Leaderboard

Popular Content

Showing content with the highest reputation on 03/11/25 in Posts

-

Also money. Start setting some aside because by the time these guys are done with you, you'll have a full machine shop and be manufacturing your own hairsprings.5 points

-

My time to shine I guess! So you might want to make a lapping setup to make sharp edges on your case. I have a few threads in my profile on what I built. I would machine the top surface to a decent finish. The lugs and side can be done on a belt sander with a high grit. Just go slowly. I should note, this is just for the prefinishing stage. Once you have the general case shape, youll want to start getting more accurate with your finishing. Low speeds and light hands. The 1625 has a brushed top surface, and polished sides, with a very slight polished bevel on the transition. The brushed surface is circular, so you'll need a way to rotate the case while you brush it, ideally on some sort of spindle. The polished side are easy to do, but youll need to brush the top first, then mask it off before you polish to get a sharper edge. Then you do the polished bevel. I've attached a photo as a reference. Don't mess up a turn-o-graph, they are one of my favorites!4 points

-

4 points

-

3 points

-

There is a 15 minute interview and workshop video with independent watchmaker Makihara Daizoh now available on the NHK website. He's sitting next to his lathe and there are clips of bridge engraving, pinion cutting and magnified running movemements. The primary watch discussed has the unique complication of an automata that makes two flower buds open in the daytime and close at night, which isn't everyone's cup of tea but he talks about the effects of gravity in different watch positions which made it difficult to come up with a design that works. He also uses engraved glass to make transparent or translucent dials. https://www3.nhk.or.jp/nhkworld/en/shows/2105199/2 points

-

Oh wow, I'm overwhelmed by the response. You are all correct, i should not attempt to repair these myself. I will visit a watchmaker to preserve the history of heirlooms. Also many thanks for sharing the links and downloads. Aamazing community!2 points

-

Conductive paint would just short everything broken together so don't think it would work. Yes a drop of flux and fresh solder on the iron and it should reflow OK but you need to be careful with the temperature so not to melt the plastic.2 points

-

2 points

-

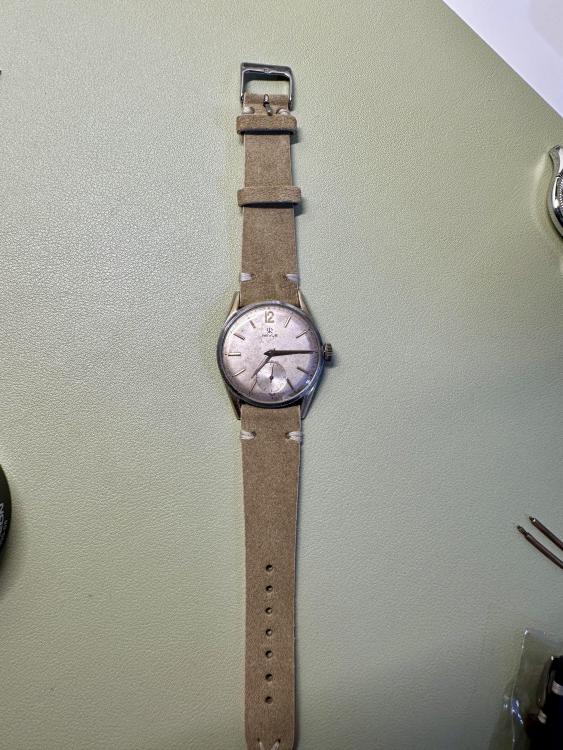

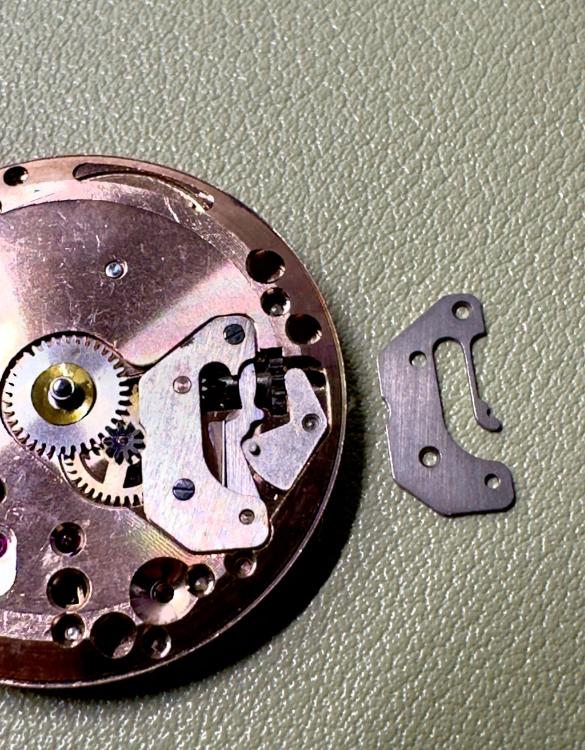

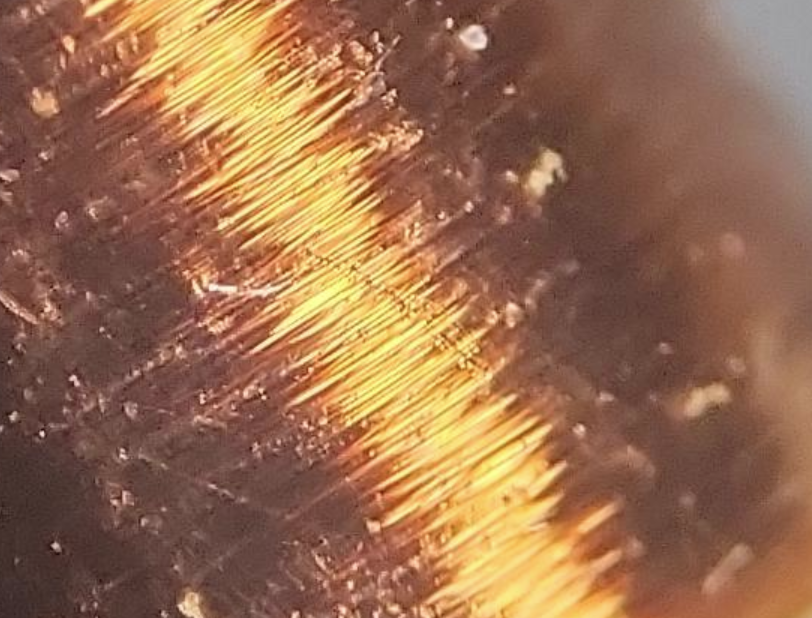

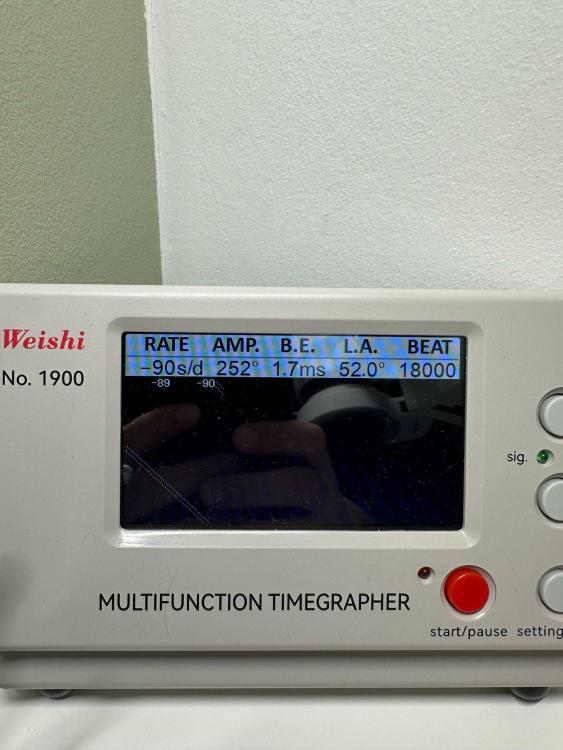

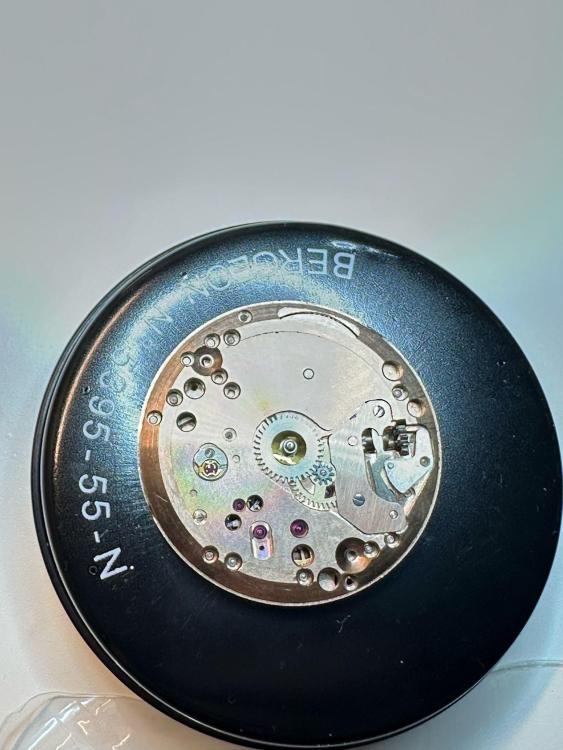

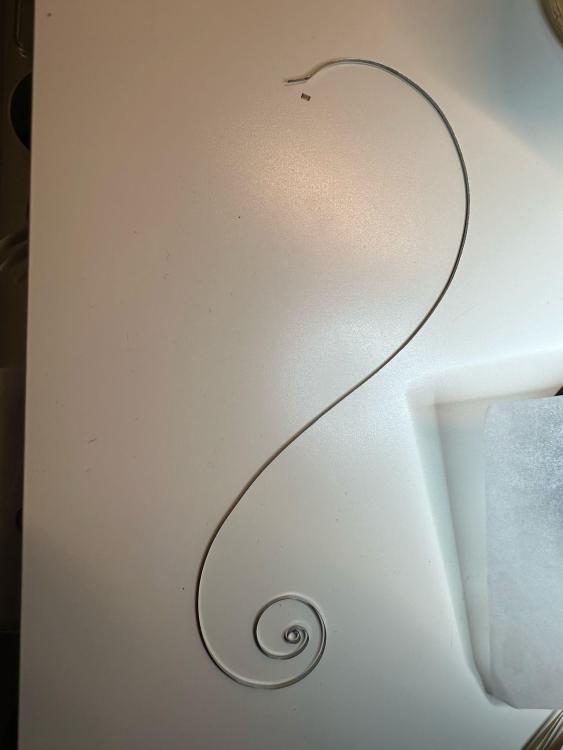

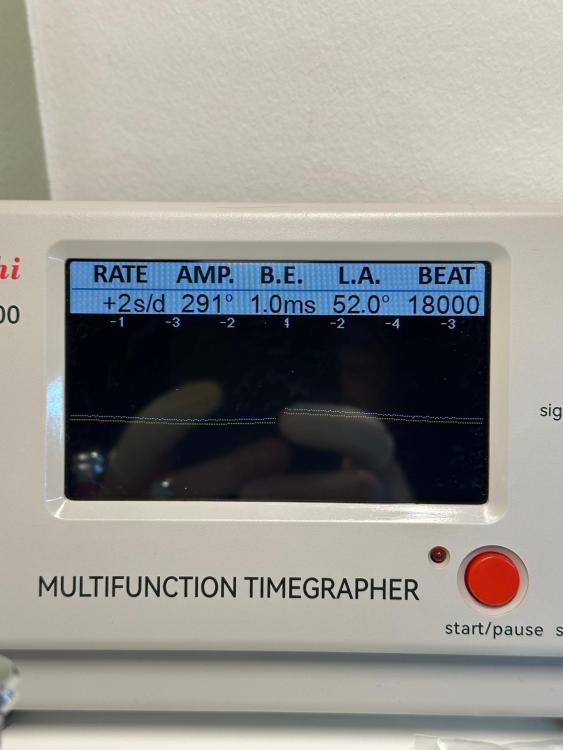

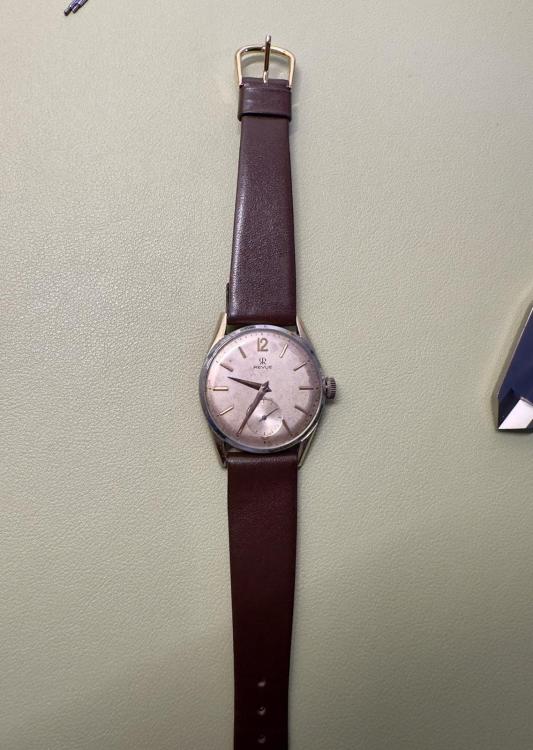

Finally, I’m creating this thread to share a very special watch that I recently serviced. Given that I only started learning this skill not long ago, I’m really proud of this milestone—especially since, over the past month, I’ve already serviced quite a few vintage watches as practice. I bought this Revue Cal. 81 (cca. 1945-1950) at an eBay auction for a great price (under €100), and honestly, considering the movement, the vintage aesthetic, and its history, it could easily be worth more. The seller advertised it as a WWII-era watch from 1940, but I have my doubts about that claim. Here are some before-and-after photos of the restoration process. I did some manual sanding and polished the case; while I’d love to have it chrome-plated at some point, this will do for now—perhaps in the future. I also replaced the crystal with a lower-profile one, brushed the hands, and swapped out the mainspring, which had a broken hook. Of course, I also fully disassembled, cleaned, and lubricated the movement. The beat error is not perfect, but I'll have to check again after 24h if it will improve, but overall I am pretty happy with the results considering it's age. Looking forward to hearing your thoughts!2 points

-

Eh, jacobs chucks are overrated IMO. They are faster, but less accurate than using a collet.2 points

-

I had a sweet set of step collets and a screw thread plate arrive yesterday, though I lost an auction on a jacobs chuck.2 points

-

Yes the jewel ihole is the correct way up for being non-capped. The next set lever bridge you can make rather than buy. I know what you mean Michael, but I've bought nice looking job lots of straps in the past and found that they break or delaminate at the lug fold.2 points

-

I have still never spent more than about $8 on a strap. I have to force myself to sink the money when I know I could get something passable but not great from Cousins or Aliexpress for a few dollars.2 points

-

I came across this article online. It gives a lot of background to Benjamin Harlow and the Harlow family who were originally from Derbyshire. Quite a long read but I've highlighted the section about him. Harlow-mvts-1(1).pdf2 points

-

1 point

-

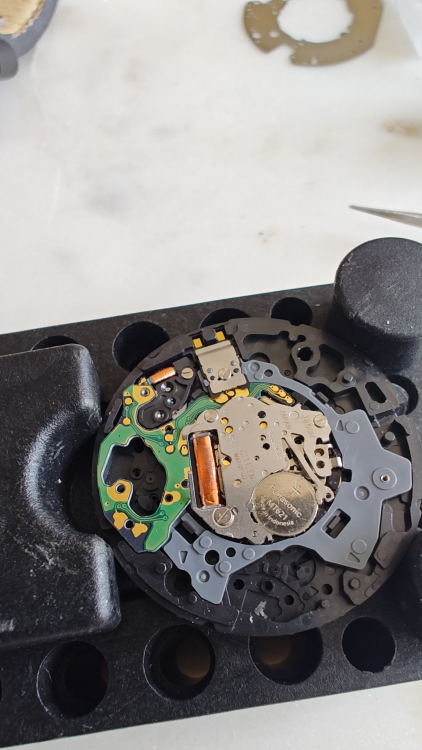

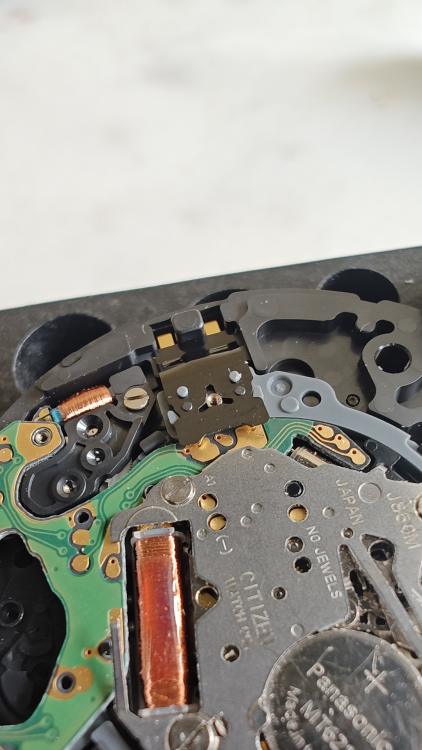

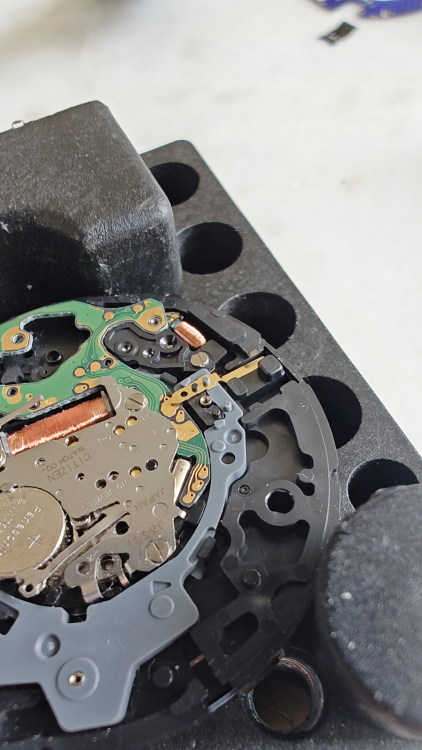

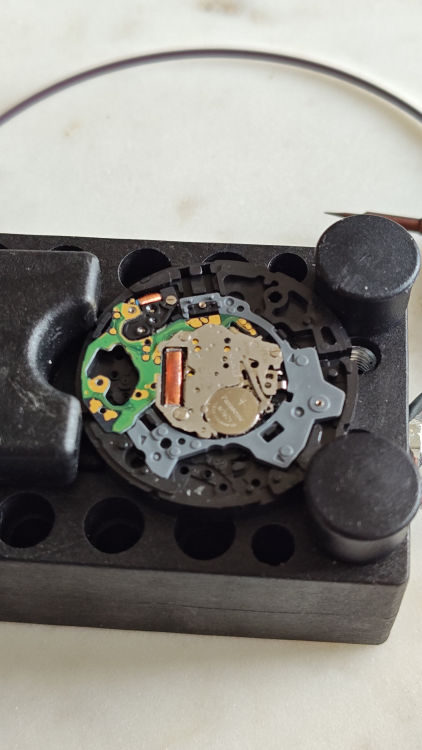

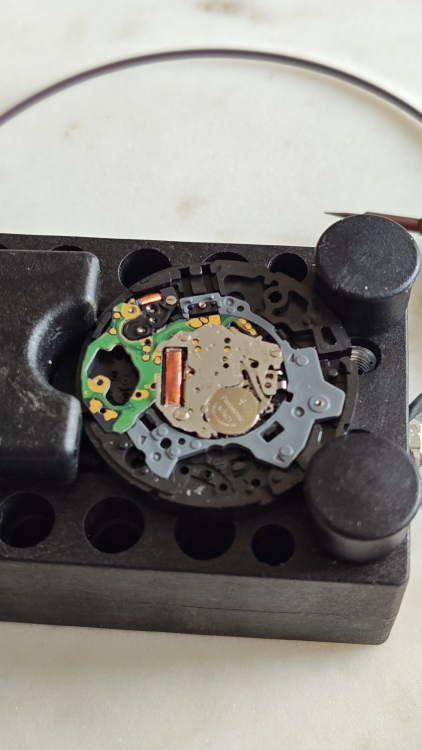

Out with a daughter that loves shopping at thrift and consignment shops I came across a Citizen PRT. I already have this exact watch and its one of my favorites. The watch was not running, the case scratched, and the nato had so much skin cheeseI didn't want to touch it. Brought it home and went to work on replacing the battery, which got it working. First pic is with a new strap. Notice the PRI is at zero, bezel scratches and cracked glass During the battery change I got curious and removed stem and movement as I wanted to see the solar cells and the workings of the movement. I thought they would be under the dial. Nope. Its a small solar strip that vertically lines the interior of the dial/movement. During my bout with curiosity, the solar strip/cell fell out. My attempts to easily reseat it failed. You'll see the strip in the first pic, then look for the purple on the side of the dial in the second pic. So off I went down the rabbit hole of fixing something I broke without knowing how to do it. First thing was to remove the silver plate at the top of the movement in pic. Under the holding plate was this piece that transfers power from solar to battery. That had to be removed. Next the gold colored bars were removed. These are the conductors of electricity and hold the solar strip in place. Then turn over the movement, place the solar strip in place. After that, reverse order on everything. At one point, using the tweezers, the plate screw went flying away to never be found. Had to sacrifice an old crap movement by taking a screw off and using on this movement. The first pic is after reassembly, the 2nd pic is after an hour in a window seal. May not replace the glass to keep some of its history in place. I'm taking to my watch guy to at least get a quote on new glass without cyclops.1 point

-

Typically for watch repair I was always using a purchased an extremely long time ago $20 digital volt meter. Technically if you're going get nitpicky about thing is if there is a semi conductor involved then the voltage out of the meter for measuring resistance has to be low enough not the cause the transistor and/or semi conductor to turn on which would give you false readings. Then the reason for current measurement I like an analog meter is I find it easier to see trends. Versus numbers that can be fluctuating and you may be not quite sure where exactly they're going. At one time although they come up on eBay both citizen and Seiko sold an inexpensive analog meter with a really nice low current range of 12 µA. Citizen soul that is part of a basically a kit which I'm attaching a article on. So I didn't worry about the bottom part I just like the meter which I still use to this day and mine says Seiko which is basically rebranded from somebody else. Is like Bulova made their meter test set for doing the tuning fork watches and it has a really nice big analog meter but as I might have mentioned before trying to find those anymore is nearly impossible which is why everyone's gone to digital. Then depending upon whether it's analog or digital you need a slightly different circuitry to smooth out the readings. Analog meter is quite simply is need a large capacitor and I don't quite remember what the digital meter needed. Citizen-Meter-CMT3002 quartz watch tester and power supply.pdf1 point

-

The guide pin you pictured - is that a movable banking pin? They were eccentric pins on a brass screw, found on American pocket watches. There's a chance if you got ahold of an early 18s plate from Elgin or Waltham that a banking screw might fit yours. Certainly no guarantee.1 point

-

Going back to the start. Where did you get it from and was it new? Have you done anything with the movement apart from fitting it? is it the correct case for the movement?1 point

-

wahoo! Success - well, maybe 87% success. Replaced lens, swapped out the quartz JS25 movement and swapped the 3 o'clock date wheel for a 6 o'clock. The 3 little hands went on easier than the seconds hand: I used a hand tool with a hole too large, and the seconds hand folded up inside it Ordered a new bracelet as the yellow is REALLY faded, but it wouldn't fit the existing curved ends, nor take the original MK clasp, but I'm not worried about that so much. Total outgoings £20, I don't care if I sell it for £161 point

-

Those accessories are building up nicely1 point

-

Oh come on Michael,it was just an iddy biddy lathe. You enjoyed restoring it , you know you did .1 point

-

Welcome to the group always nice to give pictures so we don't have to look up whatever it is you're talking about. Often times we've had experience with similar watches as we just need to see a picture of whatever it is you're talking about. The word disintegration In watch repair is not really a desirable word to use. We have to see how much disintegration you're talking about as to how much repair is going to be needed. Or the possibilities of just replacing a sizable part depending upon how much destruction were talking about. Or maybe the destruction is not as bad as you think we still need pictures to see what's going on.1 point

-

Hello and welcome to the forum. Plenty of knowledge to be tapped on here. TZIllustratedGlossary.pdf1 point

-

Rixy thanks for the doc, just a small part of the Longcase clock and how they developed over time. Outside of London the styles were a long way behind. That is one of the first things I learned when I became interested in the Longcase clock, there are so many books about Longcase clocks and makers you could spend a fortune on them1 point

-

Not sure if the .8382mm measured is correct as I'd have expected a 0.9mm stem.1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement. If there is anything we can help you with don’t be afraid to ask. Nice clear photos can help a lot.1 point

-

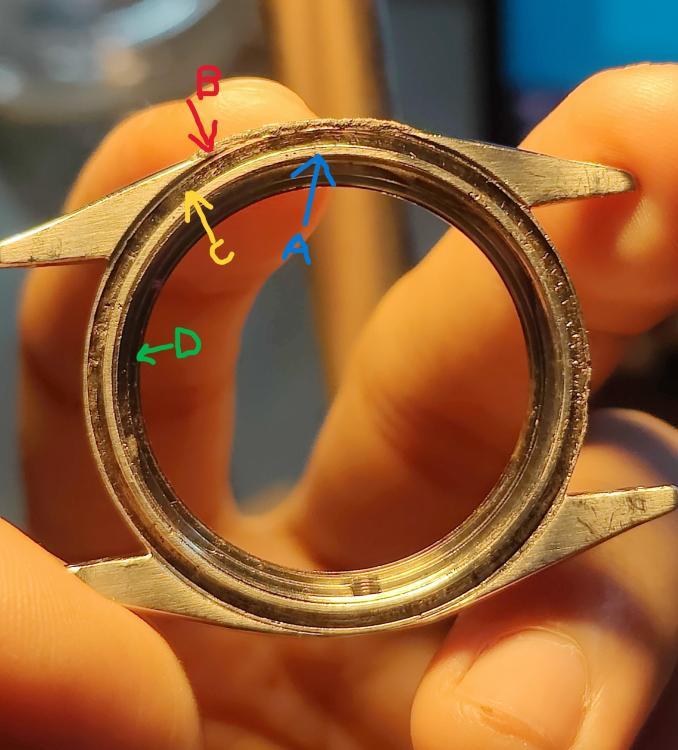

Update time: Diamond burrs on a lathe worked quite well for case back cleaning. Case back threading is turning out to be more difficult than I thought. A special tool will have to be made (Easy Part) and I will have to figure out a better lathe since the current option is old and requires several replacements to get tolerances right for finer work. On the bright side, I have figured out nitrogen welding and it has given me confidence that cutting threads on the weld will be possible. I am also addressing the mid case issues discussed Here The outer ring Marked B welded and machined. The area below the bezel was welded and machined 2 lugs and 1 side is being rebuilt. (Side is ambient air weld | Top lug is single layer (0.2mm) nitrogen weld on top of air weld | bottom lug is double layer nitrogen weld on filed air weld) The other 2 lugs and side will be rebuilt The crystal and retainer ring area will be further welded and machined. @caseback@Neverenoughwatches@RichardHarris123@AndyGSi@praezis@SwissSeiko@Knebo Thank you for participating in this thread, I would appreciate if you can link to some good resources in polishing and case reshaping, since i am having a bit of a difficult time with it.1 point

-

1 point

-

Sounds easy if you have the tools and the knowledge, which I don’t at this stage. As for the straps, I would be careful what to wear on the wrist, especially when you wear the watch for a lot of hours. Dust, sweat, in combination with a synthetic strap might cause some rashes no ? I either use stainless steel bracelet or some natural soft leather like Suede, which feels very comfortable especially on colder days. These straps were 45€ each, but because it’s Suede, the calf leather is around 35€ which in general can be less than 5% of the value of the watch A good watch that you love so much should deserve a quality strap I believe!1 point

-

One is an 8230, the other 8233 - the difference being a change of wording on the dial from sportsmatic/diashock to automatic/waterproof. '66 and '69 I think.1 point

-

1 point

-

I had an Optivisor but don't use them anymore for the same reasons you cited. I think the eyestrain is caused by off-centred optical axes. That is the same problem with dental loupes. If the optical axes are not lined up correctly with your eyes optical axes, you will feel the eyestrain. But adjusting the toe-in angle and optical heights of the loupes would void the warranty, that's why I waited 3 years until the warranty ran out before I started fiddling with them. I think some of us are just built differently. Some people can pick up someone else's loupes and use them with no problem. Some people can sit in a room with the speakers of the sound system out-of-phase and not get irritated. Some people can walk with sand in their sandals and are not bothered. Maybe it's some form of autism that hasn't been diagnosed yet. But for some of us, and I suspect many of us on this forum, cannot tolerate such things.1 point

-

Welcome! You will find this place to be far, far more knowledgeable than Reddit. Lots of experienced pros spend time sharing their knowledge here in much greater detail and are very welcoming to novices.1 point

-

1 point

-

1 point

-

In the 50s and 60s everybody jumped on the theme of space. This was either a microbrand that wanted a piece of the action or possibly a sub brand of a bigger company. Either way the movement is unsigned. One day some info might turn up that points towards a bigger brand, but for now it's just a "Space Liner" watch that ETA made the movement for.1 point

-

1 point

-

1 point

-

The cap stone plate here is not missing. The hole stone is put in a manner that the oil sink is faced outwards, so this for sure means the stone has flat side inwards, the EW is not meant for cap stone on this side.1 point

-

Unless it is wildly different in other positions from the one in your timegrapher photo, 1.0ms is just fine for a movement this age. You reach a point where perfecting it carries too much risk of hairspring damage and there is no shame in living with 1.0ms. Nice work, I love this dial.1 point

-

1 point

-

The one in my set was blunt so I put it in a cordless drill, and used a stone to sharpen it. Easy1 point

-

1 point

.thumb.jpg.8408ecc5772716d5f70d8692f2139c3b.jpg)

.thumb.jpg.9794ce72c4c73c9f12e4b6b802a76fe0.jpg)

.thumb.jpeg.91bc8750897e6ee7bb493946392ea24f.jpeg)

.thumb.jpeg.33b10cafbaad3acb10449a3b89bde86a.jpeg)

.thumb.jpeg.38edb939165d9667d42a6ac5dbb20fa1.jpeg)

.thumb.jpeg.b35beaf70272f2290d9860e3878d2d17.jpeg)

.thumb.jpg.19a9c4ff164d78d516aa9f05a063752b.jpg)

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)