Leaderboard

Popular Content

Showing content with the highest reputation on 03/04/25 in all areas

-

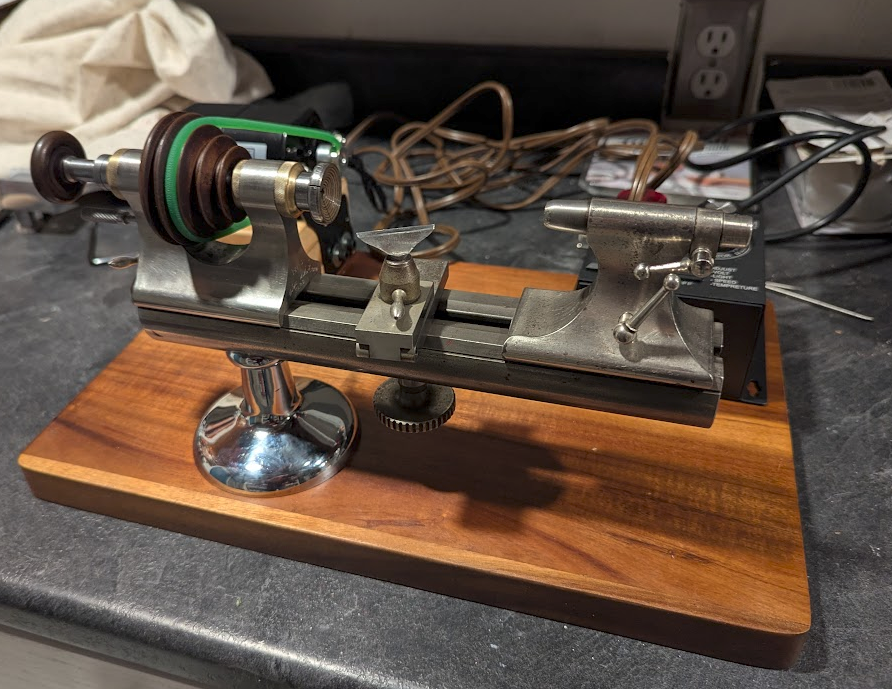

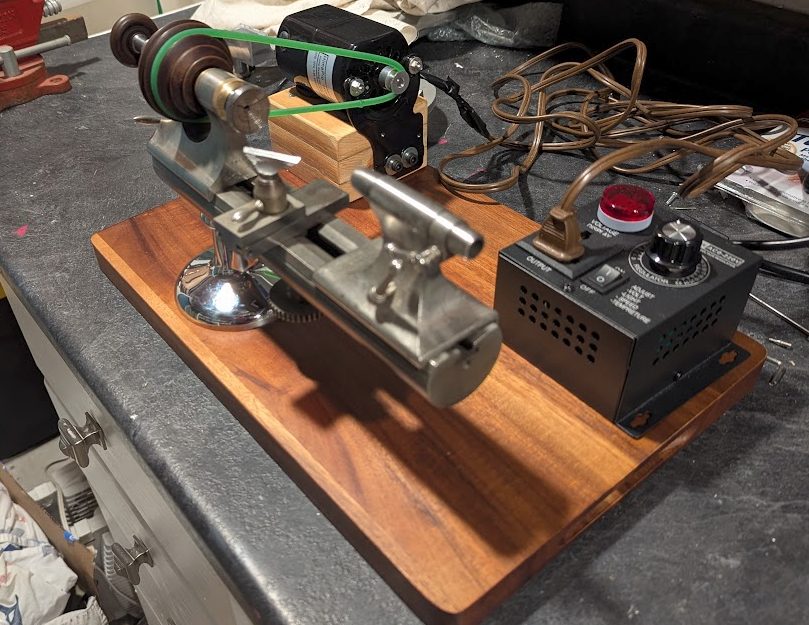

I have finished setting up my lathe! It took a lot more effort than I hand planned to get it running. It turned out that the rear bearing was seized together, and the bearing part that was supposed to be attached to the headstock frame was spinning freely (and surprisingly smoothly). Once everything was cleaned up, I refit the bearing to the headstock with Loctite sleeve retainer (nickelsilver's suggestion) and then found that the rear bearing was still capable of locking up completely on rotation, needing to be tapped on the outside with a brass hammer to jolt it free (caseback's suggestion). To make the bearings run smoothly, I lapped them with green Timesaver Lapping Compound, hand turning until both bearings were nicely refinished and turn without obstruction (again, nickelsilver's suggestion). This was all a lot more information about machining than I expected to be confronted with so soon. I didn't like the aluminum Borel base it arrived with since it was a poor fit to the short 10in bed, and so I mounted everything to a hardwood cutting board. For that, I had to wait a few weeks until a pedestal base turned up in a random lot of clockmaker tools on ebay. It is harder than it should be to procure a long M8x1.0 bolt in the USA where we still like our inches but that just arrived today so I could finally finish assembly. The cheap sewing machine motor is fixed to wood blocks and damped with a soft rubber pad. It came with a foot pedal that was janky as hell and I didn't want to use, so I am instead running it with a voltage regulator. I know at some point I will probably need a solution for more torque but this is a start. I just got the belt in place and spun it up for the first time tonight. It works great and I am very happy with the results. Much gratitude for the patient help I received from @nickelsilver, @caseback, and @Dell over in my other headstock setup thread. They all worked through explaining to me how things should work and discovering what was out of sorts as I got the headstock to turn. So thanks again everyone - now I'll have to start turning some stock and you can look forward to more silly novice questions as I do. I'm beginning to collect collets. And I am bothered by how shiny the pedestal is compared to the underside of the bed, so I may eventually give in and take a buff to that. The circle of space where the bed has always been in contact with a base is still shiny so I can assume the whole thing had a polish in the past. Finished job photos:7 points

-

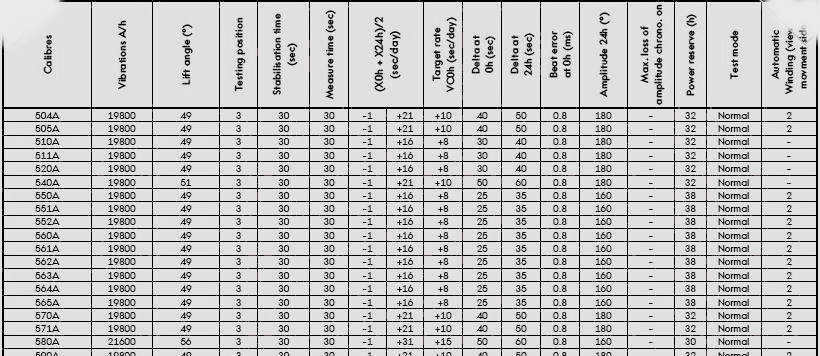

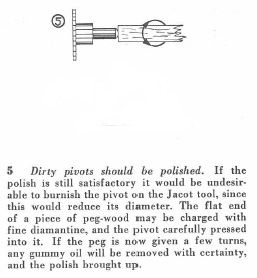

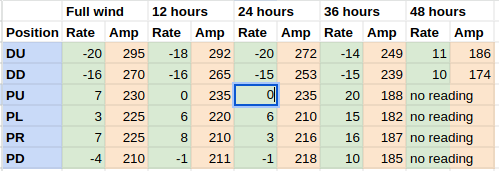

Interesting technique for all the pivots? Was there a problem concern rust? 800 grit to me doesn't seem very fine and tapering pivots doesn't seem good either. Then there's the problem of things that look bright and shiny and clean versus the reality of the situation. As an example of what I'm suggesting here of shiny is not necessarily shiny I'm attaching a PDF. One of the samples and let me quotes they're using Polished with Cratex™ abrasive stick – X-fine grade. Zero idea how extra fine grade compares to 800 grit? Acceptable amplitude for a fully wound up freshly serviced watch is typically only a concern of discussion groups and some YouTube channels. . Typically watch companies are concerned with timekeeping. After all that's what the consumer is most concerned about is their watch on time. I've snipped out an image of the specifications for your watch. So as you can see the lift angle is 56°. You have your timing specifications and 160° Minimal permissible amplitude in vertical positions after 24h in degrees. Then of course they have a power reserve will the watch in this case run for 30 hours. Pivots finishing burnishing electron microscope.pdf6 points

-

The cap stone plate here is not missing. The hole stone is put in a manner that the oil sink is faced outwards, so this for sure means the stone has flat side inwards, the EW is not meant for cap stone on this side.5 points

-

In case you don't know this resource, there's an "official" online dictionary for the English, French and German horology terms: https://dictionary.fhs.swiss It also exists as an App, e.g. for Android: https://play.google.com/store/apps/details?id=ch.fhs.android4 points

-

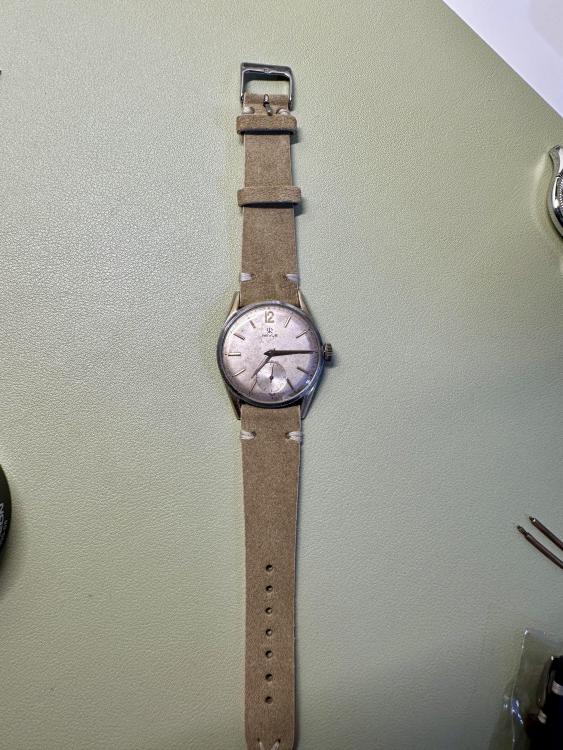

Thanks a lot guys, really really helpful and I appreciate your inputs. The setting lever spring has been ordered and will be replaced soon. I will then take a closer look at the plate and hopefully I can take a few higher quality photos with it. Meanwhile I am fully enjoying wearing it even on this cheap strap, until a new and more suitable one is arriving4 points

-

On small calibers like this just a little too much lubrication on the escapement can drag the amplitude down. On the extreme, when I do LeCoultre 101 calibers, I found that 9415 is too thick, and even 9010 would zap the amplitude if more than just a hint was applied. On most "ladies" calibers I do use 9415, but just the tiniest amount. You should really get the amplitude up to a healthy 270, especially as these small movements tend to have a larger drop in the vertical positions. Some have 60 degrees. Try cleaning the fork and escape wheel, and see what the dry amplitude is (with the correct lift angle as Knebo mentioned, if you haven't been using it). Add just the smallest amount of 9415 you possibly can, and see how it does. It will need some time to settle in. Keep adding until you get to your normal amount, and see what happens. It could be that the escapement needs some adjustment too, imagining everything else is really 100% OK. There are weeks where I adjust it on almost every watch that comes through, others where I don't, but I would say probably 25-30% get adjusted in order to have a correct amplitude.4 points

-

Finished up these two recently. Came to the conclusion with the Revue that I hate working on incablocs (2 Hours looking for a cap jewel on the floor), but I love mobile stud carriers (So much easier to work with than the Omega), and having a separate bridge for the escape wheel is nice, too. The previous owner of the Revue had superglued down the dial after it flaked. Managed to buy a parts watch a few months later, and it came out quite nicely in the end. I'm going to experiment using Aquazol on some flaked dials I have at some point. The Omega was my second balance staff replacement. Cutting out the balance hub on the lathe was probably the scariest part of the process. Now, to spend the next 3 months waiting for an Omega to show up on eBay at a reasonable price.3 points

-

3 points

-

I used to do overflow work for a Big Brand known for using these 101s, would see a couple a year. Stopped doing that a few years back and have had a 104 in (it's like 0.5mm bigger) but no 101s since. They are a bit nerve wracking to do as even LeCoultre doesn't really have parts for them. A colleage split a 104 pallet fork once and we had to remake it in house.3 points

-

I think it's always a good idea to consider how long the watch keeps good time for as well as a healthy amplitude. If the reserve is lasting almost to the watch spec and the timekeeping is still good..then you make a decision as to leave it as is, like Klassiker suggested. I think about the first watch I ever repaired, a Soviet model, would only run at 220° at full wind, but would unwind completely and keep good time. Four years later it is still the same...and my favourite watch.3 points

-

I don't know how it may have affected your amplitude, but I recommend being extremely careful with EveFlex, as prolonged polishing can taper the wheel pivots. I never use anything other than the light green EveFlex, which is very soft, and only for the shortest possible time—just until I see that the pivots are clean. On that note, if the pivots are even slightly damaged or deformed, have micro-rust, or show signs of oxidation, it can have a dramatic effect on the amplitude. In such cases, you may try replacing the affected wheels or repairing them with a Jacot lathe. In general, that is very sound advice, and I do agree! We shouldn't be too hung up on what the timing machine shows. It almost killed my interest in watch repair. However, in this case, if the amplitude is truly just 190 degrees (yes, timing machines aren't always reliable), I would continue the fault-finding. If unsure if 190 degrees is the truth, record the balance wheel in slow motion. Here's an example with the opposite problem of too high amplitude:3 points

-

Your list is good, but there are still a few other things to check. Any clues from the timegrapher traces? What is the power reserve? What is the shape of the hairspring like? Is it clean? Excessive lock on the pallet stones? Fork horns rubbing on the impulse jewel? Safety pin rubbing? I'm sure others will add more. In the end, if the timekeeping is good in all positions and you have checked everything you can think of, be satisfied and move on.3 points

-

This brings up an interesting problem. The watch companies when manufacturing watches burnish their pivots. With the factories burnishing their pivots to very exacting specifications. Then we get these two interesting quotes. How much cleaning is really needed on a pivot in the field? How aggressively do they need to be cleaned to be clean? I have a concern with the aggressive nature of people in discussion groups and YouTube videos aggressively doing things to their pivots without thought as to the consequence of what they're doing. Then as we saw in the PDF things that are shiny Are not necessarily smooth. Then there is the other problem of burnishing. Done at the factory to exacting specifications. But in the field on the gear train is there a consequence to this? Now I'm excluding the balance pivots but even there you do have to be careful not to reduce the diameter down when you're aggressively burnishing or changing the shape of the pivot if it's that far gone he she just replace the staff if you can. Here is an image snipped out of the Swiss watch repair manual I believe on consequences of burnishing pivots.2 points

-

2 points

-

2 points

-

As always @JohnR725 contributes great documentation to help our understanding. Eveflex is pretty much the same as Cratex I have found. I have used the extra fine Eveflex to clean up pivots, looking at the document John attached I think I will be inclined to follow up any cleaning with Eveflex with some quality time with the Jacot tool. Tom2 points

-

2 points

-

I imagine that whether or not the escape wheel is intended to rest in the hole jewel vs. riding on a cap jewel would affect the shape of its pivot (and shoulders). In other words, could the pivots of the escape wheel tell us if the cap is missing or not?2 points

-

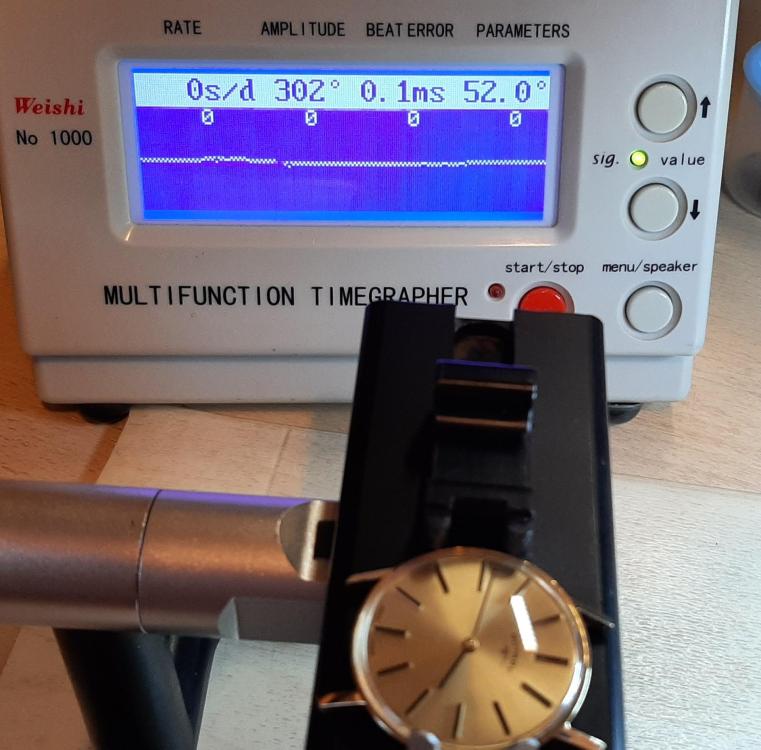

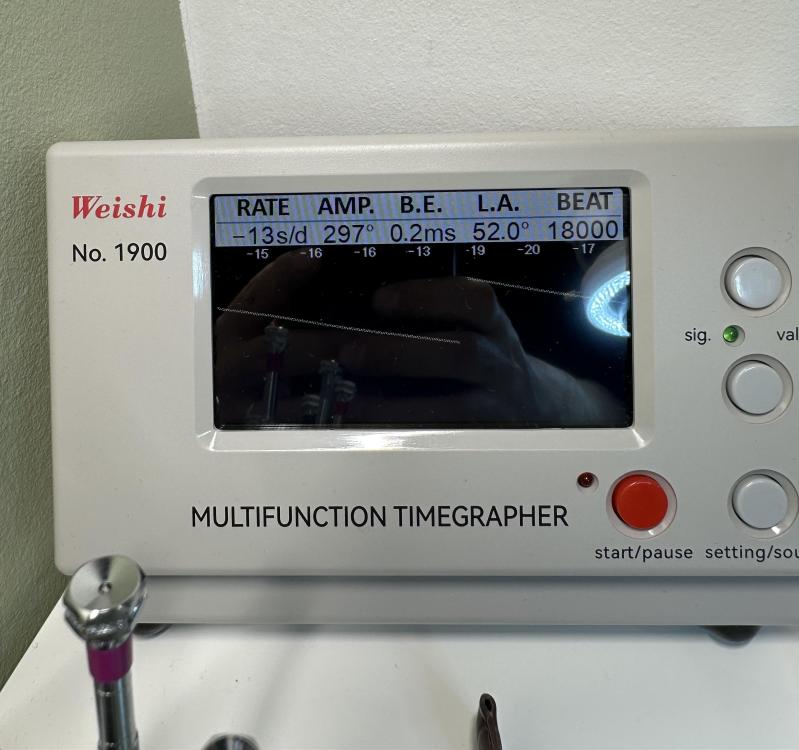

Hi @joelcarvajal All sounds good on paper, but we need to see pictures of the movement and timegrapher readings to help more. For the movement, it would be good to see pictures of the balance (in situ, but not running) straight from the top and directly from the side. I'd advise against using lighter oils. 9010 is already very thin on the train. Anything lighter and you'll run a significant risk of the oils creeping away from where they should be. Omega (as @JohnR725 will always remind us) is mostly concerned with amplitude after 24h of running. The vertical amplitudes after 24h should usual be no lower than 160-180°, depending on the specific movement. Oh, and one big one to keep in mind is that the lift angle of the Omega 580 should be 56°! If you are using 52 on the timegrapher, you can will be positively surprised when setting it to 56. Expect an increase of around 25°. Cheers, Christian Agreed.2 points

-

2 points

-

Hello everyone, I would like to present to you my latest project, a Vulcain Cricket (yes, another Cricket), model S2315A. I always wanted a Cricket, and it looks to me that Vulcain has made a lot of different variations of dials, watches etc. Cannot really find much info on the one I have. Initial condition overall: is running, but definitely needs servicing. It has a lot of DNA allover the place. Also, the watch came with its original bracelet (I wonder how that will turn out). Movement: looks to be a cal.120. Not 100% sure as googling for this caliber brings different results. What do you think? Also had tested it on the timegrapher, results on the picture. Crystal: needs a new one, as the original is cracked and has oxidation on the tension ring. Dial: looks pretty clean. Case: gold plating has some ware. Honestly not sure what to do as I have no setup of my own yet. Is it worth sending for replating? I am a newbie in the trade so any thoughts or suggestions are super welcome! Thank you!1 point

-

Hello folks I been reading and learning from this forum what to do and not do I collect pocket watches and I also have several wrist watches.1 point

-

Hello fellow watchmakers! My name is Luciano, a 24 years old watchmaker. I started my journey in 2019 when I attended a watchmaking course in Campania’s interland, thanks to which I was able to perfect my skills in repairing mechanical and quartz watches. In 2021 (once I graduated in watchmaking school) I partecipated to an ETA training internship in Grenchen, where I had the possibility to master my knowledge of ETA movements. Eager to explore other branches of this craft, I joined two separate courses at the Wostep Foundation in Neuchâtel, focused on the latest lapping and laser welding techniques. The best thing of my journey has been the connections I have been able to create with inspiring people from all around the world, the supportive participation in learning and imparting knowledge. In general, the human enrichment that comes from being part of a community of people willing to spread the beauty of watchmaking in all of its forms. I hope this forum will be a fertile ground for me to expand my knowledge and I hope to share my impressions with other users. Thank you!1 point

-

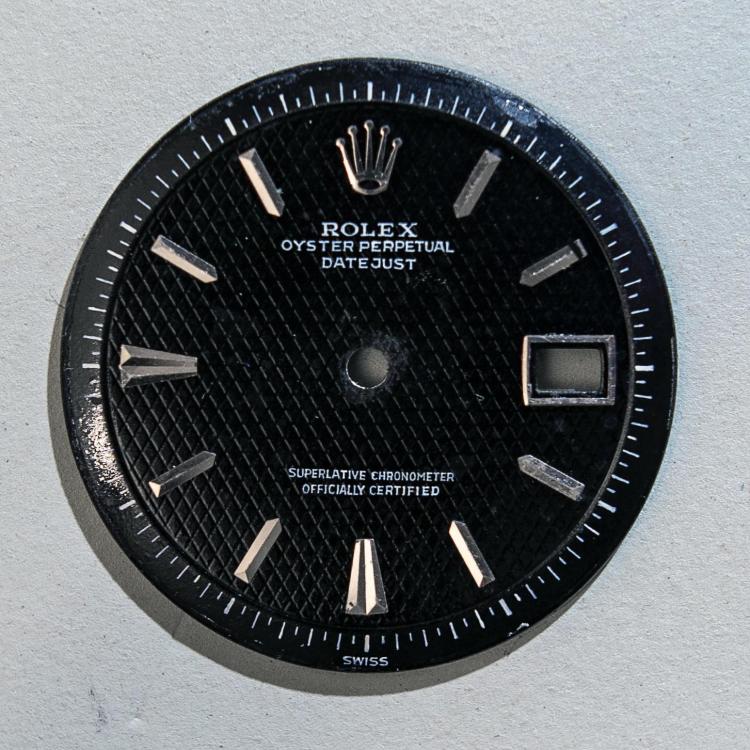

Yes, clear varnish tends to be the go to but if the goal is maintaining the exact look you have a caution- I have a couple DD watches where it is obvious previous preservationists have done this and it looks a bit the bodge…1 point

-

To add if it is just the mainspring you're looking for then you maybe able to find a generic one by measuring the existing. Key dimensions are height, thickness and barrel diameter along with length if possible.1 point

-

1 point

-

No experience but I have seen clear nail varnish recommended. I would think that Matt acrylic clear coat could also be an option. Worth an experiment if you have some old hands kicking about that don’t matter. Tom1 point

-

This is exactly what I'm doing. A few manual turns. But not with pegwood+diamantine, but with extra fine Eveflex. When the only objective is to remove dried-up oil, I wonder what is more gentle and less likely to scratch up the pivot. My logic was always: if I need to peg jewels to remove dried up oil, why wouldn't the pivots also need similar treatment? I assumed the the extra fine, soft, rubber-based, pin-polishers by Eveflex would be the gentlest of approaches. But the article posted by John is making me unsure.1 point

-

I think that less is more, in other words, do the bare minimum to make the movement run to what is acceptable.1 point

-

Welcome! Happy to have you on board and learn from you - and maybe sometimes the other way around1 point

-

1 point

-

Welcome to the forum. What watch is it as it looks like a generic Chinese movement that you'd probably struggle getting parts for.1 point

-

1 point

-

Yes, the roller table in French is the plateau. The roller jewel is ellipse, fork is ancre and pallet jewels are levees. So this has visible pallet jewels, as opposed to the older style that were fit in horizontal slots that completely covered them (they are a nightmare). Those forks also had a boss sticking up to work with the single roller (other watches like the American models used a vertical pin). The double roller is a vastly better design. The original roller jewels were oval shaped, thus ellipse. High end watches tended to have triangular roller jewels, then the D shape proved the best, and luckily easiest to make. I reckon this didn't go through any chronometer testing, but with the proper "state of the art" escapement, Breguet spring, and that nice whiplash regulator it has all the goods to be a chronometer, thus "Mi-Chronometre" on the dial.1 point

-

wow, this is indeed very interesting. in fact, it makes me reflect on my use of Extra Fine EveFlex for pivot pre-cleaning. I sometimes stick the pivots into the EveFlex and turn it just a 4-5 times. No intention to polish, but just to remove potential sticky oils (the equivalent of pegging the jewels with pegwood). But I am now worried that this may actually scratch up the pivots. Next time I'll just stick the pivots into degreaser-soaked pithwood. impressive, as always. can't even imagine how you'd do that.1 point

-

That's a really interesting read on the burnishing John. There's good reason why companies go to the expense and effort to burnish pivots.1 point

-

Proper old looking quality watch matey, well done1 point

-

fitting accompanying classic H ,I sat on my sofa drinking coffee, I almost spat it out laughing1 point

-

Plates are sometimes manufactured with upgrades in mind. Capped or uncapped lever, escape and fourthwheels, often some plates appear to have all three missing.The jewel hole orientation and pivot design will dictate if a plate stone is missing. This can be picked up by checking caliber variations with their jewel count. In this photo hou can see the jewel hole is placed ready to accept oil, uf it were capped it would be dome up.1 point

-

Yeah that’s where my head is at. I have a fake Seamaster 300 based on a Miyota 8215 where the hands are C1 and the dial is like the OEM one. So I could practice on that first: I’d like to use decent lume but seems like eBay is the only place I can find it. Is there a reputable source I can buy some from? Ideally the proper stuff (Super-LumiNova I assume) and no idea what grade I need to match the dial.1 point

-

Based on my findings (ChatGPT and Google) base oils synthesized from alcohol and esters are expensive an offer a very high quality. Ether is a well known additive for synthetic oils. Ethers: - Base Fluid Component: Some synthetic lubricants use polyalkylene glycol (PAG) or polyol ester (POE) bases, which often contain ether linkages. These provide excellent thermal and oxidative stability. - Low-Temperature Performance: Ethers help maintain fluidity at low temperatures, preventing thickening or gelling in cold environments. - Lubricity & Compatibility: Certain ethers enhance lubricity and compatibility with seals, reducing wear and extending component life. Alcohols: - Precursor in Ester Synthesis: Alcohols, particularly polyols (e.g., pentaerythritol, neopentyl glycol), are used to produce synthetic esters, which are key base stocks in synthetic lubricants. - Polarity & Solubility: Alcohol-derived esters provide good polarity, allowing better solubility of additives and reducing deposit formation. - Thermal & Oxidative Stability: Alcohol-based esters resist thermal breakdown and oxidation, which enhances lubricant lifespan.1 point

-

1 point

-

Hi. No I did not, how can you tell from that photo ? But I did noticed that when setting the time and pulling the crown, it tends to jump back in quite easy…but the spring looks good from my point of view. Edit: now that I checked again, yes I see it. So that’s the reason the crown jumps back in while setting the time. Thank you ! Good eyes. Oh no….I missed that completely !!! It came like this. I’ll have to look for that part now. Many thanks. There are some deviations on different positions and the beat error goes a bit higher but not that much.And I agree, especially at the learning level where I am right now…works decent ?! Leave it as it is - but sure, later on the road I might work on these sensitive hairspring adjustments. Few more photos under the natural light Found the setting lever spring. Now for the escape wheel end cap… I found the lower cap jewel as well but it’s from a slightly different Revue movement, caliber 59…not sure if will fit. Looks like it will but still…1 point

-

How long ago was it serviced. I suggest if you're not 100% with watch repairs then you either take it to a repairer of leave it till you've more experience.1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement. If there is anything we can help you with don’t be afraid to ask. Nice clear photos can help a lot. I'm going to need a lot of photos of both the Tavern clock sounds very interesting.1 point

-

1 point

-

1 point

-

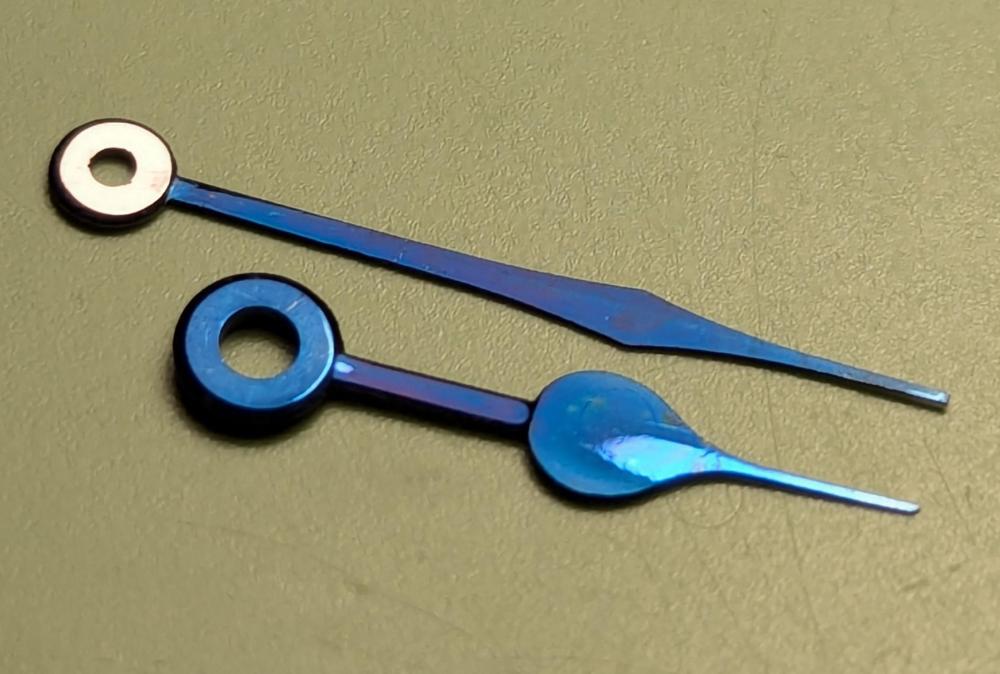

After a little over a year of restoration work, I am finally finished with my Hamilton 992 16 size railroad watch project. I'm really proud of this project because it was my first end to end restoration, with multiple repairs, banking pin adjustments, extensive poising & regulation, custom case work, hands restoration & bluing. This movement came into my possession sort of by accident when I was just starting out and recognizing it was nicer than most I had worked on I set it aside until I had a couple years experience. The movement was made in 1925, and the case I ultimately put it in is probably 20 years older than that. I started with a movement and dial - the dial was in perfect condition and the movement could tick weakly but had broken lower balance jewels. Sourcing correct replacements took a few tries. I also attempted a few replacement mainsprings, ultimately unable to form a workable inner coil on a contemporary white alloy spring and going with a genuine NOS Hamilton steel spring that in the end is performing great. I acquired loads of vintage tools for this project to do measurement, static poising, timing washers, screw undercutters, and while I was doing what I thought would be the final dynamic poising, I .... broke the balance staff. Replacing the balance staff, as stressful as that was for this project, had the positive effect of a major amplitude gain after leaving behind the worn old pivots. Before I broke the staff, I did have it running at 0.0ms beat error. After replacing the staff I really couldn't get it under 1.0ms but I decided I had to leave it there rather than risk hairspring damage. (the difficulty was probably due to nonparallel regulator pins which were fixed later) The case I chose is a Fahy's Oresilver with screw-on bezel and caseback. Since I wanted to install a glass caseback, I had to find two identical cases with good front bezels. That was one of the more difficult parts of this project - 16 size cases are far more scarce than 18 size. And though this railroad movement would most likely have been in a gold case, I will settle for an alloy that takes a good polish. I had to cut a slot for the setting lever under the bezel, and fit new glass to both sides. Plus it still has a solid metal caseback as an alternate option. Special thanks on this project to @JohnR725 who helped me with a lot of minute details in the escapement and mainspring and parts sourcing, @Neverenoughwatches and @mikepilk helped when I was learning heat bluing, and many others who probably contributed. Okay photos! The hands are Hamilton 16s railroad spade originals, polished with 10 phases of diamond paste and blued. And the minute hand hub mirror polished. Thanks to several of you who helped me build a workable bluing pan for this and develop my technique several months ago. I am happy enough with the rates, though I think the horizontal/vertical delta lands outside of railroad specs. I suspect this is due to pivot wear in the train that I could not address without a jacot lathe. But the vertical rates are all very close after dynamic poising. And since this watch is most likely destined to live as a desk clock, it has been regulated to run near 0s in the pendant up, slightly angled backward position where it stays steady for 36 hours. I'm not sure if dialing the beat error back to 0.0 would make any difference, but I doubt it and I ran into a deadline where I couldn't risk more mishaps. As it stands, if it gets wound up daily it will keep great time, hopefully another hundred years.1 point

-

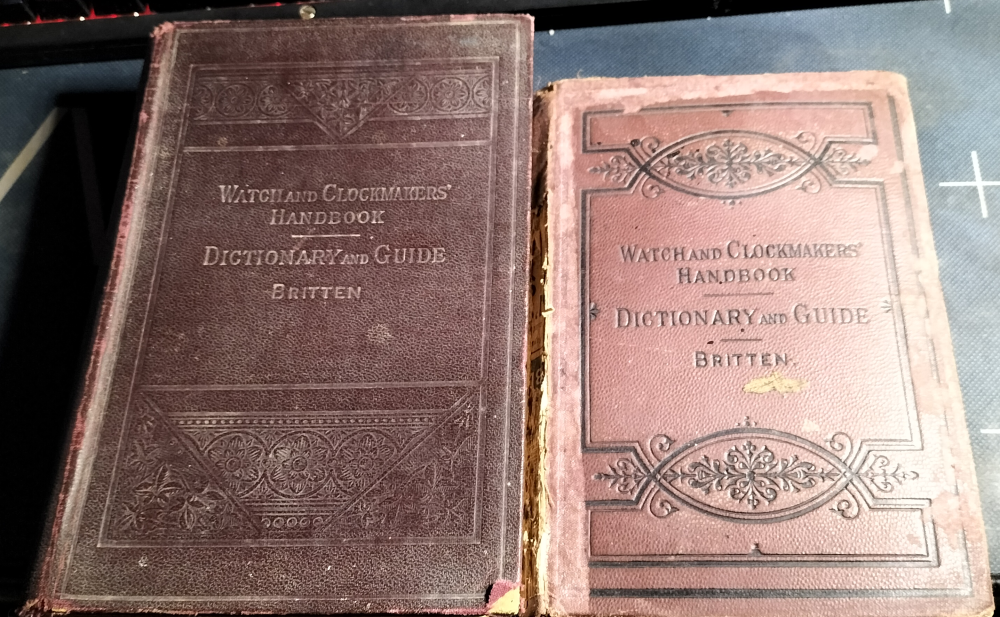

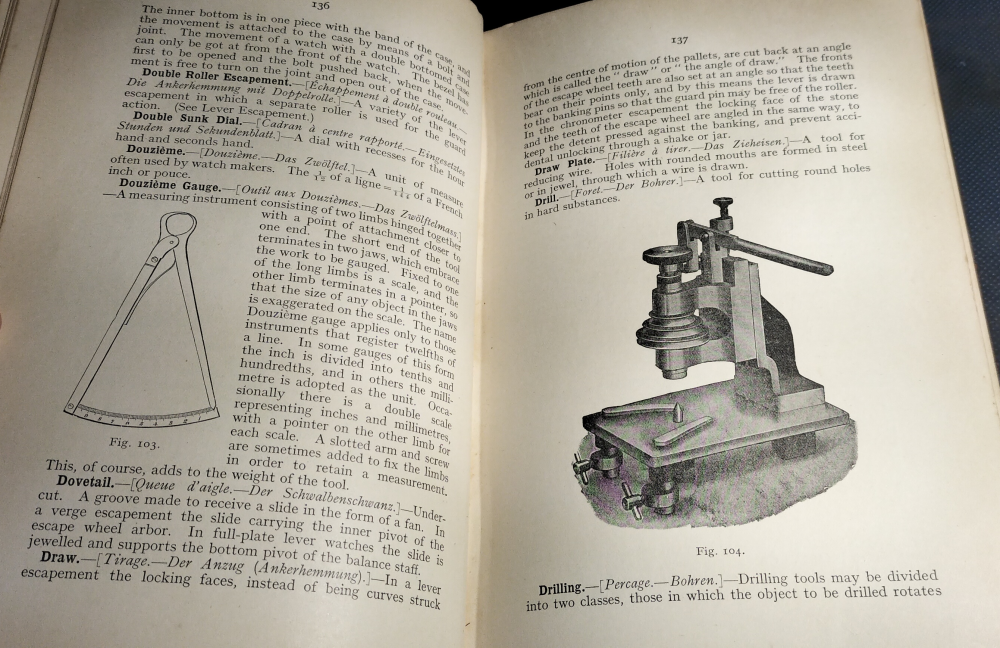

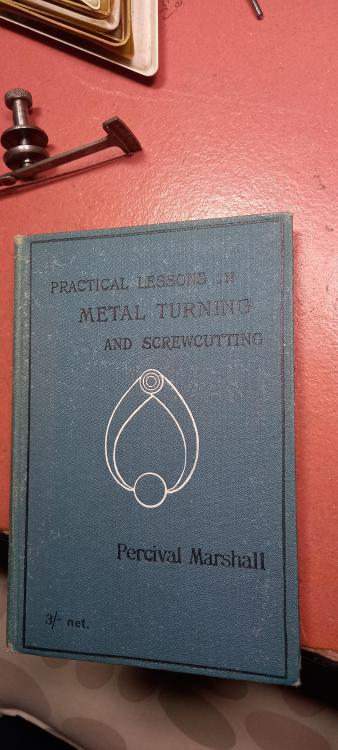

There isn't a whole lot in the De Carle book regarding technique, the lists are useful, I cant think there was much about handtools either..it was an ok- ish read. I actually got more from this old geezer about general lathes, just a cheap whimsical buy that was worth the effort, i dont think it was as much as a fiver for a couple of hundred pages. More about bigger lathes but a lot of the same principles apply.1 point

-

Just arrived, a Longines 30L. I've been looking for one of these for a long time. I've been a fan of Longines since I got my first, I love the quality and elegance. In the thread "looking for a simple, ultra-precise hand-wound movement - suggestions?", @nickelsilver suggested the larger Longines (30mm movements). The higher grade version of this movement (30Z) were used as observatory chronometers. So I decided I needed one. I'm expecting good performance. It's not going to just sit in one of my cases, I'm going to regularly use it. I bought it as "spares or repair", so was expecting a damaged balance. But on first look, the balance and hairspring seem perfect. It just seems to have a broken mainspring. Result BTW @nickelsilver, you also recommended Peseux as good movements. I bought a cheap Rotary with a Peseux 7050. Looked like it had been serviced by a gorrilla - the pallet fork was bent about 30°, missing pallet jewel, hairspring all out of shape. So I wasn't expecting great performance. On the timegrapher yesterday, looking good ! (I'll be buying more Peseux - good quality at a good price )1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)

.thumb.jpeg.cd6d20f3fd1f21747a43456b96dd785d.jpeg)

.thumb.jpg.ca502b3e67e1e13936648168231d15c1.jpg)

.thumb.jpg.b2036d29fafacc5dd87762d69c98ea08.jpg)