Leaderboard

Popular Content

Showing content with the highest reputation on 03/06/25 in all areas

-

I am screaming at the sky this morning. Somewhere else on this forum I think I mentioned acquiring the "stuff" of a deceased watchmaker. Incidentally, I have already sold three items (watches) that have recovered 80% of what I paid, so I am jazzed about that. Here is what is driving me nuts. I have about 300 pocket watches--almost all without cases. No doubt the movements were separated from their cases during the gold rush. While that pisses me off, it is not today's beef. Some numb nuts, thought of a great idea. He disassembled the watches and put them in cheep @ss plastic containers that do not fit together and secured them with rubber bands. Over the years, the rubber bands deteriorated and compromised the erstwhile sealed enclosure. Why not leave the movement intact? In addition, somebody thought it a wise idea to separate wheels into their respective function, irrespective of caliber and brand. Geez. Well, I discovered while restoring a Waltham that had a rusty hour wheel, there are other Walthams of different caliber with the same hour wheel. In addition, I found rachet wheels to be similar across calibers, so maybe these "assortments" will pay off down the road. Quien sabe. So, I have been going through these one at a time and carefully transferring the movements into truly sealed containers. After I complete this task, I am going to catalog everything, so I will know what I have. Some good news...there were some cases...20yr and some silveroid, etc. I have rebuilt two Waltham 16s PWs and they are running nicely. Anyway, I feel better now. Thanks for listening. Examples4 points

-

4 points

-

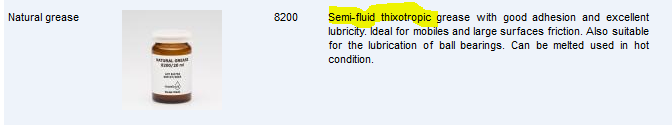

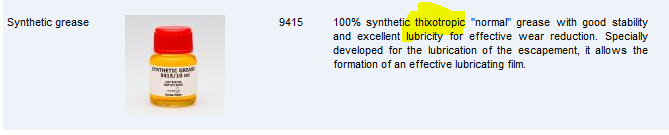

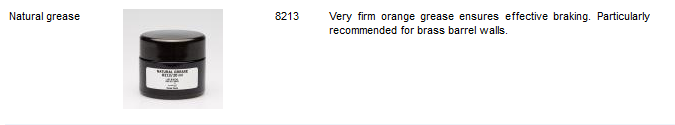

The problem here would be the word grease is a pretty broad term. If we go to the website of the lubrication you'll notice a interesting word which is very important for mainspring lubrication and strangely enough escapement lubrication Oh and I have a theory? Notice 9415 a synthetic and it is typically referenced in all technical documentation. But 8200 typically isn't reference in any modern documentation? Because in modern documentation we typically don't see the mainspring at all because were supposed to replace the entire mainspring barrel. So I think is the Swiss move on in new directions we don't get a synthetic lubrication for mainsprings because they don't lubricate their mainsprings the way we do including the breaking grease it's why we have things like P125 which is probably synthetic although I have no idea where that actually comes from which I find interesting? Then there's that word I highlighted thixotropic. As you can see a very interesting lubrication like in the case of 9415 stays in place on the pallet fork jewels until impact and/or sliding becomes extremely slippery. Or 8200 kind of a grease except when things are sliding again than it's basically a oil in a way. Another reason why it make for a very bad breaking grease because once it broke free it's now an extremely slippery oil like substance with zero breaking properties at all. Then what makes 8200 interesting is if you put a blob on top of the mainspring and go away eventually ill be gone because it's absorbed by capillary action into the mainspring so it really does stay in place. Oh by the way it doesn't entirely stay in place if you put too much mainspring grease in the barrel. Because when it becomes fluid conceivably it will leak out and make a big mess and I'll skip over how I understand that problem. Yes the interesting lessons we learn in life don't put too much of it on the mainspring. https://en.wikipedia.org/wiki/Thixotropy It's supposed to be a PDF. If you click on it it should open up in whatever he used to look at PDF files. Then the website doesn't have any central location for files as they tend to get scattered all over the message board and they get repeated all over the message board taking up lots of valuable message board space whereas we really should have a library someplace of all these files. I'm not sure that it's entirely guesswork of what's happening in their. Like for instance do we even need a mainspring barrel? Yes we need a mainspring but do we need a mainspring barrel? If you look at some of clocks you'll find that they have no mainspring barrel at all So you can actually can see what happens in between fully wound up tight and fully Let down the mainspring is just kind of floating of their. Then lubrication err on the side of caution I like that? I'm attaching another PDF and then I'm going to quote something? Then know it really isn't as simple as what I quoted below. We see the name of the mainspring company we find out that there is Teflon on their mainsprings lubricating isn't good for the Teflon. This would explain why Omega recommends just dry wiping the mainsprings if there mainspring indeed has Teflon? Because other problem here is over time various lubricants have been used for the pre-lube mainsprings. Omega at one time had some sort of liquid lubrication and their claim is that yes you can lubricate it doesn't hurt but then in later generations it's dry and don't lubricate it all and definitely don't clean at all. All the way up to the suggestion of the right form of steel itself is lubricating properties and doesn't need any lubrication. Oh and in some cases I suspect even using 8200 like quoted below sort of were somebody said it doesn't actually help I remember one particular incidents I think it actually made it worse because it was just sticky enough to interfere with the power off the mainspring. But that's only a speculation on one particular watch in one particular time and space. 2000-08-web-2 mainspring -1.pdf3 points

-

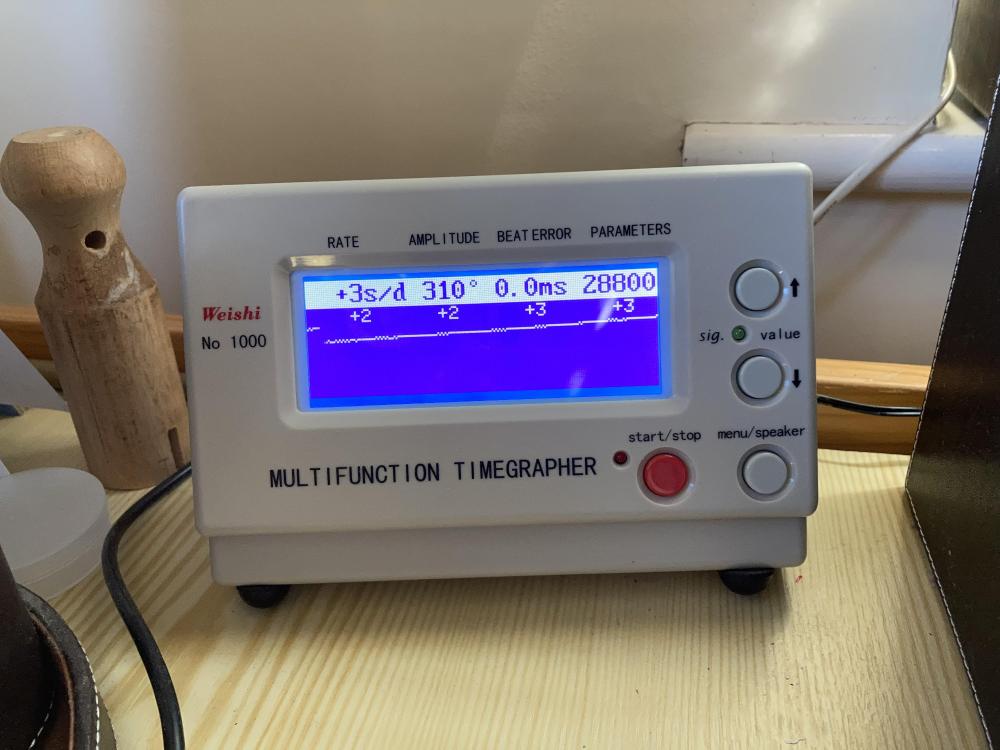

I am absolutely thrilled to announce that I finally fixed it !!!! Only took around 2 months and several parts ordered that either didn’t fit or had other faults, a lot of trial and error, somewhere around 150€ spent on parts. The good thing is that I have a bunch of spare parts for this watch now I regulated the watch with dial up and dial down for now since it’s very late, but I believe there should not be major differences in other positions. Dial down: Dial up: The aftermath3 points

-

Not oil but grease. It's usual to apply a thin coat of 8200 to a cleaned mainspring. I put a touch on some watchmakers tissue paper and pull the spring through. When the spring is in the barrel I also add a touch of HP1300 oil on to the coils and base of the barrel. Some do some don't. As two watchmakers about lubrication and you will get three different answers.3 points

-

Its the loudest watch I've ever heard run. My wife thinks a man must've drowned wearing it and it's haunted.2 points

-

If I had a barrel with a mainspring for which I had neither a replacement spring nor a suitable mainspring winder, I would wash and dry the barrel with the mainspring inside but without the cover, and then lubricate it. This is not the best practice, but it seems to be a fairly common one.2 points

-

This is an interesting and important question, I think. Honestly, I don't think the spring (should) touch base and lid. I think the mainspring hovers between base and lid and only touches the arbor and barrel wall. The protruding center rings (see orange arrows in pic below) in base and lid keep that distance, I thought. I think the gap is also visible on this picture2 points

-

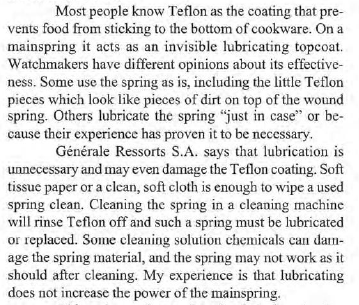

8200 grease for mainsprings but without any of that I would put a little bit of HP1300 on 4 spots around the top of the mainspring after it has been wound in and before closing the lid over. The oil should distribute throughout. But don't use 9010 on the spring. Those timegrapher traces are perfect. I would be very happy with that especially if they stay straight over 24 hours.2 points

-

The other watch doesn't have the crown and it was sold to me as the movement was broken, but the balance wheel appears to be ok. I know that the M24 is especially hard to disassemble and re-assemble. I might try to fix it later. In the end, the work that I'd do on weekend, was done now and the old watch has a new case, new crystal and movement ring.2 points

-

A couple of things here which cost me most of yesterday to learn and may help others as more of these movements age and start to need servicing. There is a lot of Valjoux 7750 here so some parts will be obtainable but please be aware that any damage could be a real headache. Worst case you may have to resort to buying a used replacement movement which are available at around £1000. If you are doing the job for a friend - are you happy to give them back a good looking paperweight ? The CoAxial Escapement parts are Omega only and thus unobtainable to watchmakers outside their AD network. Still willing to take the risk ? I did and got away with it but the stress levels took the fun away so I will hesitate to do another. The main challenge is assembling the balance safely and doing a professional job of the precise lubrication required. Have a read of Omega's Working Instructions No 40 - it's on Cousins site but and Omega search will not find it. Search under "Working". You will need a good Stereo Microscope and a very experienced oiling technique. Mr Daniels and Omega had a struggle over many years to get this escapement developed enough to suit mass production. It's more complicated and less tolerant to imprecise clearances and wear rates when running at 28,800 were an issue. Hopefully all resolved on the latest variations but only time will tell. The main advantage of not needing oil was certainly lost early on in the expensive battle. So still feeling lucky punk ? The struggle to get things reliable has left a development trail of three main types : The far right Starfish style is the latest. Mark has an excellent video assembling a 2500 Omega which has that variation. The 3330 has the middle one - early 3 level and seems to need a different installation approach. Whereas Mark comes in from the left and then turns clockwise - the 3330 seems to favour the opposite : Comme ca : You have to understand with this design the roller assembly is upside down and also has its own vulnerable pallet jewel: Winding the balance cock in anticlockwise keeps that tiny jewel out of harms way whilst you fiddle the roller jewel into the fork. You have to get the balance arbor sat in the baselate pivot jewel and the fork around the roller jewel before you swing the cock into place otherwise it is very easy to get things in a jam. Easing up the wheel in order to get a fit often works with a conventional escapement but this is upside down. Check things are in place under the microscope before applying any power. Now this is hard enough but when tried with any power wound on it proved impossible. With this version of the CoAxial the fork will sit stubbornly in one set position - it will not flick obligingly between the banking stops. At this point you will start to imagine you have broken the movement. Did I mention stressful ? Do not despair - this appears to be normal. LET DOWN THE POWER before assembly. The fork now swings freely and it will go together. Check things are in place and apply some power. The design seems to rely on inertia to get things pulsing both ways. And another possible snafu : The pallet fork bridge is retained in precise position by the two ears shown above. Mine were so tight that they needed a crow bar to release. When trying to assemble this meant the bridge was sitting with one ear in and one ear out which was sufficient to prevent the two pivots from dropping into place. I had to just stone away a tiny amount of metal to get a good push fit without any slop. Dangerous work. Neither was I impressed with the amount of play on the pallet fork pivots once assembled - nothing worn just not as tight as it should be. To be fair to the the good people at Omega it runs very consistently - almost no positional variation - just like a decent Rolex. Hope this diatribe will amuse the experienced and alert the nervous. Neil.1 point

-

I was pleased to see a decent increase in amplitude but I don't really know what to expect from a movement of this age. I guess I should definitely see an improvement with either a cleaned or new mainspring. Expand That looks fantastic indeed. You should be pleased! Especially compared to the baseline. Thank you - itll be interesting to see what playing about with the mainspring does. I've never opened a barrel before or wound in a mainspring so, in case movement performance comes out worse, I have a new spring on order!1 point

-

Yes I'd say the axel is most likely and the parts I've shown are new, not donor.1 point

-

1 point

-

1 point

-

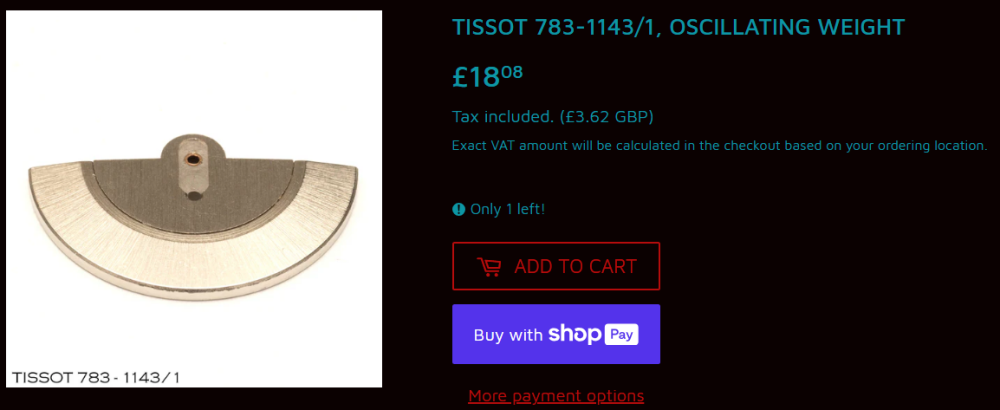

I think that's a good deal for a nice watch like this. I once serviced this calibre and ended up buying 3 or 4 rotors until I got one that didn't wobble too much. Quite a tricky one. A little rotor play, however, seems to be normal on this calibre. But yours has clearly too much. Where are you located?1 point

-

This is where we run into the interesting problem of distortion of the spring by inserting it into the barrel. For instance this would be an example of a worst-case example. That's why it's typically frowned upon the hand wine Springs into the barrel as is a concern of distortion like we see below. On the other hand does one set a lecture were somebody claims even using mainspring winders I don't) stated number but even mainspring winders can be hard on mainsprings. Especially if you try to cram it into a barrel too small when your winding it in that leads to all kinds of interesting distortion of the spring. This brings up the interesting problem of should we be lubricating the mainspring at all? Depending upon whose literature you look at the recommendation is adding lubrication isn't a problem all the way to adding lubrication is a problem. o that means if it is a problem you can't add lubrication anywhere except breaking grease and the arbor as it's going to touch the mainspring and wake in the mainspring. Like for instance in the Omega document for recycling a mainspring they just wiped the mainspring off inserted in and there's no other grease at all other than HP 1300 on the arbor with of course epilam for practically everywhere to keep it from running away and the breaking grease.1 point

-

I'm not entirely sure what you mean by a general reference? I have a link to the website that covers the greases and yes it's confusing. It would be really nice if the company that makes so much lubrication would have application notes on how to apply things etc. but they don't. I'm a snip out a whole bunch of images oh and notice how these are all listed as natural versus synthetic? Looks like they have one more breaking grease just to add to the confusion https://www.moebius-lubricants.ch/en/products/greases1 point

-

Oh dear. I used to believe machines were logical. Enough watch work will get you to believe that some pieces are out to get you. Then l read up on quantum theory and now l know it’s all smoke and mirror. Now we are all breakfasted here is the picture at 38 degrees. It matches what l saw manually. Wish all my efforts looked this good.1 point

-

1 point

-

Definitely not. 8200 is a grease designed to reduce friction of mainsprings in a barrel. Breaking grease has very interesting properties. It's a very peculiar grease it's basically very sticky. In other words it's kind of the opposite of a grease in a way it's not designed to reduce friction it's designed to hold something until sufficient force allows it to slip. Then once energy is dissipated it grips again.1 point

-

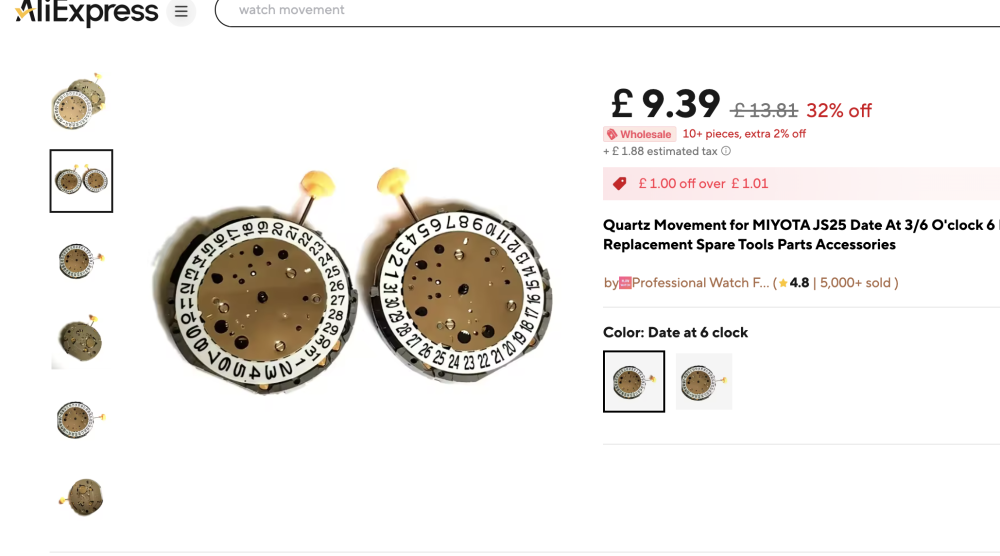

Worst case scenario, if you can't get a date @6 version, you can transfer the old date wheel over, making it a date @6 version.1 point

-

1 point

-

Looking at the first vid it looks like the outer coil is touching the next inner coil. First step is to remove the balance and soak in a de greaser and dry . Once dry de magnify the balance re fit and test. if no improvement inspection under strong magnification to see the fault.1 point

-

Welcome to the forum Yes that looks like too much wobble and thought I could hear something rubbing.1 point

-

What You need to check is if the hairspring, when the balance is in the movement, is not resting on the balance arms. So You need to look at the spring from a side and it must be parallel to the balance/cock, there must be safe distance between it and the balance arms and the cock.1 point

-

Sometimes it's possible to find a tech sheet where the manufacturer specifies what amplitude and deviations are acceptable at full wind and after 24h. That is more common with modern movements made when timing machines were common, but the cal 1900s might have info out there somewhere. If not, I'd be looking for straight lines and not more than a 35 or 40 degree amplitude drop over 24 hours. If the crown positions are still over 200° at 24h I'd say that is very good because it will mean the rates stay pretty stable too.1 point

-

1 point

-

Agree with @mikepilk and @mbwatch, this is the biggest issue of what you mention. Where are you located? A new mainspring doesn't cost much, e.g. at CousinsUK, if you don't have a mainspring winder. The timing results look ok in the table. Amplitude a bit low, but this may very well be caused by the barrel. However, we'd be much wiser if we say actual pics of the timegrapher readings. Straight/clean lines? As @mbwatch already wrote. This will eventually become an issue. But overall very good for a first time! You should be happy.1 point

-

Loved your Avatar at first sight. Though I find all wild life beautiful , donkeys are not just my favourite, but best friends Dogs are too. Welcome to the WRT forum and good luck, Pal.1 point

-

It won't affect timekeeping. One thing to be aware of though is if there is some dirt trapped in the friction pinion, it will cause extra wear on the parts when setting the hands. That will eventually cause handsetting to become very loose without friction, and then the hands may lose time on the dial even though the movement is running at good rates and amplitudes. A loose/malfunctioning friction pinion was found in every AS 19xx I have opened in the past; it's just a wear-prone part. You may still be able to get a little bit of oil into it even if you can't disassemble the two parts. Just a very tiny amount of HP1300 poked into whatever seam you can find between the two pieces should be drawn in and held between them. I see no issue here at all, no big differences. Your DU/DD delta is a mere 7s. Totally acceptable for a movement like this. And amplitudes are within 10°. You should worry if you are seeing >20s between the dial positions, and a big amplitude difference. Those would indicate that you don't have equally clean or equally oiled balance jewels, but your deltas are so small here I doubt that is the case. Regular movement wear on an old watch that wasn't chronometer grade to begin with would easily account for this small difference. If you did manage to service the mainspring, I can imagine you might squeeze out another 5-10° amplitude overall. I would be pretty concerned about any moisture or cleaning fluid trapped in the barrel though.1 point

-

He’ll Stefano and welcome to the forum enjoy. Waded a little reading foryou TZIllustratedGlossary.pdf1 point

-

A big one. It would be like rebuilding a classic car, and hoping it runs well on the old original fuel left in the rusty tank. Do you have any spring winders? If not, I would still take the spring out to examine and clean. You can hand wind it in, or make a DIY winder using an old washer - people have posted how to do it. I don't always see what you call backlash either. It depends on the design of the gear train. This is most critical on the balance, but also check each wheel in the gear train. You need some, but not too much. I like to imagine the correct amount as being about the thickness of the pivot. So it decreases in amount as you go through the gear train to the balance. For regulating, it depends on the type of watch, and who wears it. On a wristwatch I only really care about dial up, crown down and crown left, as these are the positions the watch is mostly in. You don't need them to be all nealy zero, just cancel out in the most used positions Your rates are very good, with DU at +4, CD +3 should help to cancel out the CL -7. You will only know when you wear it for a week.1 point

-

"Please allow me to introduce myself " Are you a man of wealth and taste? Welcome to the forum1 point

-

1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement. If there is anything we can help you with don’t be afraid to ask. Nice clear photos can help a lot.1 point

-

You can do but with all watches they're worth what someone is willing to pay. Michael Kors is a name, not a quality watch.1 point

-

The other thing that affects all of this would be which grease your using. For instance a very long time ago when I was doing a Seiko someone advise using the P125 but applying it all the way around as a thin layer and no that was not the right method at all. As I wound the watch up using the ratchet wheel screw which Seiko does recommend when I hit the end I'm truly amazed at the head did not fall off the screw because the definition of breaking was extremely severe not wanting to slip at all. Okay it slipped a super tiny bit but this would suggest that Omega's sparing quantities of P125 is a better method. Or basically too much of this stuff and it's not go through all. Then there used to be a YouTube channel which strangely enough still exists with zero content called perplxr. Unfortunately the channel still exists but they took all their videos down ages ago we should have figured out how to save some of the videos can some of them were extremely good well okay all of them were extremely good. One of them was on what happens when the breaking grease doesn't work you have too much amplitude and what it looks like on the timing machine. Then followed up with applying breaking grease which would be the Rolex version which basically looks like a creamy white semi translucent substance from memory. But he applied it in a quantity that I would consider unacceptable it was a huge quantity all the way around the outer edge and apparently that is the quantity for the Rolex lubrication. How about instead of nine watchmakers we go with one Association? Is a document too good to pass up I find it very bizarre. So for instance on page 42 we find 8201 listed as breaking grease. Now the amusement I'm having with this is I was thinking of acquiring some of this but not for breaking grease but for general purpose mainspring a lubrication. Because my understanding back.by what the manufacturer says that this is really the grease 8200 that you typically use for mainsprings with an addition of Molybdenum bisulfide (MoS2) Basically a really nice high-pressure dry lubricant mixed in. n the PDF. What interesting about this particular lubrication is when I was a student in school in the early days for the bottles were necessarily labeled as nice as they are now I needed a bottle of breaking grease I grabbed what looks like breaking grease and I'm pretty sure it was 8201 but I thought at the time of his breaking grease? So how did I figure out and why have I remembered all these years? That is because if you're breaking grease is it really breaking grease when you reach the end and instead it's a really nice high-pressure grease it slips really nicely well it lose like almost all your power which means this is an extremely poor breaking grease. So other than the amusement factor not the best PDF at all found that the first link. Second and third links cover lubrication with the third link Greece and yes they do list Their breaking grease and unfortunately they do not tell how to apply it. Then fourth link solves a problem I was actually looking for magazine. I'm a lot happier giving a source of where PDFs come from August 2012 issue covers lubrication. They even show the Rolex breaking grease which unfortunately or fortunately depending upon point of view we cannot obtain. https://www.awci.com/wp-content/uploads/2020/05/Lubrication-1A-Slides.pdf https://www.moebius-lubricants.ch/en https://www.moebius-lubricants.ch/en/products/greases https://www.watchrepairtalk.com/topic/28284-awci-horological-times-all-issues-i-could-find/1 point

-

I have been replying to this for LadyLost by message. It certainly is a Tavern clock early 1800's that you can be sure of by the size of the dial. The clock tax ended in 1798, but the design carried on but the size became smaller. The very early ones had very large dials. The name on the dial is the maker.1 point

-

That's the million dollar question. If you ask 10 watchmakers, you'll get 10 different answers. This forum's owner, Mark Lovick, shows on a few YouTube videos, just a tiniest bit applied to the grooves of the barrel wall. I've tried that and found that on some watches, the slippage can be quite bad. I could hear the spring go "kerchung" and end up with less that 24 hours of reserve power. But that's when using the crown to wind the mainspring. I have not tested whether this kind of slippage happens on autowind. Now, I prefer to smear a thin coat of braking grease around the whole barrel wall. I don't feel the huge amount of slippage when I do it this way. Now we wait for another nine watchmakers to give their opinion.1 point

-

Håkan, thank you very much for your kind words! A few small responses to your points: 1. I'm certainly not ahead of your regarding hairspring manipulation. Knowing you a little bit, you probably set yourself targets of perfection. I try the same, but with hairsprings I just want them to be fully functional, not necessarily aesthetically perfect. In the case of this Vostok, my "fixed" hairspring is now as ugly as it could be -- while still fully functioning. The terminal curve is not nice at all and the hairspring is only central between the regulator pins in this particular position... if I had to regulate it again, I'd have to bend to, too. 2. Endshake: very true. It took me a few attempts to get it just right. In fact, I over-shot once by a tiny margin. The last half-turn of the screws on the train bridge caused the train to lock up. But the next go (pushing the jewel back ~2/100th) brought it to "just right". 3. Yes, you are right about the very respectable functional quality of these movements -- when considering the (high) quantity and (low) cost of these movements. So no offence to them. But if you forget about quantities/costs and just compare them to e.g. a ETA/Selitta (I know that this is an unfair comparison regarding costs!!)... then they're pretty shitty1 point

-

The other thing is to try the balance on its own without the fork and see how is oscillates.1 point

-

Firstly remove the balance and check that the pallet fork (lever) snaps back and forth will a gentle push. If it does then power is getting through to it and then balance is where the fault lies.1 point

-

I'm not sure if I posted this one before but I recently serviced it and was able to get a crystal that fit. I had an issue finding one that was both the correct size and was an 'underlay' type but found one on Cousins. This one fits although the corners are more rounded than the original. The watch came as part of a watchmakers estate and was labelled as an AS970, which it is also marked on the dial side of the mainplate. These seem to be few and far between with the vast majority of AS970's having a sub-seconds hand.1 point

-

I would like to share a check list made up by a master watchmaker. I take no credit for it, only think it would be helpful for us hobbyists. Here it is! CHECK LIST I decided to write up what is called a 16 point check that is meant to be a guide to steps required to service a watch this is slightly bias towards a wrist watch but very relevant to pocket watches also: This is a guide and not the definitive answer after going through it a few times add you own additional tests and observations. This is of course for a basic time only non-automatic or any with additional features, I also leave out things like demagnetizing, actual cleaning procedures, a good chunk of common sense needs to be applied also as I say its meant as a good starting point to a correct disciplined procedure, This is version 1 may add or edit/delete later. Check number 1 a Check the winding to see if the mainspring is broken. b Check to see if the setting bridge or sleeve is broken by pulling the stem out and testing the proper snap of stem. A broken setting bridge/sleeve is easily detected c. The balance wheel should be oscillated to see that it is true and the balance pivots should be checked by looking through the upper jewel to see that there is not a flash on the pivot. d. The hairspring should be checked to see that it is not damaged. e Check setting of hands f. The watch should be looked over in every respect, paying particular attention to any rust spots that may appear on any part of the movement. When rust is evident around the stem or setting mechanism, it is most important to remove the dial and hands in order to check this mechanism to see if the rust is very extensive. Check Number 2 a. Examine each part as it is being removed from the movement. b. Check for rust on every part. c. Check every pivot to see that it is not damaged or bent. d. Check the jewels in the watch, to see that there are no cracked jewels. e. Check pallet stones to see that they are not chipped or damaged. f. When removing barrel cap, make sure that it snaps off only after sufficient pressure has been applied to it. g. In the examination of each part, a close check is not made at this time as many of the parts will not be clean enough for that purpose. a much closer check will be made on the parts as each part is handled in the assembly of the watch Check Number 3 a. Upon completion of cleaning and parts removed from the basket into the assembly tray, each part should be checked over with the use of a watchmaker’s loupe special attention should be paid to the jewels, because if there is gum oil still remaining on the jewels, the cleaning job was not done satisfactory . It is also worthwhile at this time to examine the pivots. If the jewels are clean, and the pinion leaves are clean, it is almost certain that the cleaning operation was performed effectively. Check Number 4 a. Examine the condition of the mainspring. b. Check the width, strength and length of the mainspring. c.. If correct, replace mainspring using correct mainspring winding tool, not by hand d. Check the lubrication of the mainspring if required e. Check the fit of the mainspring around barrel arbor. f. check the mainspring end for proper shape to catch in barrel. g. Check the snap of the cap on barrel and replace in correct position h. Check the end shake and side shake of barrel arbor is it also sometime recommended to do this without mainspring fitted to test for free run and end shake i. Check the cleanliness of the barrel and barrel teeth. j. Check the oiling of the barrel arbor after the cap is on. k. Check the condition of the barrel teeth to see if they are bent or worn. Check Number 5 a. Jewel holes must be cleaned with peg wood if necessary. b. Jewels must be checked for chips or cracks. c. Check the train wheel pivots for rust, polish, cuts and straightness. d. Check the pinions for rust’, pits and polish. e. Check the pivots for pitting check that clean pith wood is being used. f. Check plates for tarnish, fingerprints, and polish jewel settings. g. Assemble time train and check end shake and side shake. h. Check wheels for trueness arid upright. i. Lift each wheel with tweezers to check for end shake and to see if each wheel is free enough to fall back to its original position. j. Spin train to see that is spins freely, in dial up, dial down and a vertical position. Check Number 6 a. Replace barrel and barrel bridge and check the oiling of the barrel arbor upper and lower bearing. b. Check oiling of crown wheel. c. Replace ratchet wheel. d. Note: do not oil remainder of movement until after kick-back is checked or cap jewels are present oil those now e. Wind watch slightly to check kick-back and recoil. This check should be made in dial up and dial down positions. If the watch does not have kick¬back, this indicates that the train is not as free as it should be. First, however, before checking into the train itself to determine if there is some frictional error, it would be worthwhile to examine the mainspring around the barrel arbor. Many times the loose fit of the mainspring around the arbor will prevent kick-back from occurring within the train. In such instances, the arbor is simply slipped in the mainspring instead of the train receiving the reversal torque, that normally occurs. If the barrel is found to be satisfactory, then the train. should be checked to see if the trouble can be located. first, the train should be examined carefully to see if each wheel is free, and if no trouble can be found, then it is advisable to remove the train wheels from the watch and replace each wheel in the watch individually and to check the spin of each wheel. If each wheel spins freely, this indicates that the pivots and the jewels are in good condition and that one need not look further for defects or faults in those areas. Next, place two wheels at a time in the watch and check the spin of the wheels. Thus, any error of improper depthing or a badly formed tooth on a wheel or pinion will be detected. It is simply a process of elimination in order to locate the particular trouble, and of course, proper corrective measures must be taken to correct an error when one is found. Check Number 7 a. Oil all the train jewels in the watch, and at this point it is advisable to oil also the balance jewels. b. Check to see that there is a ring of oil around each train pivot and that the jewels are not over-oiled or under-oiled. c. Check the jewels that have caps to see that the globule of oil has been formed properly between the flat cap and curved hole jewel and no keyhole shape if so remove re clean jewels and check seating the re oil and repeat check for perfect ring. Check Number 8 a. Oil stem properly. b. Oil friction parts of setting. c. Oil wolf teeth of clutch wheel and winding pinion. d. Oil clutch wheel groove. e. Oil points on setting lever that contact the setting bridge or the clutch lever. f. Never oil dial train. Note: ‘dial train means all wheels following center wheel staff. g. Seek expert advice on some types of intermediate wheels connecting clutch at setting positions that require oil. Check Number 9 a. Check condition of pallet arbor pivots. b. Check for chipped or loose stones, shellac or gummed oil on pallet stones. c. Check guard pin for straightness and proper shape. d. Check polish of pallet arbor, pivots and fork slot. e. Check end shake of pallet fork. f. Check height of pallet stones in conjunction with escape wheel teeth. g. Check matching stones. h Check drop lock i. Inside and outside drop. j. Draw. k. Hang-up of stones on escape wheel teeth. Check Number 10 a. Check tightness of roller jewel in roller table - uprightness of roller jewel. b. Check the height of the balance wheel in conjunction with the fork bridge and the center wheel. c. Check the clearances. d. Check the height of the guard pin in relation to safety roller. e. Check the proper length of roller jewel and fit of roller jewel to fork slot. f. Check the guard clearance. g. Check the corner clearance. h. Check the jewel pin shake. i. Check the guard test, j. Check the corner test. Check Number 11. a. Check the hairspring in-the-flat. b. Check the hairspring in-the-round. c. Check the quadrant of the hairspring to see that it is formed properly between the regulator pins and stud d. Check for beat of the watch by equalizing the force to receiving and discharge pallets. e. Check for the collet wobble. f. Check for trueness of the balance wheel, and for the flash of the balance pivots g. Check for trueness of roller table. Check Number 12 a. Place the watch on the timing machine and take a rate in the dial down position, then turn the movement over to dial up position and take a rate. There are three things that should be observed from the rate that was taken: 1. Dial up should indicate the same time as dial down. 2. Observe the closeness of the lines to determine if the watch is in perfect beat. 3. Observe how the watch is running in reference to the time error over a 24-hour period. b. Adjust the mean time rate of the watch so that the dial up and dial down positions will record on time. Do not move the regulator more than one degree in adjusting the mean time rate. Any other alteration must be made by adjusting mean time screws or by adding or removing weight from the balance wheel in such a manner as not to affect poise, static or dynamic,. c. If the rates in dial up arid dial down are found to be different from one another, then this indicates a mechanical error in the watch which must be traced out before proceeding. d. If the watch is found to be out-of-beat, then of course, it should be put r in proper beat at this time. We might emphasize that if the watch was put in proper beat in accordance with the proper procedure at the bench, then an out-of-beat condition or minimal amount would not be indicated on the timing machine. e. When the above conditions have been satisfied, the next step would be to take a rate in positions and errors corrected. If everything has proved to be satisfactory, the watch should be tested for isochronal test be made on the timing machine, which consists of re-testing at different winding levels and rate in the dial up position. Check Number 13 a. Check for proper lubrication of cannon pinion on center post. b. When replacing the cannon pinion, be sure that the leaves of the cannon pinion do not come down on top of the minute wheel teeth so as to bend the teeth of the minute wheel. c. Check tightness of. cannon pinion d. Check to see that cannon pinion does not ride up when watch is being set. and smooth consistent operation. Check Number 14 a Make sure that the hands are fitted securely to the parts to which they are attached b. Make sure that the hands are adjusted so that there is equal space between the hands and the hands are set as close to the dial as possible. c. Check to be sure that the hands are shaped to the contour of the dial. d. Check to see that\ the hands are positioned so that they are synchronized with one another. Check Number 15 a. If there is no case for the movement, simply disregard this check and proceed with the next check, number 16. b. Check for proper snap/screw back of the case. c. Check for the clearance of the hands under the crystal. d. Check the crystal to see that it is securely fitted into the case. e. Check to see that the crown is next to the stem and reasonably close to the case. f. Check for tightness of movement in case. g. Check the spring bars to see that proper spring bars are used for the particular type of case so that the band is held securely to the case. h. Check the lug holes to see that they have not been worn badly by the spring bars to a point where the hole may break through and allow the spring bar to come out of place. Check Number 16 a. Set the watch on time with a master clock. b. Let the watch run for a period of 24 hours and check the error in the time repeat in several positions. c. Allow the watch to run until it completely runs down and check the length of run. The watch should run a minimum of 30 hours, preferably 40 hours, if it is in “A. I have no answers to any of the steps since I didn't make this up. Maybe Mark might.1 point

-

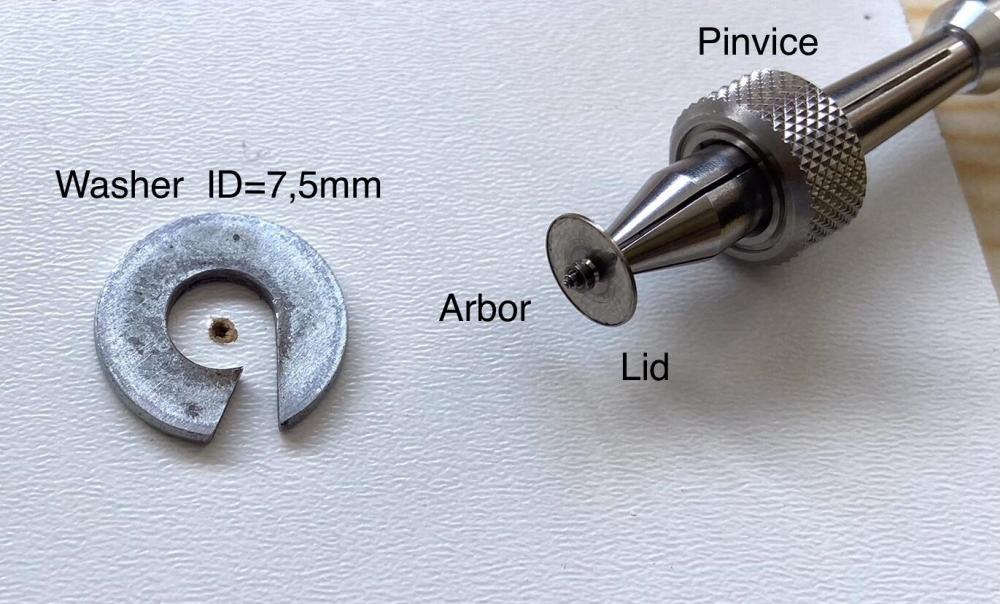

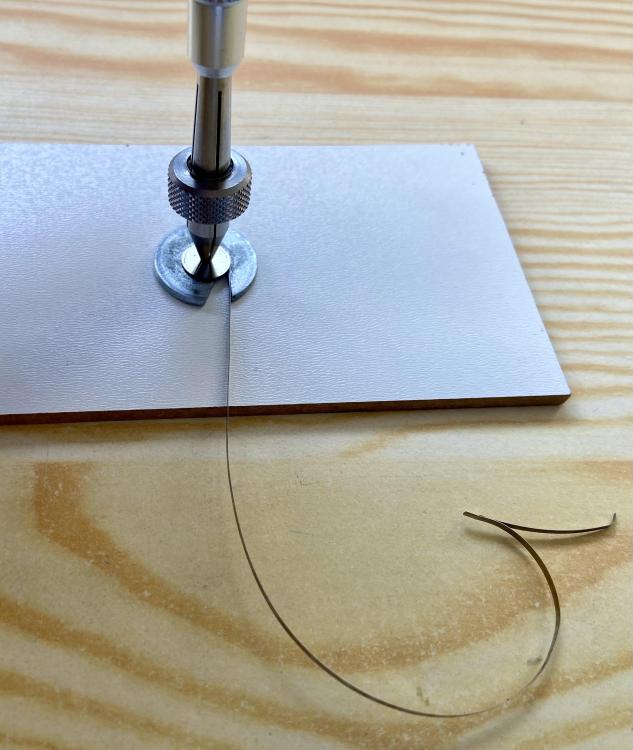

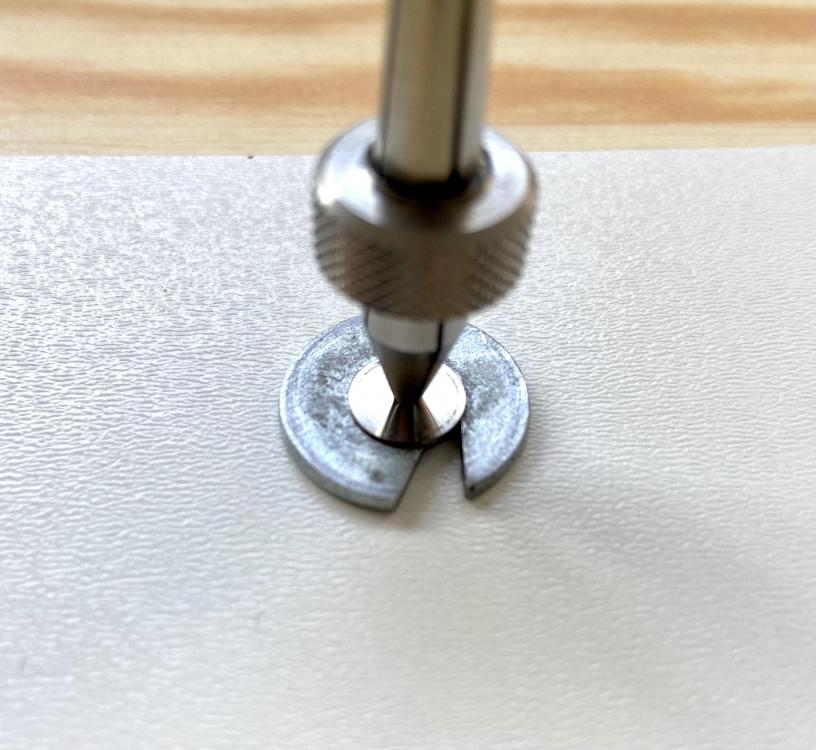

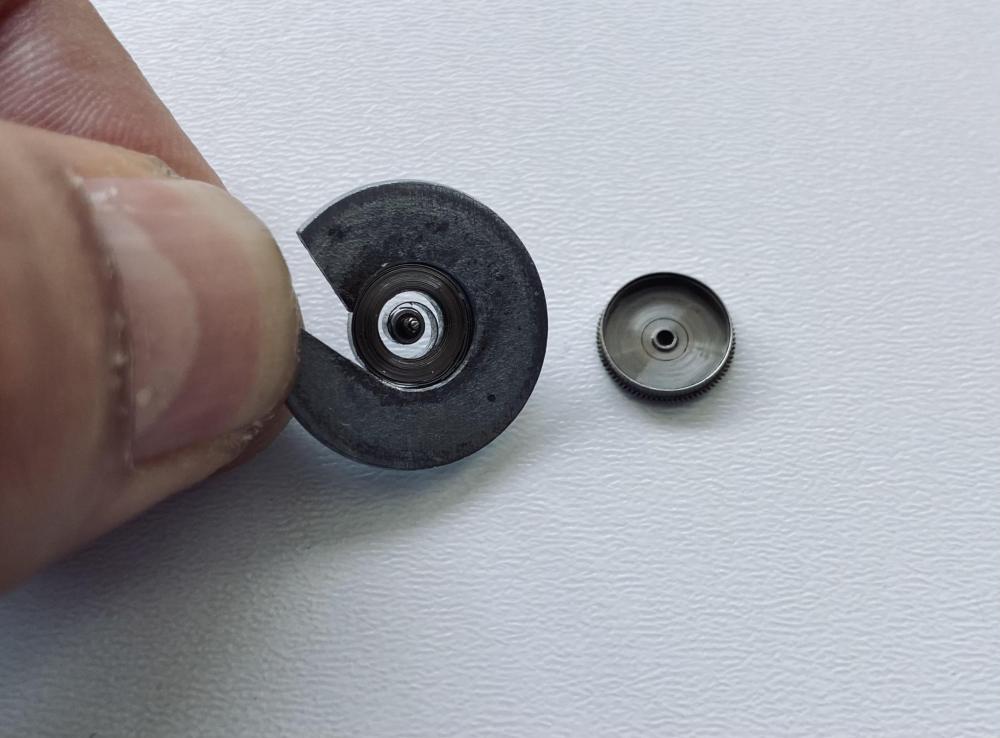

Inspired by the Mastercraft winder I tried to use its principle for a „quick and dirty“ mainspring winder. The spring I used for testing has an arbor diameter of 2,2mm (left wound) and the barrel has an ID of 8mm. The mainspring has a hight of 1,2mm. So I found a washer with the right thickness of 1,2mm, drilled it to 7,5mm ID and cut a slot in with my dremel. Then the washer was fixed to a board with three tiny drops of super glue. I used the original lid and arbor and my pin vice to complete the tool. The rest is selfexplaining looking at the pics. Any thoughts?1 point

-

Too much math. I would just make another stem on a lathe Sent from my GT-N5110 using Tapatalk1 point

-

I have replaced the crystal on my 1675. You have to remove the bezel first by getting a case knife in-between the case and bezel and lifting the bezel off. It should clip off fairly easily. There will be a very thin friction washer below the bezel, lift that off carefully. The bezel retaining ring then holds the crystal in place. To remove this you have to get a thin bladed knife in-between the case and the retaining ring and gradually working around the ring start to lift the ring. once the ring is removed you can simply remove the crystal. I had the movement in place when I put the new crystal in to centralise the cyclops over the date window. The bezel retaining ring is then pressed evenly over the crystal, friction ring place onto the retaining ring and then the bezel simply clicks back in place. Here is the assembly parts http://www.ebay.com/itm/RETAINING-RING-BEZEL-INSERT-ROLEX-OLDER-GMT-BLACK-1675-16750-/160812131467?pt=LH_DefaultDomain_0&hash=item257126648b1 point

-

I think the setup for these is similar to the 1680, which you can see about 1/3rd of the way down this page: http://www.watchwallpapers.com/sw.htm There's the retaining ring which is press-fitted over the crystal, then a spring washer which sits on top of the retaining ring, and finally the bezel snaps over the edge of the retaining ring. The washer acts to create friction, so that the bezel doesn't rotate by itself, by making contact between the retaining ring and bezel (via the small lip where they overlap). The bezel can be pressed down (against the force of the washer) to allow it to rotate. That's how it works to the best of my knowledge, but hopefully someone that has experience with them can confirm.1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)