Leaderboard

Popular Content

Showing content with the highest reputation on 03/05/25 in all areas

-

Just saw this reply and thought I’d chime in with what I see, from looking at these sets every day. This set appears to be one of the original K&D Inverto sets. It could possibly be a 17 or an early 18, I’ll look at mine really fast and make sure which ones were closed front. I think the anvil itself is an original Inverto with the closed front. I have numerous versions here in my hobby room I could compare it too if you need. It’s definitely K&D in nature. I see at least 7 stakes that are broken, damaged or modified in some way. 1 stump appears to be broken. There’s a wide assortment of stumps that are period correct and also a period correct centering stake. There are extra stumps in the stake holes so you should be fine in that area. The key points would be your skill level and if you are willing to take the time to check each stake for being bent, mushroomed on the end, plugged holes, broken tips and any chips, scratches or rust/corrosion that could prevent smooth inverting and accurate tool usage. The more sets I do, the more I’m learning daily and it’s really a fun hobby. It could come down to price also. If you could get this set for under $275-$325 (after reading your post again I’d jump all over it for that price and at least double my money when sold after complete restoration) it would be the perfect candidate for restoration and would make a very nice set with some limitations, because these older sets didn’t have a lot of the newer stakes that K&D 18R/600 series or C&E Marshall made at later dates. Hopefully this helped you some and if there’s any questions you may have, please don’t hesitate to send me a message Good luck Rick Edit to attach some photos. these are 5 examples of early 1900’s anvils from K&D c. 1902-1925 L-R R1 77G (unknown 2 piece exact model #) New Style Frame D 6/1/1909 2 -Original Inverto 4/7/25 open fronts. 1- Inverto 17 closed front aug 6 or 26 19023 points

-

Doober on the side says she's in SoCal. Can't tell much about the movement from the photos, but the walnut case is going to need some top tier talent to get back to good condition. That appears to be a genuinely nice clock. Don't cheap out and take it to some hack, or it'll just be destroyed further. Advice about taking the case and movement to separate people is correct. Very different sets; skill, tool, TV, etc. You'll want to take it to a good clockmaker, who will remove and repair the movement. Then you'll take the case to a VERY good furniture restorer. Case will probably take more and longer than the movement. I have both of those skillsets (more on the woodworking side than clockmaking, to be fair), and with the figured walnut there, and I'm guessing a French polish finish (seems to have been fairly shiny, and would have been appropriate to the time and place), you don't want some hack just sanding it down and slapping on some Home Depot canned crap and gooping in wood filler. If the restorer doesn't have a glue pot (a little slow cooker looking device for keeping hide glue at the right temperature), and a huge stack of walnut lying around, it's probably the wrong restorer. Save every splinter; carefully fitting a shard is WAY easier and better looking than trying to grain match.3 points

-

In time that will come as you become more proficient at handling small parts, and the learning of tricks to help you manage it. Tweezers might seem like a simple tool but there is a lot more to them than one might think . Most lost parts are due to tweezers pings, making sure they are dressed correctly at the ends so the tips close together evenly, parallel and don't open up when squeezed together. Tweezer choice is also a consideration, tip shape and size to match the part being handled, keyless springs require a good firm pair ...ahem .......to manipulate them in and out of their homes. The type of metal the tweezers are made from is again something to think about, steels, brass, bronze,titanium, wood,ceramic, plastics. Some of these grip better than others,scratch less and have different compression tension. A nice light tension will prevent part drops, this can be adjusted to suit the feel that you want from them by reducing the tension at the tweezer join achieved by removing material from the thickness and the width, though that does require tip width adjustment as reducing the tension will close up the ends. And back to part gripping, you can add to the inside of the tips some texture with an abrasive paper, I like a 400g, best done with titanium or brass so the tweezers are less likely to scratch parts. As to the handling of the missing parts in question, inca springs are springy, counteract that with something that will absorb its springyness, a tiny amount of rodico on a stick serves. And lost jewels are better seen in the dark with a uv light.3 points

-

I will suggest to make the free oscillations test and share the results as to know if the balance and related parts is not the main source of the problem.3 points

-

That's the million dollar question. If you ask 10 watchmakers, you'll get 10 different answers. This forum's owner, Mark Lovick, shows on a few YouTube videos, just a tiniest bit applied to the grooves of the barrel wall. I've tried that and found that on some watches, the slippage can be quite bad. I could hear the spring go "kerchung" and end up with less that 24 hours of reserve power. But that's when using the crown to wind the mainspring. I have not tested whether this kind of slippage happens on autowind. Now, I prefer to smear a thin coat of braking grease around the whole barrel wall. I don't feel the huge amount of slippage when I do it this way. Now we wait for another nine watchmakers to give their opinion.3 points

-

Agree with @mikepilk and @mbwatch, this is the biggest issue of what you mention. Where are you located? A new mainspring doesn't cost much, e.g. at CousinsUK, if you don't have a mainspring winder. The timing results look ok in the table. Amplitude a bit low, but this may very well be caused by the barrel. However, we'd be much wiser if we say actual pics of the timegrapher readings. Straight/clean lines? As @mbwatch already wrote. This will eventually become an issue. But overall very good for a first time! You should be happy.2 points

-

I use a 10mm Pultra but then I only restore clocks what ever you get just make sure to buy complete as possible & if you have the money then you would not go far wrong with this https://www.lathes.co.uk/chung/ And yes I know it’s Chinese but do some research you will find nothing but good reviews, if I serviced watches & could afford it I would have one in my workshop2 points

-

A big one. It would be like rebuilding a classic car, and hoping it runs well on the old original fuel left in the rusty tank. Do you have any spring winders? If not, I would still take the spring out to examine and clean. You can hand wind it in, or make a DIY winder using an old washer - people have posted how to do it. I don't always see what you call backlash either. It depends on the design of the gear train. This is most critical on the balance, but also check each wheel in the gear train. You need some, but not too much. I like to imagine the correct amount as being about the thickness of the pivot. So it decreases in amount as you go through the gear train to the balance. For regulating, it depends on the type of watch, and who wears it. On a wristwatch I only really care about dial up, crown down and crown left, as these are the positions the watch is mostly in. You don't need them to be all nealy zero, just cancel out in the most used positions Your rates are very good, with DU at +4, CD +3 should help to cancel out the CL -7. You will only know when you wear it for a week.2 points

-

You can do but with all watches they're worth what someone is willing to pay. Michael Kors is a name, not a quality watch.2 points

-

You wouldn't guess by looking at them, but a magnet will usually pick them up. Get some strong magnets, glue them to a ruler and you have a very valuable new tool.2 points

-

2 points

-

The other watch doesn't have the crown and it was sold to me as the movement was broken, but the balance wheel appears to be ok. I know that the M24 is especially hard to disassemble and re-assemble. I might try to fix it later. In the end, the work that I'd do on weekend, was done now and the old watch has a new case, new crystal and movement ring.1 point

-

Fair comment guys. The Timegrapher was still at the usual 52 degrees instead of the 38 l believe should be used. Frankly l tend to use slow motion on my phone and do things the old visual way. It looked very healthy. I do occasionally get odd amplitude readings from some watches on that machine .1 point

-

1 point

-

1 point

-

1 point

-

Thank you for taking the time to help. This place is special.1 point

-

1 point

-

It won't affect timekeeping. One thing to be aware of though is if there is some dirt trapped in the friction pinion, it will cause extra wear on the parts when setting the hands. That will eventually cause handsetting to become very loose without friction, and then the hands may lose time on the dial even though the movement is running at good rates and amplitudes. A loose/malfunctioning friction pinion was found in every AS 19xx I have opened in the past; it's just a wear-prone part. You may still be able to get a little bit of oil into it even if you can't disassemble the two parts. Just a very tiny amount of HP1300 poked into whatever seam you can find between the two pieces should be drawn in and held between them. I see no issue here at all, no big differences. Your DU/DD delta is a mere 7s. Totally acceptable for a movement like this. And amplitudes are within 10°. You should worry if you are seeing >20s between the dial positions, and a big amplitude difference. Those would indicate that you don't have equally clean or equally oiled balance jewels, but your deltas are so small here I doubt that is the case. Regular movement wear on an old watch that wasn't chronometer grade to begin with would easily account for this small difference. If you did manage to service the mainspring, I can imagine you might squeeze out another 5-10° amplitude overall. I would be pretty concerned about any moisture or cleaning fluid trapped in the barrel though.1 point

-

1 point

-

1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement. If there is anything we can help you with don’t be afraid to ask. Nice clear photos can help a lot.1 point

-

1 point

-

1 point

-

1 point

-

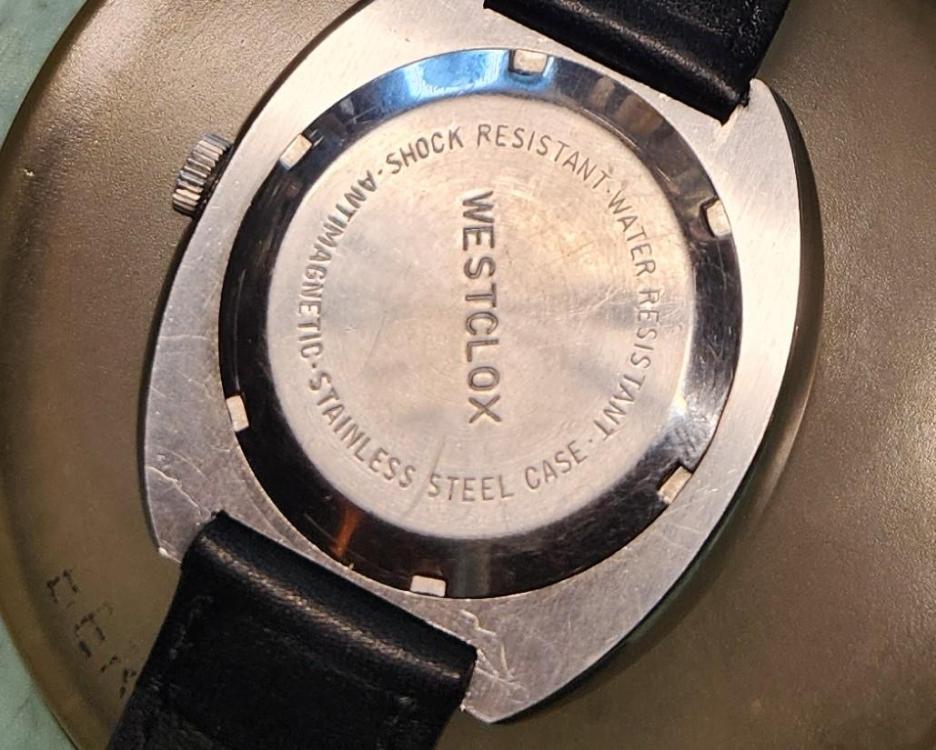

If you scrapped all the rest, that Westclox would still land you in the 10:10! I'm right there with you in generally giving Westcloxes a pass for the PITA movements. Great example of the name on the dial meaning nothing! That's a pretty serious score right there!1 point

-

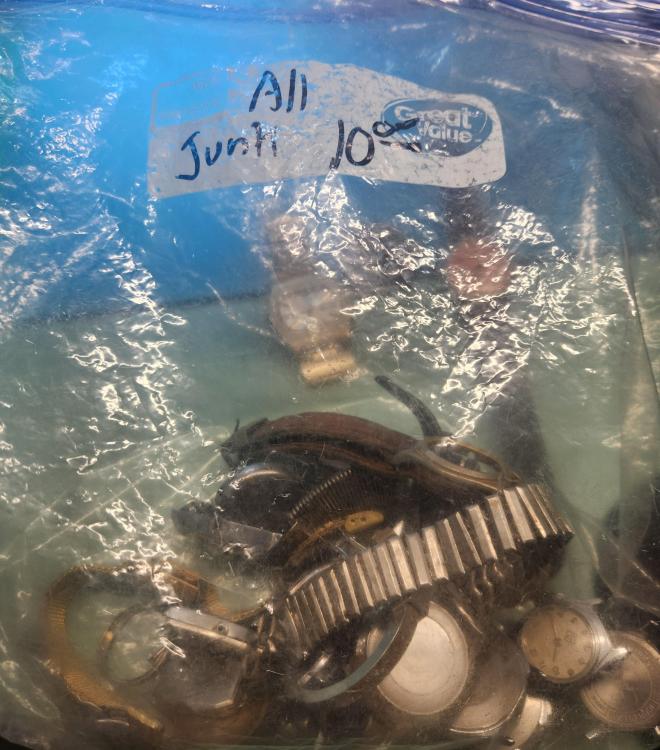

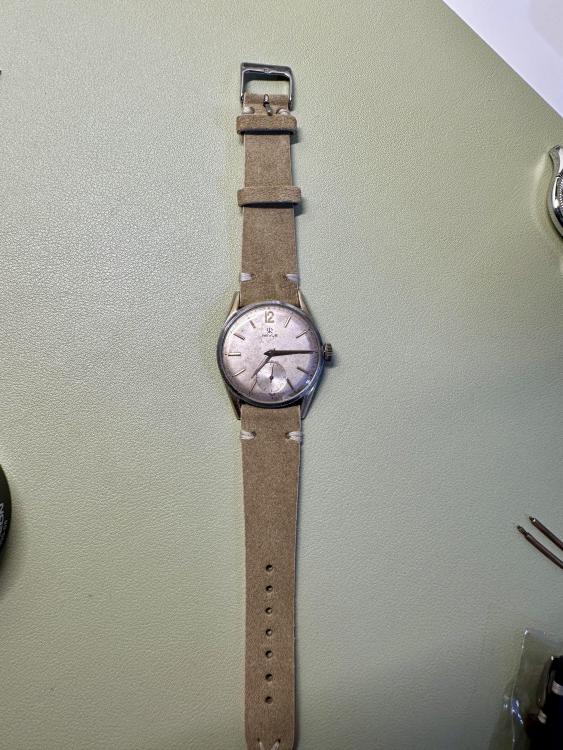

My latest score for last weekend. 33 watches plus a couple of cases and some other junk. 4 of the watches are runners with the gold color seiko with a 6106-6007 and all original H link bracelet. The best one may be a sleeper Westclox. I tend to overlook westclox because their movements are not that great to work on. This one was different and seems to be a seiko 7006a as a base caliber to the Westclox A361-1 in a all SS case that is 41mm and 39mm lug to lug. This hunk of metal, while not a turtle does have its DNA in seiko, just have not figured out yet what it's corresponding Hattori case number is...not bad for less than 30 US cents apiece. Worth the price of admission to the fun!1 point

-

Good day everyone! Thank you all for the replies. I appreciate all the suggestions. The following are my action items to aid in further analysis: ( ) Share pictures of timegrapher results, after 24 hours from cleaning ( ) Take a picture of the hairspring ( ) Capture videos of pallet fork and balance assembly in operation ( ) Take pictures of balance assembly from various angles ( ) Measure power reserve and performance near unwound ( ) Do free oscillation tests on the train and escapement ( ) try to capture how much lubricstion there is on the pallet fork / escape wheel some comments/replies: * I use lift angle of 56 * I used the Eveflex in an effort to increase amplitude. There’s no corrosion on the pivots. * Adjusting the escapement is beyond my skill level. In fact my usual remedy is to replace parts. Again, thank you so much!1 point

-

Exactly. For the other part of your message, I think I've chosen the right tweezers: bronze ones made by Horotec. They're perfect. In the two months I've been practicing with a dozen watches , I've never lost a part due to the tweezers. However, I have lost a few springs (some were found, others not), but that was due to poor handling on my part, not the tweezers handling. I wasn't using both hands, and I wasn't employing the proper tools. Now, I make sure to use a wooden stick with a bit of Rodico on the tip, or a jewel picker, just like Alex Hamilton suggested in one of his videos. I had that thought as well, but to set it up and to handle tools from the desk around it...not sure, seems not so practical, but it theory could have other benefits, like...protecting your desk and tools under it from dust particles.1 point

-

1 point

-

It depends what experience you've got as you need to be extra careful not to lose or damage any parts. Also there will be no lubrication details so this will come down to experience.1 point

-

1 point

-

I have had my hands on a few MK fashion watches, some use Miyota and some Hattori but the prices are for the name and flash dial. Only the likes of us who peer inside see the real truth. Vastly over priced.1 point

-

I have been replying to this for LadyLost by message. It certainly is a Tavern clock early 1800's that you can be sure of by the size of the dial. The clock tax ended in 1798, but the design carried on but the size became smaller. The very early ones had very large dials. The name on the dial is the maker.1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement. If there is anything we can help you with don’t be afraid to ask. Nice clear photos can help a lot.1 point

-

I've been tempted to make a small magnet broom for the number of times I've had a Yoke spring join the Swiss Space Program. Or a tiny clear plastic tent/tarp over my workpiece which I can work under, but deflects flying parts downwards1 point

-

1 point

-

1 point

-

A very nice old clock, suffered a bit but once restored to health , a fine specimen.1 point

-

nice 19th century English longcase stiking movement, as for the maker without my Brittens at hand I cant look up that name, although that may just be the name of the shop that sold it as opposed to the actual clock maker. Where are you located? also bear in mind that the case restoration will be a separate job to the service of the clock movement unless specified when price is given for work to be done.1 point

-

1 point

-

You are supposing wrong, I suppose . I stood already in the factory premises in France and was shown the machines. Frank1 point

-

User error probably? I think I tend to dress it too thin, and use it more as a general purpose driver than is really appropriate. The blades that came with that set are on the softer side, which makes them easy to dress but of course also easy to damage. Honestly, if I had paid more for a big name Swiss set I expect I would probably be more careful with them then I am with this set and chip them less often.1 point

-

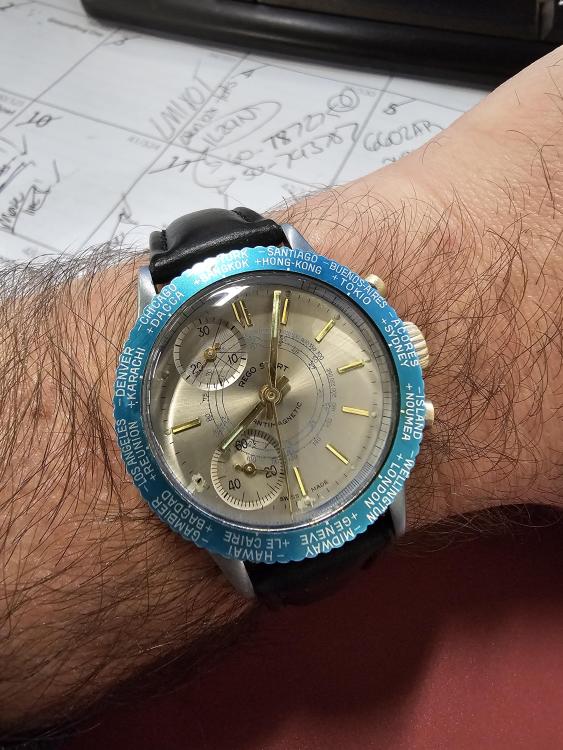

$10.50usd awarded me this cool REGO SPORT "chronograph" with a Lapanouse pin lever movement on ebay. I bought it specifically for the challenge, as it looked like it had spent some time in the pool. Some deep cleaning, over polishing, shotty hairspring work and a $7 parts movement for a replacement pin pallet and Today it is on my wrist and keeping great time over the past 6 hours. and the "chrono" functions! Im very proud.1 point

-

I guess you'd need to get it out of the case anyway to fix and issue. Clearly, it's not good as it is. One thing you could check before, though, is the endshake of the centre wheel. Maybe, when installing the chronograph seconds hand (and you, or a previous repairer, didn't support the jewel/bridge), it may have moved the jewel and increased endshake to an extent that now it goes up/down and fowls the balance/hairspring.1 point

-

The torure devices the creepy little guy lays out on a table to help get our hero to talk?1 point

-

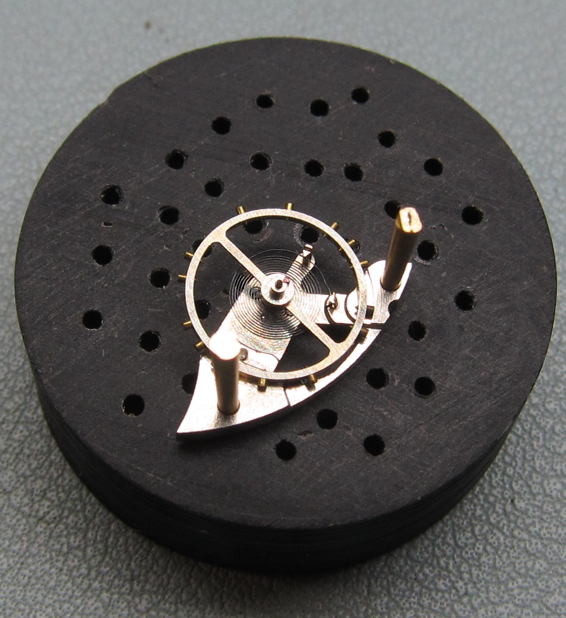

Stabilizing the balance cock while removing the balance and hairspring (removing stud, and turning the shoe) is always challenging for me because of stabilization. I think I have solved this today. I printed this multi-hole base to mount the balance cock and using brass tapered pins I do the stabilization. My example here is probably the optimal case because the cock has two holes (balance for a Vulcain Cricket 120). I will report back on success with single-hole cocks.1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)