Leaderboard

Popular Content

Showing content with the highest reputation on 03/03/25 in all areas

-

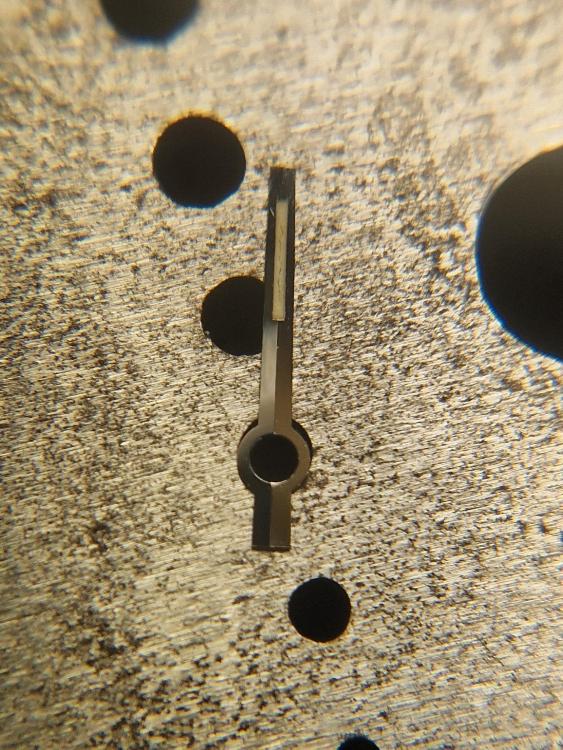

You didn't notice that your setting level spring is broken?3 points

-

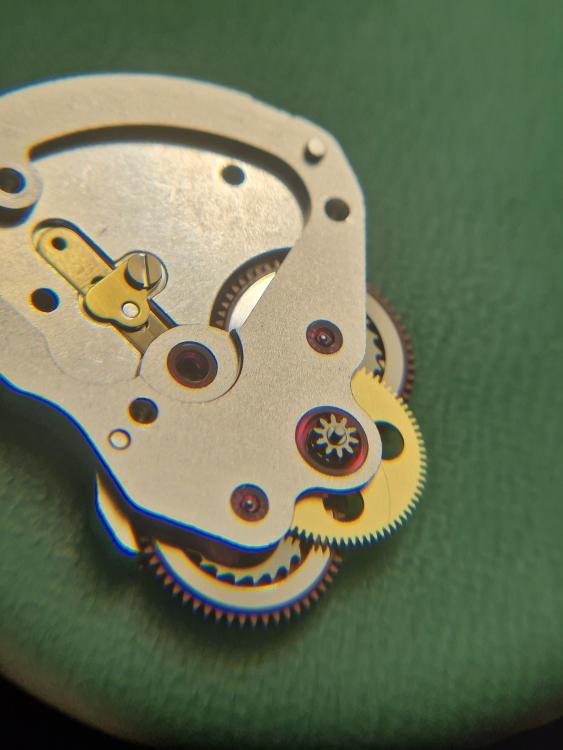

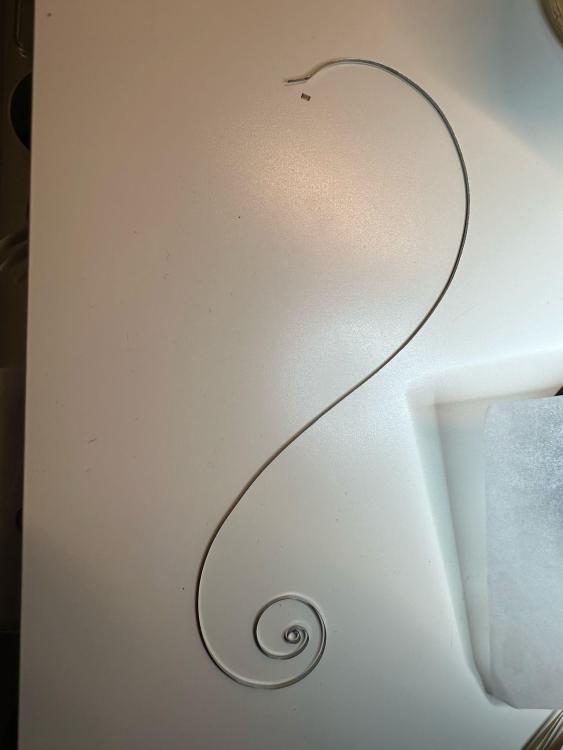

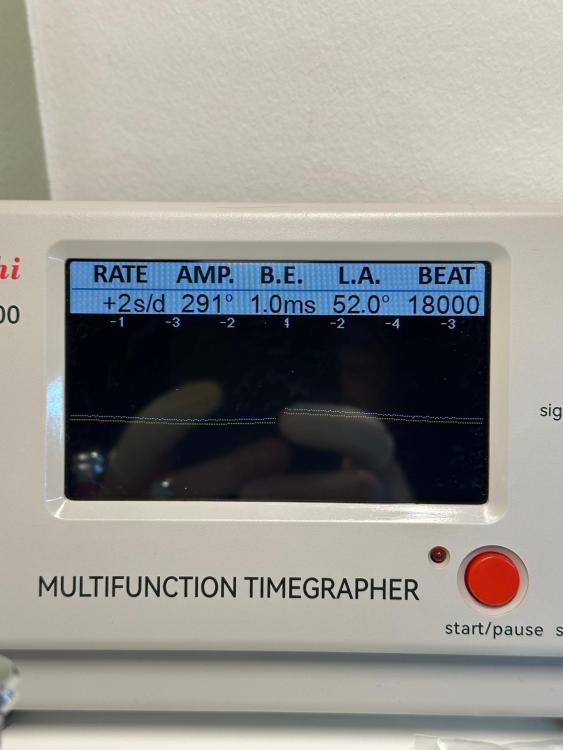

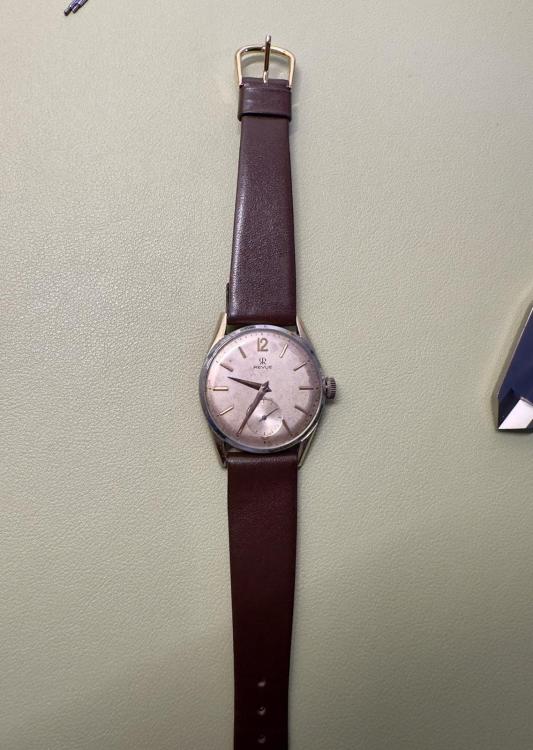

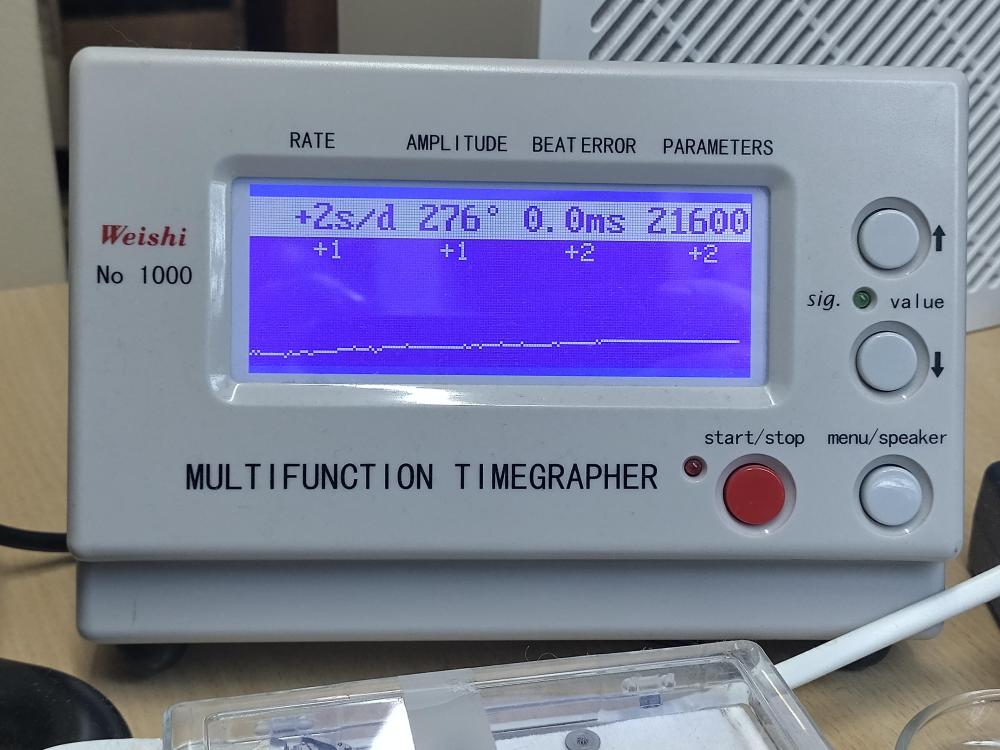

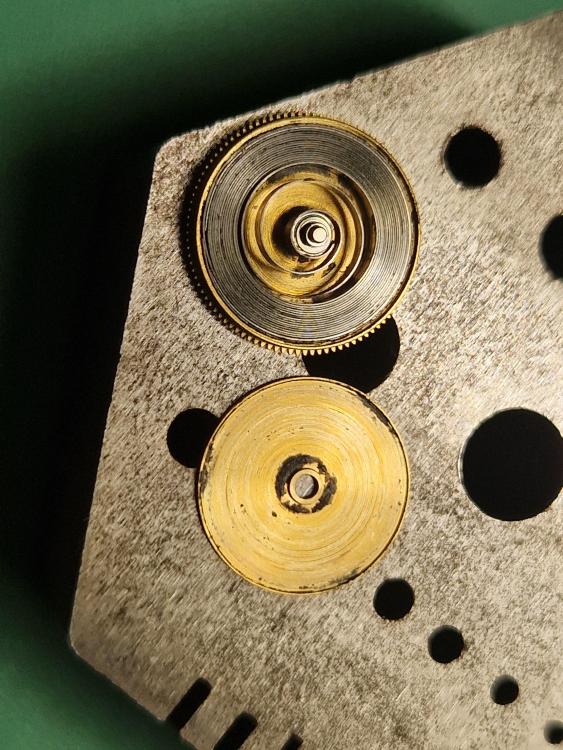

Finally, I’m creating this thread to share a very special watch that I recently serviced. Given that I only started learning this skill not long ago, I’m really proud of this milestone—especially since, over the past month, I’ve already serviced quite a few vintage watches as practice. I bought this Revue Cal. 81 (cca. 1945-1950) at an eBay auction for a great price (under €100), and honestly, considering the movement, the vintage aesthetic, and its history, it could easily be worth more. The seller advertised it as a WWII-era watch from 1940, but I have my doubts about that claim. Here are some before-and-after photos of the restoration process. I did some manual sanding and polished the case; while I’d love to have it chrome-plated at some point, this will do for now—perhaps in the future. I also replaced the crystal with a lower-profile one, brushed the hands, and swapped out the mainspring, which had a broken hook. Of course, I also fully disassembled, cleaned, and lubricated the movement. The beat error is not perfect, but I'll have to check again after 24h if it will improve, but overall I am pretty happy with the results considering it's age. Looking forward to hearing your thoughts!2 points

-

It's the box that we climb into when the thinking outside of it becomes too much. Obviously Tom I have two of these boxes and need two more for when two is not enough. I made my own but if you feel fancy then Bergeon will probably do them as soon as they discover how popular we've made them.2 points

-

Based on the Ranfft database there is no end cap missing. https://ranfft.org/caliber/9331-Revue-812 points

-

It sounds like demagnetizing won't do you any good and it needs a complete service.2 points

-

2 points

-

Not a problem here, not provoked, at least I don’t think. Just a simple question of if the two items were the same cost and as you said originally just the same, would you fly an aeroplane that has been lubricated with moebius 9010 rather than an industry standard? If as you claim they are just the same then you would be happy to do so. You have said above that moebius 9010 is not up to the task, for me that simply means the two products are not the same, nor equivalent apart from they can be classified as lubricants. please read what I posted previously about them being the same cost. Tom2 points

-

Frankly, the set doesn't nearly have enough stakes. You'll be very limited in using it.2 points

-

I assume you mean adjusting the microstella screws. Very likely not. More likely your movement will need a full overhaul. When was it last serviced? Demagnetizing might help if it is otherwise in good condition. Low amplitude and hight rate (as in your case) would indicate it has been magnetized.2 points

-

Hello, I am clueless about antique (vintage?) clocks or any items to be honest. But I have two very old clocks one I think (I'm prob wrong but this is the best I could figure from my limited knowledge and not too successful research) is a Ben Harlow Wall Tavern Clock it is 77" long, 18" across, and 7" in thickness. It was my husbands great grandfathers which he bought in 1970 (we have the receipt). Unfortunately HB parents were not very stable and moved numerous times and this beautiful (mahogany maybe?) clock was not taken care of (at all) and is in very bad shape. I will attach pictures. There was also a much smaller clock that looks to be a FRIEDRICH MAUTHE, G. M. B. H., from the symbol on the face (again I do not have any clue if I am correct). This is also in very poor shape. In all honesty I would just love to get any information on these. Since we received them very broken many years ago they have just sat in our garage. We don't know what to do with them but are hoping to get any information possible about them and hopefully we can find someone who is able to fix them or ... I have found some really great information on this site and the moderator seemed so kind I thought I could maybe post and see if I might be guided in the right direction or give any info at all. Thank you so much for your time and consideration. I appreciate any help very much. Have a beautiful day! Ugh I'm so sorry I can't figure out how to post pictures on here I clicked the little paper clip at the top and it only gives me a way to post links so if somebody can help me with that as well that would be great I would have a lot of pictures I would like to post so hopefully get some help thank you sorry I'm so clueless.1 point

-

1 point

-

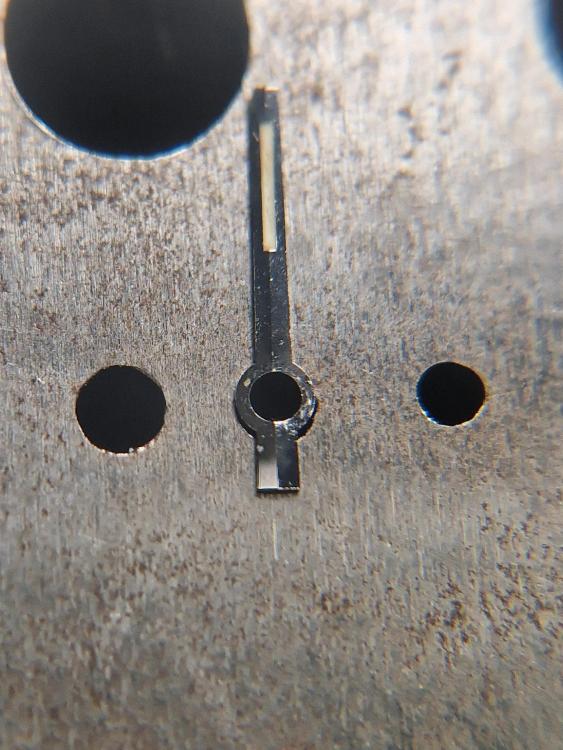

Hi. No I did not, how can you tell from that photo ? But I did noticed that when setting the time and pulling the crown, it tends to jump back in quite easy…but the spring looks good from my point of view. Edit: now that I checked again, yes I see it. So that’s the reason the crown jumps back in while setting the time. Thank you ! Good eyes. Oh no….I missed that completely !!! It came like this. I’ll have to look for that part now. Many thanks. There are some deviations on different positions and the beat error goes a bit higher but not that much.And I agree, especially at the learning level where I am right now…works decent ?! Leave it as it is - but sure, later on the road I might work on these sensitive hairspring adjustments. Few more photos under the natural light Found the setting lever spring. Now for the escape wheel end cap… I found the lower cap jewel as well but it’s from a slightly different Revue movement, caliber 59…not sure if will fit. Looks like it will but still…1 point

-

My first port in a case of rebanking would be a weaker mainspring. It's not always feasible though. Then, I would increase total lock either by moving the pallet stones or the bankings, whichever is easiest to implement. 0.005mm goes a long way here.1 point

-

How long ago was it serviced. I suggest if you're not 100% with watch repairs then you either take it to a repairer of leave it till you've more experience.1 point

-

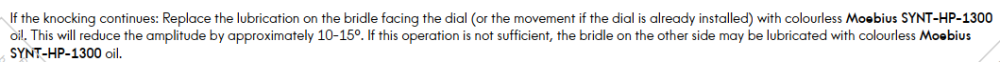

An easier fix, and one that doesn't involve physical changes, is what Omega suggest in a working sheet I have: replace the oil in the balance jewel on the dial side with HP1300. It suggests that will knock about 10-15° off. If that's not sufficient, do the same on the other jewel. I have always started by oiling the pallet pivots, but that has not usually worked for me.1 point

-

If the stem is the wrong length I'd expect it to have an immediate effect. Is the crown spring loaded?1 point

-

First of all, confirm if it is not rebanking (or if it is) and do this things only if it is not. To see hairspring ringing, in the last video, sellect full screen, settings, playback speed. custom (0.25). Then watch and will see how the spring rings sideway. Yes, I mean centering the spring when it is most compressed. Turn the balance to the end and will see that now the spring is not centered. This is normal, but try to center it better in this position, regardless what it will look like in rest position. The regulator will rather look like this. Press where the red arrow is in the presence of the spring, this will more or less make it look like on the picture P.S. Ok, we have the decision arrived until I was writing the last so forget about it1 point

-

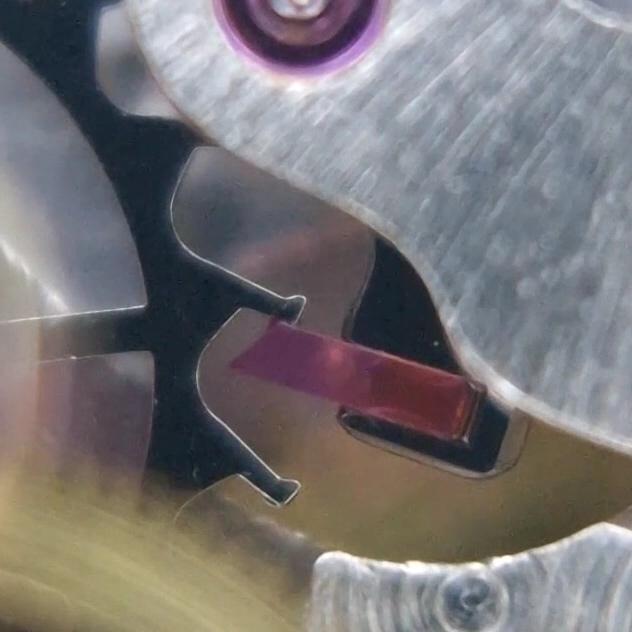

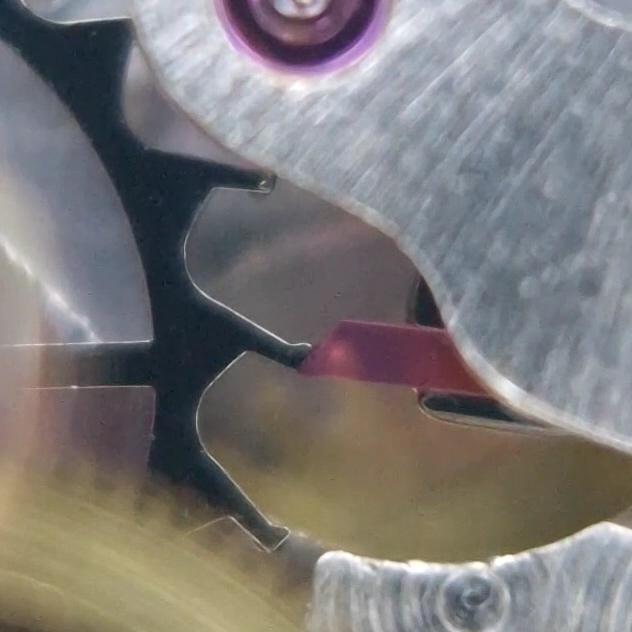

OK, I think we are ready for a joint conclusion—the one that almost all of you have suggested—namely, rebanking! In the future, I promise to listen a little more carefully to your suggestions! In the video below, you can see three black markings on the main plate. The left and right markings indicate where the impulse pin strikes the outer sides of the pallet fork horns. The middle marking, along with the marking on the balance wheel, shows the balance wheel’s resting position with the pallet fork centered between the banking pins. As you can see, we are dangerously close to rebanking, and since the amplitude is five to ten degrees higher with the dial facing up, we can be fairly certain that rebanking is occurring. BTW, listen for the galloping sound! The video inspired me to make a new recording of the sound, now with the dial facing up. This time, I placed a Petri dish against the movement to act as a resonance chamber, amplifying the sound (Wow, I had a thought outside the box!). And wouldn’t you know it—the case is closed! I must say, it feels like a relief to have finally determined the cause. Now, all that remains is to decide on the best possible course of action, and I am still strongly leaning toward @nickelsilver's suggestion. That is, moving the pallet stones out a bit.1 point

-

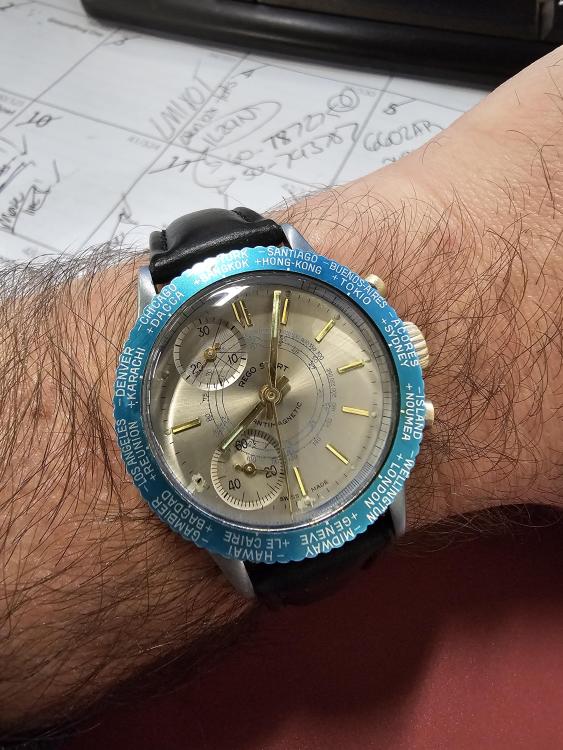

$10.50usd awarded me this cool REGO SPORT "chronograph" with a Lapanouse pin lever movement on ebay. I bought it specifically for the challenge, as it looked like it had spent some time in the pool. Some deep cleaning, over polishing, shotty hairspring work and a $7 parts movement for a replacement pin pallet and Today it is on my wrist and keeping great time over the past 6 hours. and the "chrono" functions! Im very proud.1 point

-

1 point

-

Quick update here: I replaced the staff with DCN #612 which seems to be a very good fit. The balance is running happily. This movement had more problems though. I've cleaned and lubricated it, and the timegrapher shows that the rate and amplitude vary with a period of around 60s. The variance is on the order of 40 s/d. Indeed, one of the jewels for the fourth wheel is chipped. I don't know if this is the root cause of the variance, but I can't see anything else mechanically wrong with the train of wheels apart from this. I don't own a jeweling tool, so I'll put this movement aside until I do and can replace the chipped jewel.1 point

-

Unless it is wildly different in other positions from the one in your timegrapher photo, 1.0ms is just fine for a movement this age. You reach a point where perfecting it carries too much risk of hairspring damage and there is no shame in living with 1.0ms. Nice work, I love this dial.1 point

-

It was nothing special. As pointed by @nevenbekriev, the lever above was bent. Since I didn't have the tools to fix it, I found a donor movement on eBay and after it arrived, I unrusted the lever and installed it. It was not the best option, but it was dirt cheap. After servicing, the whole watch cost me about 20 USD and I have loads of spare parts from the donor.1 point

-

Ok, so you still are looking down the path of “why can’t I use this aviation grade engine oil in my watch, it’s just the same “. I want to ask this hypothetical question, if the price of moebius 9010 and the shell aero engine oil, would you use the moebius 9010 in your aircraft engine? If not, why not? Tom1 point

-

Moving on. Moebius states that the lineup of oils they offer are ether alcohol based. This expression has bugged me for a while, as is doesn´t seems to be the choice of base oils for other commercial products. So why use this method of synthesizing? It is actually explanined in this sales document from Moebius. The last chapter "Cleaning, Lubrication, Surface Treatment" is interresting in it´s own right but it also highlights a few specific details. The first is that older, natural oils (Moebius (8XXX series of oils still in production) have some very desirable properties for horology, but lacking others, the most important one is stability, in other words it oxidies and evaporates. In this process the oil transforms from lube to basically glue. So it´s very easy to understand why this is a problem in a mechanism more or less intended to be lubed only once per service cycle. Another issue was the introduction of plastic parts in watches, not always compatible with natural oils. Problem 1 One of the main problems in a watch is the issue of having the lubes to do it´s job over an extended perod of time and not to dissolve plastic. So the syntetic oil was developed to mend these issues, resulting in modern horology lubes. But. The lubrication properties of these new syntetic very stable ether alcohol based oils are inferior. New problem. Solution? Additives. So the 9010 is a stable syntetic oil with additives to improve lubrication. Problem 2 The other main problem is to have it stay in place. The document actually mentiones this issue as a major one, as customers even complained that the oil seems to be gone (evaporated), when it in reality has migrated. To deal with that issue epilame comes into play. These liquides are very expensive, but again, the document mentions that before syntetic epilames came around stearic acids were used. The only downside beeing that is could not withstand a cleaning cycle. But maybe as a hobbyist that would be an acceptable compromise. My guess is that the price of stearic acids is like 1/100 of the price of fix-o-drop. This topic has actually been discussed on this forum before, so it clearly has some merit to it. Concluison: A modern syntetic oil is very stable in both above montioned aspects. The lubrication properties are excellent, probably superior to ether alcohol based products @same viscosity. The visco curv is steeper giving less change in properties with temp. Stearic acids could probably be used as a hobbyist´t epilame. It would not survive a cleaning process, but does it really matter? Without service history data, any watchmaker with even the slightest touch of ocd would probably like to do the treatment anyway, and the old method is better than no method, right? So if the treatment only lasts one service cycle doesnt relly matter. This gives me confidence that there are viable options available, the product i have tested beeing one of them. -------------------------------------------------------- Another loose thread for me has been the myth of oil beeing agressive to certain metals, and this should have som realtion to additives. The above documents mentions that : "Two processes are mainly responsible (for oxidation) : - reaction with the oxygen of the air and - the catalytic action of the copper from the brass particles worn off the bearings." My theory is that the fact that some loose particles can contribute to the oxidation process of the oil has been missinterpreted as the oil in some way beeing agressive to metal parts. This is clearly not the case.1 point

-

True, but I generally admire your talent for thinking outside the box! I need more of that.1 point

-

Can you tell us how you fixed the problem you had? It's useful to everyone to see the ways that worked (especially without a staking set). If you go down the mix-and-match route, you need to make sure that the base set has 4.7mm diameter stakes. I believe that's the most common. And you can buy individual stakes of that size at CousinsUK (and others). I'd highly recommend a set that can take stakes "as stumps" in an extended bottom part of the tool. Also called "inverto". Just increases the use options be a mile.1 point

-

It can vary from movement to movement. Since the reason being is the impulse pin striking the outside of the fork . The lift angle, the fork horns and impulse pin size being the deciding factors. I wondered about reducing the fork horn but that also upsets the lever poise.1 point

-

What degrees of amplitude is required for rebanking? Obviously it will depend on the distance between the banking pins, compared to a full circle, but there must be a rule of thumb.1 point

-

Nice watch and you're right about the date as the 81 wasn't made until the 50s.1 point

-

1 point

-

It took me months to figure this out for myself after being led astray by probably that same video. $250 is in my opinion a great price for this set. Even if it is missing something here or there, it is really well kitted out. It includes the balance staff removal tool and what looks like its punch near the back left, and includes just about every stump I can imagine. I see a centering punch (the one with the knurled knob on the back end) but it would be nice to get a view if it has a good point and isn't broken. Even if it is, you can get a replacement from Cousins for about $15. The condition of the punches from these photos look a little rusty but not terrible. They should clean up just fine with some steel wool and WD40, same with the die plate. It's several hours of work but worth it in the end. I think this is a good buy. A kit this complete would go for $350 on ebay.1 point

-

1 point

-

We have a thread where hairspring tweezers were discussed. I cannot imagine doing hairspring adjustments without curve tweezers, but I often see „adjusted“ hairsprings in fora with a series of small kinks instead of a curve. You should practice your skills with an intact hairspring, best of an alarm clock, make determined distortions and try to remove again. And make yourself familiar with the few rules for such adjustments. Frank1 point

-

This is a regular problem - rebanking while fully wound and continuing winding by autowind. This is bigger than needed friction of the spring bridle on the barrel wall. What is the bridle shape? Is it well polished (sometimes it is not and friction is due some bad edge or burr)1 point

-

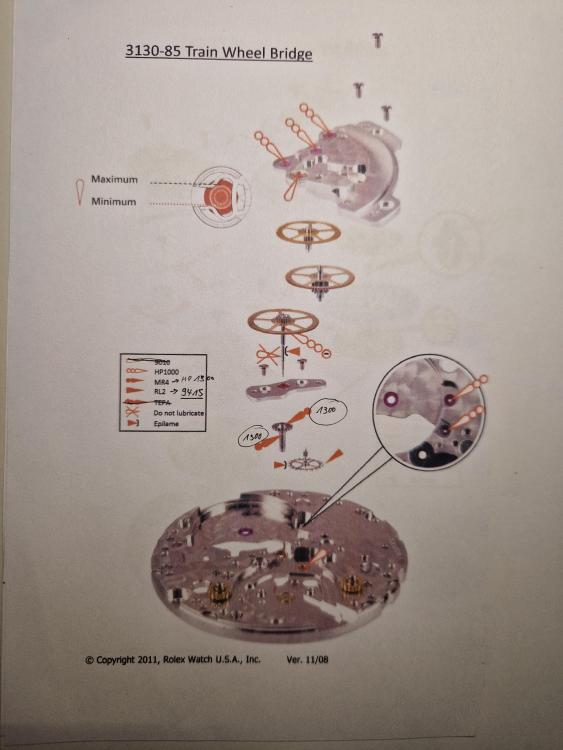

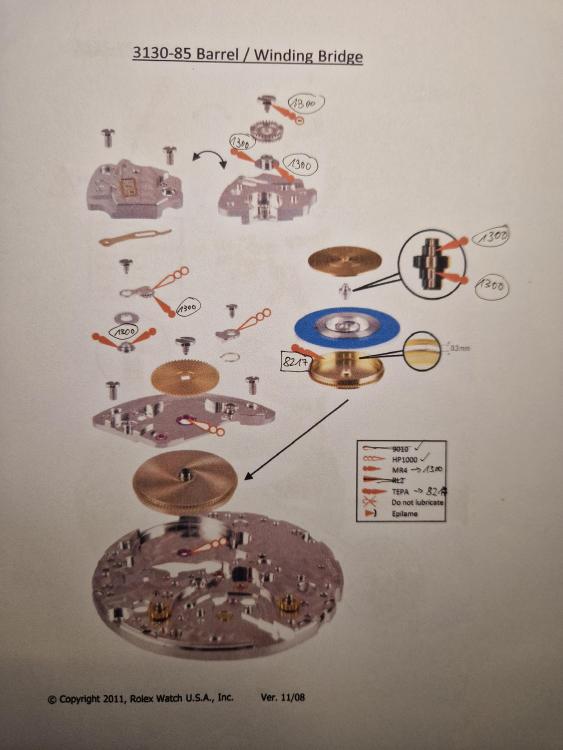

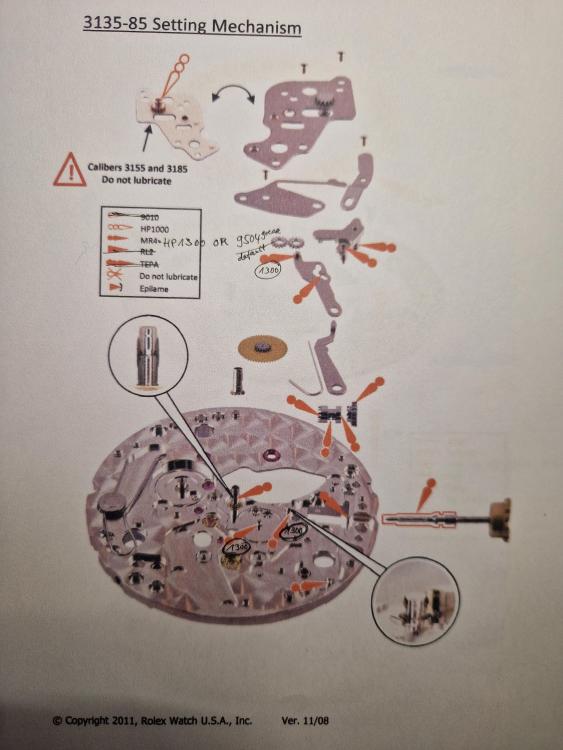

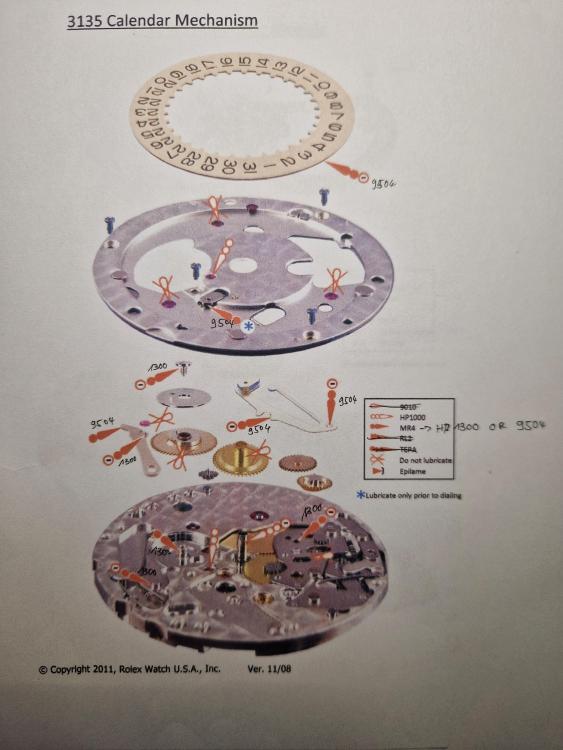

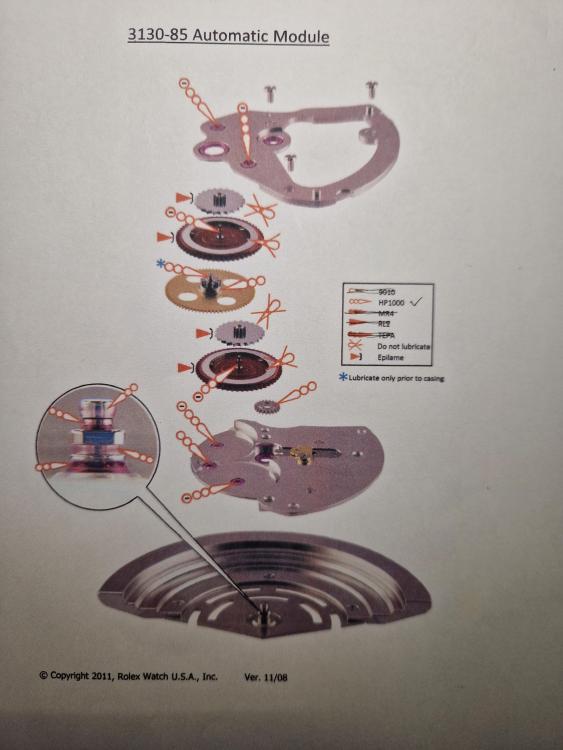

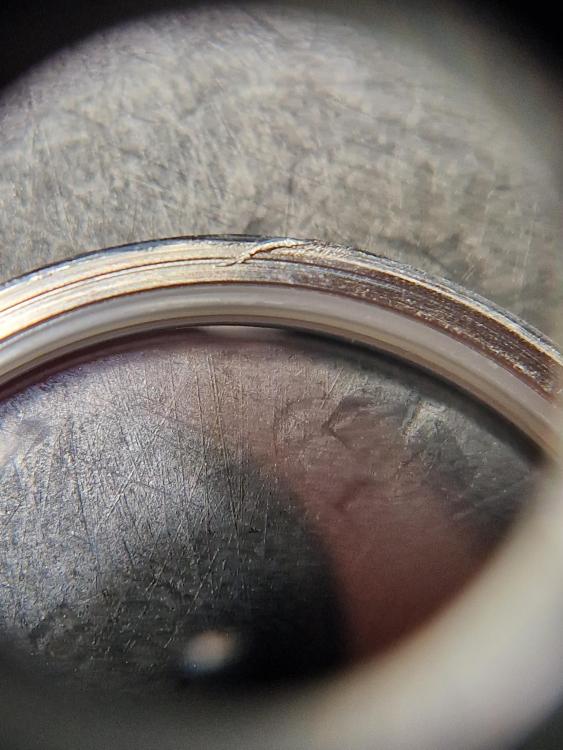

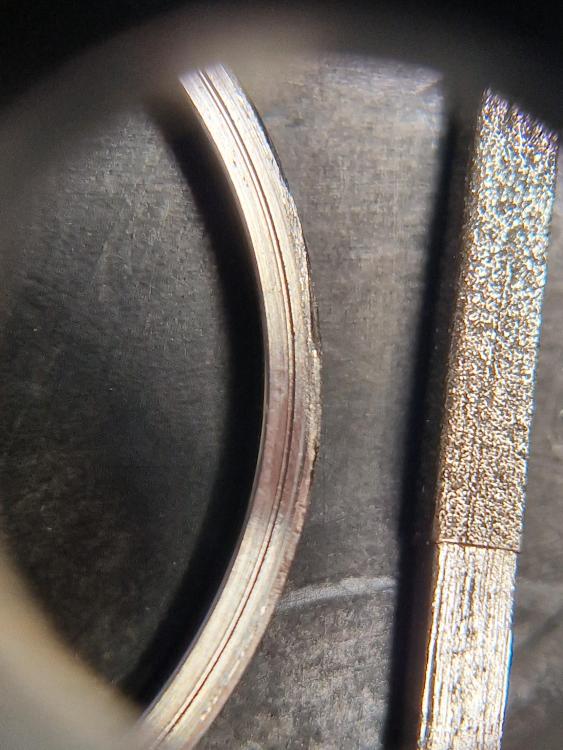

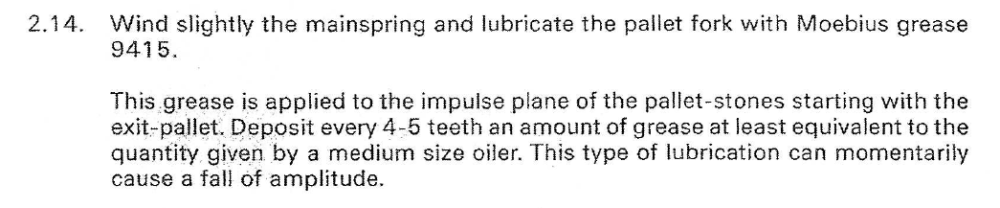

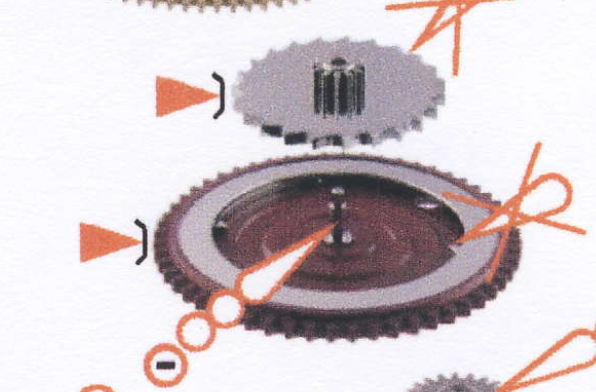

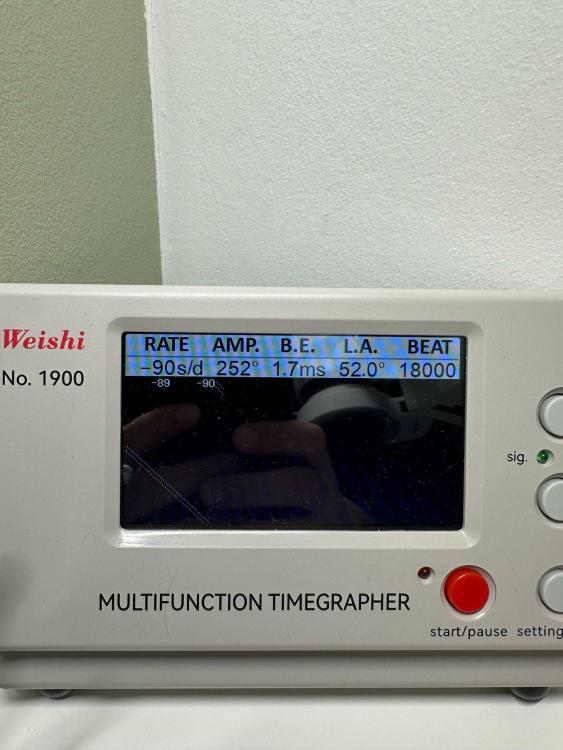

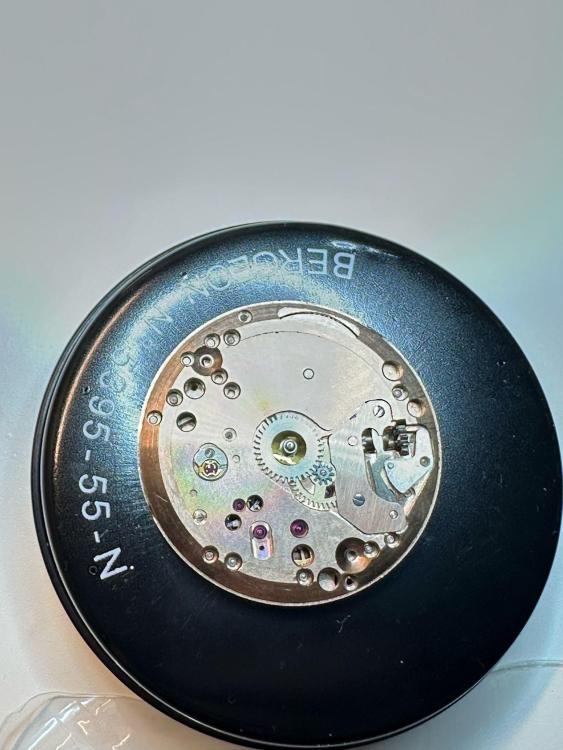

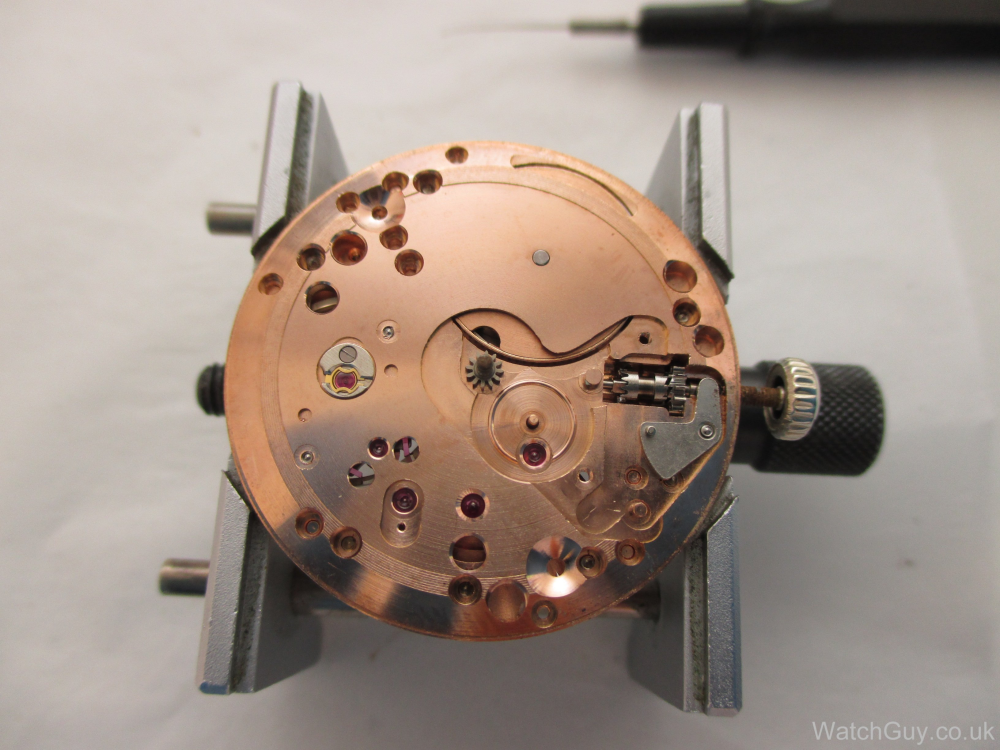

Hello all and merry Christmas (in advance)! I just finished a service on a Rolex 3135 in a lovely Datejust 16220. First, here are some overview pictures of the movement: The watch was in overall good condition, but it was running a bit fast and inconsistent (across positions) and amplitude did not reach 250 even fully wound and dial up. Upon disassembly, I did notice some a bit of dirt and some jewels/pivots had run almost dry. The barrels shocked me again (similar to the Rolex 2035 that I recently serviced): Thanks to @JohnR725, I had access to detailed oiling charts and service training guide: https://www.watchrepairtalk.com/topic/3626-rolex-3135-beat-error-adjustment/?do=findComment&comment=234180 After some good pre- and final cleaning, I assembled exactly as prescribed by the Rolex training guide that I followed the service guide in detail. For lubrication, I followed the Rolex oil chart, also posted in the link above. One particular issue is the Rolex lubricant "MR4". It seems to be somewhere between a very thick oil (like HP 1300) and a grease (like 9504). I used either HP 1300 or 9504 as a replacement and depending on the particular locations. My final "interpretation" of the oiling (with Moebious oils) is as in the pictures below. Regarding the pallet fork, the Rolex training guide seems to suggest a rather large quantity of 9415. Consequently, I put more than I usually would (but still less than the suggested amount by Rolex). See pictures below. What are your thoughts? For the automatic module, as show in the Rolex oiling chart, I treaded the reversers with Epliame and was VERY light on the lubrication of the "internal pivot" (see screenshot). As prescribed, I did not oil the internal ratchet/click mechanism of the reversers. Case: The previous watchmaker left me a present under the bezel. I noticed that it was not sitting perfectly even on the case. He (or she) must have removed the bezel in a way that damaged it a bit. I filed the damaged metal away with a diamond micro file. Bezel back on with my trusty Robur (with 3D printed adaptors for "standard" M4 dies). The dial and hands also got a bit of cleaning : Before: After: Casing: 1. align the case clamps on the movement with the matching groves in the case. That's how that looks. Turn everything around and slide the movement into position. Insert the stem. Done. At full wind/dial up. Vertical positions are running a bit faster (+8-10 seconds). I may look into regulating that further. I'll eventually post more results. To conclude, my usual "artwork": Merry Christmas to everyone!!!1 point

-

I get that: it's a significant investment. But regarding utility, until I got a staking set I had no idea how much I would use it.1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)

.thumb.jpg.8408ecc5772716d5f70d8692f2139c3b.jpg)

.thumb.jpg.9794ce72c4c73c9f12e4b6b802a76fe0.jpg)

12_17.19_4f0f07c3.thumb.jpg.06c35b9c7b71ec2123ca0a25560c27cb.jpg)

.thumb.jpg.f0fdcb904fb94600b8d08cf1e4ea5a6b.jpg)