Leaderboard

Popular Content

Showing content with the highest reputation on 03/15/25 in all areas

-

Mean while he couldn't give a rats ass about what is going on here. That's loyalty for you. It's people like us that have got this forum to what it is today.6 points

-

5 points

-

4 points

-

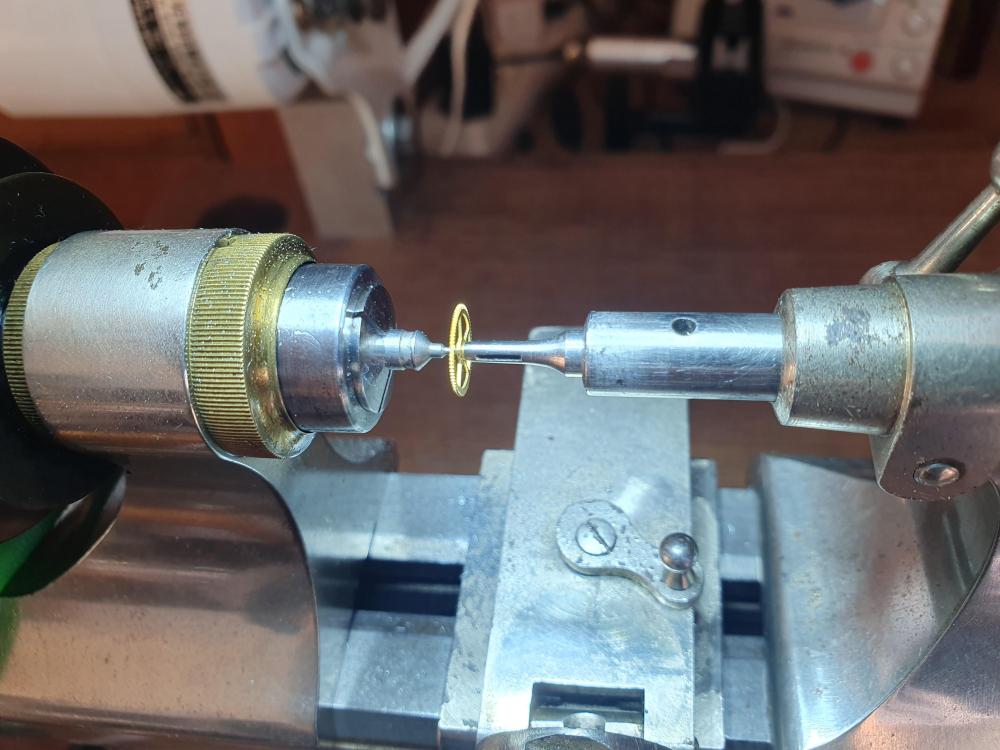

The mainspring winds in the same direction for both barrels. There is a small intermediate wheel that connects both barrels to make both barrels turn in the same direction.4 points

-

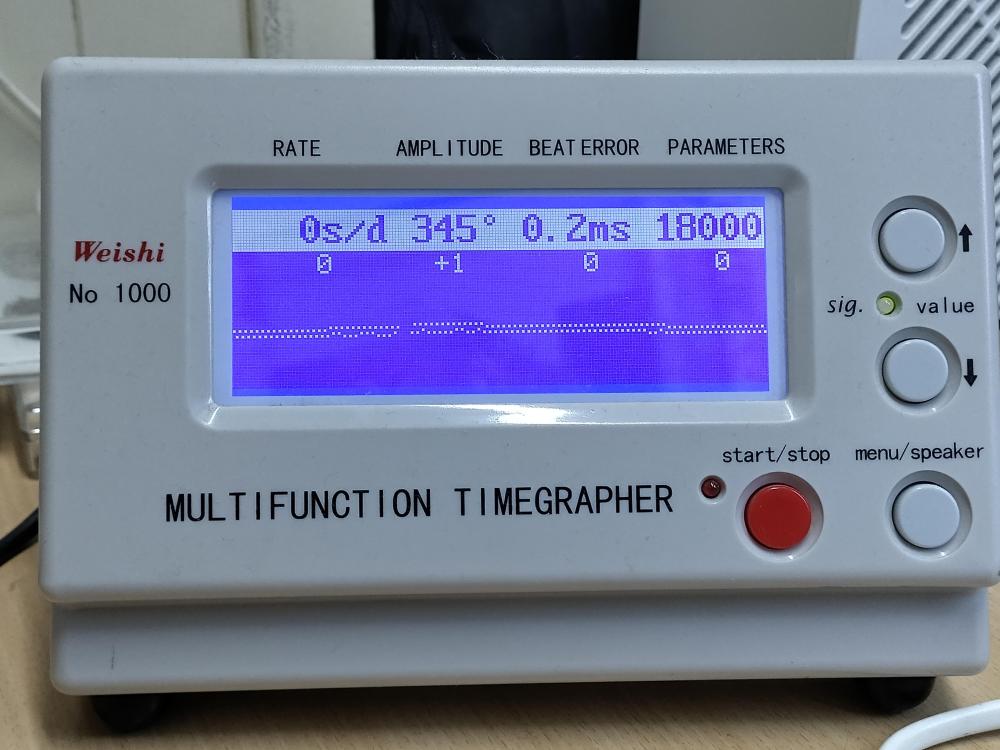

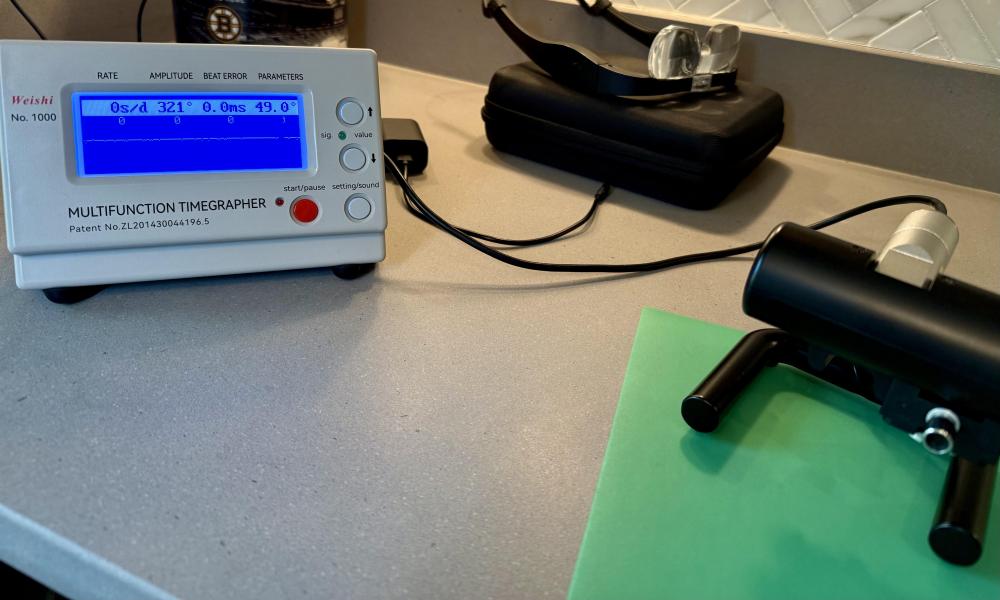

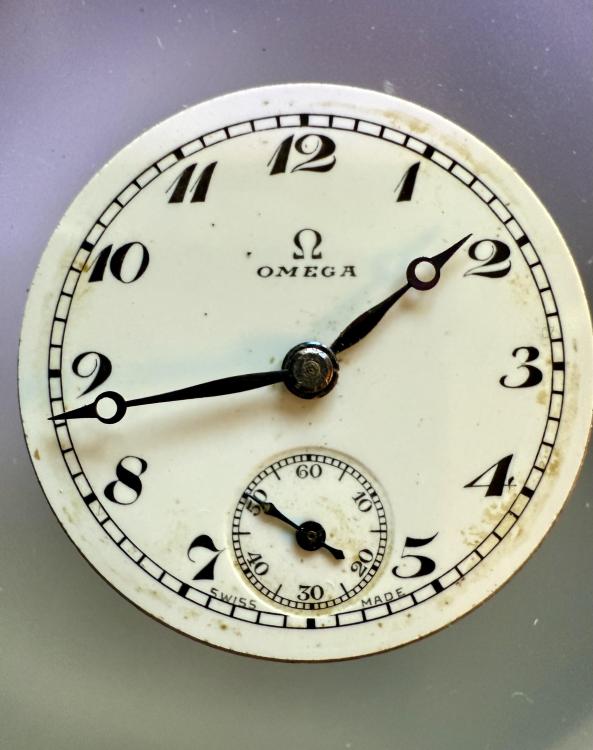

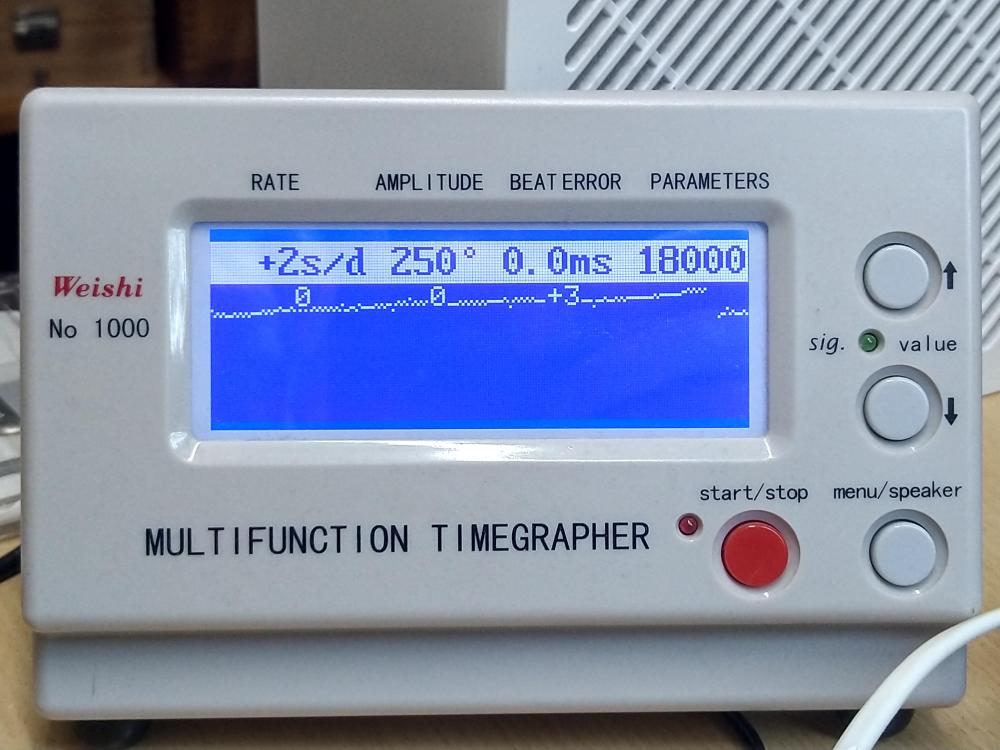

…the least exciting watch in a small lot, an Omega from 1935, 30T2…SOB of all things? , clearly once loved but neglected for decades, has blessed us with this lovely moment. TG is on the long time setting and has been running like this for a couple of hours. It asked for very little, a bit of reshaping of the end coil, a small turn of the collet, a bath. There’s a new alloy main but the old carbon one would have been just fine thank you… …I may have to turn on the tg ticks …The dial now looks factory fresh but the case warranty expired long ago. Out of respect it’s getting replated...enjoy ️️3 points

-

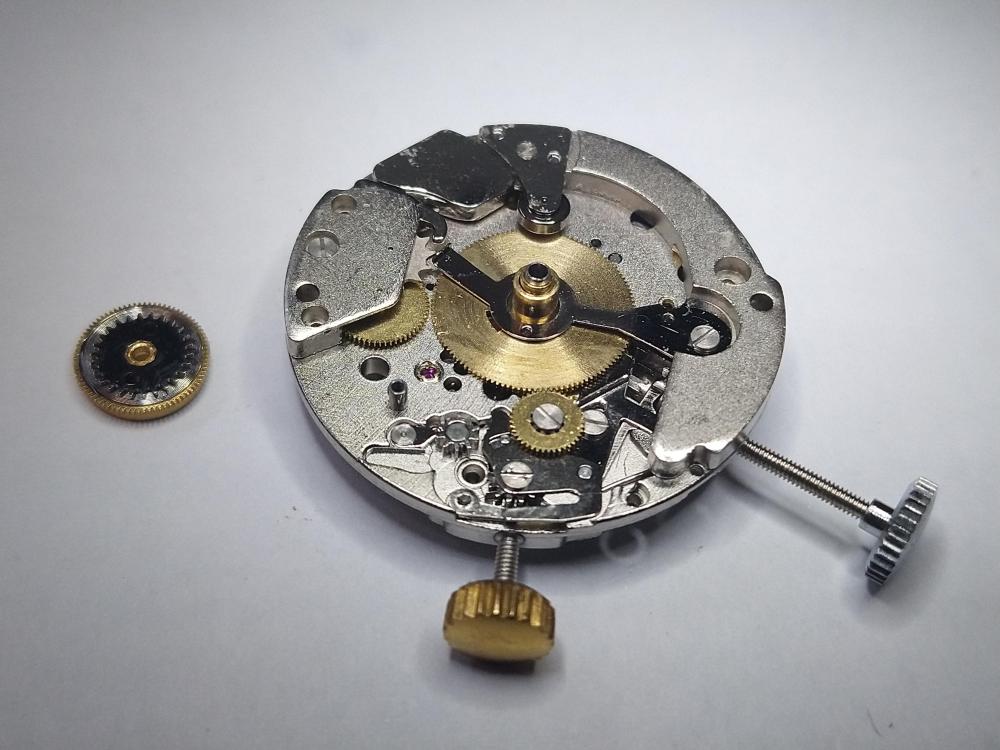

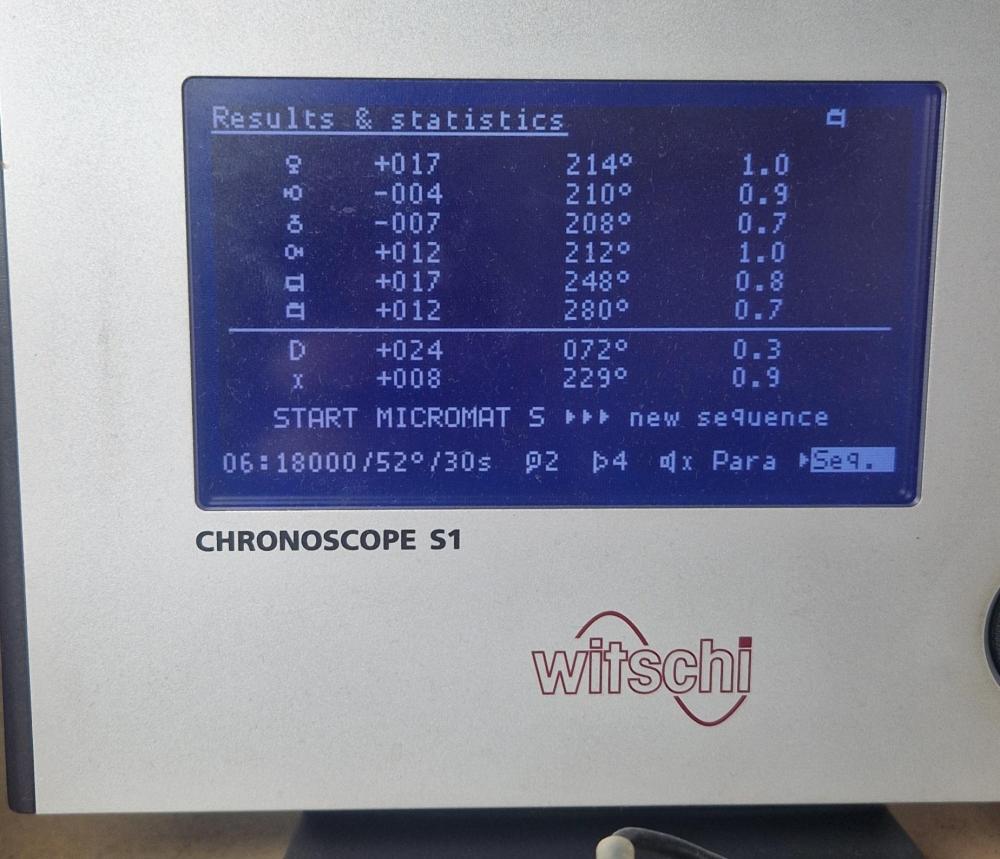

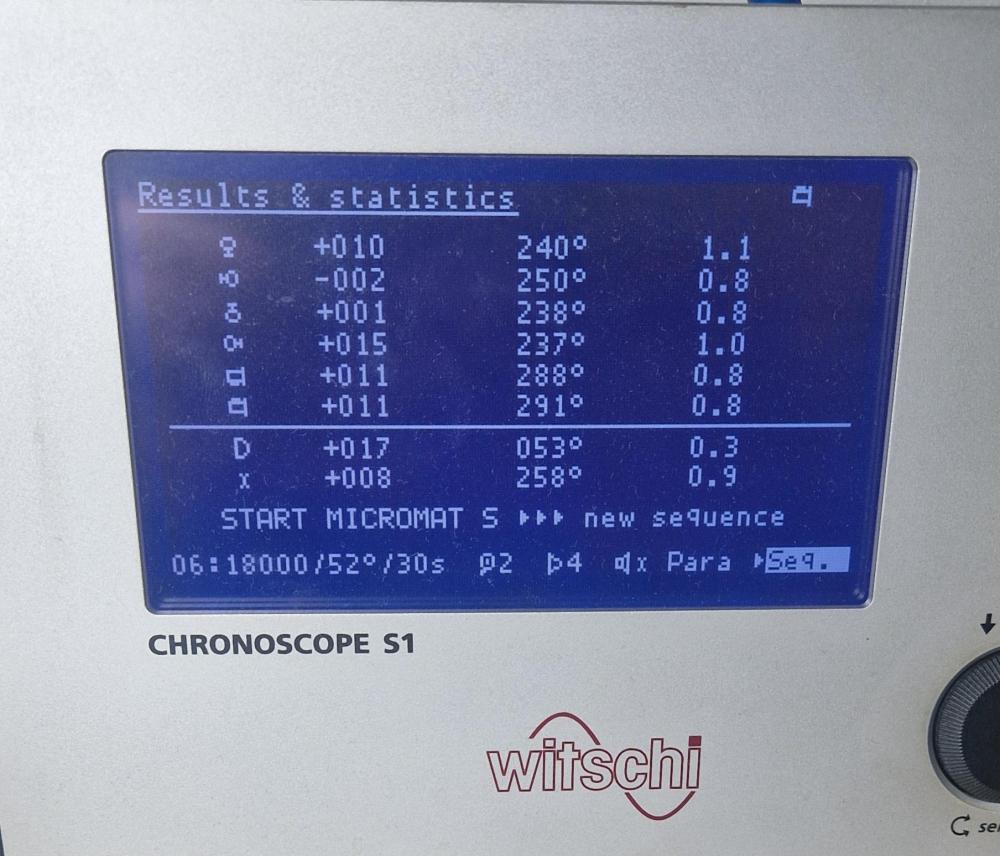

So many factors come in to play, it does become a bit dizziyng. Just had an Omega 30mm caliber (26X something). One of the best movements of all time. Serviced, ran a ticket, 32 amplitude difference in horizontals, verticals dropped from 280 (max horizontal- other side was 248) to around 210. I retouched the balance staff ends, and moved the exit jewel in 0.02mm. I write this because a lot of times you can have the best cleaning solutions and methods, but, some watchmakingishness comes into play. I know folks here know that real watchmakers exist, but go on Reddit and try to explain something " real " and you are a gatekeeper. You do have to move pallet stones, bankings, tweek hairsprings. I do it on every job. Like, 30% of the time I retouch the escapement in some way, and 75% of the time I touch up the hairspring. Here's the tickets from the Omega. It was like 20 minutes from one to the other. It'a funny to see the actual average rate didn't change. But the overall performance is a LOT better. I also didin't touch the regulator once in the whole job.3 points

-

A bit late as I already have these, but anyway: I got interested in the Seiko Kinetic watches (see the end for the reason), and wanted a smart wearable one, so found this; titanium cased, 5M23 movement and in really nice and fully working condition. It came from Japan & has a Chinese inscription on the back which when translated reveals it was someone's retirement gift after 30 years service! Also wanting something to mess with, I found a pair of non-workers from a charity shop on ebay: The one on the left (5M43 movement) has a really bad, worn away case so I'm saving that until needed. The one on the right (5J22 movement) started up after an hour on a pendulum charger and has run perfectly ever since! It easily lasts a week at a time. It's a "relay" version so the hands stop moving to save the battery/capacitor if not worn for a day or two, then it sets the hands once it's being worn or moved again. It needs a bit of cleaning and polishing, but it's pretty good for one supposedly dead. And this - given to me by an old friend, who I'd happened to show one of the old watches I'd restored. He is an Apple fan and told me he's never going to wear it again, so he wanted someone interested in watches to have it! It's complete with everything - box, paperwork, case, guarantee and receipt! It needs a bit of a cosmetic clean but is otherwise near mint, just slight wear on the raised bezel around the small dials. It has a 9T82 movement which is apparently "Grand Seiko" grade - and (officially) unserviceable except by Seiko Japan. The capacitor battery is a bit tired and it only lasts about a week rather than a month, but not too bad. The chronometer is purely mechanical and has a tenth second dial, with the hand rotating once per second; the minutes dial has two hand for hours and minutes. There a photos of one being fully rebuilt in a thread here; the capacitor change requires dis-assembly of the chronograph! Servicing this is beyond my present skill level, as a single damaged part means it's wrecked. It will have to go to Seiko once that's unavoidable. https://forumamontres.forumactif.com/t263764-remplacement-batterie-sur-une-seiko-9t82 ps. The dirt on the back was not obvious in normal room lighting...3 points

-

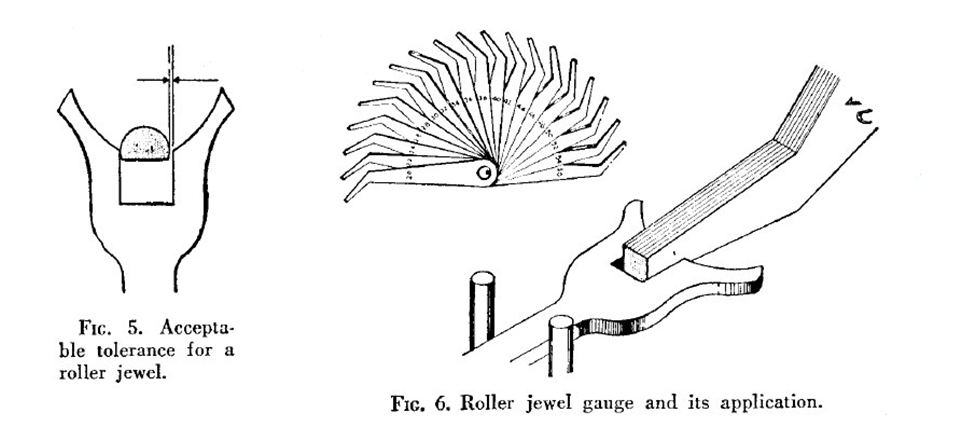

I would just replace the roller (part #730). Look here http://cgi.julesborel.com/cgi-bin/matcgi2?ref=ETA_2770 and select 'Roller', and you will see it's common to about 100 movements. I just found one. If you do an ebay UK search for "NOS - ETA - Various New Movement Parts", in the drop down list is 2783-730. A roller for cal 2783 which is the same as for your movement.3 points

-

3 points

-

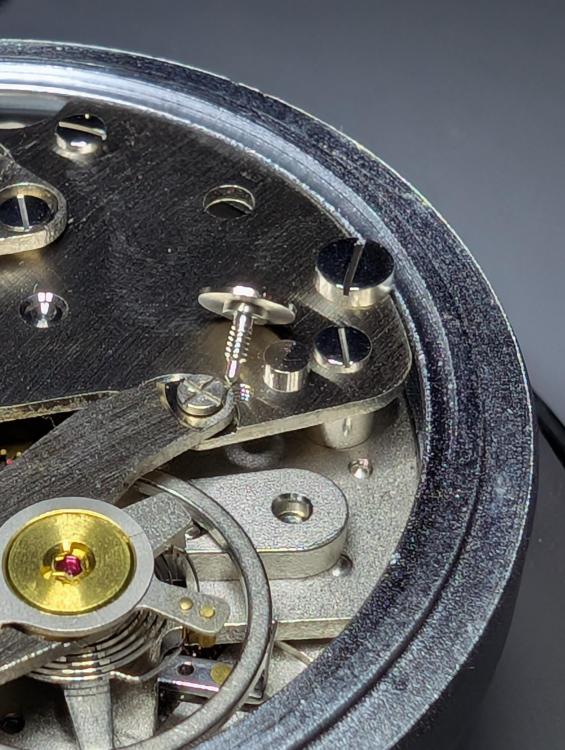

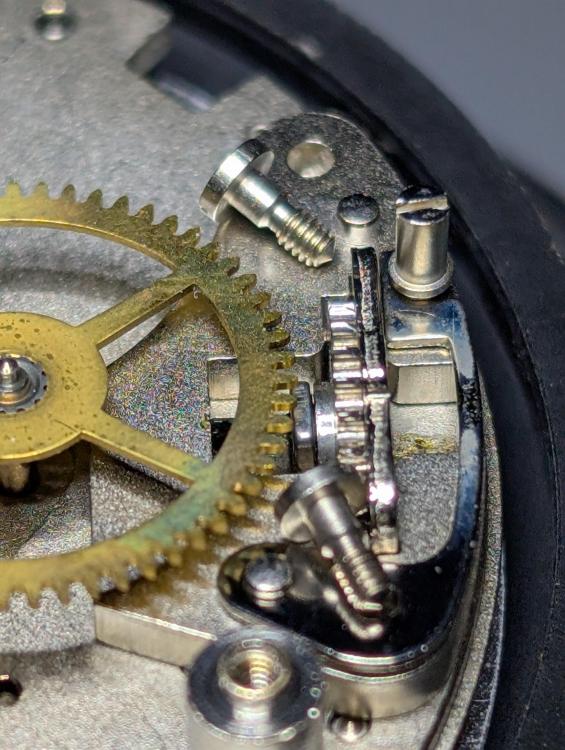

I just finished this service and since there isn't really any written documentation on how to fully assemble this movement from what I could find (there was stuff for the dial side but not mainspring side or keyless works). I'm not a seasoned professional but think some photographs that I took and some explanations could be helpful for others. To remove the pressed on case back I had to sharpen and polish the case back removal tool as the indentation for it in the case back was super narrow. I used this same tool to remove the glass and pressed on glass bezel. The original acrylic was chipped and wasn't very tight so I ended up replacing it with size 54 crystal from Esslinger. (GS PKH Pocket Watch Crystal (GS = MM Size: GS 54 = 47.0mm) 20534 To install it I placed the bezel over the lower die of a crystal press then raised the bezel up around the compressed crystal. When you remove the case back this is what you find. I bought is watch as a non runner and didn't realize at the time how to remove power from the mainspring at this point so I just went full send and removed the balance first followed by the barrel bridge. It was at this point that things flew out everywhere so I couldn't take pictures of how it was supposed to be put back together; a problem to be solved at some other time. With the barrel bridge removed and having now figured out how to assemble this section the ratchet wheel, click, click spring, crown wheel and crown wheel spring should look like this. All held in place by the barrel bridge. If you zoom in you can see how the crown wheel spring should be oriented. On a side note with some finesse it looks possible to power down the mainspring with the barrel bridge still on by moving the click out of the way from the side of the movement. The following photos are of the disassembly of the train of wheels. The balance cock/bridge has three screws. The balance cock safety screw and the end shake regulating screw (the one with the cross on top) can be seen below. The hole in the balance bridge that the regulating screw goes into is through and through so when it's tightened it lifts up on that side of the balance cock changing the end shake. I try and take good pictures of what the screws look like and where they go. Ratchet wheel, crown wheel, and crown wheel spring are removed showing the crown wheel core. Click spring and crown core removed. Case screws removed. Removing the train wheel bridge. With pictures of their location and a closeup of what they look like. Train of wheels. The center wheel/seconds wheel and the minute wheel are connected on the dial side to the seconds heart and the minute heart so will take some pressure to remove from this side. I removed everything but the seconds wheel and the minute wheel so I could get at the seconds heart and minutes heart from the dial side. Removal of the pallet cock with picture of the screw. The winding pinion, winding stem guard as they should be seated. The winding stem brace and the winding stem screw are also shown. The stem cock screws are also shown removed. It should be noted that the winding stem brace has an upward bend so it will raise when the winding stem screw is loosened.2 points

-

2 points

-

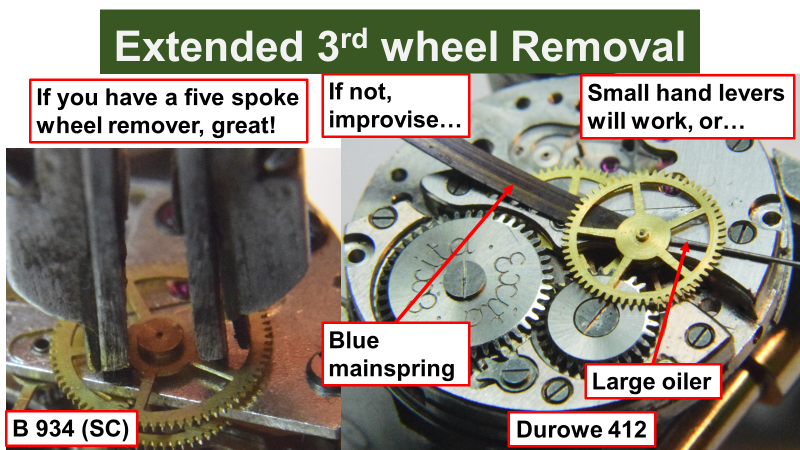

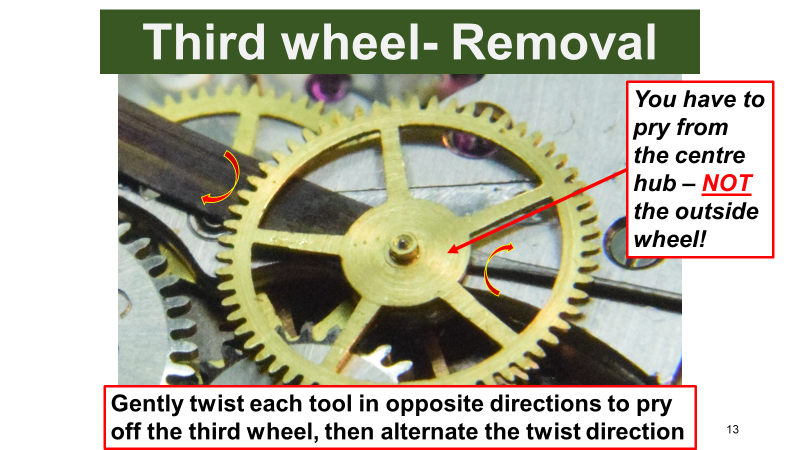

I’ll let the pros weigh in but I usually grab from the outside with larger brass tweezers and carefully twist…2 points

-

For the email in messages there is a workaround, do it like this below. fredbloggs at gmail dot com Tom2 points

-

I'll look into spinning something up. It won't be immediate. I am very tight on bandwidth these days. Mods, I'll need your help. My daughter's spring break is this week, and I'm taking it with her. I've also got a 9mo, and wife ISN'T taking a week off work, so it'll have to be done during naps. I'll update here as there are things to update. This won't be a committee effort, but I'll be seeking input here from time to time from everyone else as well.2 points

-

I'm on Facebook but don't use it greatly. At the moment this is just a means to an end to be able to contact people should the worst happen here. Please as a regular posting member would you be willing to give your details to someone.2 points

-

HWGIKE#48 Lucerne EB 8810 pendant watch, full service. pin pallet. Received a ton of watch parts including EB88xx family so I picked this one because its service helped me to better understand what is what in the boxes storing EB parts. 1 jewel only and its performance is sort of incredible considering that this is not just 1 jewel but pin pallet. Amazingly simplified it was probably the fastest service I ever done must also say that it was in a very clean state with little or no lubrication.2 points

-

It exists to make the owners money by advertising - and by selling users data, if you don't spend enough time going through all the privacy settings that allow them to do what they like, by default. My biggest objection is that the have zero interest in maintaining groups, that the users put massive effort in to. Someone I know runs a town/region group, which has more than 100,000 users at peak and so many views than the facebook vie counter limits. Then someone reports something and facebook just delete the whole thing & all the content, so it has to start from scratch again and take another year or to to build back up to similar levels. Repeat ad nauseum. (Apparently any phishing / scamming mob can pick any high usage facebook group, clone the heading artwork etc., and use a couple of fake accounts to post something obnoxious from one and immediately report it from another - instant nuke, then they use the same group name & stolen artwork etc. to post their garbage, which is initially seen by all the real group users looking for it by name). I want nothing to do with Facebook.2 points

-

It does look missing in that photo. I promise all of you, both screws are there! They have polished tips and that black hole is probably the reflection of my phone when I took the picture.2 points

-

2 points

-

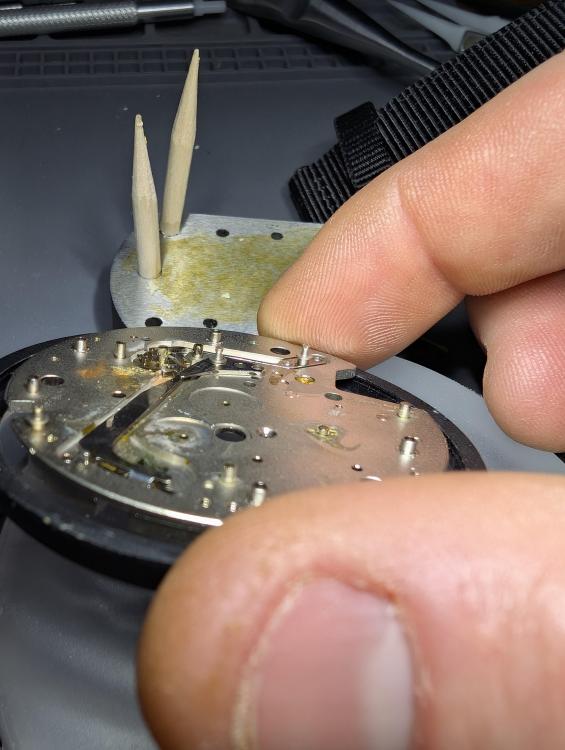

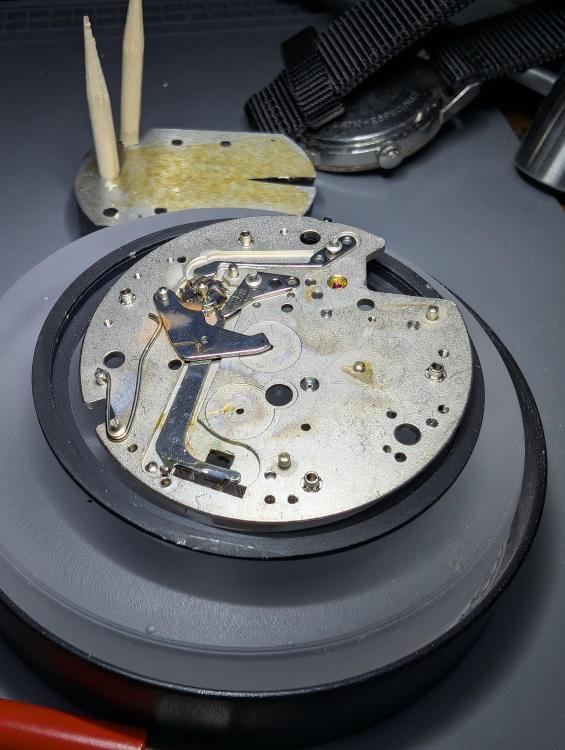

Kalle at Chronoglide (I cannot find the video) showed a method where he used two pieces of pegwood sharpened to fine chisel points to push under the hub. I think he showed that you can also just twist the wheel to get it off by pushing the spokes on either side with pegwood, gently working back and forth until it loosens. I bought one of these (before I had seen Kalle's method with pegwood )2 points

-

Yes, which method we should choose is undeniably something of a dilemma, and we can approach it in different ways, but I follow your reasoning. My fundamental approach, regardless of the situation, is to try to find a long-term sustainable solution. I dislike "quick fixes" because they usually only solve a problem temporarily and, in the worst case, shift the responsibility onto someone else. However, sometimes, that can still be better than doing nothing at all. My standpoint is that a standard maintenance service for a watch with no apparent faults, where no parts are replaced (including the mainspring), no modifications are made, and typical oils are used, should result in a well-functioning watch. The next person who services this watch, if it’s not me, will inevitably restore the rebanking (unless the mainspring is replaced), as it is common practice to lubricate the balance jewels with Moebius 9010 or a similar oil. Therefore, I believe that a permanent solution, if possible, is preferable. I just love the new design of the Bergeon logo. H-ll, I'd be happy to pay $10000 for it! Exactly, probably translated from French to English by a French work experience student!2 points

-

The people at Sutcliffe Hansen talked to Mark recently. Apparently he’s on vacation relaxing on a beach somewhere.2 points

-

2 points

-

Sorry but I can't bring myself to join. I realise it can be used as a tool but for reasons I can't verbalise, I have a loathing of it. I honestly don't know why. A few members emailed me before, feel free to do the same, one and all.2 points

-

That’s the Devil’s Option @mbwatch … I like it. The list keeps growing: a lathe, a Horia (or clone), JKA Feintaster bench micrometer. My wife is not going to be happy with me…And I’m going to have to clear some new space in my guest room workshop. But until the date when those things enter my workshop, I might have to just re-assemble this balance as best I can, give the watch back to my friend, and tell her I might be able to resurrect it sometime soon-ish.2 points

-

Option 4 is keep hanging out with us here until you end up buying a lathe, reduce the size of the roller seat by slightly turning down the staff you have, and install a NOS Elgin double roller which are fairly easy to get.2 points

-

With the bezel and glass removed your first job is to remove the hands. These bad boys are on there insanely tight. Removing them without special tools is a problem. I used these to take the hands off. Made pretty easy work of it. With the dial and hands off you are rewarded with this view. It becomes apparent why this was a non runner. Someone poured melted hard candy inside and there was a broken retention spring on the seconds heart. If you zoom in to the middle you can see it the piece laying inside. The hands are hard pressed onto the posts of the hearts and the hearts are held onto the seconds and minute hand by a small spring that engaged the respective arbors. The seconds and minute wheel will now come out. I recommend removing the springs before you remove the dial rest plate. This will prevent stuff from shooting everywhere if things aren't properly seated. I also recommend waiting to replace these on assembly so that you don't struggle to get the winding pinion and winding stem guard as they relate to a tab on the hammer lever. This also shows the dial plate screws and their locations. You can see how much corrosion and dried hard candy was inside this with the dial support plate removed. Obviously my spring removal recommendations were based on personal experiences. Lucky enough everything was super stuck together that nothing flew out. Positions of the springs. Chronograph levers being removed The pillar wheel was stuck solid. This photo also shows that the screw retaining the pillar wheel jumper does not seat flush. It's the screw that's located right by my index finger. This shows the two screws retaining the pillar wheel jumper and the operating lever bridge. The operating lever has the tab that extends through the main plate and interacts with the winding pinion and winding stem guard on the other side of the main plate. The operating lever is the super long lever that extends from the pillar wheel to the keyless works anatomy. After a thorough cleaning I essentially assembled this in reverse. I began with the train of wheels first, installing the train bridge. Then back to the chronograph side so that I could install the minute and seconds hearts and finishing the dial side (without springs) then installing the winding pinion and winding stem guard and winding stem so that everything lined up. Then the springs followed by the dial support plate, dial, and hands. Then finished off with the winding works ( crown wheel, ratchet wheel, ect.2 points

-

2 points

-

I hold the wheel in a lever type jeweling tool, between a pusher and a stump on the wheel hub. You can turn it by finger and see where it's high/low, then adjust with stout brass or nickel tweezers gently bending until it turns flat. If it's flat in the tool, it should be flat in the watch, unless the hub has gotten tweeked in the wheel (rare), or if the extended pivot it fits to is bent (common).2 points

-

1 point

-

1 point

-

If they don't have a slot, they usually have a hole. I use an old oiler to twist them.1 point

-

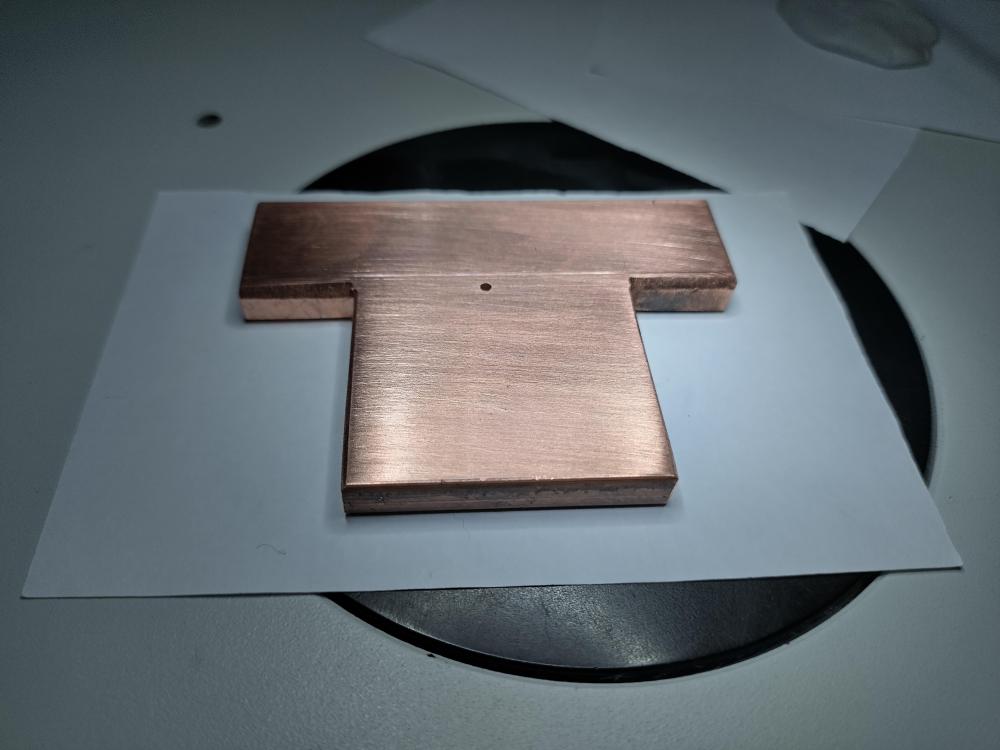

I believe it may be a specimen holder for an electron microscope, TEM or similar??? There are many variations in designs, but it's very similar in the generic form. Or it may be a custom or prototype design? See the links: https://wileybiomedical.com/products/philips-fei-transmission-electron-microscope-specimen-holder_125536581916_ https://www.axt.com.au/products/model-2020-advanced-tomography-holder/1 point

-

1 point

-

Hi using a dremel or such or even file a slot in a brass or steel rod to twist it round and back.1 point

-

Some regulator boots don't have a slot to insert a screwdriver into. Stout tweezer to turn it.1 point

-

1 point

-

Maybe you could get a 48mm lens extension kit and add enough rings to clear the objective lenses. M42 M48 Extension Tube Kits 3/5/7/10/12/15/20/30/40/50mm For Astronomical Telescope Photography T Extending Ring https://a.aliexpress.com/_mtt6UfN1 point

-

When I replace my 10x with 20x eyepieces the FOV decreases whilst the working depth stays the same. So the 5x eyepieces should increase the FOV, but I don't know if it would be limited by the main lens.1 point

-

The barlow lens is supposed to fit to the front of the shroud. Are there any threads there?1 point

-

Spin the knurled ring that has a split in it. Split to the top then you will see the oil hole that lubes the bearings. The ring turns to expose and recover the hole, it will be tight to turn. It should turn by hand, thumb and index finger.1 point

-

1 point

-

So the stem does look central which was one of my concerns.1 point

-

Hi Guys. I have been on this forum for the past six years, and in my wanderings have never encountered another site like it . The closest is the watch site (mainly Seiko Citizen) but they don’t interact like this one where social chat is mixed with genuine help and documation . Most sites just point posters to links and leave you to get on with it . Here we follow up most questions and await an out come. A lot of feedback we get from out posters is welcome and to know that you have helped some one achieve a repair or supplied the documentation that has assisted in the successful completion of a repair is great and long may it continue. It’s the best site for free information and advice. By the way MODERATORS in the six years I have been posting none of my posts have the thumbs up logo attached. Just curious . Watch Repait Talk, best site for informal interaction and help. Keep it going Mark.1 point

-

1 point

-

1 point

-

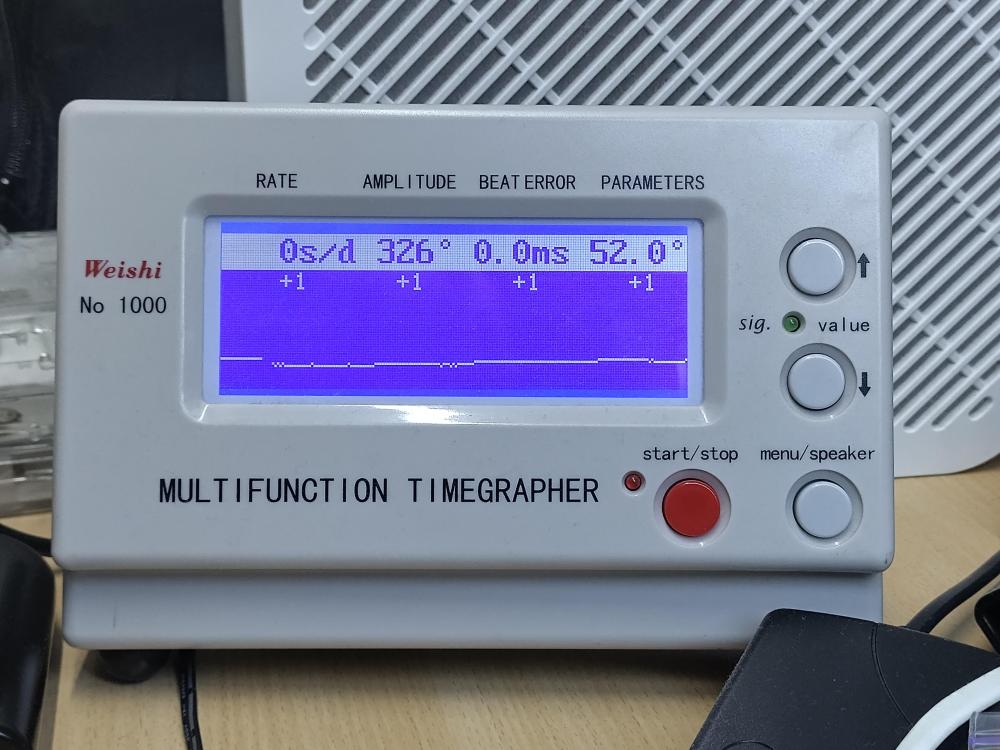

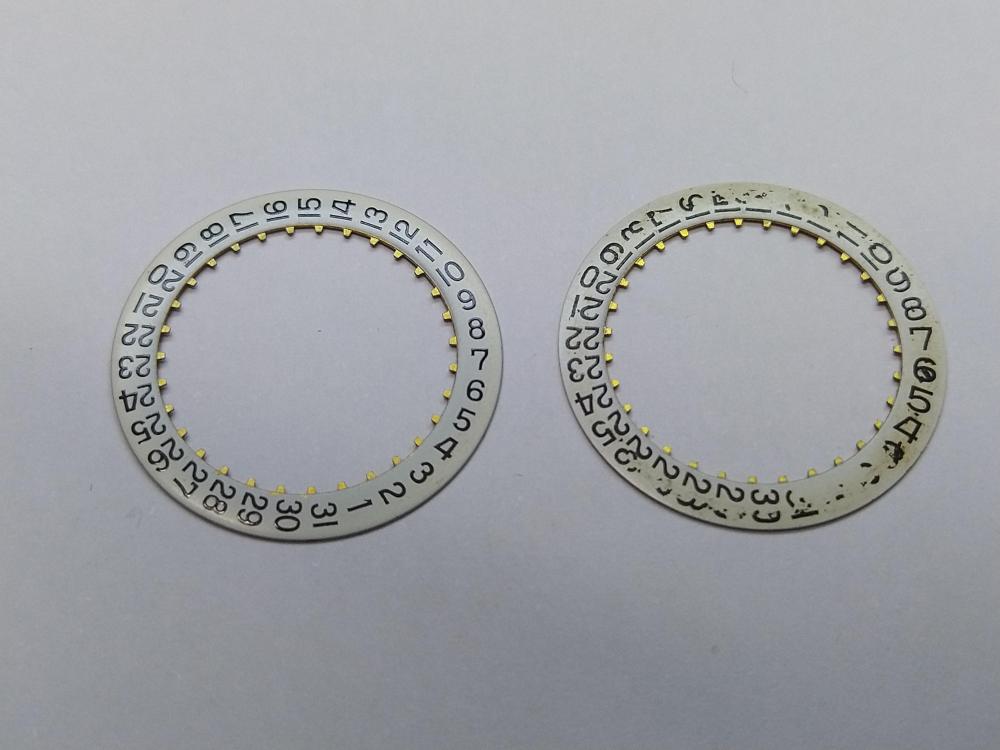

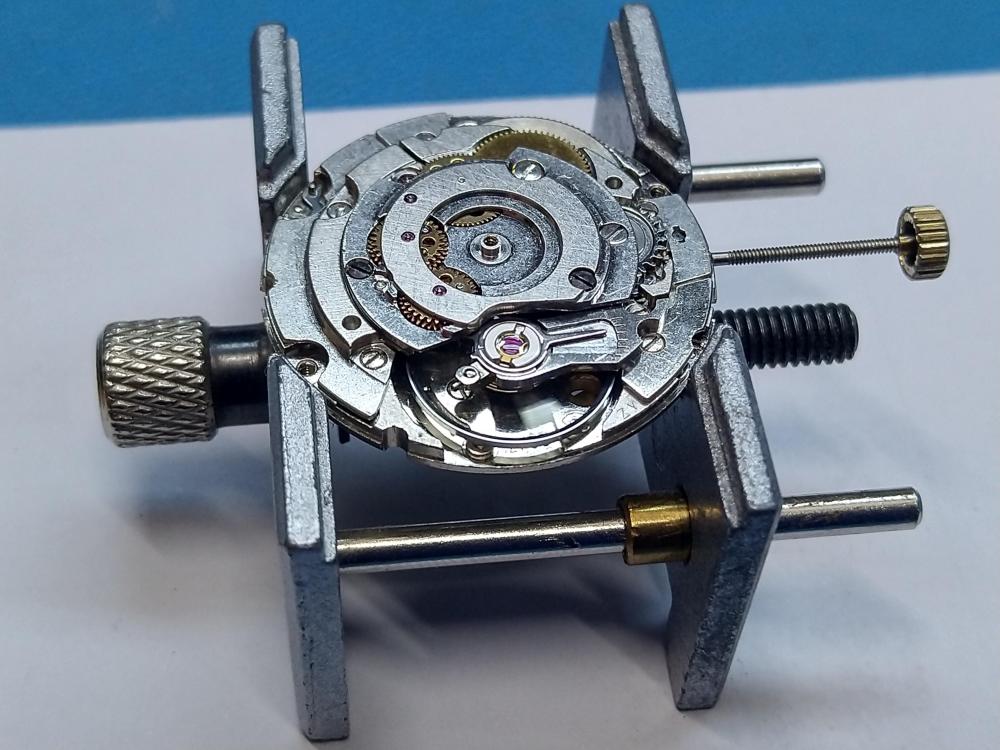

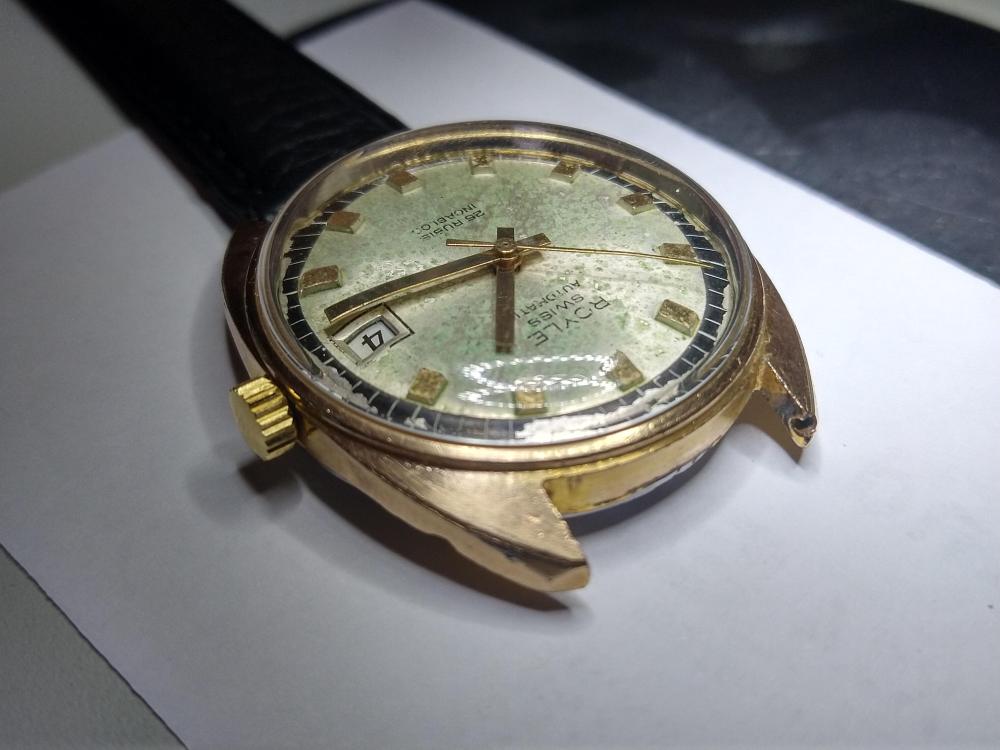

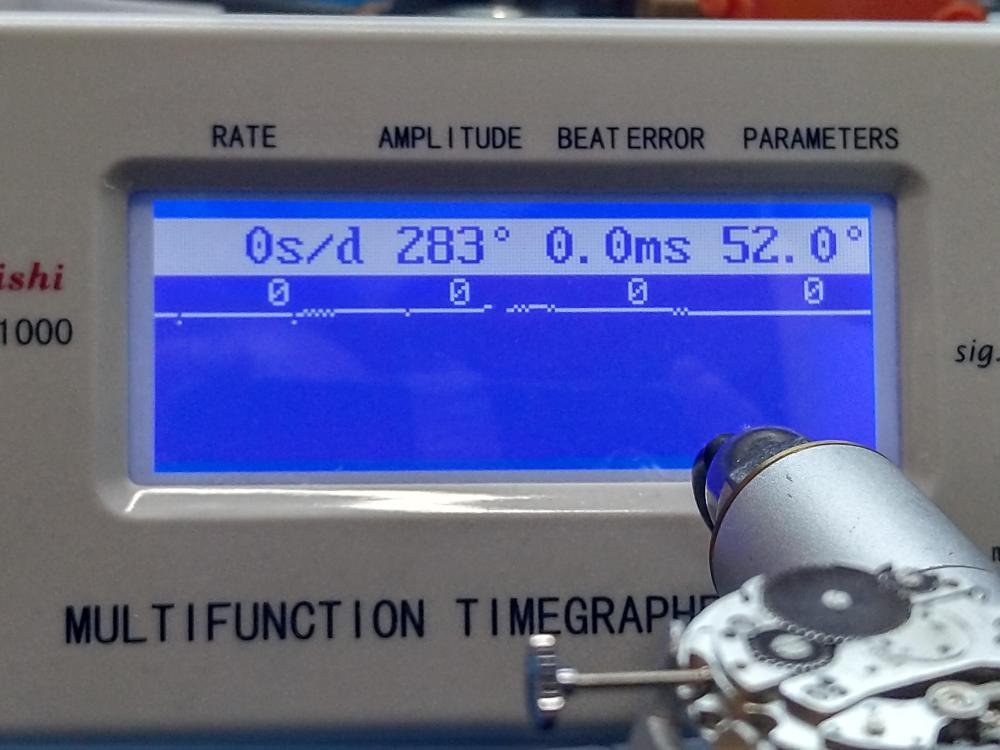

HWGIKE#40 ETA 2783 Full service, very nice performance. Moisture damaged, moisture went in along the stem ruining the stem itself, the dial and the calendar ring. I bought a new calendar ring from the US, a new stem locally from eBay and a new glass from cousins for it. You might question this as why would u spend money on a watch with a broken dial and with one case lug damaged. I thought i would be able to fix the lug somehow, but i failed to find a professional method what could be done at home. HWGIKE#41 Swiss chronograph pocket watch. I have been slowed down for the last 2 weeks or so because i was finishing the flooring in the attic. This is where I store most of my watchmakers related cartoon boxes and it became so chaotic that I had no choice, but to finish the complete flooring and to build shelves not just for watch parts but for everything. I still managed to find some time... with very little sleep...to do watchmaking. Here I have my first chrono pocket watch which was a real watchmaker job. Had to replace one rub in jewel cap for the balance, i had to re apply shellac juice for the pallets (had to quickly build a pallet warmer, going to finish it later, but for the job it was ok, i was holding it with a pair of pliers), the yoke spring is not original and had to work on its shape a bit aaaand... it has a Breguet overcoil hairspring where someone before me shortened the HS by pushing it out a bit and not cutting it... i had to bring it back from there keeping the beat error low and the amplitude high. I am very very satisfied with the end result. My memory is pretty bad nowadays, i cased this a week ago, had no time to take pictures since ... not like we had any sunshine for natural light since last Friday... however I believe no major mistakes were made. At the end I pushed the minute counter hand too hard and it stopped the whole movement... it took me a while to realize that. HWGIKE#42 Rondal RL 1223 alarm Full service where i first experienced knocking or galloping. I have a number of RL1223 movement in my drawer, but none of them are a runner as they were stored in a purpose made foam container, the foam disintegrated over the years and the little particles went everywhere. So I cleaned this one and dial down it produced a strange not always present noise I could hear from where I was sitting during the day, I was working while the watch was on the mic stand. First I did not understand whats going on so I checked the HS, checked the balance staff pivots, checked the bottom jewel and re-cleaned it, washed the pallets once more and so on so on again and again... then I narrowed it down to the balance and then i narrowed it down to the amplitude. Ohh.. it has to do more than 360 degrees.... the pic of the graph on the timegrapher was taken when the watch was only half wound, but when it was wound fully that was the time when the issue came back every time... so I set the test period to the lowest possible 2 seconds and i slowly started to wind the watch keeping an eye on the amplitude...i could go as high as 335 degree, but then that was it.... not good enough so I made a video and played it back slowly... Yipee, more than 360 degree the impulse jewel is hitting the pallets. Luckily it only happens dial down and when fully wound. The graph what I saw during knocking was like this: https://adjustingvintagewatches.com/amplitude-attacks-dealing-knocking/?fbclid=IwY2xjawIchUJleHRuA2FlbQIxMAABHZ28piDWfDu6lWbErREkucg2HEysYVmu9fjW3OpbZMaHqbFRK_sL3CgscA_aem_FfQZh_rjoNq4egAfp3sq1A1 point

-

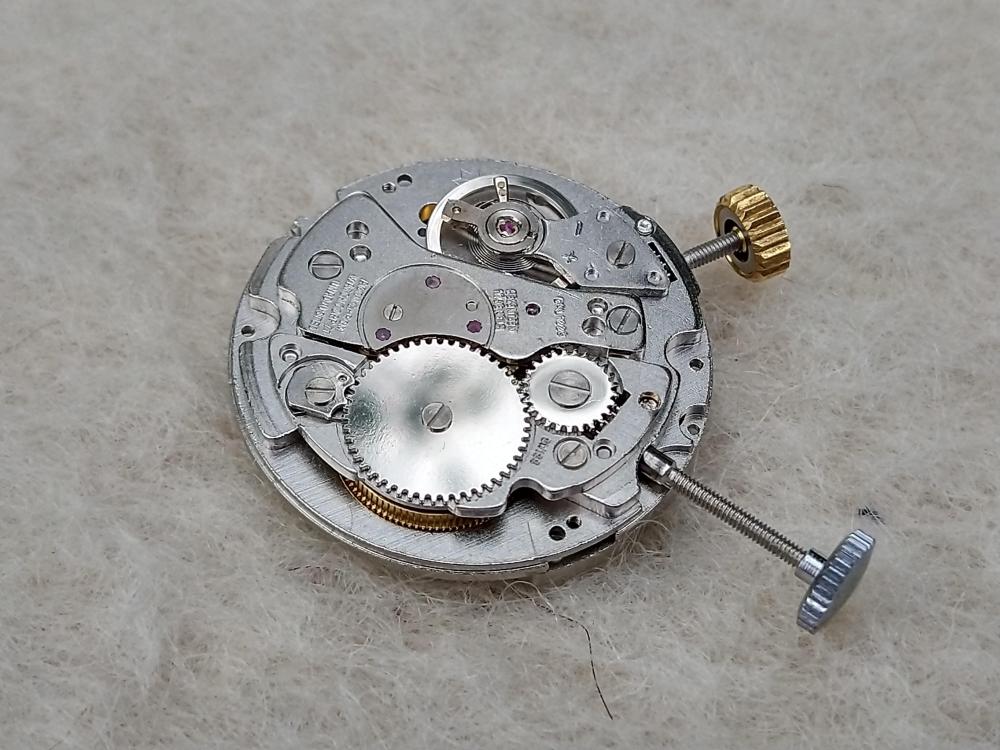

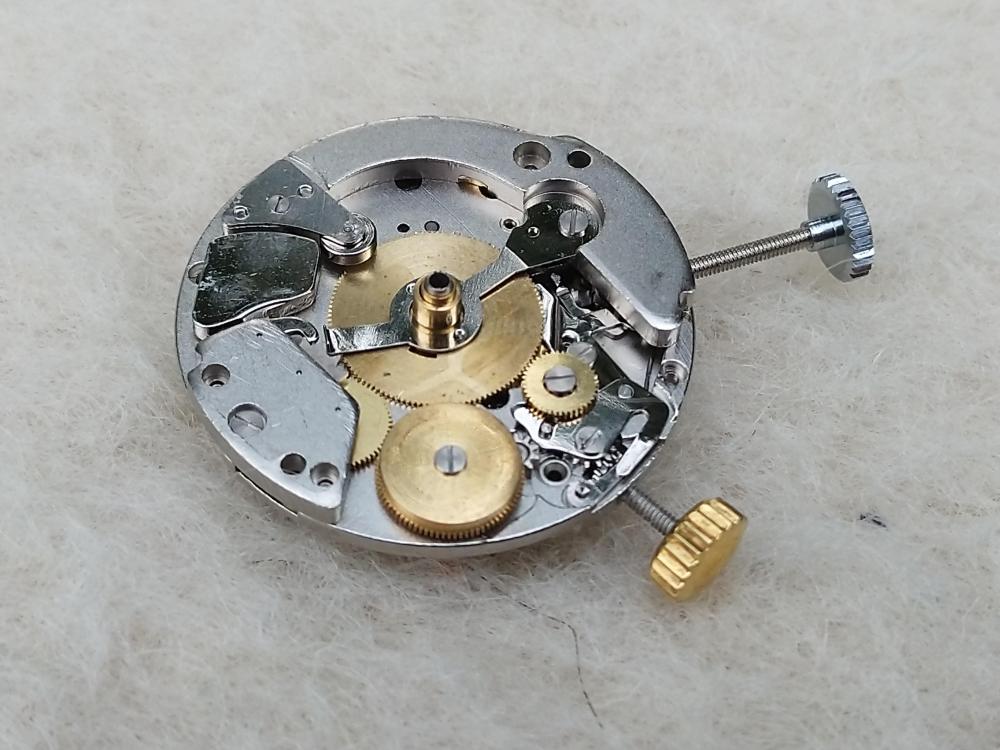

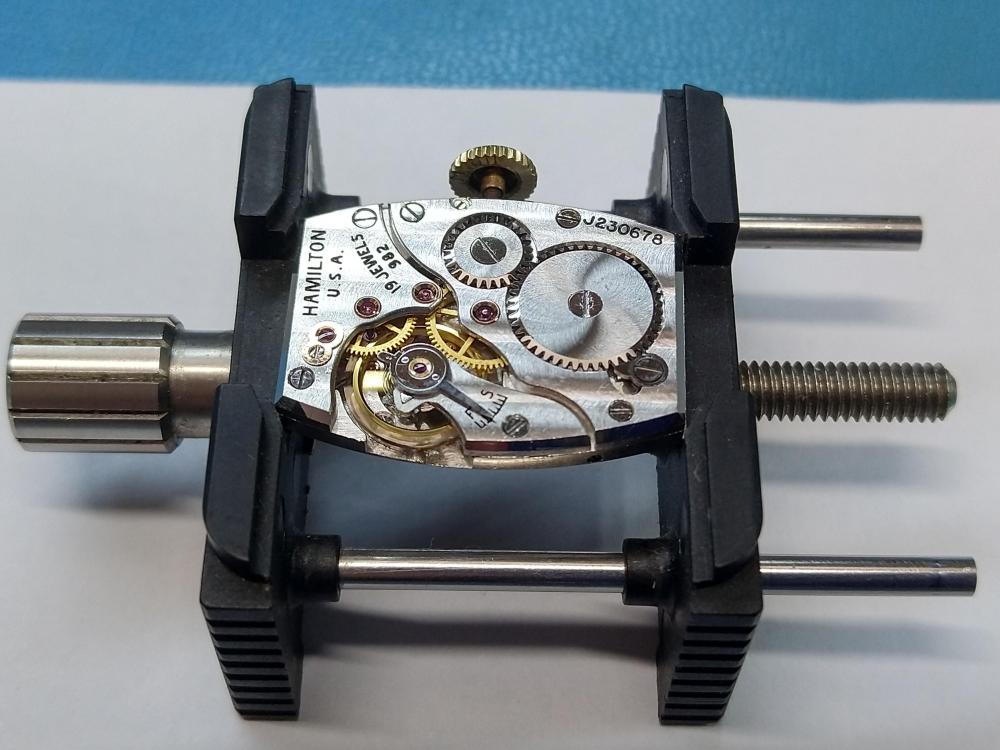

HWGIKE#37 Hamilton 982 Full service, acceptable performance. Amplitude 265 fully wound, beat error 0.2 ms. Had to use the old MS because the one I ordered came damaged, dirty and even rusty and I would not expect a better replacement. Broke the escape wheel when I first tried to get the movement out from its basket... that little hole seemed to be a nice place to put my screwdriver in.... Bought a donor half a year later. I had to replace the screw for the escape wheel top jewel plate dial side... meaning that i had to find a candidate and file it down to size... luckily i am using a microscope... I still don't understand how could they handle these tiny parts in the past without modern technology...1 point

-

Hello All; I managed to get the little booklet originally supplied with a Boley's staking set. It shows where the punches belong, their numbers & sizes and a cross-section of the tool. Minor detail; it's in German, but that's to keep the excitement going I scanned and converted it to a PDF file. Perhaps it has been uploaded before but better one time too much than nothing at all Boley set.pdf1 point

-

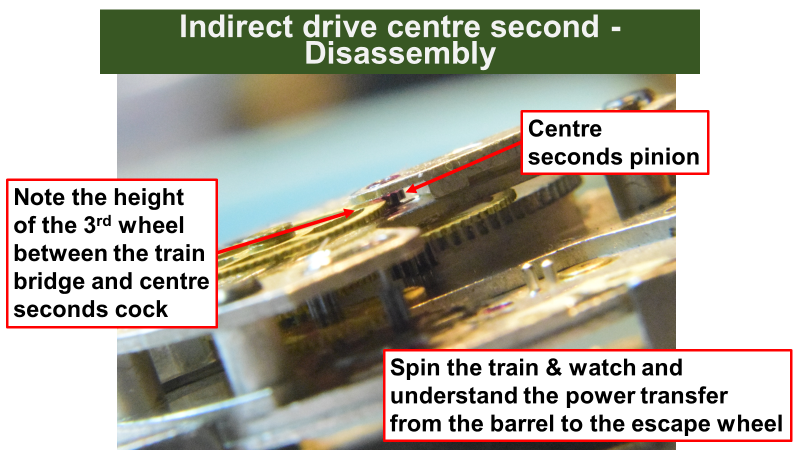

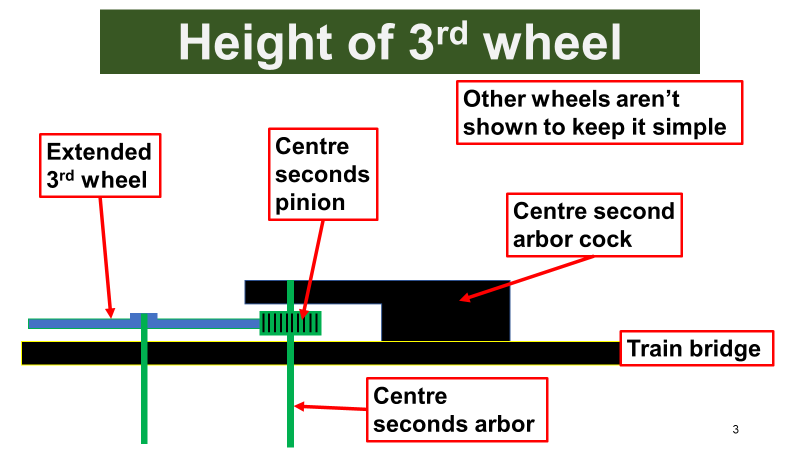

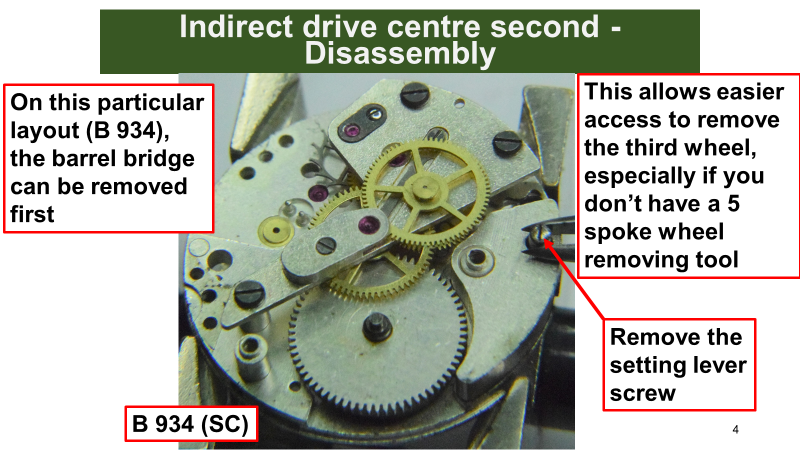

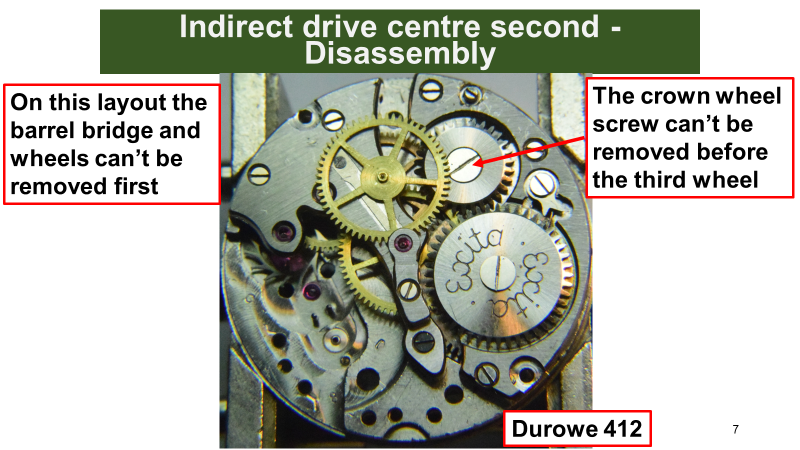

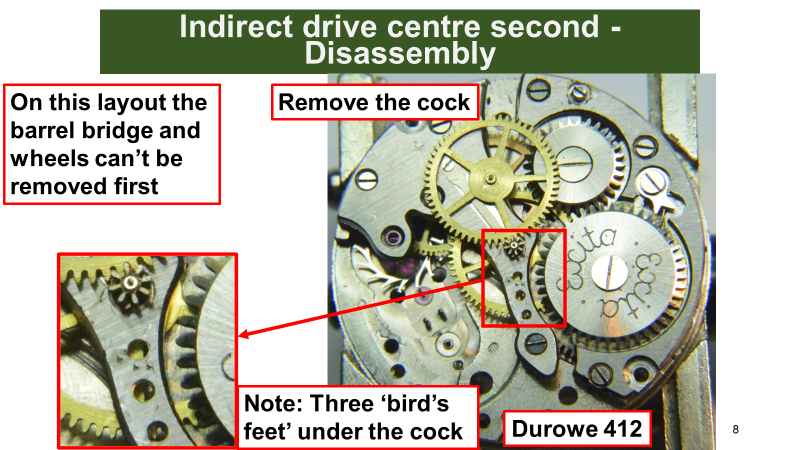

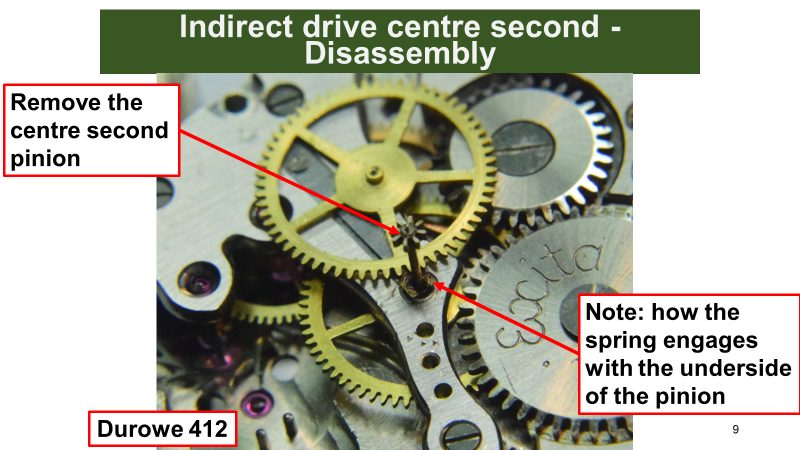

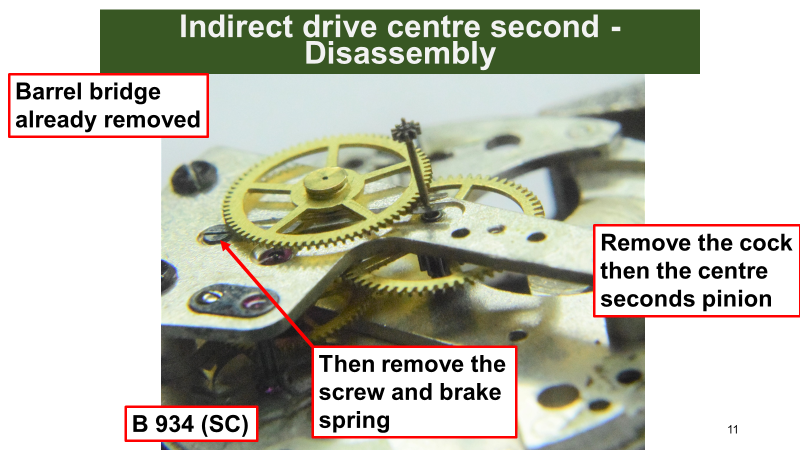

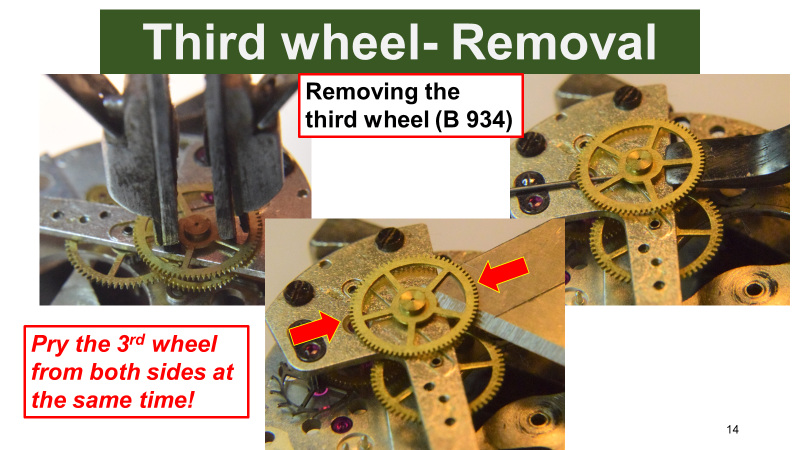

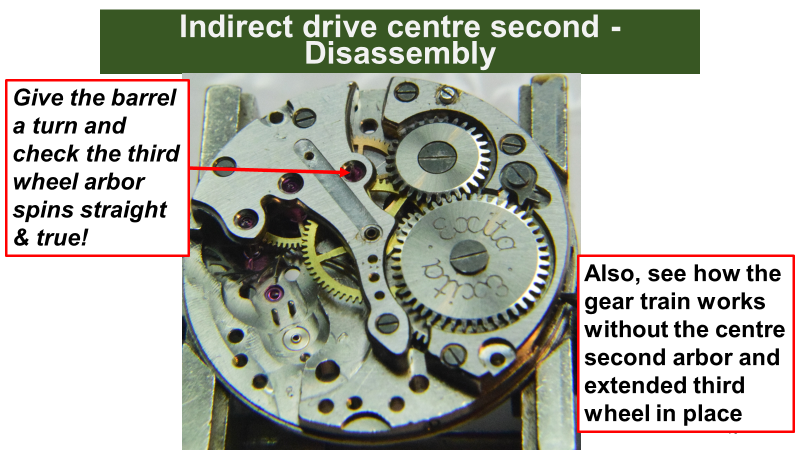

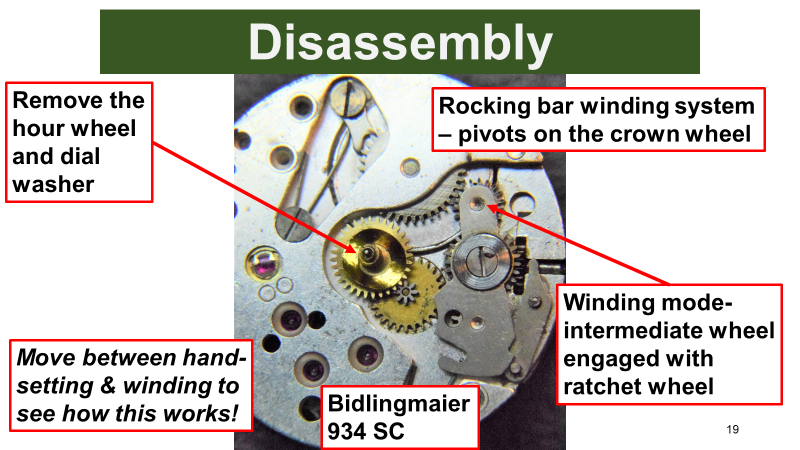

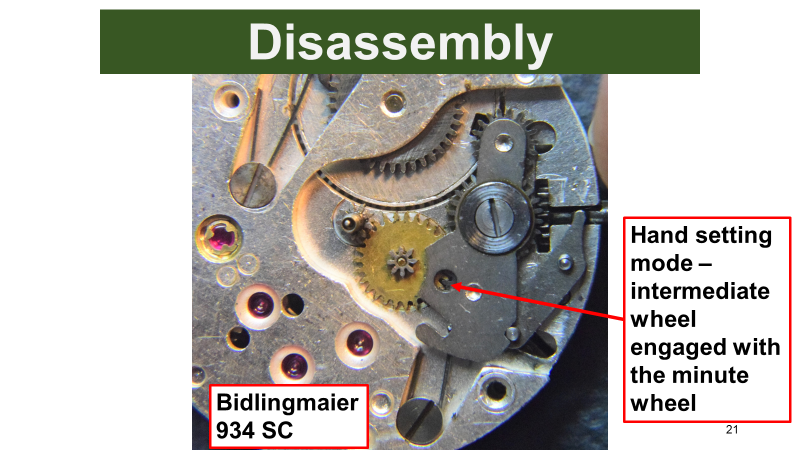

I posted some of these slides from a lesson I take on an indirectly driven sweep second movement. I hope it help anyone. I really should post the set of lessons on a sweep seconds movement sometime soon. The Bifora (Bidlingmaier) 934 has a great rocking bar winding system, which isn't usual to see, as seen in the last two slides1 point

.thumb.jpg.19a9c4ff164d78d516aa9f05a063752b.jpg)