Leaderboard

Popular Content

Showing content with the highest reputation on 03/17/25 in Posts

-

4 points

-

It could also be the addition of modern high-quality synthetic watch oils. Only guessing!3 points

-

3 points

-

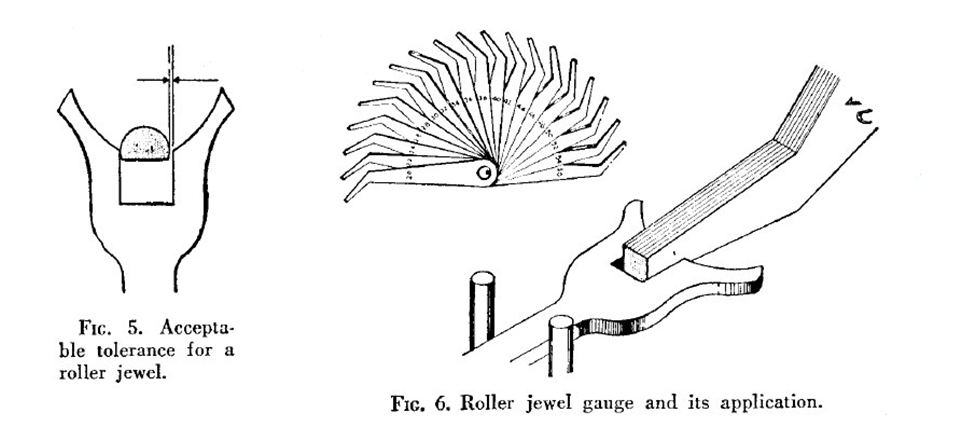

Not broken, it's the way it's held into the plate. https://www.vintagewatchstraps.com/watchjewels.php#:~:text=Rubbed In Jewels&text=The first method of setting,plate around the jewel hole.3 points

-

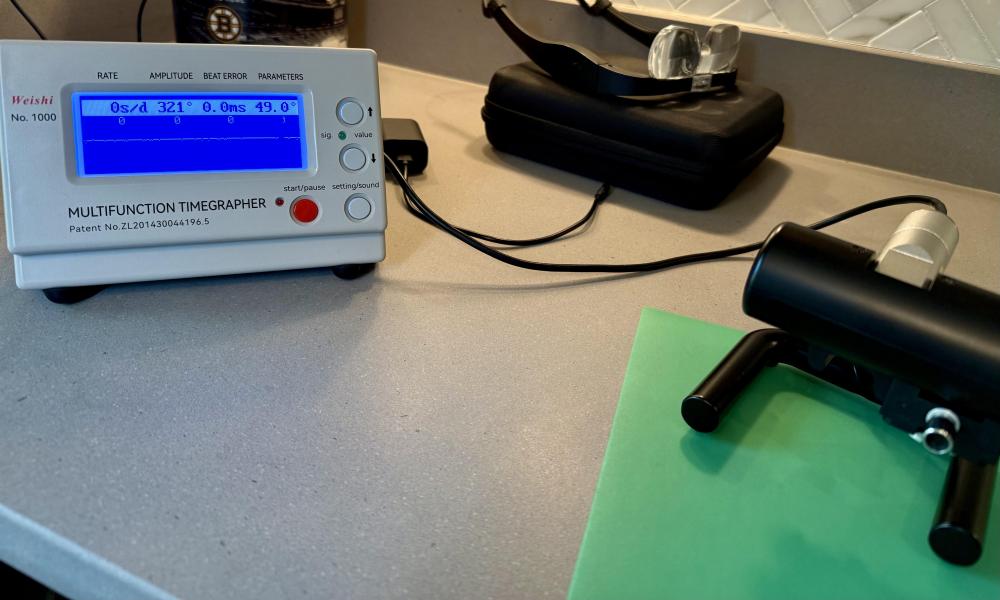

Looking at the timegrapher, you must be getting close to rebanking. I've had some watches from the 30s and 40s with very high amplitudes. I think it must be the modern springs being stronger than the older blued ones.3 points

-

Two spare balance staffs are expected to be in there, at list this is what I have heard.3 points

-

A number of stopwatches (stop timer movements from firms like Venus) had onboard spare part storage. A staff, some springs and an often-broken pinion from another wheel have been listed by people describing the contents. Those watches lived a more perilous life than standard watches.3 points

-

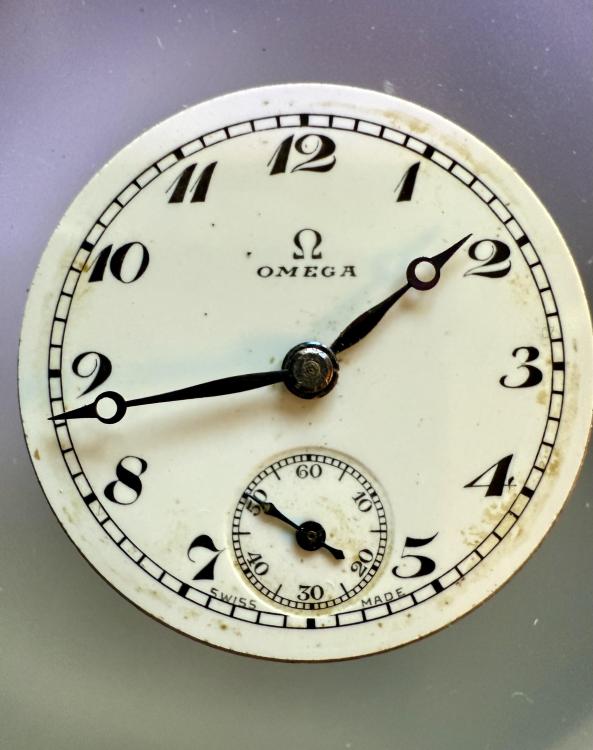

…the least exciting watch in a small lot, an Omega from 1935, 30T2…SOB of all things? , clearly once loved but neglected for decades, has blessed us with this lovely moment. TG is on the long time setting and has been running like this for a couple of hours. It asked for very little, a bit of reshaping of the end coil, a small turn of the collet, a bath. There’s a new alloy main but the old carbon one would have been just fine thank you… …I may have to turn on the tg ticks …The dial now looks factory fresh but the case warranty expired long ago. Out of respect it’s getting replated...enjoy ️️2 points

-

I think it was in response to free selling on Facebook Marketplace. On the whole, eBay is a far better system than FB, but there are always people out there trying to screw you. Goes with the territory of online selling, I guess.2 points

-

Wine-red HMT Kohinoor I got on a new bracelet for $25. The watch isn't supposed to be new, but it looks and performs like it is. It runs well enough that I am not going to bother servicing it, as had been desperately needed with my other 4 or 5 HMTs. For all I know the bracelet was molded out of tin foil but it was still in plastic, looks nice, and the package took under 2 weeks to get from India. They even upgraded it to a display caseback.2 points

-

Lovely! Impressive that you got the beat error to 0.0.. I'm very keen on seeing the full watch when you're done. Love the case shape with the dials. I'll look absolutely spectacular when replated.2 points

-

As of a couple of months ago, selling on ebay is free (at least for UK sellers). Which is great, BUT a recently they added "Buyer Protection" - a fee added on to the selling price (of 75p and 4% up to £300, 2% over £300). So the buyer pays a bit more. If you sell using the "Global Shipping Programme" on ebay, then you pay local postage to a shipping address, and all customs forms, taxes, postage, and tracking are taken care of by ebay. Couldn't be easier.2 points

-

I don't think I've ever actually seen one in person but I was aware of the existence of spare parts. I would agree that the balance staff would be the most likely spare parts to be in.2 points

-

I like working on Hermle movements; I service them all the time. I've serviced and sold many Hermle-equipped clocks that are 40 to 50 years old, still going strong with minimal wear. They may not be top-end quality, but they are reliable and have parts readily available. It's a double-edged sword, though, in that they keep going for years, even when they need a service. Consequently, owners don't bother having them serviced, and they end up wearing out. I have a Comitti grandfather clock that also uses a Hermle movement. The new price is up towards £10,000, which I think is insane. The movement is about £400 brand new, and there's never £9500 worth of case. There's probably £9000 of profit after making the clock. Does the bush fitment hole have a hexagon shape on the bushed pivot hole you've circled? I've seen several that do on the same pivot hole. It makes me wonder if it's a factory retrofit to address a common wear problem with that pivot. In my experience of these, the sluggish chime is just down to basics. Ensure it's clean, has good lubrication, good mainspring, etc. Also, don't forget to strip and lubricate the hammer assembly, as it can get pretty gummed up. If the mainspring is set, pop a new one in. All parts are readily available from Cousins. One alternative explanation is that if the chime mechanism hasn't been set up correctly, it partially lifts the hammers at the end of the cycle, which doesn't allow the chime to gather enough momentum to get going properly. If you need a hand give me a shout.2 points

-

Yes, that is an odd design on these movements. I really like working with the Parashock system though. Just be careful with the HMT movements, as they are the flimsiest metal.1 point

-

Interesting, thanks! Yes, it sure looks like a Citizen/Miyota and of course the Parashock jewels. I only have the best experience of working on Citizen and Miyota movements. They are, as you put it, straightforward (for the most part), especially compared to Seiko's movements which I find to be pretty quirky.1 point

-

1 point

-

Looks like the Caravelle 11DP, which is also based on the 0231. Bulova was nice enough to indicate the left handed threads on the crown and ratchet wheels though. I really like working on this movement, very straight forward. The spring on the setting lever can be a little tricky but once you know how it's straight forward.1 point

-

Yes, it did do some rebanking at a full wind but I manually unwound the mainspring just a bit and it stopped and it hasn't recurred but clearly it's close. I have observed this kind of temporary rebanking on a few other quality movements- IWC, Eterna, where it happens for for a few cycles then disappears... ...and thanks for everyone's interest. I'll post a more complete photo journal when I get it cased...1 point

-

Sure - as far as I am aware, all manual wind HMT use the HMT 0231 which is based on the Citizen 0201. They bought the tooling from Citizen in the 1960s. This example has the nicer ratchet and crown wheels. Most have plain unpolished, undecorated metal. I can't open the case back now but you can find other pictures of the 0231.1 point

-

Thanks for the link, that was most educational and extremely relevant to a jewel I'm trying to decide how to fix. Knowing what rubbed in means and the explanation in the link gives me the insight to proceed forward! Again Thank You!1 point

-

They're very simple and straightforward as long as you make no assumptions and take nothing for granted.1 point

-

1 point

-

They have a few surprises. First, the ratchet wheel screw is left hand thread in addition to the crown wheel, but there is almost never a 3-slot screw to indicate that. You learn by breaking one. The mainspring is lefthand wound like a lot of Japanese movements (which ancestrally this is). The newer ones (as opposed to one from the 1960's or 70's) are made from extremely soft metals. The screws are like butter so it is very easy to twist the head off that ratchet wheel screw or to strip out other screws. The stems are also very soft. Twice I have tried to unscrew a crown and just twisted a stem in half. And because of that, the watches can be in all kinds of crazy states. This one is pristine, but my others all had workarounds like shellacked hairspring studs, stripped or missing plate screws, the dials are often redials on other models, badly painted onto brass blanks having no dial feet, missing movement rings, missing case tubes, etc, etc, etc. The "Parashock" system is nice. It has a hole jewel set into a tiny spiral spring, offering both lateral and axial protection, and then an end stone set in a thing with only two tabs. Drop in the hole jewel then insert one tab of the end stone and align the other with the slot, turn. It is the easiest of any type I have had to install and even managed not to break or lose any on one of my first watch services.1 point

-

It surprised me when they changed the rules. They advertised the fact on TV. Businesses still pay a fee, and there is a fee if it sell overseas This from their site: Free selling for UK-based private sellers It's now free for UK-based private sellers to sell on eBay (excluding motors: Cars, Motorcycles & Vehicles listings). You won't pay final value fees or regulatory operating fees when your items sell. Fees will apply if you list more than 300 items in a month, if you add optional upgrades to your listing, or if you deliver to an overseas address. See our FAQs for additional details. And I expect there will be tariffs In the UK, the Global Shipping Progam is optional.1 point

-

1 point

-

OK, my advice will be to destroy the brass part as I said in first message. Then grind a groove as shown with blue using dremel with dental separator disk. Thus You will have access to the broken tip and will be able to get rid of it. The next thing to do is to turn the pinion on lathe to get rid of that toothed portion and have clean and very slightly tapered end. Then, pivot inserted, turned and burnished to fit the hole of the bearing. Then, new brass bushing for the wheel is to be turned and riveted to the wheel. The hole in the bushing has to be wit a little smaller diam and after the riveting, the hole should be broached to tight fit the pinion. Then the wheel to be pressed in place and it's position adjusted to correctly mesh with the verge. This is very important for the wheel to be as much true rotating as possible.1 point

-

1 point

-

I was trying to remember where I found out about this? It might've been when I was in school because we took in a variety of things and one of the first things I did as a student was I was handed a bag of stopwatches to deal with. yes in the school they took in watches and I get a whole bag of stopwatches. So this is where I probably learned. But just because I knew that the last one I worked on a 736 I didn't have it in running mode. Because I forgot about that and removing when it's returned to zero makes it a little bit harder to remove things. Then for anyone else that comes here. Snipped out an image from the pictures up above Springs that are nicely color-coded. Plus a photograph so you know where they go. The last one I worked on a 736 the two spring is appeared to be almost identical. There are about the same color they both looked may be the same. The parts list indicated different part numbers which might imply there different and. The really important not the mixup the spring is if they're not color-coded.1 point

-

Actually, this is joint that is not meant to be disassembled. I am not sure if it is brazed or some other way is used, but inside the brass thing the steel axle as part of the pinion is not round. It has hexagon walls or small teeth that have remained from the pinion wire turned to pinion. The length of this hexagon or toothed portion is smaller than the brass thing and the brass fully covers it. Removing of the brass thing is not possible without destroying it. The easiest way to do it is to squeeze the brass thing to the point of deformation, then turn to 90 degr and squeeze again and do it until it breaks. What happened? Why is it needed to be removed?1 point

-

I expect that would be well in tolerance for the application as nominal 25mm Tom1 point

-

Welcome. I’ve always appreciated these clocks. As a kid dad would bring home concept models of these things from General Electric. We kids had fun with them…1 point

-

I used to use Windles clock oil. You can use that for the springs and pivots.1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement. If there is anything we can help you with don’t be afraid to ask. Nice clear photos can help a lot.1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

Hi Melissalea. I reckon Robs explanation to be pretty close, never seen anything like it for clocks.1 point

-

I believe it may be a specimen holder for an electron microscope, TEM or similar??? There are many variations in designs, but it's very similar in the generic form. Or it may be a custom or prototype design? See the links: https://wileybiomedical.com/products/philips-fei-transmission-electron-microscope-specimen-holder_125536581916_ https://www.axt.com.au/products/model-2020-advanced-tomography-holder/1 point

-

Hi Dell, I don't want to burst your bubble but these movements are horrid, made of soft brass? and steel? hardly any sinkholes for oil, springs are too powerful for the movement so wear is very common. From what I can see of the plate not only the hole that you marked but the center one is the same, looks like part of the manufacturer process just looking at it from the other side will tell you if it has been re-bushed. As the whole thing is soft check all pivots and holes for wear, take all the springs out of there barrels and clean. These movements wear out in about 20 years, yes they are pricey.1 point

-

1 point

-

I would just replace the roller (part #730). Look here http://cgi.julesborel.com/cgi-bin/matcgi2?ref=ETA_2770 and select 'Roller', and you will see it's common to about 100 movements. I just found one. If you do an ebay UK search for "NOS - ETA - Various New Movement Parts", in the drop down list is 2783-730. A roller for cal 2783 which is the same as for your movement.1 point

-

Reading the thread, I found this: Don‘t know which yokel recommended this in his video (though have a suspicion). You will destroy the vertical fit of the arbor this way. If you want to use this short term procedure, use a flat stump inside, the domed stake outside! Frank1 point

-

I think it's a throwing star for killing people who mod, redial or use a non genuine part.1 point

-

Fantastic! Best of luck! Nothing greater in life than becoming a parent!1 point

-

I might have a solution to the solution creep issue: ONLY put clean tap water in the US, and put the various solutions in small jars with lids on them. Seal up the jars and empty/clean/dry the US at the end of every day (it's just water). I've never experienced/noticed any creep, but anything that did happen to get out would immediately be diluted beyond notice. I have one of the SS Chinese 3L models. I use it for things other than watches too, so I got the big one. Helps also that I can get three of my little solution jars in there at the same time, which is nice for my cleaning process (I keep parts separated by system through the process to make it easier to get things back together). The big guy also has multiple transducers, none of which have detached on me so far after 5 years or so of casual use. At this point in my watchmaking hobby, there are a number of tools I'd really like to invest in/upgrade. The only upgrade I can think of that I have any desire to do on the cleaning side is figure out a way to make the US quieter/less obnoxious. Another upgrade occurred to me while I was sitting here typing this: I have an 8 month old baby (in a few days), and if those tiny baby food jars will fit a typical main plate through the opening, they'd be even better for cleaning than the small mason jars I've been using... I can fit three mason jars in the US, which is 3/4 of my cleaning process. I could probably fit five or six of the little baby food jars in there though, and that may allow me to really speed up that aspect of the service process! Every time I put one in the recycle bucket it pings my "this seems useful" sense, but then immediately also triggers the hoarder alarm. Now I have a good excuse to set a few aside without feeling like I'm just adding to my clutter!1 point

-

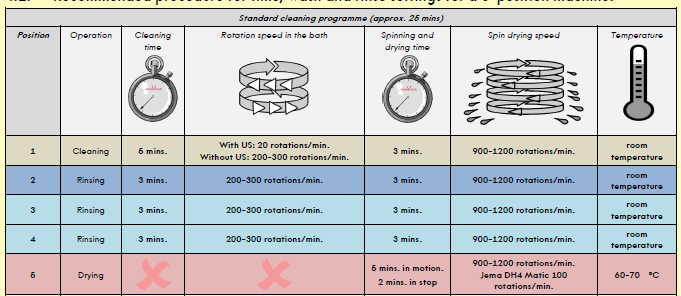

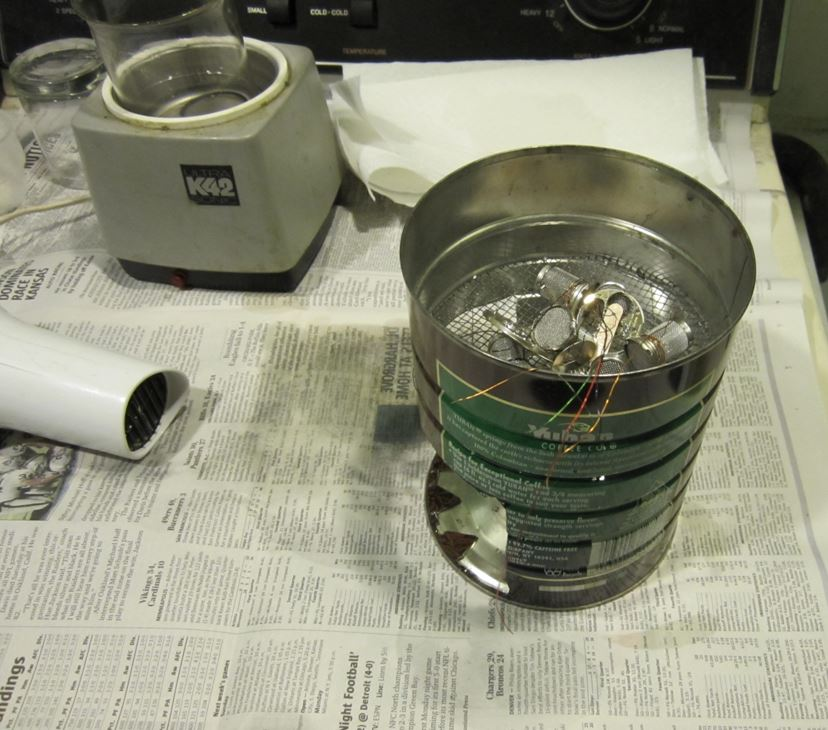

sometimes I think the fantasy versus reality catches up to people. For instance you watch the wristwatch revival channel and it's so easy and quick. then you discover that cleaning doesn't repair everything and more tools are required more skills and it's expensive when you break things. one of the things you have to be very careful of his products designed to make things bright and shiny. The watch cleaning products work extremely well and do make things nice and bright and shiny. But if you leave them in the solution to the long and they go beyond bright and shiny they will start to make things frosty especially brass. this is because the right and shiny aspect does not have some sort of time limit and it will start to etch things. The solution will turn blue green color and that really isn't what you want to do it all. Worst-case in another discussion group somebody went on vacation with their watch in the cleaning machine I assume the machine was off and when they came back they were now in need of a new movement. So that would be a worst-case scenario of. So basically are time-limited on bright and shiny. I was thinking what you need to look at is how professional watchmaker's clean their watches? In other words typically they put all the parts in the cleaning baskets and put it in the machine a push the button and walk away. here's a things like balance wheels pallet forks you win just toss them in with all the plates and stuff they would either go in a smaller basket in the machine or smaller section where there less likely to bump in the things. The greatest danger to a pallet fork is the person trying to put it back into the watch. here's a recommendation on cleaning. Notice it includes both ultrasonic and non-ultrasonic at least for the first cycle. So with ultrasonic the machines spin slower. Then notice how fast it's going when it's spinning off. I wonder how fast you can hand cranked the machine? then this thing is really have to spin no. Why are there so many procedures because everyone has a different point of view everyone has exposure to different stuff etc. So when I was cleaning watches at home here's what I did. This is a modern watch with a modern balance wheel where it's easier to leave the balance wheel attached to the bridge. Which means I took the balance jewels out and there in one of the baskets usually I put the jewels found on the dial side in with the dial side components and the jewels from the other side in the components on that side to keep them separate. Then the balance bridge is screwed back on the plate and the balance wheel is safely protected oh and yes the pallet fork is in one of the little baskets somewhere then the next image usually gets people scolding me. Typically with ultrasonic machines are not supposed to play stuff directly into the tank there should be a little but the spacing between whatever and the bottom of the tank especially with bigger machines as I believe this or variety reasons like cooling but this machine was purchased at a drugstore a very long time ago and is being used exactly as it was described. In other words small quantity of water surrounds the beaker in the ultrasonic take in the beaker is placed directly in the tank. so basically a very inexpensive purchase lasted of extremely long time. So is using one cleaning and technically three rinses you just don't see the third one as I usually tossed it afterwards. Parts large strong on the wires tiny parts into the baskets whole thing went into the beaker. Clean for about four minutes came out I placed it on paper towel to wick off the cleaning fluid while I changed the solutions. and I believe some more in this discussion you might have commented that you want to purchase an ultrasonic machine a lot of the machines will have holders for beakers or even jars or stainless steel containers or whatever. oh the final rinse that we don't see was alcohol. Then don't worry it wasn't isopropyl alcohol it was alcohol that's actually designed to dissolve shellac. Well it's used for a variety of purposes but one of the purposes is to dissolve shellac. But I was just using it as a final final rinse as the regular rinse had a habit of not evaporating as it's now more environmentally friendly that doesn't like to evaporate. So basically just a quick rinse in alcohol to rinse off the rinse so that everything would dry properly. Then originally I had a different hair dryer for drying it didn't blow as aggressively as the current one and didn't get as hot. So before I just place the baskets the parts in their path of the hairdryer on the newspapers and that was the drawing simple. Because the new hairdryer is way more aggressive much hotter and much much faster air blowing I got creative and made by coffee candleholder for the baskets. They usually one is drawing a place a piece of sheet metal on top with just a little opening so get nice and toasty warm up there. So all kinds of different methods because people have access to different things and have different ideas.1 point

-

`Don't think of this as a hand holder only. Is used any time you need to hold anything flat and open up the hole in it. Then pictures might help complements of the Internet. But let me read the description first Yes this is a really interesting description isn't it. So you unscrew part of it then you squeeze like shown in the image and it opens up. It is a spraying keeping it together. Once you get your item where you'd like it to be then you can tighten it back up and be careful when you're holding it not to break off the hand that sticking out typically1 point

-

1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)