Leaderboard

Popular Content

Showing content with the highest reputation on 03/07/25 in all areas

-

3 points

-

2 points

-

2 points

-

I must admit, this has got me beat. I have no likely explanation why these two screws will not release on a movement which is only 5 years old, in decent condition, with no signs of rust. Sorry to ask, but are you sure you are turning them the right way, i.e. anticlockwise? The only thing I can suggest is to strip as many of the other components as you can from the mainplate and then use a combination of penetrating oil, impacts and heat from a soldering iron to break down the bonding. Unless you are prepared to use it as a manual wind you have nothing to lose. The movement is only good for spares as it is.2 points

-

2 points

-

Looks like the balance wheel is bent and needs truing. May be rotating out of true is what You call 'dancing'? A video of balance rotating will help...2 points

-

I think Spencer Klein said that if you try to remove the rot there's just more hidden underneath. Nice thing about these dials is that the hour markers are stamped so there's no fear of breaking them off if removing lume. I just relumed a moisture damaged MM200 dial with similar construction.2 points

-

Hi there are organisations in America such as the AWCI and the NAWCC who like the British BHI will be able to point you in the right direction as regards finding the right people in your area who can restore your clock which will look superb once restored. If you contact either or both of these organisations I'm am sure they would be able to help.. Good luck in your endeavors and keep us posted on any progress as to how you get on. We remain interested. Cheers2 points

-

Thank you to everyone who has responded to my post I truly appreciate your help and guidance as I am clueless as most of you can tell. Everyone on this forum has been so kind I'm actually kind of shocked most forums are not like this. I live in Southern California if anyone knows of people that might be interested in helping me get this beautiful piece restored I would appreciate it. If not I just wanted to say thank you to everybody for your help comments and guidance hope everyone has an amazing rest of their week!2 points

-

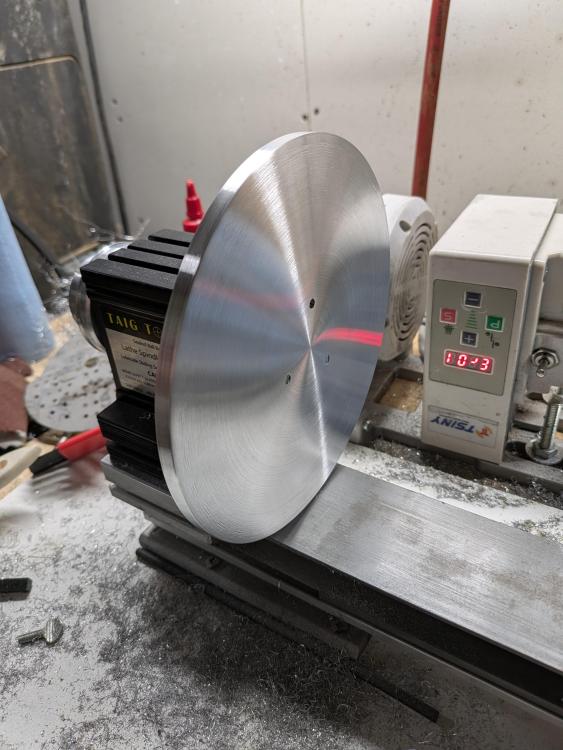

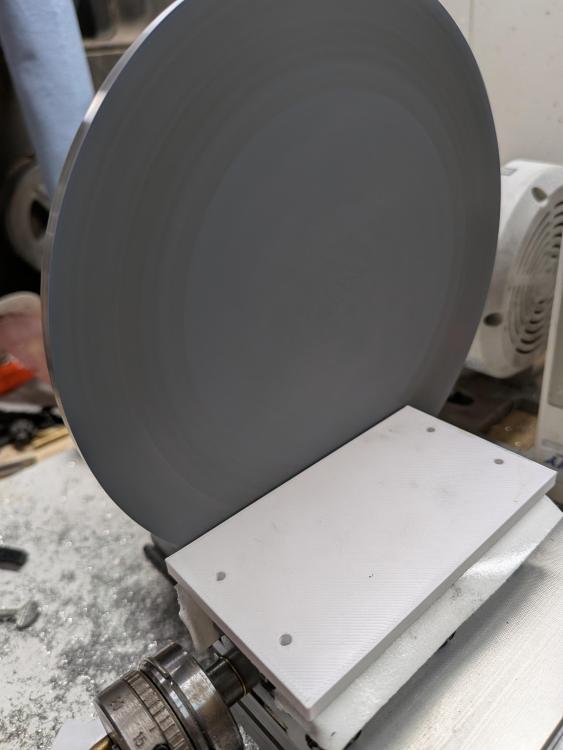

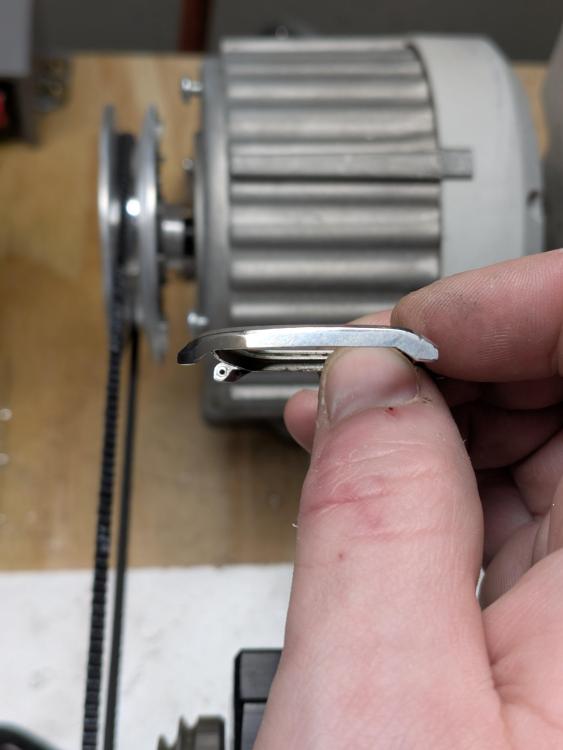

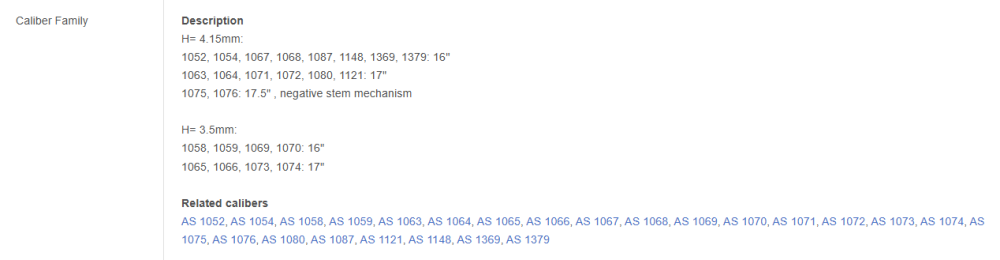

Hello all. As stated in other topics, I'm working on a lapping table setup, as I do a fair amount of restorations, and things are needing to get more precise. With my recent addition of an impulse micro welder, lapping is necessary. To start off, I have a few lathes, and the one I'll be using is my Taig Micro Lathe. I purchased it unassembled, as I wanted to modify it readily. I use a sewing machine motor to drive it, and it has a lot of adjustment on speed. In order to do this, you need this tailstock riser to use on the headstock, and this spindle mount to attach your Lapping Plate to. I ordered some 6 inch aluminum disks that are 1/4 in thick. After finding the center, I placed the spindle mount on the center, then drilled and tapped the holes. Then I used a vertical belt sander to reduce the OD of the disc enough to mount the piece on the lathe so it spins freely. Then I faced the part as best as I could(cross slide only has so much travel) and finished it off with 240 grit sandpaper. I attached some 2k grit sandpaper for now, but will be replacing it with lapping film. As for the table, I'm 90% done with the build, and should have it done this week. I'll add that to my post. The white plate below is just the base and is not centered on the headstock axis. The lapping vise as seen in some European restoration videos is extremely expensive. I have designed and made a fixed polishing device, similar to the one by horotec. I have designed and am prototyping a 2 axis vise for rotational bevels. My last design is going to be the 3 axis vise, but I'll get to that one later. Attached are some photos of the lapping plate for the lathe.1 point

-

The only explanation I can think of is when the original damage was done to the boss the bridge has twisted and that's what's jamming it. I think the problem is they don't have the knowledge or experience to risk digging into the movement further.1 point

-

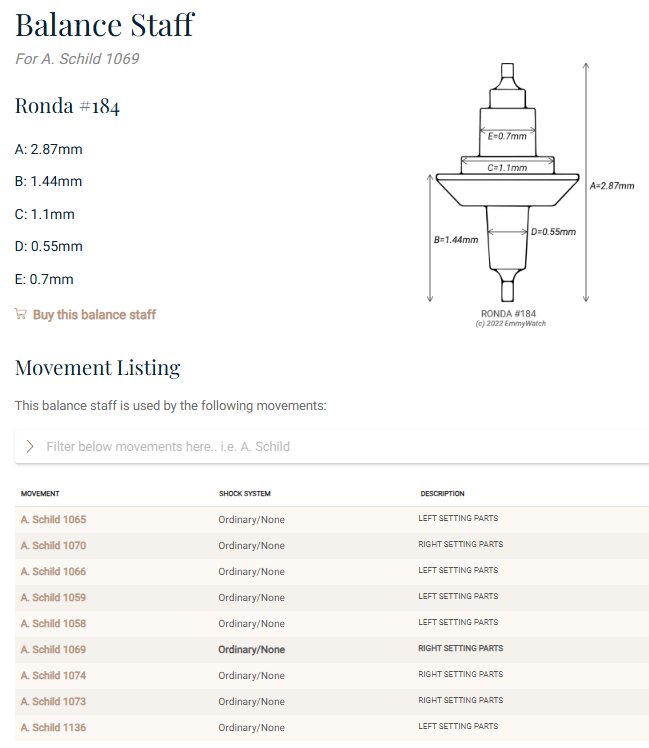

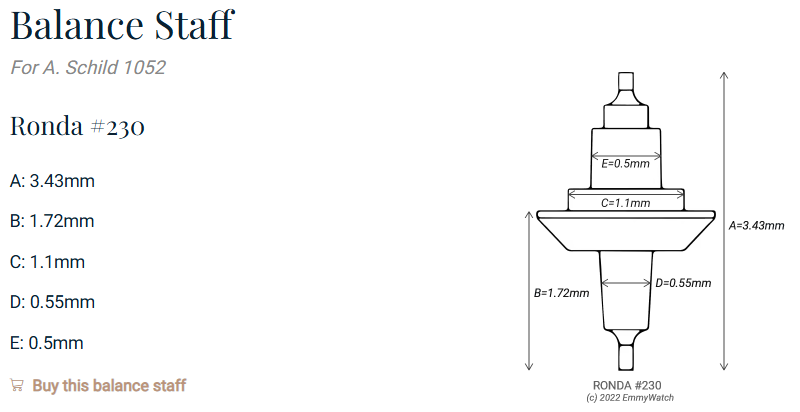

184 looks to be right. I got to play with my new staking set, successfully retrieved the old staff, and measuring with callipers came pretty close to those numbers. Cousins have them - it’s in the basket. Thanks all for your help.1 point

-

When I set hands I use a jeweling tool. Use the stumps and check the size against the canon pinion and hour wheel before placing the dial. It applies even pressure so the hands are installed parallel to the dial, and using a micrometer makes setting the depth very accurate. There's your 2-in-1 tool!1 point

-

1 point

-

Welcome to the forum. It's always best to start a new post and provide photos.1 point

-

Regular size seized screw require a lot more torque to snap, and like I said, you should be able to apply enough force to snap these with just a screwdriver.1 point

-

1 point

-

I mentioned removing the hands and dial as a last resort by giving you direct access to the setting lever. The screwdriver head should be the same width as the screw and sit in the slot so it touches the sides without bottoming out. You could try a stem extended but this would need to be secured with the movement in place. Also finding a generic crown wouldn't be a problem. Edit Can you post a photo of the movement back in the case as to me the stem looks long enough.1 point

-

In answer to your question. 1. Yes I'd expect you'd need to do a full service. 2. Don't think so, again without having to do a full service. 3. I wouldn't expect superglue to give you any more purchase on the screw than you've already got. Not sure if it's already been posted but what are you trying to achieve here? Edit Rightly or wrongly you should be able to apply enough force to this screw that would shear the head if it was so tight.1 point

-

1 point

-

I am screaming at the sky this morning. Somewhere else on this forum I think I mentioned acquiring the "stuff" of a deceased watchmaker. Incidentally, I have already sold three items (watches) that have recovered 80% of what I paid, so I am jazzed about that. Here is what is driving me nuts. I have about 300 pocket watches--almost all without cases. No doubt the movements were separated from their cases during the gold rush. While that pisses me off, it is not today's beef. Some numb nuts, thought of a great idea. He disassembled the watches and put them in cheep @ss plastic containers that do not fit together and secured them with rubber bands. Over the years, the rubber bands deteriorated and compromised the erstwhile sealed enclosure. Why not leave the movement intact? In addition, somebody thought it a wise idea to separate wheels into their respective function, irrespective of caliber and brand. Geez. Well, I discovered while restoring a Waltham that had a rusty hour wheel, there are other Walthams of different caliber with the same hour wheel. In addition, I found rachet wheels to be similar across calibers, so maybe these "assortments" will pay off down the road. Quien sabe. So, I have been going through these one at a time and carefully transferring the movements into truly sealed containers. After I complete this task, I am going to catalog everything, so I will know what I have. Some good news...there were some cases...20yr and some silveroid, etc. I have rebuilt two Waltham 16s PWs and they are running nicely. Anyway, I feel better now. Thanks for listening. Examples1 point

-

Oh come on Richard chip in after all I tried to teach you have you forgotten all ready.1 point

-

1 point

-

Hi. You have obviously removed the balance hence pictures. Powerdown the watch remove th3 balance and fork/ pallet re fit the balance and check its freedom of rotation, give it a blow with a the puffer, should oscillate for 25/30 seconds before stopping. If not investigate the balance jewels for dirt and cracks and the pivots for being straight. Even a slight bend can have a detrimental effect.1 point

-

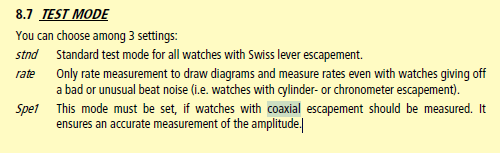

That is typical Witschi: make it mysterious, don‘t tell what exactly you will do (e.g. ‚rate‘). The coaxial esc. shows narrower gaps between pulses in the esc. noise, so the TM may have problems separating those pulses in standard mode - or may not, depending on electronics and software layout. True is, this will affect amplitude numbers only - not rate or the highly important beat error . Frank1 point

-

I should have been clearer, I know he's trying to loosen the set screw but do they know which is the correct screw.1 point

-

1 point

-

Welcome to the forum. Which screw are you trying to remove and do you have the equipment to remove and replace the hands if necessary.1 point

-

A lot of times one of the best ways to find thing is is to simplify your search and working works really well at least for Omega working instructions then I assume that you got number 54? Something helpful when you're working on these watches. I was just now looking at the Chinese timing machine manuals and it doesn't mentioned coaxial? I'm sure I've seen it in the advertisements when there selling the machine? The reason I ask is witschi machines typically have a setting for coaxial I wonder if that makes any difference at all? I know some of the newer machines actually do say coaxial this was snipped out of the watch expert two manual.1 point

-

Strange about the chrome it seems like it should build open a PDF? But I run into similar things as I'm using a browser called SeaMonkey? A lot of the websites I end up at have blank pages they don't recognize it. This means I have to switch to Firefox to look at things quite annoying. Then it's outstanding that you look at the watch in six positions but for official timekeeping positions typically it's only three. It's easier to have pleasant numbers if you're only pleasing three positions not five or six which typically would be chronometer grade watch. Then the other thing a try with your timing machine is to change the averaging number to something longer than whatever it defaults to. Typically with witschi the recommendation is 20 seconds but the Chinese in the witschi average the numbers slightly differently. But still it might smooth out some of the things a little bit as you're trying to really look for more of an average and not an absolute instantaneous because there can be quite a bit of variations watches do an outstanding job of averaging things over time1 point

-

OK, do the free oscillations test without the pallet fork in several vertical positions and compare the oscillations count. Of course, what is expected is to find there is no differences. Pivots wear will hardly cause differences in vertical positions. Stones practically will never wear, but if there is some defect, may cause such difference. You can rotate the whole stone settings in inkabloks and thus the difference will change position too.1 point

-

This is all still very good. Rates tend to spread a lot when amplitude is below 200 but these are still totally respectable numbers for an old watch of average quality.1 point

-

So I just did some more readings after 24 hours and for all 5 positions the average amplitude dropped from 241 to 211 so a drop of 30 degrees. The average rate across all positions fell from 1 s/d to -8 s/d For the crown positions average amplitude dropped from 233 to 198, a drop of 35. The average rate for the crown positions dropped quite a bit though from -4 s/d to -17s/d It seems that the amplitude drop is within what is to be expected albeit from a lowish starting point. I'll repeat this with a cleaned mainspring and maybe a new mainspring to get a feel for the difference changes to the spring can make.1 point

-

I just finished servicing one of these in a pogue. Definitely check the jewels, hairspring, and pivots. If it's not been serviced in awhile it probably needs it. Also can't hurt to demagnetize it.1 point

-

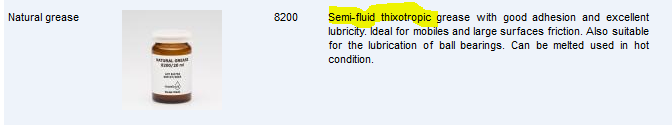

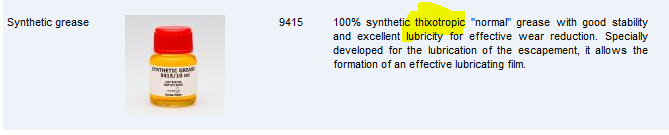

The problem here would be the word grease is a pretty broad term. If we go to the website of the lubrication you'll notice a interesting word which is very important for mainspring lubrication and strangely enough escapement lubrication Oh and I have a theory? Notice 9415 a synthetic and it is typically referenced in all technical documentation. But 8200 typically isn't reference in any modern documentation? Because in modern documentation we typically don't see the mainspring at all because were supposed to replace the entire mainspring barrel. So I think is the Swiss move on in new directions we don't get a synthetic lubrication for mainsprings because they don't lubricate their mainsprings the way we do including the breaking grease it's why we have things like P125 which is probably synthetic although I have no idea where that actually comes from which I find interesting? Then there's that word I highlighted thixotropic. As you can see a very interesting lubrication like in the case of 9415 stays in place on the pallet fork jewels until impact and/or sliding becomes extremely slippery. Or 8200 kind of a grease except when things are sliding again than it's basically a oil in a way. Another reason why it make for a very bad breaking grease because once it broke free it's now an extremely slippery oil like substance with zero breaking properties at all. Then what makes 8200 interesting is if you put a blob on top of the mainspring and go away eventually ill be gone because it's absorbed by capillary action into the mainspring so it really does stay in place. Oh by the way it doesn't entirely stay in place if you put too much mainspring grease in the barrel. Because when it becomes fluid conceivably it will leak out and make a big mess and I'll skip over how I understand that problem. Yes the interesting lessons we learn in life don't put too much of it on the mainspring. https://en.wikipedia.org/wiki/Thixotropy It's supposed to be a PDF. If you click on it it should open up in whatever he used to look at PDF files. Then the website doesn't have any central location for files as they tend to get scattered all over the message board and they get repeated all over the message board taking up lots of valuable message board space whereas we really should have a library someplace of all these files. I'm not sure that it's entirely guesswork of what's happening in their. Like for instance do we even need a mainspring barrel? Yes we need a mainspring but do we need a mainspring barrel? If you look at some of clocks you'll find that they have no mainspring barrel at all So you can actually can see what happens in between fully wound up tight and fully Let down the mainspring is just kind of floating of their. Then lubrication err on the side of caution I like that? I'm attaching another PDF and then I'm going to quote something? Then know it really isn't as simple as what I quoted below. We see the name of the mainspring company we find out that there is Teflon on their mainsprings lubricating isn't good for the Teflon. This would explain why Omega recommends just dry wiping the mainsprings if there mainspring indeed has Teflon? Because other problem here is over time various lubricants have been used for the pre-lube mainsprings. Omega at one time had some sort of liquid lubrication and their claim is that yes you can lubricate it doesn't hurt but then in later generations it's dry and don't lubricate it all and definitely don't clean at all. All the way up to the suggestion of the right form of steel itself is lubricating properties and doesn't need any lubrication. Oh and in some cases I suspect even using 8200 like quoted below sort of were somebody said it doesn't actually help I remember one particular incidents I think it actually made it worse because it was just sticky enough to interfere with the power off the mainspring. But that's only a speculation on one particular watch in one particular time and space. 2000-08-web-2 mainspring -1.pdf1 point

-

"Please allow me to introduce myself " Are you a man of wealth and taste? Welcome to the forum1 point

-

Doober on the side says she's in SoCal. Can't tell much about the movement from the photos, but the walnut case is going to need some top tier talent to get back to good condition. That appears to be a genuinely nice clock. Don't cheap out and take it to some hack, or it'll just be destroyed further. Advice about taking the case and movement to separate people is correct. Very different sets; skill, tool, TV, etc. You'll want to take it to a good clockmaker, who will remove and repair the movement. Then you'll take the case to a VERY good furniture restorer. Case will probably take more and longer than the movement. I have both of those skillsets (more on the woodworking side than clockmaking, to be fair), and with the figured walnut there, and I'm guessing a French polish finish (seems to have been fairly shiny, and would have been appropriate to the time and place), you don't want some hack just sanding it down and slapping on some Home Depot canned crap and gooping in wood filler. If the restorer doesn't have a glue pot (a little slow cooker looking device for keeping hide glue at the right temperature), and a huge stack of walnut lying around, it's probably the wrong restorer. Save every splinter; carefully fitting a shard is WAY easier and better looking than trying to grain match.1 point

-

1 point

-

ETA 2836-2 Disassembly walkthrough here ETA 2836-2 Assembly walkthrough here When I started out servicing watches (Vostok cal. 2414) I was desperately looking for easy to follow walkthroughs and tutorials. That was several years ago. I did find a walkthrough on WUS, and I did find the YT-videos of former car mechanic Dan, the “Ratfaced Git”, and although his approach was much that of a car mechanic, rather than that of a skilled watch repairer (he hardly knew the names of parts, didn’t care much, and was proud of it), it inspired me endlessly and gave me - at that time a complete mechanical idiot - the courage to try it myself. Without those videos I’m not sure my interest would have taken off. I know Dan struggled with many difficulties in his life including cancer, and it has been close to three years since he published anything on his YT-channel. Anyway, I hope you’re still with us “Ratfaced git” and I say thank you for the inspiration and dedicate this walkthrough to you. In ETA’s technical communication for calibre 2836-2 the assembly is made in seven steps in the following order: 1. Keyless works 2. Train of wheels 3. Mainspring barrel and bridge 4. Balance assembly 5. Self-winding mechanism 6. Dial train (/motion works) and the calendar works part 1 7. Dial train (/motion works) and the calendar works part 2 However, if you follow my assembly procedure, I put it together in a different order as I find it more convenient and wish to test the running of the watch as soon possible, that is, as soon as the train of wheels, barrel, and balance have been replaced. If at that point it’s not running well, I can more easily deal with it before continuing on with the assembly. Also, should problems arise at a later stage I’ll know it’s (very likely) not related to the train, barrel or balance. The downside, of course, is that the balance is exposed to potential damage for a longer period, although it can of course be removed. So, here are the steps of my assembly procedure: 1. Train of wheels 2. Mainspring barrel and bridge 3. Balance assembly 4. Keyless works 5. Dial train (/motion works) and the calendar works part 1 6. Dial train (/motion works) and the calendar works part 2 7. Self-winding mechanism Apart from the click spring and the pallet stones, the oiling suggestions follow ETA’s technical communication. Finally, I make walkthroughs for my personal use and enjoyment. They are not meant to be tutorials (for that I wholeheartedly recommend watchrepairlessons.com), but I like to share them in case there’s someone who would find them useful. So, without further ado…1 point

-

Sounds like the problem you get with dirt in the move ment wandering around, dry or dirty movement. Service required.1 point

-

Just looking on eBay there seems to some sort of unreported plague wiping out watchmakers around the world, with so many deceased watchmakers job lots being sold. Should we be worried0 points

.thumb.jpg.19a9c4ff164d78d516aa9f05a063752b.jpg)