Leaderboard

Popular Content

Showing content with the highest reputation on 03/13/25 in all areas

-

Read the room people...... Mark is not talking to moderators, and not even commenting on discussions like this one - it has his name on it - no excuses. I agree with @Neverenoughwatches that it is only a matter of time before this site just stops. If Mark lacks the motivation to visit and interact with the site, why would he be motivated to keep paying the bills? There are several options to set up discussion boards for little or no money that would closely match this one and I played with this a while ago as a 'proof of concept', but there was little interest from the group in looking into this, actually this is an understatement - people were actually hostile to the concept, even sharing a common email list was deemed to be an act of treason, so I stopped working on it. I could look again, but only if there was genuine interest from the members and I wasn't outcast as some sort of heroic.5 points

-

I'm struggling to understand why you keep testing it with the crown not screwed in? I think it has been established that the stem/crown are the issue, unless I glossed over this thread to quickly.3 points

-

I don’t think we should be looking at creating a competing/replacement site at the moment. I, as many of you, have concerns if this site goes away for whatever reason. I would propose that we have an alternative way to keep in touch that doesn’t replace this site but would rather allow us all to keep in touch and decide what would be an action to move forward with if the worst happens if we lose this place. As Rich, @Neverenoughwatches has said we have built relationships here and are a welcoming and inclusive community. so, definitely not a replacement for this site as it can’t and doesn’t work the same way, I have created a discord server so we can keep in touch without the security issues of an email list or anything like that. if you’re interested in that idea as a backup to the great community we have here then let me know and I will publish an invitation link. i have to reiterate, this is not a split from here but a backup in case we lose this site due to circumstances beyond our control. Tom2 points

-

2 points

-

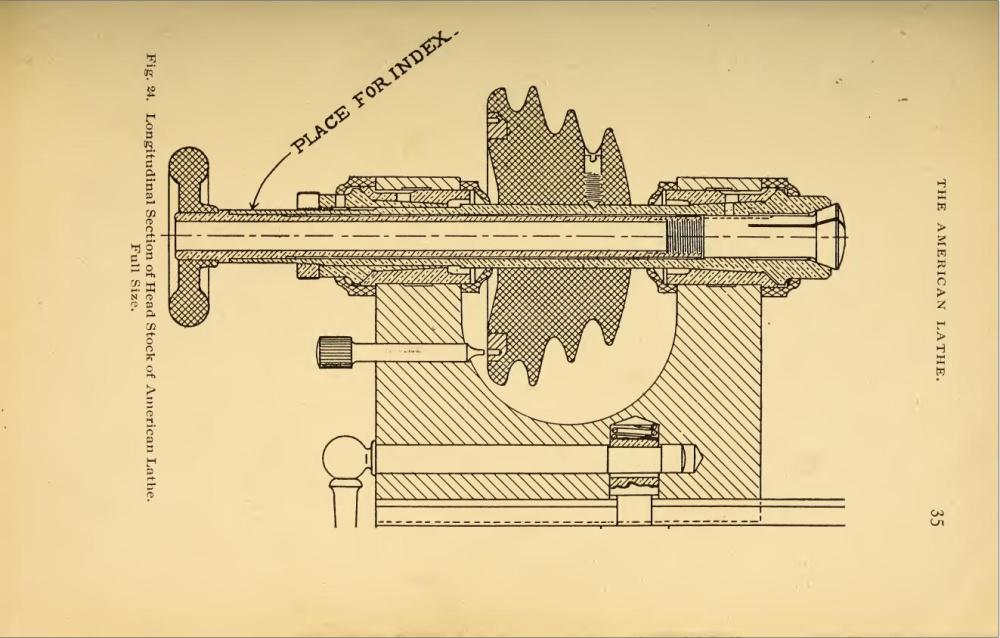

It should turn quite easily and completely smoothly - though if it's the normal taper & angle bush setup, I'd not expect it spin freely more than 1/4 turn to a turn after you give it a flick; if it does that implies something too loose to me. Ballrace bearing spindles can keep spinning after a flick, as they don't have the large metal to metal surfaces the taper bush style do. If it's tight or gritty, in needs dismantling and cleaning. Don't try to remove the outer bushes from the headstock frame, though, they are pressed in and the alignment is critical.2 points

-

I don't think I could have worded it better myself Scott. Maybe there is a reason for Mark's disinterest in the forum, maybe he does have other issues to deal with in his personal life, maybe he doesn't even know what goes on here. But if he doesn't visit he wont know, I seem to remember Tom left word for someone in his Facebook group to contact him. I'm quite happy to message Mark's profile , no skin off my nose, I feel quite confident he considers me as a troublemaker anyway after last time. When I think I upset folk I like to know why that is, so I ask. Anyone else can make that same move to discover why they are unpopular with a particular person or persons, but they have to care enough to ask why. Someone just ask and I will message Mark, It honestly doesn't bother me, if you wanna know you wanna know, besides I can't say I have a great deal of trust now, and felt fobbed off with no assurances last time we had a reply from him. I would hate to lose contact here and with many of the members, and such a shame lf all the information stored here was lost. What will be will be.2 points

-

I have a small set of winders I bought from ebay. Keep a watch for them, you don't need a big set. The GR database is useful for looking up mainspring sizes : GR Mainsprings.pdf And here is a spreadsheet I copied for calculating spring size. (I cannot attach xls files, so download and change the extension to "xlsx")MainspringCalculator .pdf2 points

-

My first thought was too much lubrication. Too much 9415 on the pallet stones? Maybe. I suggest you test your theory by cleaning it off and running the tests with nothing on the stones.2 points

-

2 points

-

1 point

-

Every one I've seen has the nut on the back; possibly under a friction fit cover. The spindle comes out the front once the nut and pulley are released. That nut is also the main adjustment for the bearings. The biggest problem I've had trying to dismantle spindles is getting the locking screw out of the pulley! I have two that I cannot (so far) remove the screws from. Both are paxolin type pulleys. ps. Can you provide the make, and/or photos?? According to the Castrol data sheet, that's hydraulic oil?? pps. For info, a significant percentage of drive system problems on the large machines I generally work with are caused by lubrication problems, varying from wrong types of oil to plain lack of oil or oil leaking faster than it put in, so I have learned quite a bit about different types of lubricants over the years. One of the commonest problems is places using gear or hydraulic oil in place of slideway oil - or suppliers recyling oil and selling it as slideway, though it's not got the additives needed!1 point

-

OK, 20 min. is much beyond normal. I don't suppose the balance is so heavy, simply no way. It must be some kind of energy loss which is provoked by position change and slowly disappears when in rest. Such thing may be guard pin touching the safety roller due lack of draw in the escapement. Is the draw present and reliable on both sides? Another thought - the drop lock can be minimal /unreliable. I expect to it be some kind of escapement problem. In case it is not the escapement, can You do something like the free oscillations test, but to change the movement position while balance running and see if sudden drop of amplitude happens? It is normal to have some amplitude drop as there is gyroscopic effect that leads to forces that increase friction in balance bearings, but do it with another similar normal movement to have some idea what is expected and normal. Did You check if the balance axial free play is normal as @nickelsilver suggested?1 point

-

I don’t necessarily think the following is the cause of the problem, but it came to mind when I read what you wrote. It took me a long time to figure out how difficult it can be to detect pits in cap jewels—something I overlook far too often. If the pits are shallow, they can be very hard to spot. Nowadays, I always examine cap jewels under my stereo microscope at 40x magnification, angling them so that light reflects off the flat surface in the same way one creates a sunbeam reflection.1 point

-

1 point

-

Decent rate doesn't neccessarily mean the right spring and balance wheel match. You can practically get exact beat/rate out of any spring and balance wheel. Other parameters such as acceptable dynamic stability come to the picture with a watch wrist specially, and if real bad match, heavy balance wheel will take many impulse to reach max amp on bench, as its an inertial body. But then what do I know? Richard Harris knows I know nothing, but keeps it secret.1 point

-

1 point

-

I have left a message tagged to Mark on the Facebook group asking him to contact Old Hippy here. I don’t have anyway to contact him directly there, only through this site. Tom1 point

-

I admit I was one that was not into setting up something new by leaving this site. I have changed my mind and I will except what needs to be done. I would just like to add I would like it to include clocks. How we have been left like this I think it is disgusting. Mark don't you have the guts to tell us what is going on.1 point

-

What I find so interesting here is that the moderators have zero method to talk to Mark other than leaving a message on the group? Then he appears to be visiting the Facebook discussion group has anyone tried to leave him a message there?1 point

-

1 point

-

Also there was a "sister thread" with deeper info on headstock refurbishing1 point

-

Yep, 0W?? or 10W?? (20/30/40) should be fine1 point

-

There is a 15 minute interview and workshop video with independent watchmaker Makihara Daizoh now available on the NHK website. He's sitting next to his lathe and there are clips of bridge engraving, pinion cutting and magnified running movemements. The primary watch discussed has the unique complication of an automata that makes two flower buds open in the daytime and close at night, which isn't everyone's cup of tea but he talks about the effects of gravity in different watch positions which made it difficult to come up with a design that works. He also uses engraved glass to make transparent or translucent dials. https://www3.nhk.or.jp/nhkworld/en/shows/2105199/1 point

-

I'd go with engine oil, preferably synthetic but normal is OK. Oil grade is pretty much down to the size of the parts and the forces involved. The spindle is quite big and can be subject to quite high forces while cutting. The spindle bearings need small quantities of oil fairly regularly to prevent friction and wear. The next most important are any leadscrews - move whatever part one way, apply a trace of oil to the screw and immediately move the part back so the nut is over the oil. Every point where two parts slide against each other in use should have at least a trace of lubrication; also any bare iron or steel parts need something to prevent corrosion. Anything with working movement involving precision pre-loaded (V or dovetail style etc.) slideways such as a compound slide must have regular lubrication on the slides as well as the leadscrew nut. Only tiny amounts, but they should never run dry, else they will start sticking and / or wear, losing accuracy. Just apply a minuscule drop against the moving part on each friction surface, then move the slide over it so capillary action can distribute it within the parts. Any surface that has curling or frosting (small scrape marks spread over it) is explicitly intended to have an oil film. The scraped points act as tiny well and stop the oil being pushed away, so it can be carried between the two surfaces. To do the oiling, I'd suggest you get some disposable syringes and luer lock blunt tip applicator needles, similar to this type of thing - there are many types and packs available: https://www.ebay.co.uk/itm/135015500545 https://www.ebay.co.uk/itm/365256781089 They are brilliant for controlled oil application or applying glues etc. Half fill with oil, and pull the plunger back slightly to drain the needle after use. (And store needle upwards to prevent drips).1 point

-

Before you loctite the stem can you post a photo showing how it sits in the tube.1 point

-

How much endshake does the balance have? I have a feeling it's too much.1 point

-

I'm willing to bet they would, this forum is a strong community full of like minded guys that all get on like a house on fire.1 point

-

1 point

-

Hi there, I recently moved to Manchester, but my tools are still in transit, so sitting on my hands. Let us know if there is anything we can help with. I would echo what @AndyGSi says and practice for a while before you go at anything of value, or there could be tears before bedtime1 point

-

Welcome to the forum from another Mancunian. You may want to practice with other mechanicals before you start on anything with sentimental value. No such thing as a stupid question, if you don't know then ask.1 point

-

1 point

-

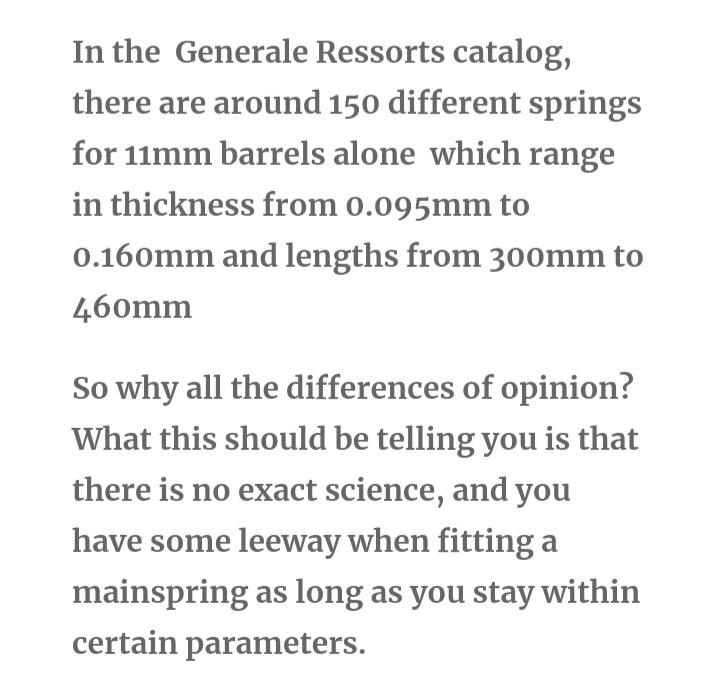

I like to always check the mainspring size of any movement I am working on, often just out of curiosity.A cross check using the rule of thirds and by halves.1 point

-

1 point

-

Alex's first option really threw me, and to suggest that wear in a movement unvaluable or not to me, can be compensated for by supplying more energy from using a stronger mainspring goes completely against my thinking. Would someone install a higher horse powered engine in a car to overcome wear friction in its gearing and running systems to make it go faster ? Maybe if they wanted to shake the car to pieces. More torque from a stronger mainspring will exacerbate the wear conditions associated with the original lack of power, and create wear in places that wasn't already there. There may not be another option for the repairer at that moment in time, but that option will lead to a much larger repair job fairly quickly. Again I don’t fully understand this. These two paragraphs appear contradictory. In the first instance there are over one hundred different sized mainsprings for a set barrel diameter, yet Alex's single formula is used to calculate the strength and length. I wasn't sure what dimension Alex was asking for here, total internal area, internal free area with an arbor fitted, or internal diameter. Only one dimension will change, the one with an arbor. His example... every 11mm barrel will calculate to the exact same strength and length spring. Sorry Alex your formula appears to make no sense. As regards to the first statement - what this should be telling you is that there is no exact science- . What it tells me is that there are many variables between movements that have 11mm barrels and that calculating the mainsprings for them is an exact science based on these variables. The arbor isn't factored in, I dont get it1 point

-

Thanks - I have bought a new mainspring which, as you say, came in a washer. I haven’t tried installing yet though. They do look interesting - on the eBay listing it makes reference to using a specific type of staples which may not be available in the UK. Will look into these more though. Thanks for the heads-up.1 point

-

Hi, I restored a Bell-Matic in 2023 and used the spring Andy suggested "GR40187" for the alarm spring which was purchased from Cousins in the UK I did have an small issue which was overcome, I think it was the arbour was a lot larger than the eyelet in the aftermarket spring. TIP: don't forget the install the washer part no: 419.805 before installing the spring1 point

-

It's not listed in the GR database, or on Cousins. Try either of those suggested by @AndyGSi. As long as it fits, the dimensions aren't as crucial as the mainspring1 point

-

Hello all, I thought I would start to make an effort to be somewhat more active in this forum. After my intro post and subsequent ask for help with some tricky lugs here https://www.watchrepairtalk.com/topic/29445-help-for-a-novice-fused-spring-bar/#comment-249241 I’ve been somewhat quiet. So, I’m going to give a summary of my first year as a beginner in watchmaking. I am very much a hobbyist; self-taught from YouTube tutorials, internet resources (this forum extensively) and a few simple books. In a year I have attempted: ST36 movement from Amazon to practise on. Stripped and rebuilt (no oiling yet) a couple of times. On 3rd rebuild an escapement pivot snapped. I begin to get the sense that I will love this hobby. Two pocket watches, a Smiths and an Ingersoll. Non runners. Full strip and clean on both, very simple oiling. The Ingersoll needed a new mainspring which I sourced and fitted. I accidentally (?!) put one of the dials through the wash adding some… patina. Amazingly, they both run, lovely loud ticking. I gift one of each to my daughters. They put them in drawers never to be seen again. A Sekonda DeLuxe with a Luch 2209. A few ticks only, stuck at full wind. Stripped, cleaned (in my early cack-handed way). It works but with weirdly varying amplitude. I think the hairspring is sticky/gunky and I don’t yet know how to clean them very well. I also lost the click spring (UK Space Program) and bent the seconds pinion. Abandoned. Hafis ‘Incabloc’, AS 984 movement. (Linked above). An early very proud moment. Was a near non-runner; would give a few ticks then stop. Stripped, cleaned (again, in an early fairly clunky manner), and oiled. And it runs! Losing up to around 15s per day, 310 amplitude, 0.1 BE… this was some serious beginner’s luck. A couple of problems; the crown is very worn down and difficult to grip to actually wind the watch. I tried to replace it with some basic parts, but no good. And I lost a screw for the keyless works portion, but this seemed not to affect any function, and the plate had 3 screw points, and seemed to function fine with just the 2. An old Tissot ladies watch, 709-1 movement. Runs fine, but I want to service it anyway. I discover I hate ladies watches with a passion. I break the incabloc spring. I get a donor movement, and… break an incabloc spring again. Sigh. It’s ok still got one spare… and then it flings off and away. I find it, try to seat it back in but it’s near impossible. ‘Set aside’ until I have the patience to look at this again. Seiko automatic, probably from the 70s or so, 7025 movement. Non runner. The automatic winder was loose, watch started up after screwing this in properly. Stripped and service. I donate a cap-jewel to the Space Program, and try to source another from a ‘lot’ of jewels from ebay. One seems to actually fit. Reasonable outcome keeping ok time, but amplitude a little low at 218. Mount Royal De-luxe, Felsa 4002 movement. Running but poor amplitude 180. Stripped and serviced. Wouldn’t run, escapement seized. Turns out I’d mixed the screws up and used a too-long screw on the dial side that was now poking through and touching the escapement. I managed to file it down in size and reseat it and everything working ok, amplitude 259, gaining 30s a day, but snow-storming in certain positions. Couldn’t figure out why and left it as is. Badman Swiss, FHF 72 movement. Non-runner. Full strip and service, not clear at all why wasn’t running. Despite doing everything ‘right’ it barely runs now and spontaneously stops. It is beyond my skillset to diagnose and I abandon it. Another Seiko automatic 6309-8060. Running, +74s per day amp 172. Very scratched mineral glass. I try to source a replacement glass, but it’s an odd profile, and of course not in production. Replacements exist, but expensive. I decide to try replacing with equivalent sized acrylic and… it works perfectly. Chuffed. Strip and service goes well (no lost parts! Nothing went flying!), now gaining 14s per day amplitude 232 (not brilliant but I’m chuffed), BE 0.1. And it looks stunning. New strap and I wear it regularly now. Favre-Leuba Seaking, FL 259 (almost certainly a Mumbai franken-watch, but the movement is genuine). Ticks for a few seconds then stops. Interesting double-barrelled movement. Some tinkerer has replaced one of the main springs with a tiny spring, so the two barrels outputting different power. I replace both and strip/service. Sadly, running very poorly with amplitude 149 after all that. Just can’t figure out why so little power getting to the balance. I suspect it’s to do with a weird intermediate wheel which is riveted in, between the barrels, and is oddly stiff. I can’t fix it despite lots of tinkering. Abandoned. Casio Oceanic OC-504, OS80 movement (quartz). Running, but very scratched mineral glass. I have a go at replacing with sapphire and it goes perfectly; very pleased with myself. I leave the movement well alone. Mondia Ladies watch FHF 57-21 movement. Trying to run, few ticks. God I hate ladies watches. Everything is so small and tightly packed. The work is frustrating. I finally get it together and oiled and… it runs only in certain positions, but snow-storm on the timegrapher. Some pivot is bent I suspect, but I am angry and I give up. No more ladies watches! Enicar Sport, AR (enicar) 190 movement. Likely from the 40s. This one hurt… really pretty little thing. Non runner, but everything looks intact and in good condition. Wheels are stuck with gunk so should clean up great. Mainspring is original and relatively set. Acrylic is original and yellow stained. This is the first watch I take cleaning very seriously; pre-cleaning, gentle brushing, pegging all jewels, slowly slowly. I get a brand new mainspring and glass, get to re-building it when disaster strikes. The balance slips out of my tweezers and the hairspring inexplicably twists on itself. I spend literal hours studying untangling techniques, and hunching over with a small oiler, unwinding, twisting, carefully now… and finally success, but now the spring is essentially bent to buggery in several places, out of round, and out of flat. I have not the skills or tools to fix, and there are no donor movements out there. Proper gutted! My pending project is Velona Automatic 1800, with an ETA 2783 movement. I’m looking forward to working on what seems to be a well regarded work-horse movement (for which donor parts should be readily available!). And that’s it! Happy to answer any questions or queries, and apologies if this was the wrong sub-forum. I’ll try to post my individual projects more regularly and start contributing more generally. Sam1 point

-

So are there any other forums that people already use? I know I've looked at a few and never really got on with a lot of the members as they were more interested in how much they'd spent on their latest Rolex.1 point

-

1 point

-

The problem is with the mainspring winder sets you can't have enough of them. Then there is a problem of when the Chinese cloned a set they cloned the ETA set of specific calibers. It would've been nice if they had clone the general-purpose set. Plus even if they did that it brings up the minor issue of the handles themselves. The problem with having a Winder for specific caliber is it should only fit that specific caliber so like the handle would be the same size as the arbor more or less and that might not correspond to any other mainspring other than that specific one. As opposed the general-purpose set where they're in different increasingly increment sizes. But sometimes when I use one of those sets typically for smaller pocket watches I might have to do a mixing and matching of handles and the outer barrel part to get something that's going to work. In addition to back she make three different handles or did make three. In other words had the standard right-handed and left-handed which you need for water to Seiko watches may be a few other things perhaps. Then the vintage handles that have a much more aggressive hook part that sticks out for the blued steel Springs which is why the newer handles are sometimes extremely problematic for blued steel Springs1 point

-

I assume the nonsense would be the spinning part that's not normally found on a watch? Then maybe the software was thinking a watch like this that does have spinning disks just doesn't have a mechanical escapement One of the YouTube channels I watch uses something else with a peculiar name degenerate images of himself as he does not appear as a human being at all? Somewhere he basically said he wanted you to listen the whatever he says and seeing him wasn't important.. So basically generate new images based on things that are going on in the discussion and has commented that whatever he's using has a really hard time with Hamilton's the fingers just don't quite look right or there might be they basically just don't look right.. But then I've seen other stuff on YouTube that is very very good..1 point

-

I asked OpenAI's Sora to generate a video of a running watch movement. It's funny how realistic it looks while also being complete nonesense. These AI models don't understand mechanics very well, but they are darn good at people. Here's what Sora generated from "Close-up shot of a watchmaker wearing a loupe inspecting a watch movement. He is using his tweezers to regulate the balance." I wish I could use tweezers with only my thumb1 point

-

This is a pretty old thread and you are unlikely to get a response here. You might be better off trying to contact Stian via his YouTube channel “vintage watch services” Tom1 point

-

For over 20 years, I've been repairing and restoring watches in Belgium not far from the coast. Recently I joined this forum, but didn't get to introduce myself yet. Now I do.1 point

-

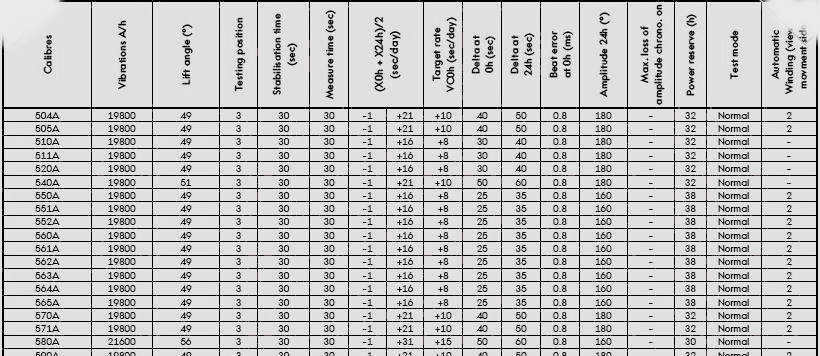

Interesting technique for all the pivots? Was there a problem concern rust? 800 grit to me doesn't seem very fine and tapering pivots doesn't seem good either. Then there's the problem of things that look bright and shiny and clean versus the reality of the situation. As an example of what I'm suggesting here of shiny is not necessarily shiny I'm attaching a PDF. One of the samples and let me quotes they're using Polished with Cratex™ abrasive stick – X-fine grade. Zero idea how extra fine grade compares to 800 grit? Acceptable amplitude for a fully wound up freshly serviced watch is typically only a concern of discussion groups and some YouTube channels. . Typically watch companies are concerned with timekeeping. After all that's what the consumer is most concerned about is their watch on time. I've snipped out an image of the specifications for your watch. So as you can see the lift angle is 56°. You have your timing specifications and 160° Minimal permissible amplitude in vertical positions after 24h in degrees. Then of course they have a power reserve will the watch in this case run for 30 hours. Pivots finishing burnishing electron microscope.pdf1 point

-

I am very impressed with the Kwong Yuen screwdriver set. It is at least as good as my Horotec screwdrivers. The bearings are very smooth, the feel is just right and the blades hold up well, I haven't seen any issues after servicing a couple of watches. The action of the base feels almost exactly like the Horotec, just bigger. And while not necessary I do like having the sizes on the base color coded with the screwdrivers. I really appreciate having more sizes too. And at less than half of what I paid for my Horotec set it's a fantastic deal.1 point

-

Do you have any documentation of this? I don't recall seeing anything like that, and I've not had problems with the stem pulling out on my daily. Seems like an odd change for Sellita to make. The other changes all have a clear logic.1 point

-

I would get a couple of these selections first, good chance of finding something to fit https://www.cousinsuk.com/product/battery-clamp-screws-wristwatch Tom1 point

-

Really? I remember mine was one piece. Maybe because mine had plastic lenses. It worked fine for short periods but extended use causes eyestrain.0 points