. If you want to use this short term procedure, use a flat stump inside, the domed stake outside! Frank2 points

-

Thanks for your insight and advice! Much appreciated! I’m having trouble seeing the vibration (ringing), probably because I don’t know what to look for. In which video is the vibration most visible? Does the vibration occur sideways or vertically, or maybe both? In short, what should I be looking for? How do you do that in practice? I assume that by "max shrank position," you mean when the hairspring is at its most compressed, that is, when the coils are closest to each other, yes? That’s also something I find unclear in terms of how it should be done. As far as I understand it, the index pin should always be parallel to the boot. Here is my attempt at illustrating how I interpret your description of what needs to be done. Is this correct? If so, I’m also wondering how this is done in practice. Do you first bend the regulator pin at its attachment point under the arm and then bend it back slightly lower down, towards the anti-shock setting? Practical advice on how to proceed would be greatly appreciated!1 point

-

Yes: I'd actually realised that the contact angle could have such a complicating effect & am careful to check the angle of the tweezers before gripping the spring. In particular, I rotate the work surface so that the tangent at the point of the spring I intend to hold is pointing along my line of sight: this has helped me to correct/avoid introducing vertical divergence which I find the most annoying issue!1 point

-

1 point

-

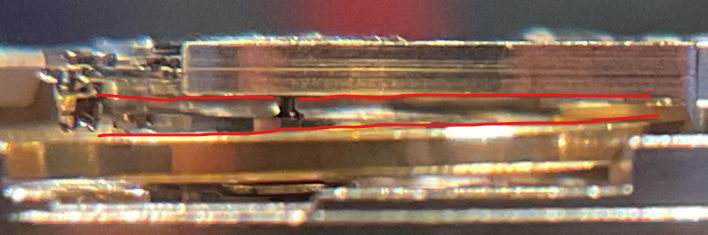

As I actually don't expect this to be real rebanking, will try to say what else it can be. The hairspring of 2609HA has small gaps between coils. This brings to danger when the spring is wound (shrank) to the maximum balance amplitude the coils to touch or get very close to touching. More, the spring can vibrate (ring) and this will cause coils to touch when they are close. Now, What we can do is to try to better center the spring but not in rest position - in the max shrank position. AND, decrease the ability (the main reason) for ringing by closing the distance between regulator pins as much as possible so no free play to be at all and still the spring not to get stuck when moving regulator. On the video, there is hairspring ringing, this is well seen when the playback speed is reduced1 point

-

I'm listening for rebanking but what I belive I am hearing is George Harrison stuck in there. He was the smallest of the 4 after all.1 point

-

I'm starting to lean toward that conclusion as well. 46°! The movement is specified to a 42° lift angle, but I have to adjust my Weishi 1900 to 46° for it to display 180° when the balance wheel is actually swinging 180°. I find it strange and have no theory as to why, but I still believe that 46° is more accurate, at least for my particular example of the movement. This is also strange, and I don't have enough experience to know whether the galloping sound always accompanies a movement that is re-banking. Perhaps we are dealing with re-banking, but to such a minimal extent that it isn’t audible. I’ve recorded the sound and increased the volume but haven’t heard the slightest hint of a galloping noise. Puzzling! Yes, it seems like that is probably the explanation, but it would have been nice to be able to verify it audibly. You’re right, there is definitely a difference, but if you look at the picture of the adjusted hairspring when the balance wheel isn't moving (the AFTER picture), the difference is nonexistent. I’ve never thought about it, but maybe that’s how it always looks? I’m not an expert either, so it would be extremely interesting to get an assessment, or maybe even a qualified guess, from @nickelsilver and/or @nevenbekriev!? This could be a strong argument for the theory of re-banking being the correct one. Again, I lack enough knowledge and experience to know how a movement behaves when the coils of the hairspring collide with each other. I actually asked this question in my first post: 'Could this be causing coil-to-coil contact and how bad is that?' So if anyone knows, it would also be very interesting to gain more knowledge about it. I agree! The only thing we know for sure is that the symptoms occur at high amplitude, and since we don't want the amplitude to be too high, we could focus on trying to reduce the amplitude and worry less about what it exactly causes. Thank you for the suggestions, but unfortunately, I don’t find any of them particularly attractive. Oiling the pallet fork staff pivots is a temporary, albeit very tempting, solution. The problem will most likely resurface at the next service, regardless of whether you, I, or anyone else performs it. Granted, I’m an amateur, but I still have the ambition to try to work as seriously as I can. Perhaps it is still the most rational solution. Hmm... I don't have the specifications for the original mainspring, but long story short, I find it relatively unlikely that someone has replaced the original mainspring. The movement was in good condition but had a broken winding stem, which was probably the previous owner's attempt to counteract dried-up oils. And when I look at the screws, they don't appear completely untouched, but they do seem to be in very good condition. I believe I’m the first to try repairing the movement, but of course, you can never be completely sure. It's funny that you suggest flatter balance staff pivots because I was surprised by how unusually flat they were when I looked at them while disassembling the movement. So no, I don't think there's any room to flatten them more than they already are. The action I’m leaning towards, since the we're dealing with fixed banking, is the one @nickelsilver recommends in this post. What do you and the others think about it? Great tip, I'll definitely try that! Thanks!1 point

-

The amplitude is fine, don't worry about it. Did you bend the bridge? How much endshake is there - you just need a touch. As I mentioned, I like to think of it as about the thickness of the pivot I think the bridge looked OK, but the balance was clearly sitting at a slant. There are marks on the lower jewel, has someone fiddled with it and could it be sitting too low? In which case you should have pushed the jewel mounting up and not bent the bridge. A misplaced jewel is more likely than a bent bridge1 point

-

Fortunately, I was able to find a copy of the original Vulcain Cricket 120 technical sheet with parts information. I hope this helps others who are trying to restore this historic and famous vintage watch movement. Vulcain_Cricket_120_Tech_Sheet_OCR.pdf1 point

-

Welcome to the forum. As advised by @RichardHarris123 we need photos but you need to be aware that most aftermarket cases are for specific movements.1 point

-

Bent the bridge !!!!? That is not a normal method to say the least.. was the bridge bent during disassembly.1 point

-

I kind of found this tweezer holding position by accident, i was looking to increase the angle of the curve on the tweezers to make the tips more upright, which is really important when correcting a twist. Otherwise a compound bend is created ( a twist at an angle other than 90° ) A really good tip from when i was learning to understand how my bending actions affected a spring; was to use a big spring, even better practice with an old worn mainspring or the central portion of it, it's basically the same thing and will behave in the same way as a hairspring, you need a small one though, it takes a lot to bend a mainspring with tweezers.1 point

-

The membership option has been around for a long time. What annoys me is that already published and what used to be free videos have now been hidden on his new Netflix-style channel. Yes, he generally doesn't seem particularly concerned with the truth and has no hesitation in winging it when he's unsure how things work, like pushing out a jewel while banging the pusher into the decorated bridge!? Horrific if you ask me. I shouldn't complain too much, though, as I've picked up quite a bit of useful stuff on his channel, and I'm very grateful for that, so thank you, Kalle! He doesn't show it, but I'm pretty sure he banged the stake so hard into the balance arm that he didn't include it in the video. It's no wonder the balance wheel looks the way it does after the staff has been replaced.1 point

-

Are you sure about this diagnosis? Can you show us a picture (I understand that it'll be difficult to take when dial up)? Also very useful would be a picture (can be dial down) of the balance exactly from the side (to see if the balance cock is deformed). That's definitely the most logical explanation. Upper (=balance cock), no?1 point

-

I'm still convinced you're dealing with re-banking. The 325° amplitude you mentioned, is that with the lift angle set to 42 or 46° ? The difference in setting should easily add 25° of amplitude. I'm not sure how pronounced the galloping sound is if the rebanking is marginal (i.e. just "blocking" only the last hypothetical 5° of an oscillation)1 point

-

1 point

-

As it stands not yet but new glass containers the correct hight are being looked into. So at the moment, that's what the forth jar is for, wash then spin into the forth jar, don't realy need to spin after each rinse as I use IPA for rinses and that dries nice and quick without the need to spin..1 point

-

Is that fully wound? If it is then I think you first need to address the amplitude.1 point

-

1 point

-

So, my watch repair friends, the agony is over. The new axle has been riveted! As I lifted the brass hammer to whack the punch, @Jon's words suddenly came to mind: "I'm sure you will ace it. What you believe, you become!" I haven't yet had a chance to test it, but as far as I can tell it looks good. Thanks for the practical advice, explanations, videos, articles, and encouragement. Invaluable! Feeling pretty good about myself tonight!1 point

-

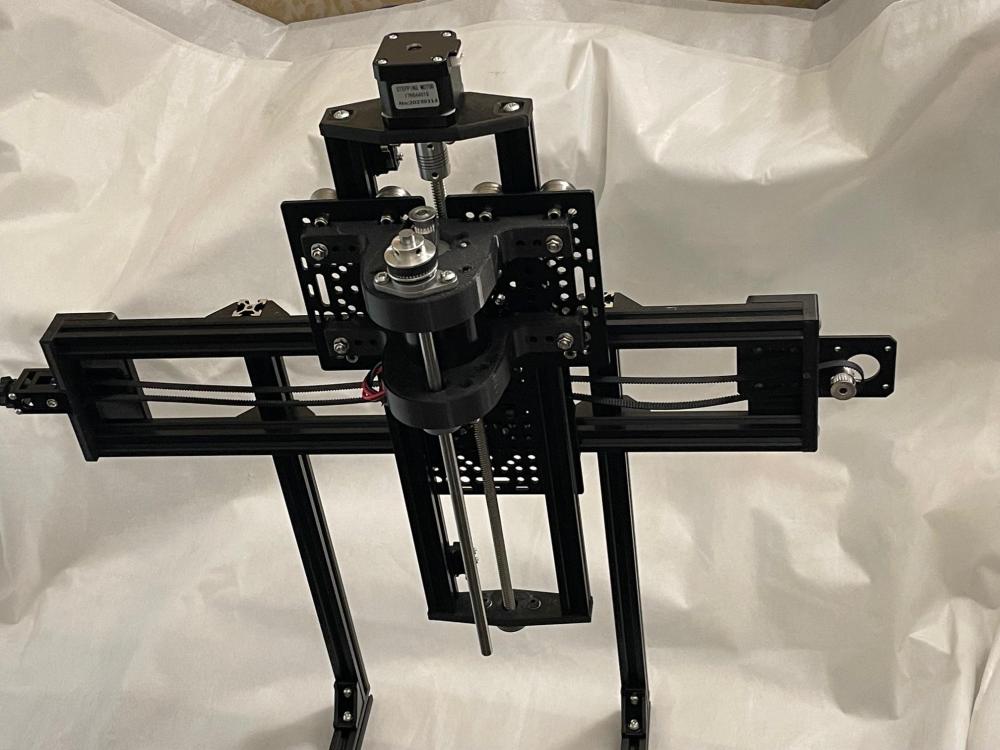

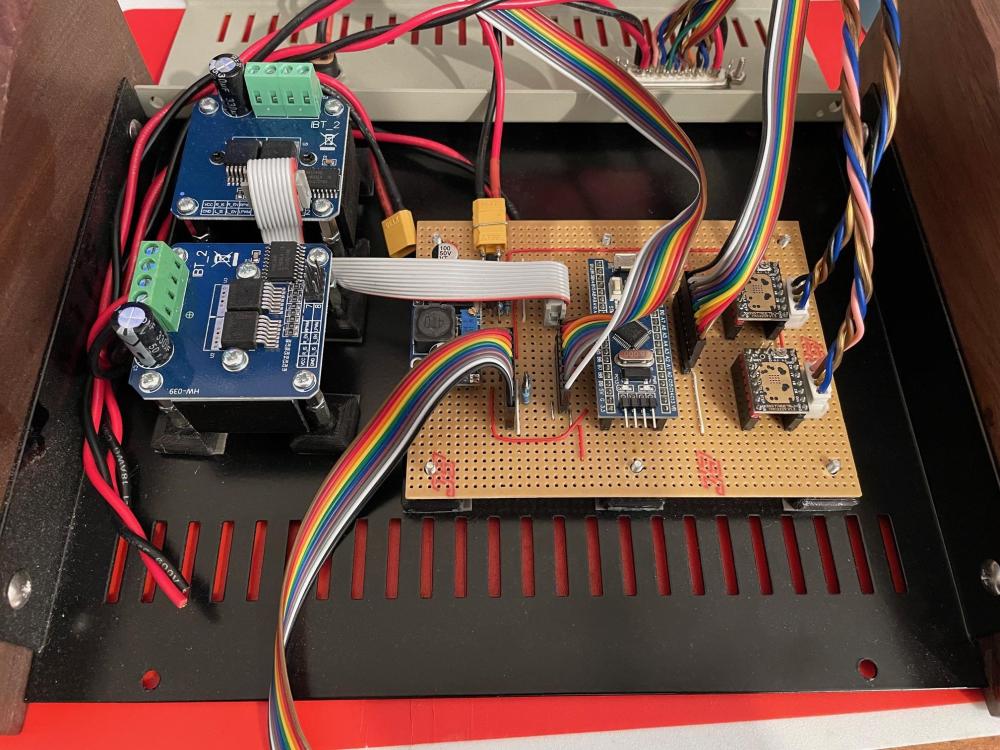

It's a work in progress, I need to finish off the servo control stuff. It uses mostly off-the-shelf aluminium extrusions & common parts for 3D printers, plus some 3D printed items. Functionally, it's the same concept a rotary automatic, except the four in a row linear system is easier to get parts for than a turntable system. It's sized to fit 1L Kilner jars, as a standardised container. The same control system could equally work a rotary turntable. It will be published as an open source design when completed. I have the X motor off it at the moment, to use for testing the servo software. These are the overall frame & control box: The X & Z axis motor drivers are the two small plug-in modules at the right, the one in the middle is an STM32 MCU and the two big lumps at the left are the spindle motor and heater power drivers. [This is all baby size hobby stuff - I program and repair industrial machine tool & control electronics, from CNC mills & borers, to literal car crushers]. Yep, a bit off topic, but video here: https://www.youtube.com/watch?v=1u4WZs5tK0U1 point

-

Nice to know that Rob, i was gonna pinch a motor from an old cordless drill i must have dozens but then realised about the brushes in the tool body, i would need a brushless motor if its naked. Van de graff generator? My estimation of you Rob has just doubled.......that machine would raise my hair by............. actually no more than it already is......about half an inch1 point

-

Here is a small update and a few pictures for those who may be interested. Finally, the cleaning is done! It's been a hard and time-consuming job, but a crucial one, as even the smallest residue of metal particles loosened from the rotor could wreak havoc. The next step will be to inspect all parts under my stereo microscope carefully. I already know that one or two pivots need burnishing. Overall, however, it seems that the damage is limited (knock on wood). I'm guessing this is because the watch probably stopped being used when the oscillating weight stopped working. We should all go back to organic watch oils so that no movement is in danger of being destroyed and users are forced to overhaul their precious timepieces! As far as riveting the rotor axle is concerned, I no longer have any qualms (thanks for all the encouragement!), but I will still wait until it is time to assemble the automatic framework. That is until I actually have to do it. Or, it could be that I'll do it when I feel inclined to.1 point

-

1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)