Leaderboard

Popular Content

Showing content with the highest reputation on 03/14/25 in Posts

-

That’s the beauty of this site is the interaction of the members, even on matters other than watch repair, I n the six years I have been on this site I have got to know and respect a lot of other members, have interest in their advice and information shared . A lot of members join for a specific reason , long term or short term they all get the same respect. This site is a one off, not repeated else where. So in that case continuation in case of disaster is desirable.5 points

-

The problem with setting up a backup to keep on standby "just in case" is that it costs money to keep it spinning. I don't think there's anyone trying to "steal" members. This is an active and functional community attempting to self preserve. There's a Pandora's box of indifference at play here such that Mark could, at any point, decide to just stop paying the bill and pull the plug with no notice. There's zero reason at this point to suspect that we'd be any the wiser prior to the lights going out. Just click the bookmark link one morning, and 404. Backing things up, in this context, means preserving all of the content that has been generated by members in a manner that it can be referred to later. I'm not sure what the legal aspects of that are... Who owns the content on this site? Might be as simple as reading the terms and conditions (not something I have the bandwidth for at this second as I get my 5yo ready for preschool this morning). It's very worthwhile if it can be done, as there's obviously a lot of very high quality content here. I've seen the loss of such information first hand a few times now in my luthiery hobby life. On multiple occasions, I've wanted to go back and look at an instrument made by a mentor of mine, and the only photos I'm aware of existing are gone (as is he). If there is desire and consensus to spin up a new forum, let me know. It's going to take some planning to nail down the time to get it done. There are undoubtedly a handful of logistical considerations that will need to be sorted as well, and those will also take time. FWIW, I'm 1000% in favor of making sure there's clock content. I'd like to see more of it, as I have my grandfather's grandfather clock just a few feet from me here in need of attention. I've been wanting a desk clock for a while, and haven't found one that's quite grabbed me enough to pull the trigger yet. I also have an analog electrical clock design I've been cooking up for a while that I'd like to execute some day. Clocks aren't as "cool" as watches in 2025, but that time will no doubt come.4 points

-

Watch repair is quite interesting for terminology. We have differing terminology over a span of time. Plus we have different terminology because of locations. You're working on an American pocket watch the terminology will be slightly different then a book written in the UK. Personally do this in baby steps. In other words deal with the roller do not put the hairspring on yet. Then with your complete balance without hairspring put it in the watch. Verify that the balance wheel can rotate and engage with the escapement and everything seems to work smoothly. Then you can put the hairspring in and if you need me to explain in more detail exactly quite easy to figure out where they hairspring goes at this instant the time. This is one of the interesting problems with learning watch repair. Often times people are told to start with a pocket watch which is both a good and bad suggestion. Good because it's nice and big bad because they think they're supposed to be repairing it. It's why it prefer people start with a brand-new Chinese clone of 6497 as nobody cares what's going to happen to this watch. So many times people start with a pocket watch thinking there supposed to be repairing it as opposed to just learning how things work which is hard to do on a broken pocket watch. Need to spend a lot of time learning how to disassemble and reassemble clean lubricates before moving on to the more challenging things like balance staff replacement. Then yes I have seen an remember at least one example of somebody starting with a six size Elgin that had roller jewel issues. Yes they started off with a lot of enthusiasm and excitement and as the list of tools piled up the frustration and soon they left watch repair. It basically is so much better if you start with watches that are running and maybe just cleaning might fix the problem rather than jumping in with both feet and it can be quite a learning process and expenses and frustrations at a time where you're supposed to be learning And having fun.3 points

-

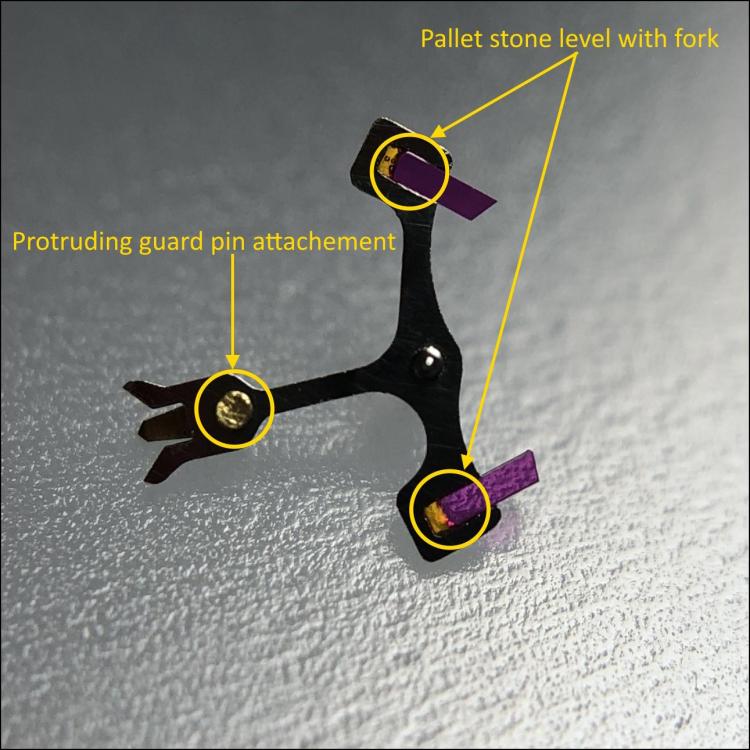

I always find it satisfying when a discussion thread describing a problem reaches a proper conclusion for future readers, so here’s my contribution. As has been evident throughout this thread, there are several ways to address rebanking. The most attractive solutions are those that do not place any responsibility on the next person servicing the movement, but that wasn’t entirely the path I chose. @nickelsilver's first suggestion was to install a weaker mainspring, and in hindsight, I think that would have been the best approach—at least as long as all other obvious sources of error have been ruled out. The reason I was hesitant to replace the mainspring was that I felt confident the original spring was installed and that the root cause was something else. But “feeling” is, of course, no guarantee. I suspect that finding the original mainspring dimensions can be quite difficult, in which case one would have to measure and then try to source a slightly weaker generic spring. I’m not sure how large the selection of mainsprings with T-shaped bridles is, but I have a feeling it’s not particularly extensive—though I could be wrong. All in all, I didn’t feel like dealing with it. Maybe next time! Anyway, I started by adjusting the total locking depth of the pallet stones from one-quarter of the length of the impulse face to slightly more than a quarter. This eliminated most of the rebanking in the dial-down position but had little effect in the dial-up position. So, I made a second adjustment, increasing the total locking depth to just over a third of the length of the impulse face. This completely eliminated the rebanking in the dial-down position, but in the dial-up position, it persisted—although not as severely. That was, of course, disappointing, as I had no desire to use higher-viscosity oils as suggested by @mikepilk, since the next person servicing it would likely encounter the same issue. Nevertheless, I decided to replace the 9010 oil on the cap jewel on the balance side with HP-1300 oil, as it was in the dial-up position that the rebanking remained. This action nearly eliminated the rebanking, but not entirely. After about 30 seconds, the rebanking would return for a few seconds, then disappear, only to reappear again. As a final step, I also oiled (HP-1300) the cap jewel on the other side, which permanently resolved the rebanking—but unfortunately, only until the next service, unless I’m the one performing it and remember to do the same. When fully wound minus 30 minutes, the horizontal amplitudes are now approximately 290 degrees, while the vertical amplitudes are just over 250 degrees. After 24 hours, the horizontal amplitudes are around 260 degrees, and the vertical ones are around 220 degrees. These measurements were taken with a lift angle of 46 degrees—the official lift angle for the Raketa caliber 2609.HA is 42 degrees, but as mentioned in a previous post, I measured it at 46 degrees. The specified power reserve for this movement is 40 hours. This extract is interesting. At first glance, it almost looks like an April Fool’s joke—it’s vague, talks about replacing the lubrication on the bridle, and recommends using colorless oil. The latter won’t be much help for the next person servicing it. Then again, red-colored oil would likely still be difficult to see against the red of the cap jewel. No matter how I look at it, I don’t see the extract explicitly recommending the use of HP-1300 on balance jewels. I’m curious—how did you reach that conclusion? I do understand that “bridle” is a typo and was meant to be “bridge.” Are you sure this extract is really from Omega? A small but useful trick I discovered this time was how to easily align the pallet stones flush with the top side of the pallet fork, something I’ve always found both fiddly and uncertain. Normally, this isn’t a major issue if the guard pin’s mounting doesn’t protrude above the pallet fork, but unfortunately, it does in this case. I simply placed the pallet fork upside down in a suitably sized hole in a staking block. Then, it was just a matter of applying light pressure to the yellow points shown in the image. Quick and reliable! I always surprise myself when I come up with tricks like this, as my first instinct, unfortunately, is always to look for a Bergeon tool One thing to watch out for with this particular movement is not to build up a bump of shellac on top of the pallet stones when re-shellacking them. This mainly applies to the entry stone since it sits just above the perimeter of the center wheel, and the distance between them is extremely small. In other words, if too much shellac is applied to the entry stone, the risk of interference is quite high. Anyway, problem solved, at least for now! As always, thanks for your support!3 points

-

Length is the least relevant size. Even the difference of reserve will be minimal. And with 260 your watch will run longer (2%), as 280 is longer than optimum. For your barrel strength 10.5 is already on the stronger side. Frank3 points

-

Facebook group created It's just a place to get together so we don't lose contact. You dont have to join it now , just make a note of the name until you are ready or if anything happens here. If you're not into facebook like OH then private message me some method of contact for you, then when something is better is set up I can let you know.2 points

-

2 points

-

Although I buy nearly all my stuff from Cousins, I recently started using Gleaves. They had some parts that Cousins had discontinued. It's not so easy to find stuff on their site, but prices are good, and the service has been excellent.2 points

-

Welcome to the forum. If there's no date on the movement then hand placement isn't critical but what I class as normal would be 12 O'Clock.2 points

-

Well I've been around all of the dates now without any issues, so I'm guessing the clean and refit did the trick, with whatever else I did not breaking it!2 points

-

I used to think the length only effected reserve, but the length does effect strength, though probably not a lot. Imagine a spring only 25mm long, how strong that would be compared to a much longer one. The spring is effectively a beam in bending, so the moment of Inertia is (width x thickness³)/12. So the thickness is much more important than the width. With your spring choices (0.11/0.105)³ is a about 15% increase in strength. The lengths are so similar, I wouldn't worry about that2 points

-

So the first question is what's the movement and is it Automatic or Manual. As @RichardHarris123 said you don't want to go for a stronger spring.2 points

-

Only the strength is related to power, not the length. Shorter spring, less reserve. You usually don't want more power, so go for the .105.2 points

-

2 points

-

I don’t think we should be looking at creating a competing/replacement site at the moment. I, as many of you, have concerns if this site goes away for whatever reason. I would propose that we have an alternative way to keep in touch that doesn’t replace this site but would rather allow us all to keep in touch and decide what would be an action to move forward with if the worst happens if we lose this place. As Rich, @Neverenoughwatches has said we have built relationships here and are a welcoming and inclusive community. so, definitely not a replacement for this site as it can’t and doesn’t work the same way, I have created a discord server so we can keep in touch without the security issues of an email list or anything like that. if you’re interested in that idea as a backup to the great community we have here then let me know and I will publish an invitation link. i have to reiterate, this is not a split from here but a backup in case we lose this site due to circumstances beyond our control. Tom2 points

-

I admit I was one that was not into setting up something new by leaving this site. I have changed my mind and I will except what needs to be done. I would just like to add I would like it to include clocks. How we have been left like this I think it is disgusting. Mark don't you have the guts to tell us what is going on.2 points

-

1 point

-

Can you measure the internal of the barrel to see if a 9mm supplied spring would fit directly as this could be vital information for someone else who comes across this post.1 point

-

Is one screw of the two that hold end stone plate in place missing ?1 point

-

1 point

-

I think I tend to use "index pins" and "regulator pins" interchangeably. I don't say "curb pins" because I can never remember if that is supposed to correctly refer to the regulator or to the pallet fork banking pins.1 point

-

Another lot of watches off into the ether and probably unable to claim as they've `Delivered' Edit As expected the seller isn't helpful and seems to have taken offence when asked why they use the worst courier possible. How do you know how the package was left? I do not have any control over how a parcel that can be posted through a letter box is left by an employee of a delivery company. You didn’t contact me about your hours of work which if you did I would have worked with you to send the parcel either to a different address or on an overnight service. The package had tracking details which is for you to review also it gives you the function of redirecting the delivery. I’ve followed what I had to do as a seller, it would appear that your concerns should be with Evri and not me.1 point

-

I think this is a trick of light plus the photo was from before cleaning the movement. It looks normal in situ after cleaning. Shimming to reduce end shake did help a lot. Instead of taking 20min to recover amplitude, now it takes only about 5min between DU/DD to recover 260-270° and less than 10min to rise to >200° when flipping to crown down (and it will still gain more if left alone). This sounds awful still but it is a major improvement over what was happening before. I'm going to case it and see how it works on wrist. "Good enough" will be good enough for this watch since I pulled it out of the bottom of a job lot box and the dial is pretty scarred up. I do not mind leaving the foil shim in place for now, but still I need to learn how to adjust end shake properly for this balance. I have shimmed big pocket watch balance cocks before, and encountered lots of times when watchmakers had raised gouges in the metal under the balance cock to adjust shake but I don't want to hack up this mainplate.1 point

-

1 point

-

1 point

-

I use Mobil Velocite, not sure who recommended it , one of the pros, might have been Nicklesilver1 point

-

1 point

-

I didn't realise you were in Canada. Are there no watch part suppliers in Canada? There must be suppliers in the US, but you may not want to use them (the way things are going the tariffs could be about 5000% by the time you order ). There is one supplier I've used many times in the US you could try https://www.daveswatchparts.com/ . A one man operation, very helpful.1 point

-

1 point

-

If you just want to use Cousins then I'd go for the GR45011 point

-

I'll try to get some photos when I'm back home today to make sure that I'm not explaining this incorrectly.1 point

-

Your best chance of finding the movement details is the keyless works once you've removed the dial.1 point

-

1 point

-

I would err on the side of the stronger spring if those are your only 2 choices. I'd bet it will work just fine.1 point

-

No idea of the maker but it is a lever escapement ("ancre") rather than cylinder. Looks like a counterbalanced pallet fork with the "bug antennae" is hiding under there.1 point

-

Cousins UK https://www.cousinsuk.com/category/filter/lanco-movement-parts1 point

-

Either way Tom, we need some sort of backup. We need some sort of backup sooner rather than later .1 point

-

Every one I've seen has the nut on the back; possibly under a friction fit cover. The spindle comes out the front once the nut and pulley are released. That nut is also the main adjustment for the bearings. The biggest problem I've had trying to dismantle spindles is getting the locking screw out of the pulley! I have two that I cannot (so far) remove the screws from. Both are paxolin type pulleys. ps. Can you provide the make, and/or photos?? According to the Castrol data sheet, that's hydraulic oil?? pps. For info, a significant percentage of drive system problems on the large machines I generally work with are caused by lubrication problems, varying from wrong types of oil to plain lack of oil or oil leaking faster than it put in, so I have learned quite a bit about different types of lubricants over the years. One of the commonest problems is places using gear or hydraulic oil in place of slideway oil - or suppliers recyling oil and selling it as slideway, though it's not got the additives needed!1 point

-

It's true that the pit can be hard to see, got to have just the right angle of view with the right lightling. I just did a cool old Zenith auto for a friend, so trying to keep the cost down on a watch they might wear a few times a year (he has lots). The upper cap jewel showed a bit of a pit. Got it all together, and sure enough there was a good 15-20 degree difference in the horizontal positions, but the rates were great with a delta of 12s in 6 positions, and the lower of the horizontals was over 270, so I left it like that. Dude was happy and I was too. I also don't think a pitted jewel is causing the issue here. I mention endshake as I have encountered some really weird issues that ultimately tracked down to excessive endshake on the balance. And in some cases the endshake was pretty OK compared to a lot of other pieces- but it was too much in these cases.1 point

-

Outstanding we will now get a? If we get no answer at all it's not a good sign if we get an answer who knows what it will be. Then as far as making a new discussion group I don't think there's a limit on how many the world can have so no one was ever stopping anybody from doing it. If you made a better group people would come to it. Then this group has anyone thought about backing it up?1 point

-

OK, 20 min. is much beyond normal. I don't suppose the balance is so heavy, simply no way. It must be some kind of energy loss which is provoked by position change and slowly disappears when in rest. Such thing may be guard pin touching the safety roller due lack of draw in the escapement. Is the draw present and reliable on both sides? Another thought - the drop lock can be minimal /unreliable. I expect to it be some kind of escapement problem. In case it is not the escapement, can You do something like the free oscillations test, but to change the movement position while balance running and see if sudden drop of amplitude happens? It is normal to have some amplitude drop as there is gyroscopic effect that leads to forces that increase friction in balance bearings, but do it with another similar normal movement to have some idea what is expected and normal. Did You check if the balance axial free play is normal as @nickelsilver suggested?1 point

-

Decent rate doesn't neccessarily mean the right spring and balance wheel match. You can practically get exact beat/rate out of any spring and balance wheel. Other parameters such as acceptable dynamic stability come to the picture with a watch wrist specially, and if real bad match, heavy balance wheel will take many impulse to reach max amp on bench, as its an inertial body. But then what do I know? Richard Harris knows I know nothing, but keeps it secret.1 point

-

I suppose it should be easier than a conversation around watch lubricating. like you I have seen all sorts of recommendations from as you say sewing machine to high performance motor oil. What does however make more sense to me is the folks who recommended a spindle oil, like I think velocite 6. The good bit about watchmaker lathes is the ways should be ok with a dry lubricant rather than the heavy and sticky way oil you would need on a larger industrial lathe. oiling of the headstock as far as I have seen is essentially a hole at either end of the headstock that you put a couple of drops of spindle oil in before every use. I’m sure there will be more knowledgeable folks along to help further. Tom1 point

-

1 point

-

1 point

-

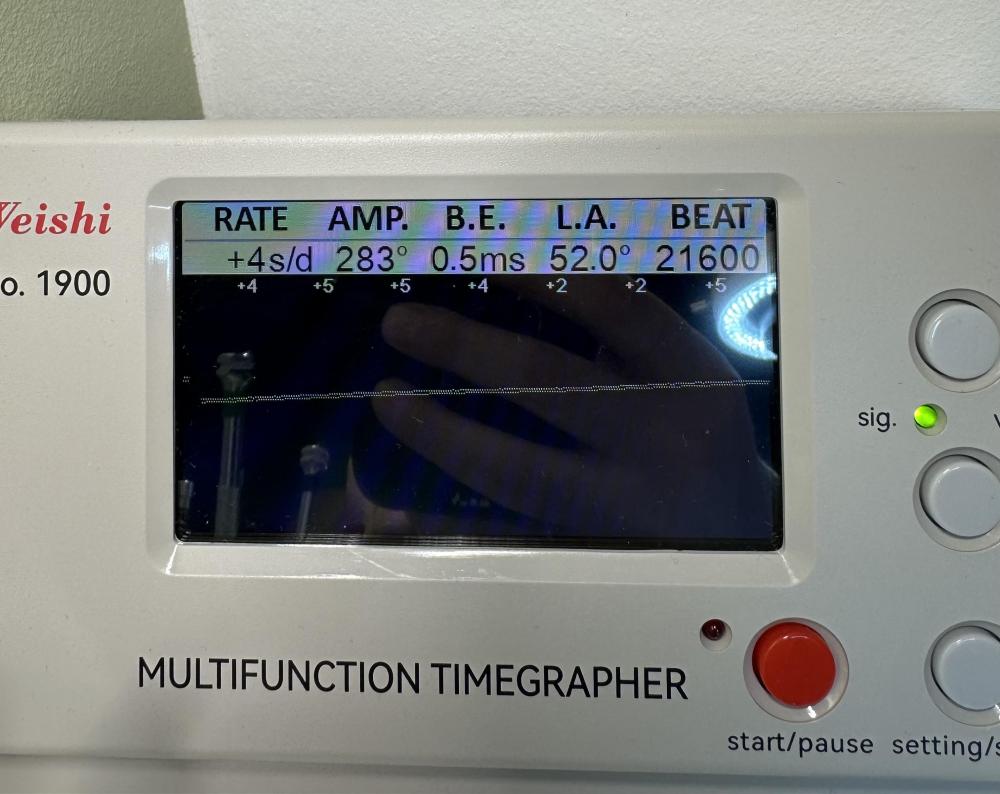

I am absolutely thrilled to announce that I finally fixed it !!!! Only took around 2 months and several parts ordered that either didn’t fit or had other faults, a lot of trial and error, somewhere around 150€ spent on parts. The good thing is that I have a bunch of spare parts for this watch now I regulated the watch with dial up and dial down for now since it’s very late, but I believe there should not be major differences in other positions. Dial down: Dial up: The aftermath1 point

-

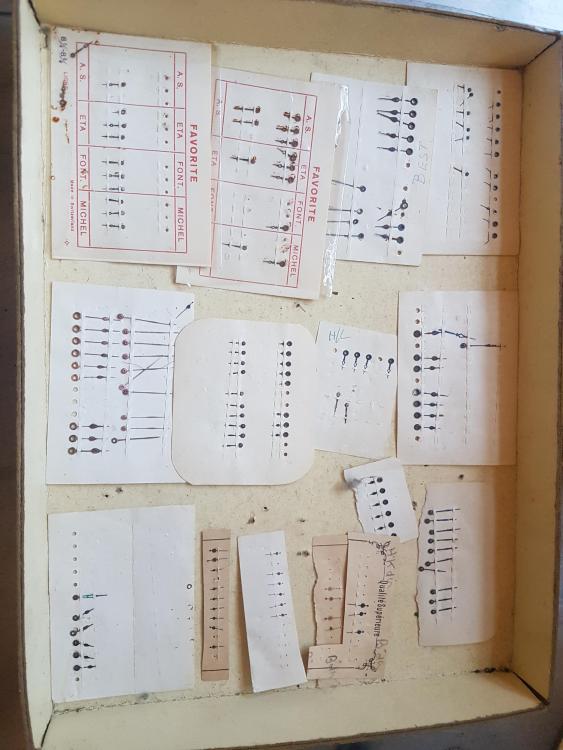

Local auction had a box of random watchmakers tat. Nothing amazing, but I spotted a few bits in the box, so I bought it. Just had a dig through to assess what's there. First off, some watches. I ignored these. Some limit, a sekonda quartz, and a rotary quartz. I may or may not see if these work. I know nothing about them but I know if they weren't tat, they wouldn't be in the box. Next layer of items were some empty tins, a glass globe (this might actually be handy!) And a tray of glass watch crystals. It's slim chance I'll have the right size if I need them, but I play with early 20th century watches, so glass is nice rather than plastic. Next grouping is all the little boxes. The watch pins will be handy, as will the dial washers and the screws. An entire tub of setting lever screws there. There is some other bits and bobs too. Don't know how the enamel is ment to be used. No idea what clock bouchons are, or what the cylinder pivots are. Bottom of the box has this assortment of hands. I need some sub seconds hands. I bought a new selection, but I think there might be something better in here. That brings us to the small selection of tools. A broken something, adjustable winder maybe? Not sure if both bits belong together, but it's broken, and not all there whatever it is. A glass pippette maybe? An old oil pot, ill mix lume in this rather than using a teaspoon. There is a packet with a load of broaches though. I figured these would be handy. Not sure if cutting, smoothing or both. Might be handy for the seconds hands! There are also some small drill bits, and a nice surprise, a tin of taps! I need a 0.8, hopefully there will be one in there. Then some pocket watch and clock bits. The dials are nice. One is a chronograph, the other says chronometer. The movements are incomplete, but I think that's the one for the chronograph. Looks way more complicated than what im used to, even with a load of bits missing. Has depose stamped on it. And lastly, the other thing that made me tempted to buy the box. A zenith trench watch movement. I think the black dial might go with this. Not sure about the case parts though. Few bits missing on the movement but some of them might be in here somewhere. I love black dial trench watches so as soon as I saw this, along with the broaches and hands, I figured I'd buy the lot. all in all, worth the £26 I think. I expected more radium, but luckily only 1 hand and the dial.1 point

-

If you are getting orange peel I assume you are spraying your lacquer, yes. Orange peel is the result of an incorrect spraying technique, often the result from too much distance between gun/airbrush and subject, so the paint starts drying before it hits the subject, or you are putting too heavy a coat of lacquer down and it's drying at different rates. Try lighter coats with more dry time between coats, or try a less hot thinner so it slows the dry time a little.1 point

-

In the title. Brass primarily. I have tested several different methods, but I keep getting an orange peel result. Looking at other clocks we have that are lacquered, the coating is flawless and I just don't know how that has been achieved? I am wondering about the purchase as well of an airbrush I have tried brushing as well with another varnish that I have and that did not test well either. It well could be my lack of experience.1 point

-

I have lacquered many French carriage clock cases and I always have used a very soft flat artist brush. brush in one way only. You don't say what you are going to lacquer. You must make sure it is clean with no specks of dirt/dust or tiny hairs. It dries very quick the one I used. You most never touch the parts because if you do your print will show. Here is the one I used, its the clear one for brass. https://www.cousinsuk.com/product/lacquers-rapid-drying1 point

.thumb.jpg.19a9c4ff164d78d516aa9f05a063752b.jpg)