Leaderboard

Popular Content

Showing content with the highest reputation on 03/12/25 in Posts

-

There is a 15 minute interview and workshop video with independent watchmaker Makihara Daizoh now available on the NHK website. He's sitting next to his lathe and there are clips of bridge engraving, pinion cutting and magnified running movemements. The primary watch discussed has the unique complication of an automata that makes two flower buds open in the daytime and close at night, which isn't everyone's cup of tea but he talks about the effects of gravity in different watch positions which made it difficult to come up with a design that works. He also uses engraved glass to make transparent or translucent dials. https://www3.nhk.or.jp/nhkworld/en/shows/2105199/4 points

-

Hi Guys. I have been on this forum for the past six years, and in my wanderings have never encountered another site like it . The closest is the watch site (mainly Seiko Citizen) but they don’t interact like this one where social chat is mixed with genuine help and documation . Most sites just point posters to links and leave you to get on with it . Here we follow up most questions and await an out come. A lot of feedback we get from out posters is welcome and to know that you have helped some one achieve a repair or supplied the documentation that has assisted in the successful completion of a repair is great and long may it continue. It’s the best site for free information and advice. By the way MODERATORS in the six years I have been posting none of my posts have the thumbs up logo attached. Just curious . Watch Repait Talk, best site for informal interaction and help. Keep it going Mark.4 points

-

Iam not conceited enough to like my own posts or consider my self above others, on this site the object is to disseminate information not look for Brownie points. And I hope we all agree on that. Thanks for the explanation Richard appreciated.3 points

-

Hello all, I thought I would start to make an effort to be somewhat more active in this forum. After my intro post and subsequent ask for help with some tricky lugs here https://www.watchrepairtalk.com/topic/29445-help-for-a-novice-fused-spring-bar/#comment-249241 I’ve been somewhat quiet. So, I’m going to give a summary of my first year as a beginner in watchmaking. I am very much a hobbyist; self-taught from YouTube tutorials, internet resources (this forum extensively) and a few simple books. In a year I have attempted: ST36 movement from Amazon to practise on. Stripped and rebuilt (no oiling yet) a couple of times. On 3rd rebuild an escapement pivot snapped. I begin to get the sense that I will love this hobby. Two pocket watches, a Smiths and an Ingersoll. Non runners. Full strip and clean on both, very simple oiling. The Ingersoll needed a new mainspring which I sourced and fitted. I accidentally (?!) put one of the dials through the wash adding some… patina. Amazingly, they both run, lovely loud ticking. I gift one of each to my daughters. They put them in drawers never to be seen again. A Sekonda DeLuxe with a Luch 2209. A few ticks only, stuck at full wind. Stripped, cleaned (in my early cack-handed way). It works but with weirdly varying amplitude. I think the hairspring is sticky/gunky and I don’t yet know how to clean them very well. I also lost the click spring (UK Space Program) and bent the seconds pinion. Abandoned. Hafis ‘Incabloc’, AS 984 movement. (Linked above). An early very proud moment. Was a near non-runner; would give a few ticks then stop. Stripped, cleaned (again, in an early fairly clunky manner), and oiled. And it runs! Losing up to around 15s per day, 310 amplitude, 0.1 BE… this was some serious beginner’s luck. A couple of problems; the crown is very worn down and difficult to grip to actually wind the watch. I tried to replace it with some basic parts, but no good. And I lost a screw for the keyless works portion, but this seemed not to affect any function, and the plate had 3 screw points, and seemed to function fine with just the 2. An old Tissot ladies watch, 709-1 movement. Runs fine, but I want to service it anyway. I discover I hate ladies watches with a passion. I break the incabloc spring. I get a donor movement, and… break an incabloc spring again. Sigh. It’s ok still got one spare… and then it flings off and away. I find it, try to seat it back in but it’s near impossible. ‘Set aside’ until I have the patience to look at this again. Seiko automatic, probably from the 70s or so, 7025 movement. Non runner. The automatic winder was loose, watch started up after screwing this in properly. Stripped and service. I donate a cap-jewel to the Space Program, and try to source another from a ‘lot’ of jewels from ebay. One seems to actually fit. Reasonable outcome keeping ok time, but amplitude a little low at 218. Mount Royal De-luxe, Felsa 4002 movement. Running but poor amplitude 180. Stripped and serviced. Wouldn’t run, escapement seized. Turns out I’d mixed the screws up and used a too-long screw on the dial side that was now poking through and touching the escapement. I managed to file it down in size and reseat it and everything working ok, amplitude 259, gaining 30s a day, but snow-storming in certain positions. Couldn’t figure out why and left it as is. Badman Swiss, FHF 72 movement. Non-runner. Full strip and service, not clear at all why wasn’t running. Despite doing everything ‘right’ it barely runs now and spontaneously stops. It is beyond my skillset to diagnose and I abandon it. Another Seiko automatic 6309-8060. Running, +74s per day amp 172. Very scratched mineral glass. I try to source a replacement glass, but it’s an odd profile, and of course not in production. Replacements exist, but expensive. I decide to try replacing with equivalent sized acrylic and… it works perfectly. Chuffed. Strip and service goes well (no lost parts! Nothing went flying!), now gaining 14s per day amplitude 232 (not brilliant but I’m chuffed), BE 0.1. And it looks stunning. New strap and I wear it regularly now. Favre-Leuba Seaking, FL 259 (almost certainly a Mumbai franken-watch, but the movement is genuine). Ticks for a few seconds then stops. Interesting double-barrelled movement. Some tinkerer has replaced one of the main springs with a tiny spring, so the two barrels outputting different power. I replace both and strip/service. Sadly, running very poorly with amplitude 149 after all that. Just can’t figure out why so little power getting to the balance. I suspect it’s to do with a weird intermediate wheel which is riveted in, between the barrels, and is oddly stiff. I can’t fix it despite lots of tinkering. Abandoned. Casio Oceanic OC-504, OS80 movement (quartz). Running, but very scratched mineral glass. I have a go at replacing with sapphire and it goes perfectly; very pleased with myself. I leave the movement well alone. Mondia Ladies watch FHF 57-21 movement. Trying to run, few ticks. God I hate ladies watches. Everything is so small and tightly packed. The work is frustrating. I finally get it together and oiled and… it runs only in certain positions, but snow-storm on the timegrapher. Some pivot is bent I suspect, but I am angry and I give up. No more ladies watches! Enicar Sport, AR (enicar) 190 movement. Likely from the 40s. This one hurt… really pretty little thing. Non runner, but everything looks intact and in good condition. Wheels are stuck with gunk so should clean up great. Mainspring is original and relatively set. Acrylic is original and yellow stained. This is the first watch I take cleaning very seriously; pre-cleaning, gentle brushing, pegging all jewels, slowly slowly. I get a brand new mainspring and glass, get to re-building it when disaster strikes. The balance slips out of my tweezers and the hairspring inexplicably twists on itself. I spend literal hours studying untangling techniques, and hunching over with a small oiler, unwinding, twisting, carefully now… and finally success, but now the spring is essentially bent to buggery in several places, out of round, and out of flat. I have not the skills or tools to fix, and there are no donor movements out there. Proper gutted! My pending project is Velona Automatic 1800, with an ETA 2783 movement. I’m looking forward to working on what seems to be a well regarded work-horse movement (for which donor parts should be readily available!). And that’s it! Happy to answer any questions or queries, and apologies if this was the wrong sub-forum. I’ll try to post my individual projects more regularly and start contributing more generally. Sam3 points

-

3 points

-

A couple of Facebook groups that I am a member of Andy inc. Mark's, but not as regularly as here , as our close knit group I have a lot of respect for and consider some as friends that I could confide in if necessary.3 points

-

I think it is bloody disgusting that he has never answered any of my massages and he never bothers with any of us. Us appointed Mods are left to hold the fort. It is out of our control if anything goes wrong with this forum. I wonder what would happen if us Mods just packed it in. I do not like being taken for granted.3 points

-

Hi Rich, The motor direction is switched by single relay. The power for the motor is not interrupted by the controller, it is directly delivered to the motor through relay contacts. The relay has only two states - on (forward) and off (reverse) This simply means no delay time. If You need delay, this means to use another relay (or may be transistor or generally some kind of controllable switch) to interrupt the motor power for the time of delay.3 points

-

It's not listed in the GR database, or on Cousins. Try either of those suggested by @AndyGSi. As long as it fits, the dimensions aren't as crucial as the mainspring2 points

-

I’m not sure what you mean by the changeover? Marshall has said on his videos that he has an agreement to sell Marks courses, nothing else was mentioned. Marshall is also a member here but hasn’t posted in a long time. Many popular and well known YouTubers have been or still are members here but rarely contribute. Tom2 points

-

Im going to to agree with Andy, the case is incorrect, and when you screw the crown in, it places too much force on the stem, causing it to spring to the side a bit, and then placing pressure on the motion works.2 points

-

Showed this piece some tender love and care. Bought it for 10$ off my local classifieds. Cleaned the date wheel from oil, cleaned the hands (unfortunately probably the previous owner messed with them and they were slightly bent, still didn't straightened them properly, maybe someone has a tip on how to do that in the future), cleaned the case and gave it a new acrylic crystal (unfortunately it came a bit scratched on the inside from aliexpress, but hardly noticeable). Now I'm looking to buy a strap as my 18mm ones don't fit, apparently the distance between the lugs is 17.6mm and I tried to squeeze it there, but just didn't fit, the springbar is also too big. Give me some suggestions on what kind of strap to go for? I was thinking a dark blue or brown silicone? Don't really see this as a dressier watch to go for leather. I also saw a milanese that comes in 17mm width. Thanks!2 points

-

Can you safely detach the balance complete from the cock? Thats to keep the balance away in case of accident. 1- I usually seperate the stud & regulator arm , clean every surface involved in moving them. 2- You can just put some oil on joints then keep moving the arms ro loosen rhem , clean in ultrasonic. Either case, balance must be separated for safety . Rgds2 points

-

2 points

-

Going back to the start. Where did you get it from and was it new? Have you done anything with the movement apart from fitting it? is it the correct case for the movement?2 points

-

Cheers N.E.W. yours a Richard’s explanation clears it all up. I am on the forum several times daily clocking what’s going on but not au fait on the nitty gritty. Thanks chaps.1 point

-

If you go to the Facebook group you can see when he was last visiting which was just a couple of days ago Did not check to see if he posted anything but at least he was there. Yes changeover seems ominous? If you look at the actual page and let me quote something from their it appears to be it's basically just a product as they're trying to promote all the products they can to promote hobbyists and watch repair https://sutcliffehansen.com/collections/watchfix-courses Yes there are other watch repair discussions out there but typically they just a tiny section of some bigger group. In other words like somebody mentioned there's a Rolex discussion group with a watch repair section. But if you're really curious you can go to your favorite search engine online and do a search and they pop up. Or you might even get a link like this that lists a bunch of them https://forums.feedspot.com/watch_repair_forums/ The problem is to find discussions in other groups can be challenging. Then we have groups on other platforms and some of those become even harder to find. War we have platforms like the group below it's a email-based group https://groups.io/g/horology-matters1 point

-

Does look great. It is so hard to find Timexes with bezels that haven't been totally worn away.1 point

-

Can you post some photos and details of the case you got. What movement ring are you using?1 point

-

1 point

-

Worked a lot in the past around Leeds/Bradford but probably 20 years now since I've been over their.1 point

-

I agree with you and Richard. by the way you have over 3800 reputation points which are basically the thumbs up people have given your posts. anyway, you have another 2 from us Tom1 point

-

So are there any other forums that people already use? I know I've looked at a few and never really got on with a lot of the members as they were more interested in how much they'd spent on their latest Rolex.1 point

-

I took the liberty of reaching out to Marshall and Alex through the contact form on https://sutcliffehansen.com asking if they know whether Mark is OK. Will update here if/when I get a response.1 point

-

Still, it is fair to wonder about that arrangement since the economics of selling one digital thing in two places are unusual (rather than some kind of referral program), unless it is part of a quiet "retirement." Which maybe it is, and that's valid.1 point

-

Hi. TM. COPY OF THE NH35 manual in case it’s of some use to you. 6810_Seiko NH3 Series Part Sheet.pdf1 point

-

If the dial doesn't meet the chapter ring yet the stem still aligns with the hole then it's not an NH38 case. As @watchweasol said the rotor should be smooth with no rattle.1 point

-

Hi. A too long stem when screwed in will cause undue pressure on the motion work and besides stopping the movement may also cause other as yet undisclosed damage . The auto rotor should be smooth in operation no extraneous noises, any grating is either the bearing post, bearing or it’s catching the plate look for scuff marks and check its parallel1 point

-

1 point

-

Cool watch, thanks! NHK World is really interesting as a channel; my wife is really into Sumo, so we watch the matches. Afterwords, there are often really nice sort of mini-documentaries on all kinds of things. Surprisingly detailed and in-depth. Last one was a 20 minute segment on a company that came up with hydraulic pile-drivers. It was fascinating, and I really appreciated that they took the time to really give the history and trajectory of the company. Who would have thought hydraulic pile-drivers were so interesting?!1 point

-

Here is my Marlin from 1971. I have the original luminous sweep second hand but grabbed a 25 from another watch and it did not quite want to fit on the pivot. Is kind of rough, but looks good on this Barton silicon elite that I probably paid more for than the watch! A little IPA and a swab got the black elapsed time ring numbers and hash marks cleaned up!1 point

-

Yes the guide pin looks like a banking pin. But I don't see what the problem is with this? Now the other problem here would be lack of standard parts between various companies. Especially in the age of 18 size where things varied between the companies themselves. So basically there's a heck of a lot of variation in 18 size watches and their parts1 point

-

They also have the Diafix prings if you look hard enough 'upper splint anti-shock spring'1 point

-

Aliexpress have bridge plates for the 46943 and some of them appear to include the diafix springs, only cheap in the region of £3.50 each. Search for 46943 upper clamp plate.1 point

-

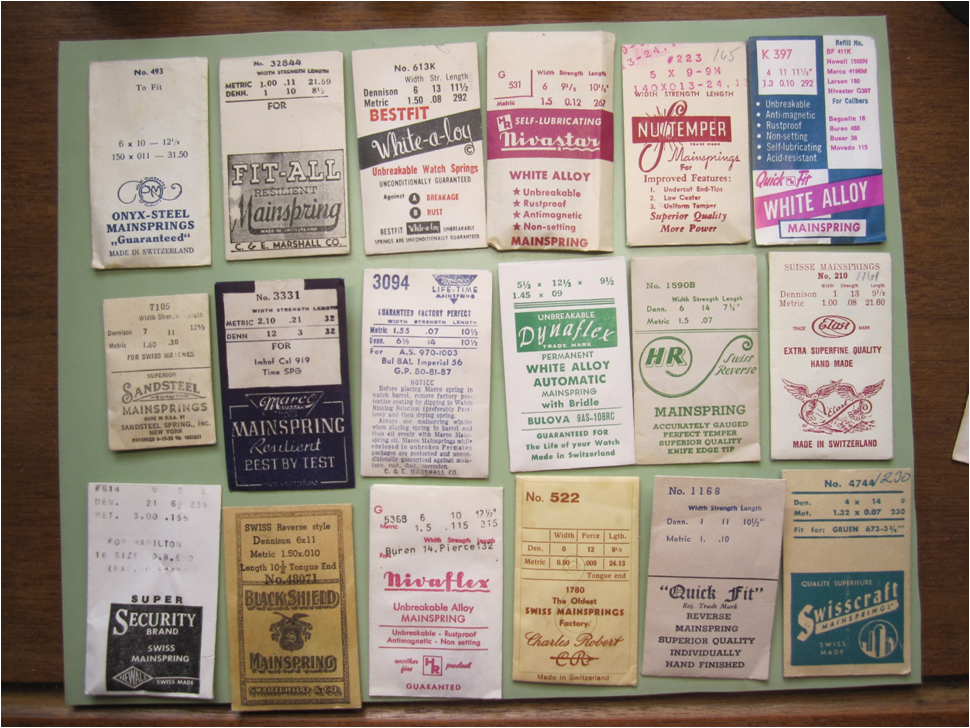

If you look at modern Swatch group servicing procedure they typically replace the entire barrel. his is why find it amusing that Omega has a working instruction on recycling a mainspring barrel. In other words taking it apart checking out the mainspring making sure it meets the requirements making sure the barrel and everything else basically making sure everything looks fine and then it tells you how to put it all back together again which for my understanding of people at Swatch group they never do this at all may just replace the entire barrel because they have a infinite supply of them. That of course if you look at newer documentation versus older documentation for the same caliber of watch the older documentation will often times list mainspring or the newer documentation does not. I'm attaching a PDF on how mainsprings are made. On PDF page 3 we get the quality and maintenance. In that particular section in the first paragraph it talks about the various qualities of spring is which is unfortunate problems for us in that it would only apply if we were purchasing directly from the factory. So for instance it indicates blue ring is better than red. One of the reasons or bring up the ring color is often times the mainsprings that I receive are not packaged in a GR package they been repackaged by someone who possibly purchased from them and other people. Previously I wasn't paying attention to the ring color I was paying attention to the quality of the mainspring when I pushed it out of the ring as to how nicely it does not typically look. So for a while now I've been noticing that some of the mainsprings and I can always tell because the spring steel itself is a yellowish color and the last couple of them came in a yellow ring. Then a lot of times the mainsprings get repackaged by whoever's the distributor is in the region so it's hard to tell exactly where mainsprings come from so the articles amusing in that we should always get a specific spring only works if we can actually order a specific spring Okay continuing on in that section on quality and maintenance the next two paragraphs talks about Teflon and the person who wrote the article experience of lubrication did not seem to matter at all or help at all? Which does bring up the problem of the Teflon is basically almost invisible except hinting of whitish powder. Depending upon where the mainspring was purchased from they may have other lubrication's including Omega at one time had a liquid lubrication and they did say yes you could use standard other lubrication's with without a problem here the indication is it didn't make an improvement at all? But we also have other companies that had other substances on their mainsprings Oh which would bring up the Omega working instruction where they recommend wiping with a soft cloth lint free no solvents. Except a lot of the mainsprings we would like to reuse have been prelubricated by others before us with sticky grease so in which case you would have to use a solvent and if there is some sort of magical dry lubrication or Teflon on the spring using a solvent wipe it off and then you will need a lubrication. Unless of course and there is a theory that some of the steels used don't actually need a lubrication at all. Then PDF page 4The at the it interesting problem of stress of mainsprings. Some more is at a lecture once where the comet made was that even using a decent mainspring winder because you have to wind it into a barrel relatively small and inserted into a watch that there is a time limit of how many times you can do that before he distort the spring. Plus of course it's generally frowned upon for hand winding Springs because that also has the possibility of distorting the spring and then it becomes cone shaped which is a problem or can become that's the fear. Then the word set? We really need to define what set means which is the mainspring loses its spring characteristic it become soft and visually looks set. But even this brings in a problem of looking set might not actually indicate that it's soft at all. Interesting your percentage is much higher than my percentage. because typically am working on vintage pocket watches. With typically all the mainsprings that are bad would be blued steel. Although I was working on a stopwatch last week with a nice shiny white steel and it was still set. But I would say the percentage of mainsprings that I change or light 90 some percent of them only occasionally do I find that the spring inside it is looking good And I can keep it in I think basically anything that is a mainspring whether it has a beautiful S-curve or doesn't have an S-curve at least one is brand-new conceivably will no longer function as a spring and can be set. Yes like everything else in watch repair it brings up all sorts of interesting problems with lots of variations. Like for instance if you had a whole bunch of pictures of mainsprings and envelopes what exactly did the envelope sitting on them? For instance the lecture I once gave an mainsprings this was the first image of the lecture. As you're looking at all as envelopes we notice things like unbreakable, self lubricating and of course unbreakable and anti-magnetic and non-setting. To basically any of the modern white spring is typically are saying guaranteed for life fever watch I wonder how we can make good on that warranty? Somewhere in the group they been discussed before the unfortunate problems the Chinese products are they can range from very good the very bad and you may or may not have any way of knowing which one you're going to get. But I do think there were some better Chinese mainspring winders out and. Then you just have to be vigilant as often times for instance Bergeon Up until relatively recent times they do make their tools when in the past and probably still do they purchased their tool. So the mainspring winder that costs well can be expensive brand-new occasionally has been sold under other brands because other dealers were selling the same sets and no I have no idea were usually made them. So yes occasionally will come up for sale on eBay they don't have that nifty name and they don't come in a yellow box and you'd have to recognize what they are but there are examples that they have come up. Or if you're in the right part of the universe may be could find a watchmaker going out of business and Make a lucky purchase of tools. Testing would become interesting? If you were going to overhaul a watch remove the mainspring popped the lid if it's a blued steel spring or if it's covered in's nasty sticky grease you can then do an experiment if it looks nice and clean you'll need another watch for the experiment but blued steel would be the best. Then it reassemble your mainspring barrel but the watch back together and see if you can test it? It's an ideal testing would be at least three positions on a timing machine following a procedure. Procedure would be a wind the watch up and let it run for 15 minutes minimum up to about an hour I'd be consistent with this. So if the watches running you can check it in the three positions record which you get then wait 24 hours because this is the more important part of the test can the mainspring and the existing condition of the watch even run 24 hours? Then you would service the entire watch not the mainspring barrel. Repeat the experiment the whole thing wound up timing 24 hours later with your bad mainspring bear. Once you've completed that now you can clean and loop the mainspring make sure you're really careful with cleaning because a lot of times lubrication's really sticky and nasty. I've noticed that occasionally even on mainsprings that I've reused that whatever they lubricate it can be quite sticky. Now you put in your nice clean mainspring lubricate repeat the test and get back to us with the results. The overall prevailing theory of a set mainspring in other words one that no longer a spring characteristics would be that the watch may not actually run the 24 hours. 2000-08-web-2 mainspring -1.pdf1 point

-

You're OK doing it naked as long as the spring doesn't come loose.1 point

-

I also wind mainsprings by hand. Finger cots are a nuisance - they get pinched. Doing it ‘naked’ is easier.1 point

-

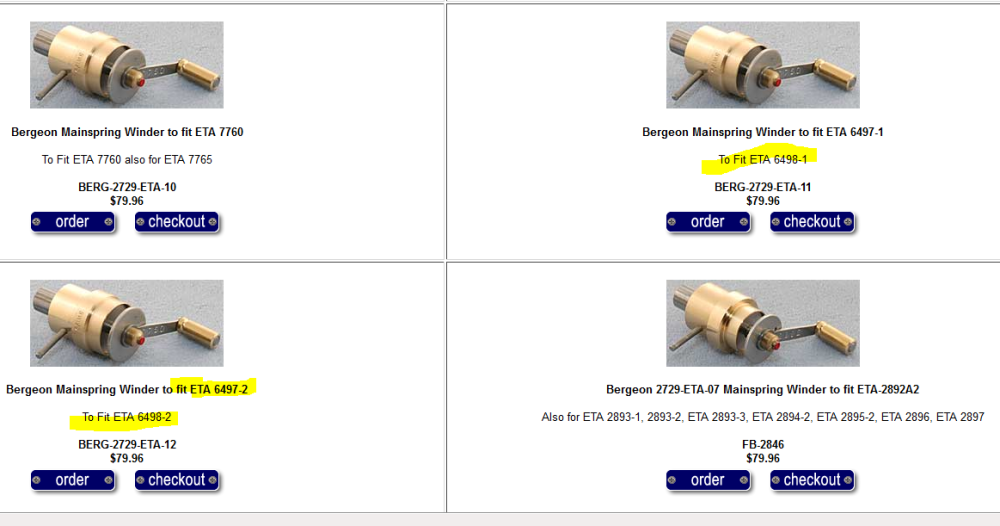

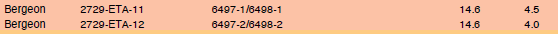

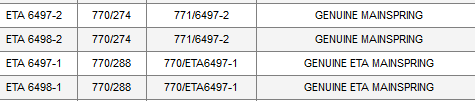

The problem is 6498 is not the same watch is a 6498 – 2. Then there's the problem of parts listing later generation ETA watches don't typically have mainsprings listed as you're supposed to replace the entire mainspring barrel. And often times the mainspring listing doesn't seem to show up anywhere. Although it looks like I'm wrong according the cousins they're exactly the same By we do end up with this weird problem if the mainsprings are exactly the same then why do we have to have two separate mainspring winders? Then someone was kind enough to make a nice PDF of mainspring winder sizes snipping out a image brings up the peculiar problem of the center part for the arbor is not the same size as the handles not the same size? I'm also attaching the PDF. Then the other thing is interesting is for mainspring looking at ETA because of course the Chinese don't list parts anywhere in the universe and we don't exactly know how exacting they clone things. In a case looking up the parts listings we find out that the barrels are different between the two types and the arbors are different and bestfit disagrees with cousins as to whether there even the same mainspring Unfortunate problem of best fit on line is you get part numbers you do not get specifications but the indication is the mainsprings a be different. HJ-Mainspring-Winders.pdf1 point

-

1 point

-

A replacement for an ETA 6498 will fit, but might not perform exactly as expected (I have been through this before with a ST36 spring in a genuine 6498). Differences in beat rate between the two will mean differences in spring thickness that need to be accounted for. If it is a 6498-2 spring, I think that 21600bph matches both. When winding it, the way you have it laid out on the table is correct. Starting from the tail, you have to wind against the spring's coil direction which is not the easiest to get started but you'll get the hang of it. I needs to end up in the barrel with the inner coil pointing left as you have it in your photo, so the whole S curve tail has to be wound backward from the position it wants to be in. Do not worry about hooking the hook onto the edge of the barrel as you had wind. You don't need to do that for a regular Swiss tongue mainspring end. Just wind it in and eventually when the watch movement is wound up that hook will slide around to catch where it needs to be and hold onto there. (this is different and easier from other mainspring types with a hole in the end or a T shaped end that have to land in place before the lid can even be closed). As you wind it in, there is a good chance the spring will make its way around the edge to catch the hook anyway. I hand wind springs frequently and can tell you I have never once worried about this. Plan on the spring jumping out of the barrel at least once or twice as you get the hang of winding it in by hand. When it does, the barrel can fly a long way away so be prepared to search for it.1 point

-

Is the stem parallel with the movement as I'd expect this to cause problems when screwed down rather then it being too short.1 point

-

I almost asked you in another thread yesterday OH if you had heard from Mark. Something seems quite wrong, tbh I wouldn't be surprised if the forum went pop in the very near future. I honestly think we need to start making provisions for it. @tomh207 Tom what you thinking matey ? I think it seems fair to discuss it openly now , considering the circumstances and the feedback from OH.0 points