Leaderboard

Popular Content

Showing content with the highest reputation on 03/18/25 in Posts

-

9 points

-

OK, there are messages in russian forum that will say often times USSR movements rebank after cleaning and lubrication wit modern swiss oils. This could simply mean that the old USSR oils used at the time were preventing movements from rebanking.4 points

-

3 points

-

3 points

-

This video is a must-see for anyone into horology! There's a lot to enjoy but one of the most fascinating sections of the video explains that the balance wasn't temperature compensated, so it constantly needed to be regulated depending on the current temperature. However, 300 years ago moving a regulator arm by hand would have been too primitive so they (Harrison) automated the process. Seeing this blew me away. Enjoy!3 points

-

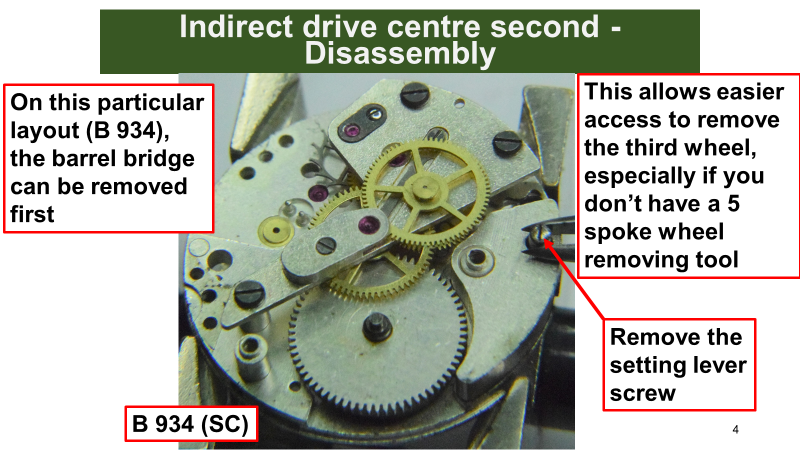

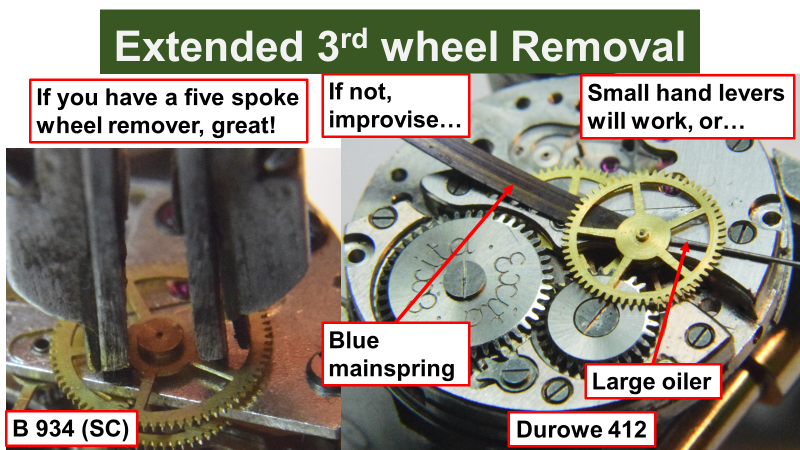

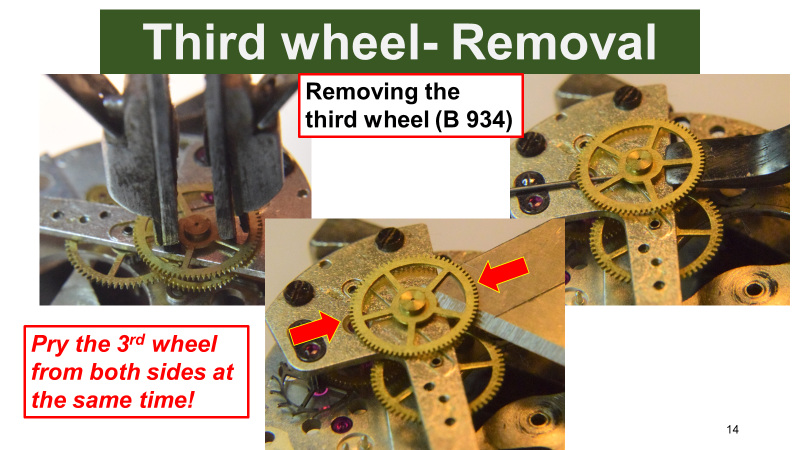

One of my students swears by this tool and it looks good in action and safer by the looks of it than the five spoke wheel removal tool by Presto, but I can't say I've ever had a problem using my Vintage Presto and I take off a lot of 'wheel over thirds' (that's what I call them - in most vintage chronograph there's a 'wheel over fourth') I reckon it's because it's pretty old and made in a much better manner with some longevity in mind as well as being more sturdy. The same tools made by Bergeon now I don't think they are as good in my experience3 points

-

At Derek's memorial service, if someone had dropped a bomb 99% of the best watchmakers in the world would have disappeared. Amazing watchmaker and amazing guy.3 points

-

Derek Pratt made a replica of Harrison's H4 in the last years of his life. The hardest part was making the pallets for the verge escapement, which were in diamond. How Harrison did it is a mystery; Derek told me he spent several years perfecting them, with modern machines and easily bought graded diamond powder at his disposal. He also said that while studying the original, he found that you could remove the upper balance jewels and the watch would continue to run, and the upper pivot would remain centered in the hole. That hairspring looks ultra basic, but Harrison shaped it very specifically. There's a fantastic book on Harrison called Longitude by Dava Sobel, well worth the read.3 points

-

Ladies watches are so tiny that working on them can be a real challenge. If it were a men's watch, I would rebush or replace the bush with a jewel. There are a few 4206a main plates available on eBay. I would probably replace the mainplate. I don't think the customer would mind replacing the movement with the exact movement. Just don't replace it with some cheap Chinese movement or God forbid, a $2 quartz movement.3 points

-

Sorry I forgot the 2427 was the auto but you need to make sure the ones in the photo are what you're getting as they're selling multiple lots.2 points

-

Yes they're the same. https://www.ebay.co.uk/itm/3852924415612 points

-

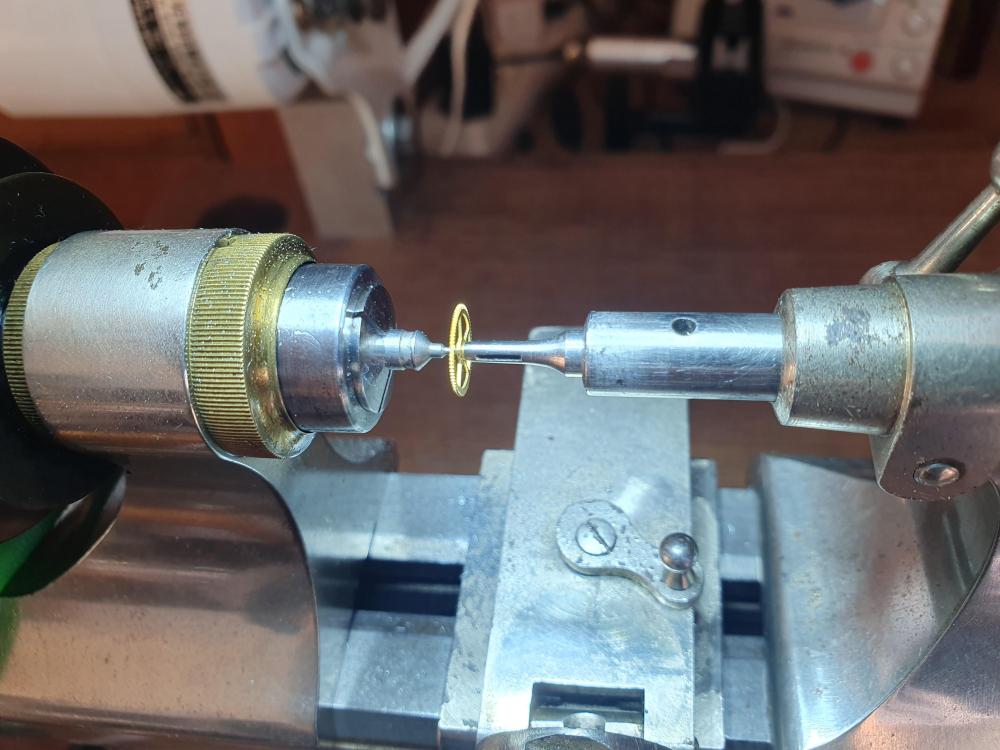

Jes John, You are right. Both balance pivots are broken, the EW pivot of the side where the wheel is was broken, the down side hole jewel of EW is broken, the detent spring stone is broken, a part of the detent spring is broken and needs attention. Still some work to do... The cutter is simple flying cutter, and some hand filing to form the spokes. The teeth surface is good enough I think, but soon will check how it works in real and will show here.2 points

-

Watch Chronoglide Watchmakers Hammer time videos on youtube. As @RichardHarris123 said you need a staking set though, if it is oval then it is a bit more trickier, hopefully can be saved. Its almost an everyday business with old movements, i recently posted two videos with the before and after state:2 points

-

I hadn't heard about Derek Pratt so I made some research: "Derek Pratt (1938–2009) was a highly respected British horologist known for his exceptional craftsmanship and contributions to precision watchmaking. He was considered one of the finest independent watchmakers of his time, often compared to George Daniels. Pratt worked closely with Urban Jürgensen & Sønner and was instrumental in developing their detent escapement. He was also known for his intricate engine-turning (guilloché) work and innovative timepieces. Despite being relatively low-profile, his influence on modern horology was profound, and his technical skills were admired by experts in the field."2 points

-

2 points

-

Yeah fair enough, thanks for your help and time anyway! Am making sure it will fit the 2427 and if so, am buying it haha.1 point

-

Thanks for the reply! I've just noticed that the 2427 actually has a jewel right next to the barrel on the left, thats for the automatic works, so 2414 bridge wont fit, but the listing you sent has the right bridge, so thank you very much! I've been looking for hours lol!1 point

-

Chronoglide videos also should cover the oval case, Kalle corrects the hole shape with a file before closing it. Perfect opportunity practicing this, there is nothing to lose. If the hole gets too big you wont be able to close it enough though, then u bush it as @Nucejoe said or u get a new bridge.1 point

-

Some folks peen & broach the hole back to size. Or Bush it. Regs1 point

-

1 point

-

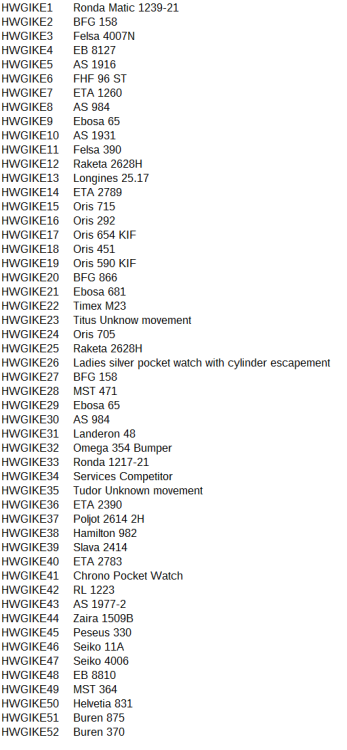

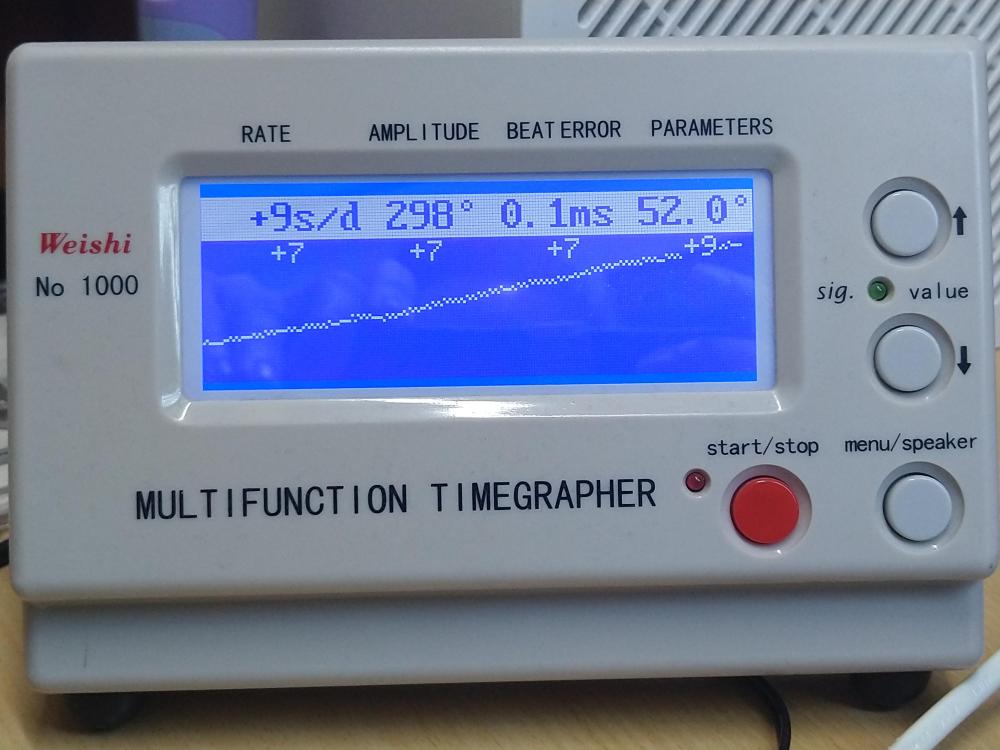

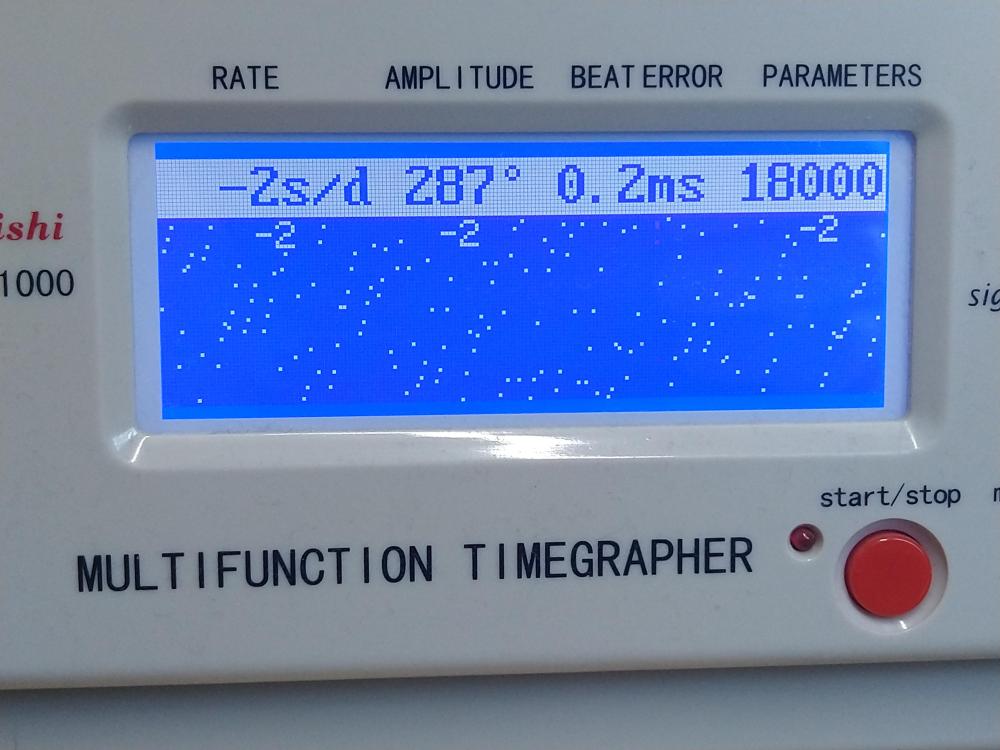

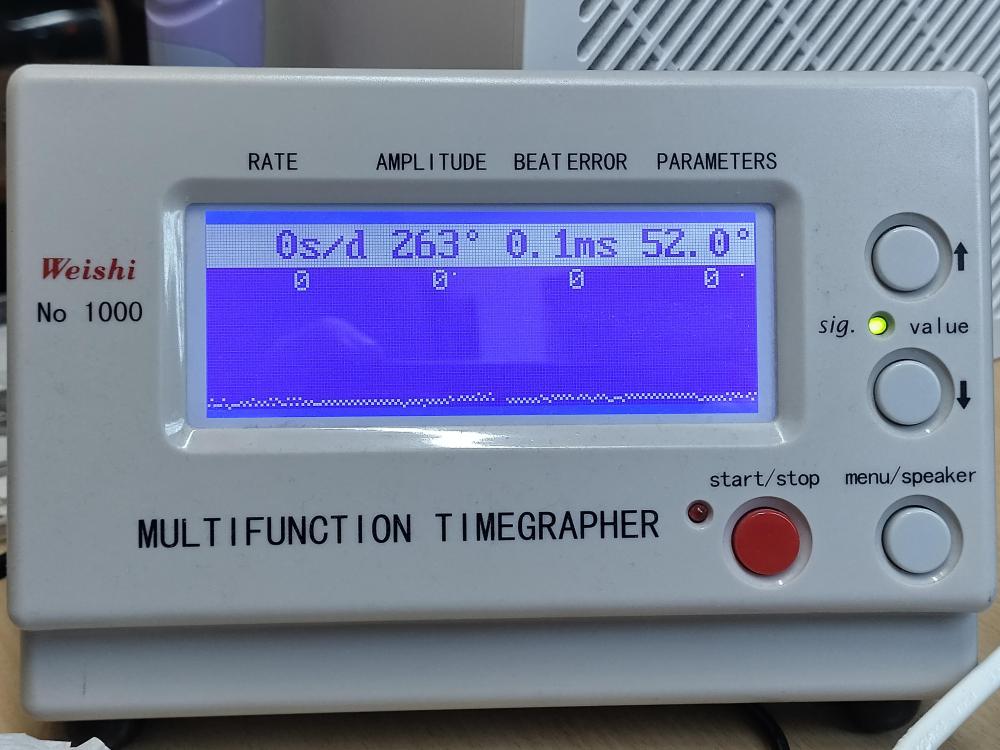

Milestone: Halfway in my Here We Go I Know Everything (HWGIKE) challenge. Halfway with 52 because I had two duplicates. The list so far: I learnt a lot, it took 8 months to complete and I invested a LOT of time in it after the normal working hours mainly when the family has fallen already asleep. It was a lot more difficult than I originally thought and I put so much effort into it that I was actually risking my health, I am still struggling with both of my arms and I have a back ache which I possibly developed spending 8 hours with IT work sitting and then the watchmaker stuff sitting again... probably my posture is not 100% right.. no wonder every watchmaker book starts with the environment and with the right posture. I tried to record my mistakes and successes as accurate as I could.. as you can imagine even recording this took a bit of time, taking pictures trying to remember what went wrong and what went right with what movement. Consistency is key, but if you dont have the time it is difficult to keep it up. I finished the Buren 875 last night and this morning I already had a few missed calls from Tompion, Graham and Breguet. Just saying..1 point

-

My initial test indicates that it is operating properly. Further testing in order.1 point

-

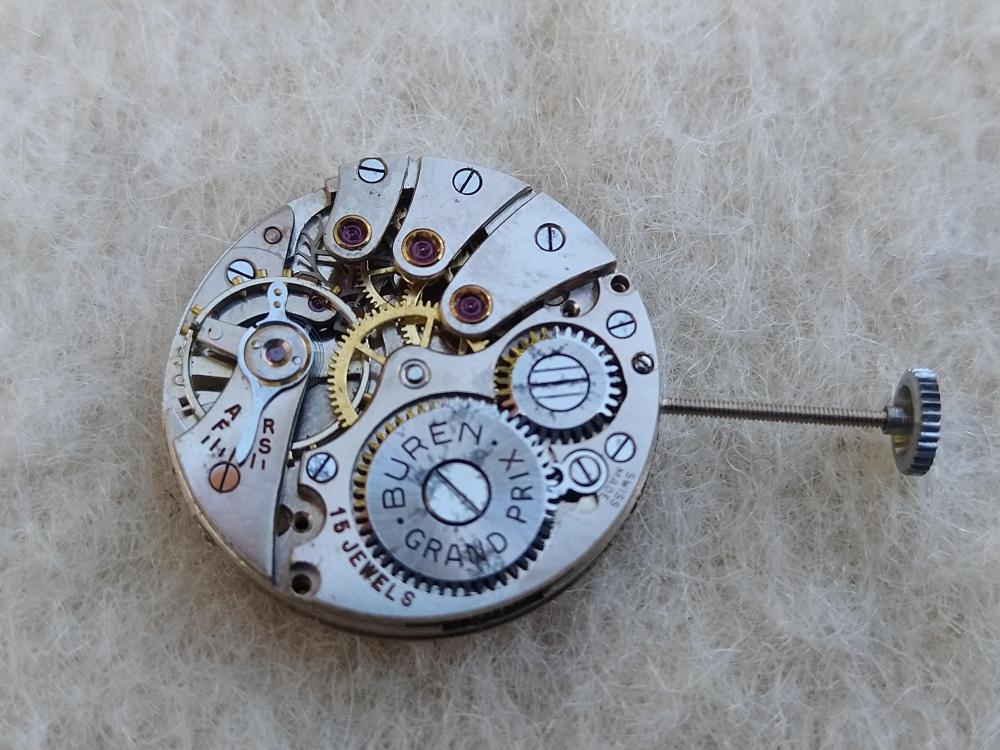

HWGIKE#51 Buren 875, Swiss lever, full service - needs balance staff replacement. Eventless service, but the balance staff pivots are both bent and worn which I have not realized until i cleaned and lubricated the balance jewels. Jacot tool cannot help they are beyond hope. No wonder they are worn there was a lot of dirt in the jewels grinding away the pivots. Unfortunately I cannot replace the balance staffs yet as I am not a master of my watchmakers lathe yet. Hopefully I am going to finish the new platform for my watchmakers lathe soon and I can practice a bit. I had only one job on the lathe so far with a second hand tube which I managed to do with a good result. The criteria to finish the 100 challenge is that I must replace at least one balance staff but not going to do it just now. So even if the time machine shows a nice acceptable performance when you flip over the movement it shows only snowflakes for a minute or two before it is a straight line again I assume the balance wheel cannot drop onto the cap jewel immediately due to the bent pivots. HWGIKE#52 Buren 370 Grand Prix Swiss lever, full service, major mistake! Cleaned the case, replaced one dial foot, sourced a new setting lever and stem, replaced the glass, but when I was about to case it and put the cannon pinion back I broke the 4th wheel pivot accidentally as my tweezers slipped. A movement I like a lot and has a very nice performance... i was devastated... this one was one of the first movements I put into the 100 challenge about 8 months ago and the reason why I am posting it now because i book it as a failure and closing the fist half of the 100, not just that, but I tried to source a 4th wheel... from Cousins UK, from eBay and from a watchmaker who has actually started my watchmaker carrier.... all of them were wrong/long as my movement is thin and all of the 4th wheels I received were made for a thicker Buren 370... maybe I am going to find one in the future but for now I book this as a failure. Recording a failure is a very important part of this series.1 point

-

Hi. I have had the pleasure of repairin*one of theses for a client. It had been round the world and when I got it , it was in a box in which it was last shipped from South Africa during the reforms there. All that was wrong was a broken glass. It was the striking version with a bell. It uses a counr wheel assembly mounted at the rear of the clock. I have another of the same type todo yet which has a peculiar method of friction for the hour wheel. It has has a soft bush in the center that grips the center wheel shaft, not very well and consequentl looses time. A job for later as time permits. Interesting clocks, some were fitted with alarms.1 point

-

I went for the mid priced one, middle of the road, i also thought they'd be lower build quality on the bargain priced ones so best to avoid, the one i got was £76, the lower priced around £50 while the higher priced £85, these are UK prices so not sure what prices ali charge in other parts of the world.1 point

-

1 point

-

Just enough tension that if you were turning a piece of rod, the band won't slip. I use a counter pulley with my set up, so I adjust the tension as little as possible for the work I'm doing. I find the counter pulley keeps up the torque when turning at quite low speeds. when not using the lathe move the band so there is no tension, so when you start her up next time there is lubricant all around the spindle. Personally, I turn the pulley by hand to begin with and add the oil then, also on my counter-shaft. I use ISO 22 Airline oil from Toolstation. It's about 8 quid for a litre. Pretty much the same viscosity as really thin engine oil. I found this oil hits the sweet spot on my WW bed 8 mm Boley and Leinen lathe I use the same oil when honing screwdrivers and the like1 point

-

1 point

-

1 point

-

1 point

-

It's genetic. Like me, you probably have Viking blood. We used to go to the British islands to pillage and enjoy the women so it makes sense.1 point

-

Thanks for your reply Mike The bush is round on both sides but it doesn’t look like it’s been bushed by a clockmaker but I was told that Hermle make two of each movement, a standard one and one with bronze bushes in high wear areas how true it is I don’t know but seems odd that they would do that, anyway the 2 bushes on the front plate 1 for stop work arbor & 1 for chime cam had very slight wear but I wouldn’t have said enough to cause the problem but I have made some bushes and done them although not back together yet so we will see , I hadn’t thought about the hammer assembly will look at that but had already checked hammer lift before taking apart. Dell1 point

-

OK, this is a little hard for me to remember what happened in cases which take long time to move, so please excuse if i have forgotten something, Now, live the roller on the balance as is. The crack will not prevent the balance from normal working, at least this is the most probable outcome and leave checking it for later. The hairspring... You original spring is good. It only needs a little attention in the center. The first thing is to grasp where the red ovals show with sharp pointed tweezers (between the coils and in the collet hole) and squeeze. The next is to grasp the coil where the green ovals show with sharp tweezers tips and press with needle where arrow is to deform the coil in order to decrease the radius - this will bring the coil to normal. The blue oval is where the angle of the overcoil is to be opened a little, but do it when the spring is attached to the cock to observe it centering correctly. Does the balance rotate free and true now if placed with the cock? (I mean no hairspring, no pallet fork, all jewel settings in place)?1 point

-

I recently had a ladies Rolex Tudor (ETA 1173). I fitted a new mainspring (the correct size) and immediately got serious rebanking. I re-fitted the much weaker original mainspring I had taken out - calculated to be about 30% weaker, and it was still on the edge of rebanking. So I oiled the pallet pivots, scratched my head, and accepted it. I've no idea what was going on.1 point

-

1 point

-

Honesty, this sounds a little frighting to me. Please, read all this thread from the beginning. There is a video there about replacing rubbed in jewels without using special tools.1 point

-

1 point

-

1 point

-

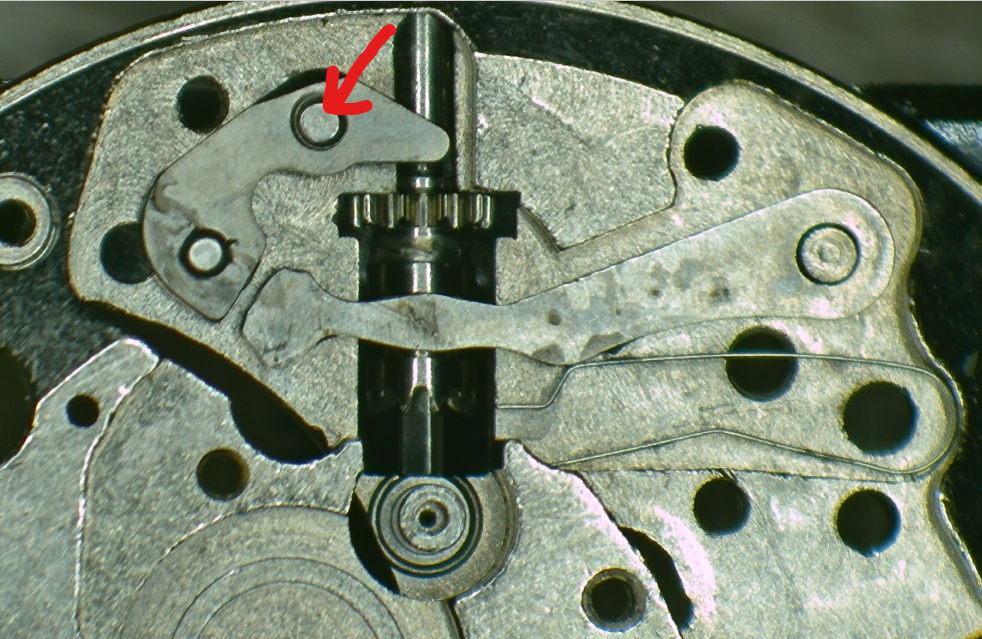

With setting lever screws, usually about 2 turns is enough to remove the stem (and pushing on the screw a little whilst pulling the stem can help). Any more than about 3 and you risk the setting lever falling off I was wondering what the movement is and noticed the design of the clip to attach the winding weight, which suggests Felsa. I had a Felsa 4000N which looks just like your movement. This is the back of the movement with the setting lever screw arrowed. The thing it's screwed in to is the setting lever, which has fallen off. The auto mechanism is a little unusual on these, and maybe a little fiddly for an absolute beginner.1 point

-

I like working on Hermle movements; I service them all the time. I've serviced and sold many Hermle-equipped clocks that are 40 to 50 years old, still going strong with minimal wear. They may not be top-end quality, but they are reliable and have parts readily available. It's a double-edged sword, though, in that they keep going for years, even when they need a service. Consequently, owners don't bother having them serviced, and they end up wearing out. I have a Comitti grandfather clock that also uses a Hermle movement. The new price is up towards £10,000, which I think is insane. The movement is about £400 brand new, and there's never £9500 worth of case. There's probably £9000 of profit after making the clock. Does the bush fitment hole have a hexagon shape on the bushed pivot hole you've circled? I've seen several that do on the same pivot hole. It makes me wonder if it's a factory retrofit to address a common wear problem with that pivot. In my experience of these, the sluggish chime is just down to basics. Ensure it's clean, has good lubrication, good mainspring, etc. Also, don't forget to strip and lubricate the hammer assembly, as it can get pretty gummed up. If the mainspring is set, pop a new one in. All parts are readily available from Cousins. One alternative explanation is that if the chime mechanism hasn't been set up correctly, it partially lifts the hammers at the end of the cycle, which doesn't allow the chime to gather enough momentum to get going properly. If you need a hand give me a shout.1 point

-

Two spare balance staffs are expected to be in there, at list this is what I have heard.1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

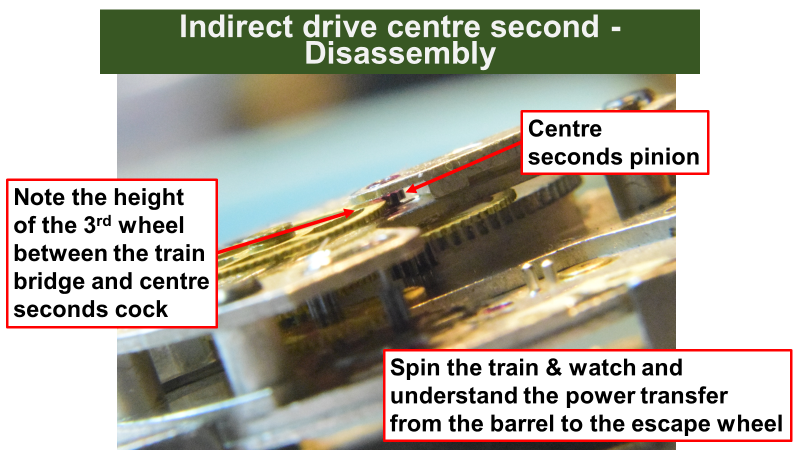

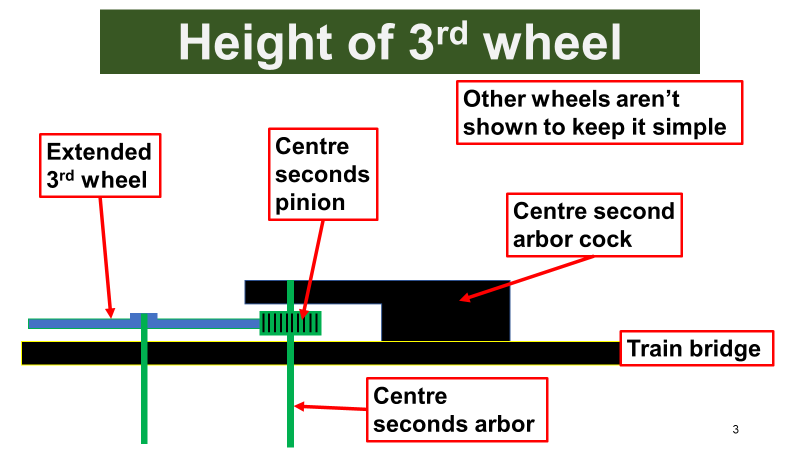

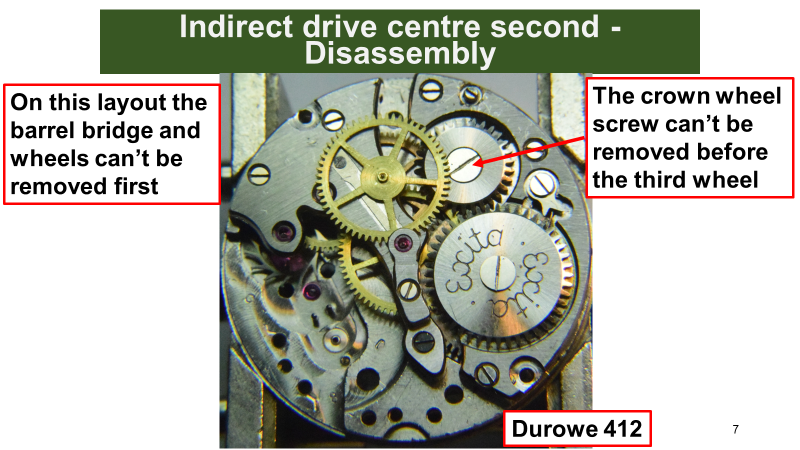

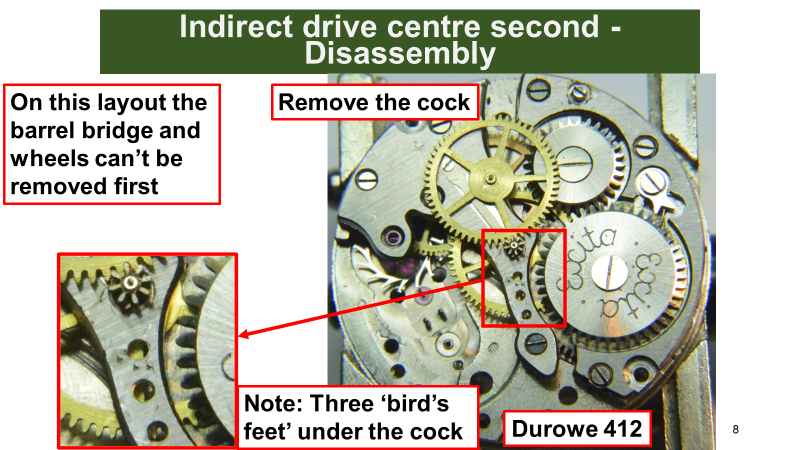

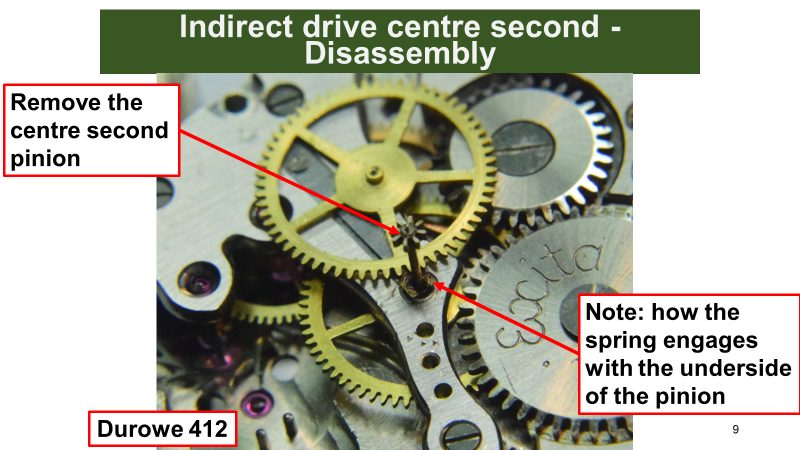

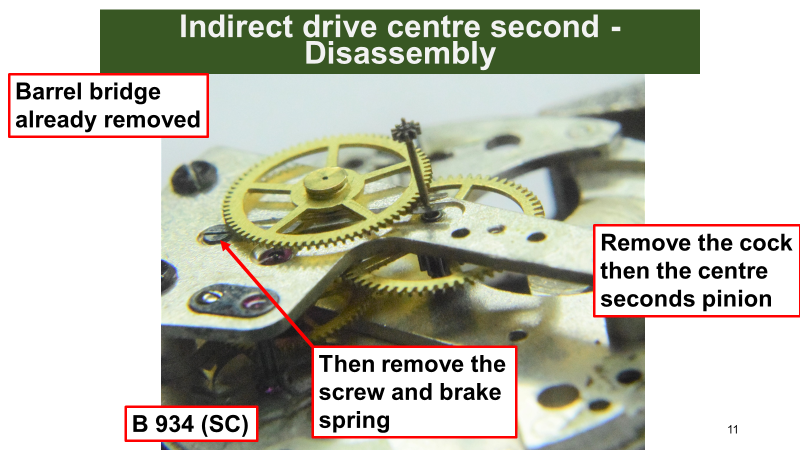

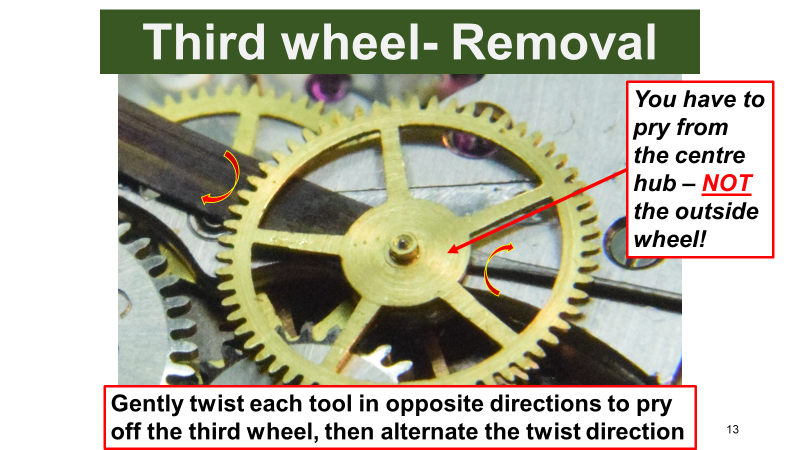

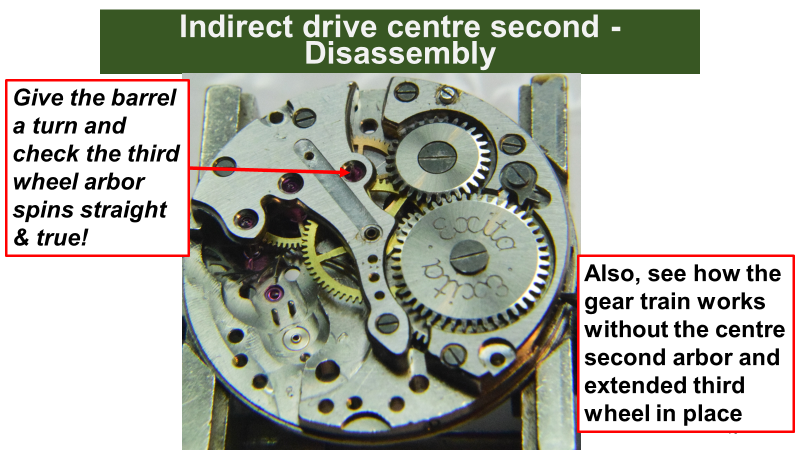

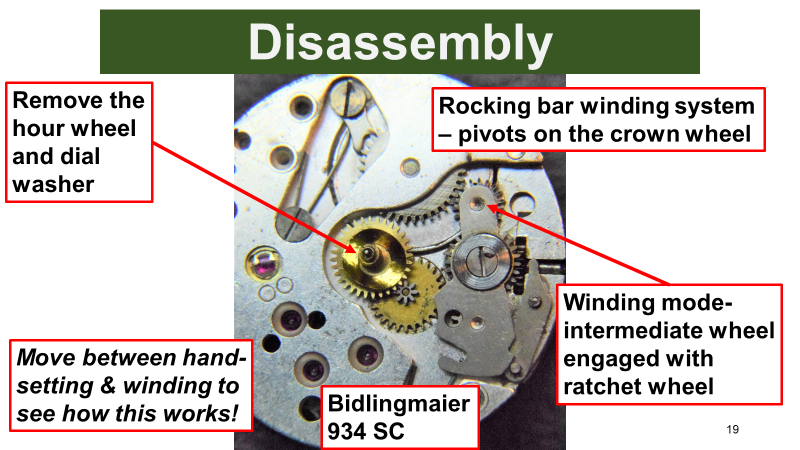

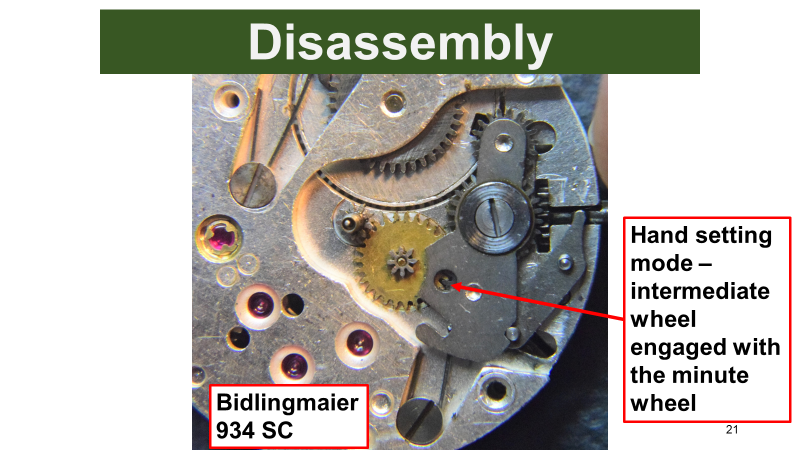

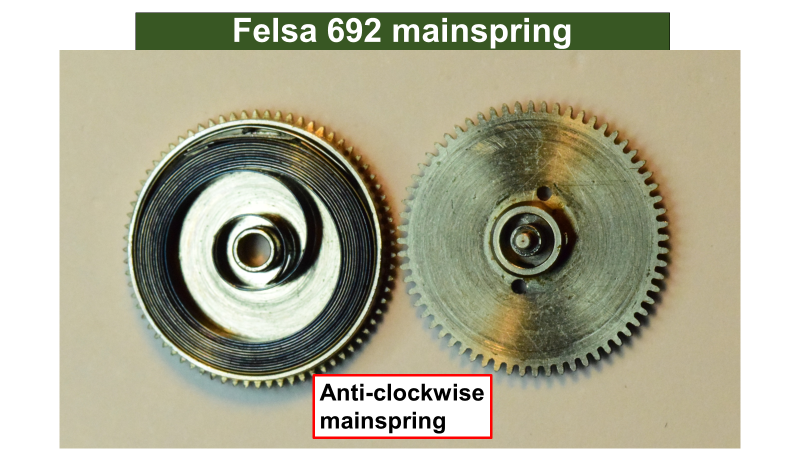

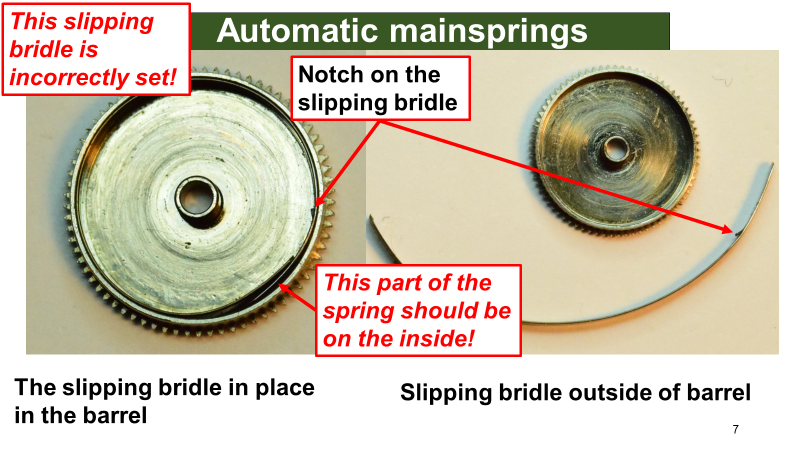

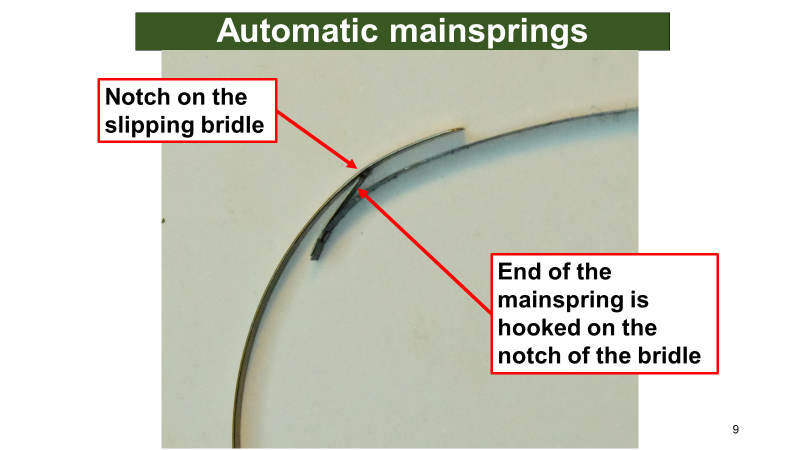

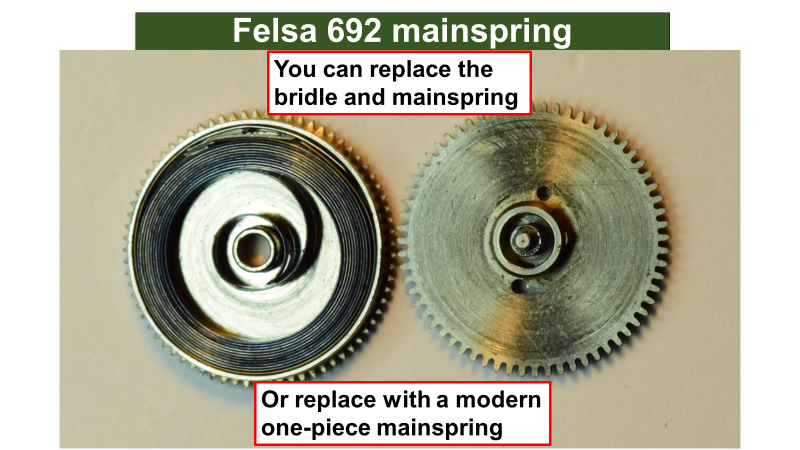

I posted some of these slides from a lesson I take on an indirectly driven sweep second movement. I hope it help anyone. I really should post the set of lessons on a sweep seconds movement sometime soon. The Bifora (Bidlingmaier) 934 has a great rocking bar winding system, which isn't usual to see, as seen in the last two slides1 point

-

1 point

-

1 point