Leaderboard

Popular Content

Showing content with the highest reputation on 03/16/25 in Posts

-

Mb, folks like me and John will always get the info out there. For those that don't know I'm "Nickelsilver" here, and on Instagram. On a few other websites I'm Maillchort (a misspelling of German Silver in french). They all mean the same thing, and I do too, haha.6 points

-

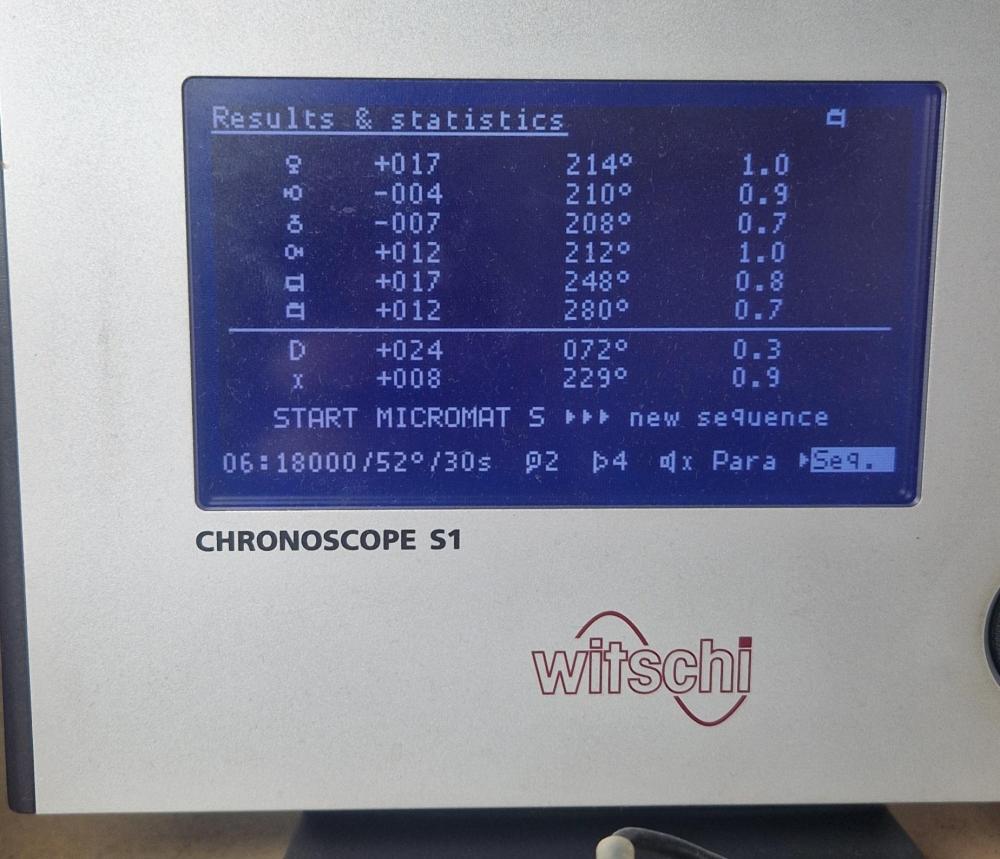

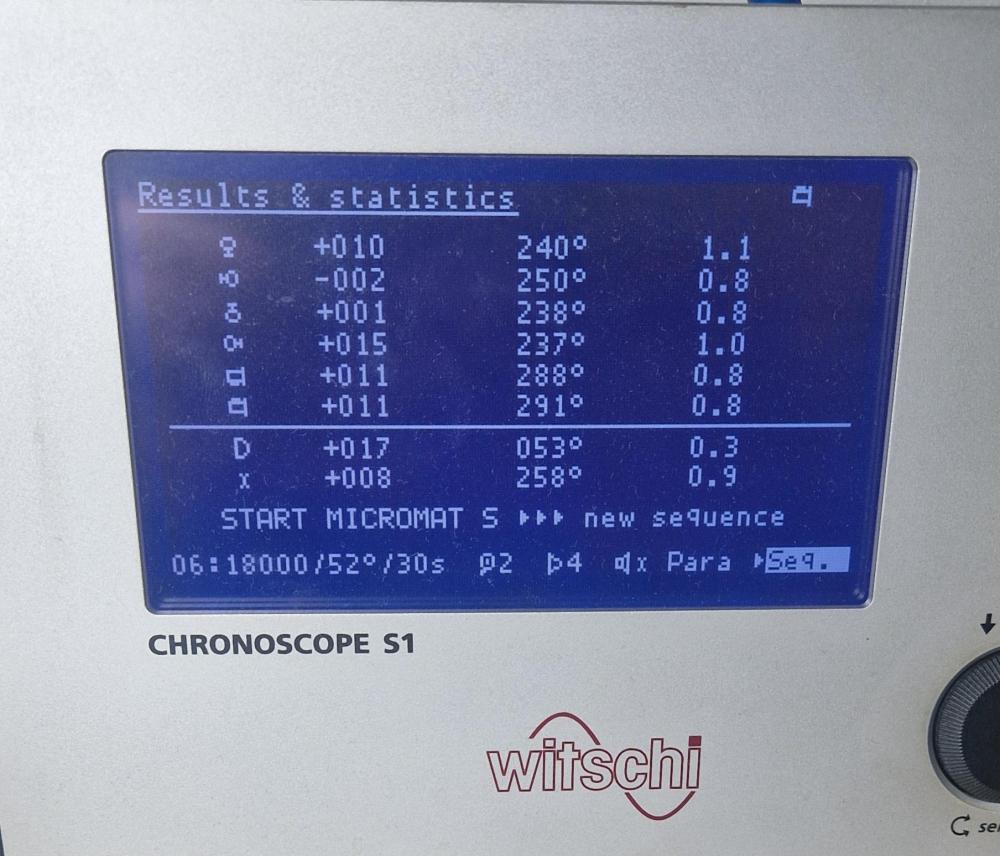

So many factors come in to play, it does become a bit dizziyng. Just had an Omega 30mm caliber (26X something). One of the best movements of all time. Serviced, ran a ticket, 32 amplitude difference in horizontals, verticals dropped from 280 (max horizontal- other side was 248) to around 210. I retouched the balance staff ends, and moved the exit jewel in 0.02mm. I write this because a lot of times you can have the best cleaning solutions and methods, but, some watchmakingishness comes into play. I know folks here know that real watchmakers exist, but go on Reddit and try to explain something " real " and you are a gatekeeper. You do have to move pallet stones, bankings, tweek hairsprings. I do it on every job. Like, 30% of the time I retouch the escapement in some way, and 75% of the time I touch up the hairspring. Here's the tickets from the Omega. It was like 20 minutes from one to the other. It'a funny to see the actual average rate didn't change. But the overall performance is a LOT better. I also didin't touch the regulator once in the whole job.4 points

-

That is the setting lever screw, it is captive between the barrel bridge and the main plate of the watch. It screws into the setting lever to hold it in place and you would partially unscrew it to release the stem from the watch. Unfortunately it seems you unscrewed it completely, this will necessitate removing the hands and dial to access and hold the setting lever so you can secure it again with the screw. It’s not a big job nor difficult but as you’re dealing with hands and dial easy to damage as they are rather fragile. Tom3 points

-

It’s kind of reassuring to hear this. As my skills have improved I’ve found myself spending more time on balance and escapement, slight tweaks to overcoils when checking positional error, etc. I was a bit worried I was becoming too ‘fiddly’ and that still may be the case but I button up more movements with tighter deltas and centered regulators. Thanks…2 points

-

I used to use Windles clock oil. You can use that for the springs and pivots.2 points

-

As Nev sais. In fact it has a function: cheat the buyer. He shall assume a higher quality type of keyless works and of the whole watch. Frank2 points

-

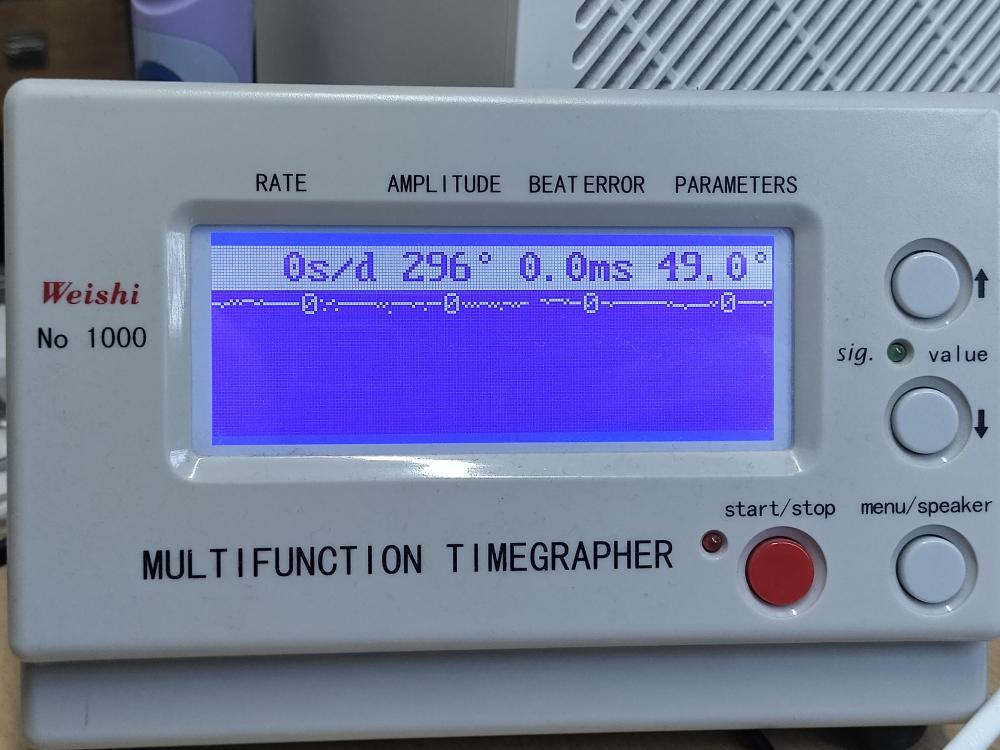

Shimming this one for end shake helped tremendously though it's still not great in verticals and I suspect the pivots need burnishing. That's still outside my tooling and skillset so I'm going to leave it alone. Can these end stones be pushed in 0.01 to lessen the shake? I am pretty sure I have spotted you on reddit under a different name, and honestly I cannot believe your restraint over there. There's a horrible dearth of experience on reddit, and very few people who hang around experienced or not, who are good communicators. This is why I try to squeeze so much out of all of you over here (thank you).2 points

-

2 points

-

I believe it may be a specimen holder for an electron microscope, TEM or similar??? There are many variations in designs, but it's very similar in the generic form. Or it may be a custom or prototype design? See the links: https://wileybiomedical.com/products/philips-fei-transmission-electron-microscope-specimen-holder_125536581916_ https://www.axt.com.au/products/model-2020-advanced-tomography-holder/2 points

-

Hello! I occasionally repair old barrel and flip clocks, and have started being interested in watches too. This seems to be a great place to learn more. Thanks, napes1 point

-

1 point

-

A number of stopwatches (stop timer movements from firms like Venus) had onboard spare part storage. A staff, some springs and an often-broken pinion from another wheel have been listed by people describing the contents. Those watches lived a more perilous life than standard watches.1 point

-

I have come across many which are very stiff to turn, would a drop of oil under the rivet help?1 point

-

I never saw it and never looked for it. I always held the boot with sturdy tweezers and rotated the cock (I wonder how that sentence would be perceived by someone not into watch repair). Great tip!1 point

-

Discord link if anyone is interested, you will of course need have a discord login. Free, no adds or similar https://discord.gg/xaJES6Wq6H Tom1 point

-

I'm far from any expert in lathes Greg, my own trade is different but I do and have used a lot of bench equipment. So with my 2 lathes, I tension the belts until they don't slip and then a touch more. So with a thick belt you would set them to a non slip and that extra touch could be too much on the bearings over time. A thinner belt would have more adjustability providing it still grips the pulleys.1 point

-

Fits nicely in the v-groove. I don't see why you should use a thinner belt, unless this is to big for the pulley on the motor..1 point

-

1 point

-

I would think the key points are, that it spins the pulley and doesn't slip either there or at the drive, and not so much tension that the bearings are strained. It does actually look too thick !1 point

-

1 point

-

1 point

-

A lot of New York Standard's watches were like a step up from "dollar watches" mostly only in appearance. Same with Seth Thomas pocket watches, many of them have fake "jewels" on the plate which were just red glass beads set into brass settings.1 point

-

I know what you mean, throw something in the bin and you desperately need it on bin collection day, useually right after the bin truck has just turned out of the street! Tom1 point

-

1 point

-

1 point

-

If they don't have a slot, they usually have a hole. I use an old oiler to twist them.1 point

-

1 point

-

In case you still have this watch on bench. Curious to see a clear top view of balance complete with hairspring attached. Funny as it may sound, sometimes I can tell if hairspring quality can belong to balance wheel. even funnier is I can't actually identify some metals . Fake and genuine gold jewelry or brass and copper for instance, not in photos anyway. Not sure but quality of parts in bulova seems superior to standard in my view, so expect to see finely finished balance complete. Rgds1 point

-

Hi Dell, I don't want to burst your bubble but these movements are horrid, made of soft brass? and steel? hardly any sinkholes for oil, springs are too powerful for the movement so wear is very common. From what I can see of the plate not only the hole that you marked but the center one is the same, looks like part of the manufacturer process just looking at it from the other side will tell you if it has been re-bushed. As the whole thing is soft check all pivots and holes for wear, take all the springs out of there barrels and clean. These movements wear out in about 20 years, yes they are pricey.1 point

-

1 point

-

It sounds like demagnetizing won't do you any good and it needs a complete service.1 point