Leaderboard

Popular Content

Showing content with the highest reputation on 03/19/25 in Posts

-

5 points

-

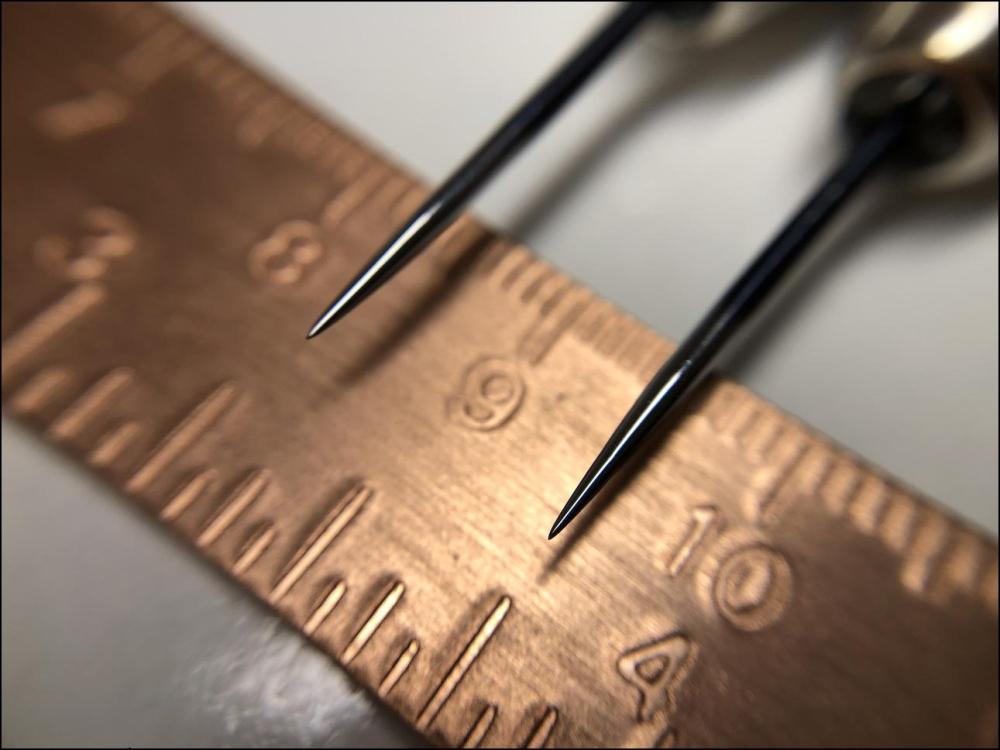

Here’s a small update for those who might be interested. After using my custom-made rods a few times, I felt their diameter and tips were unnecessarily large. So, I tapered the rods and made the tips finer. They might look too sharp in the pictures, but in practice—especially when handling extremely small springs like Seiko’s Diashock and Diafix springs—they work exceptionally well. And when I removed a couple of three-pronged anti-shock springs from a Vostok movement yesterday, I was really pleased with the result. A key detail is to highly polish the tips, which prevents them from scratching whatever you’re working on, whether it’s brass or another soft metal. While I was at it, I also had the idea to dress a brass tweezer using the rotary tool. It turned out to be a very smooth process. I’m really happy with my choice of rotary tool and keep discovering more and more uses for it. On top of that, I realized I could mount it directly in my adjustable vice and still angle it for the most comfortable working position possible. That is, no real need for the Flexishaft seen in my other post.4 points

-

4 points

-

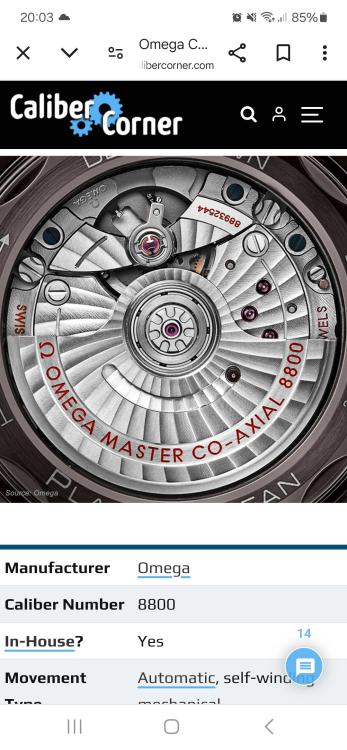

Well done chaps, yes my reputation is tarnished, i feel quite ashamed, but then i didn't buy it. The missus knew my standing to never give my money to Swatch, but not my ethics on supporting a superfake watch industry. I didn't have the heart to ask her to take it back, she won't even tell me how much it was. Its not a cheap fake , middle of the road I'd say. I googled the shop, its been established 25 years with a high reputation......in fakes3 points

-

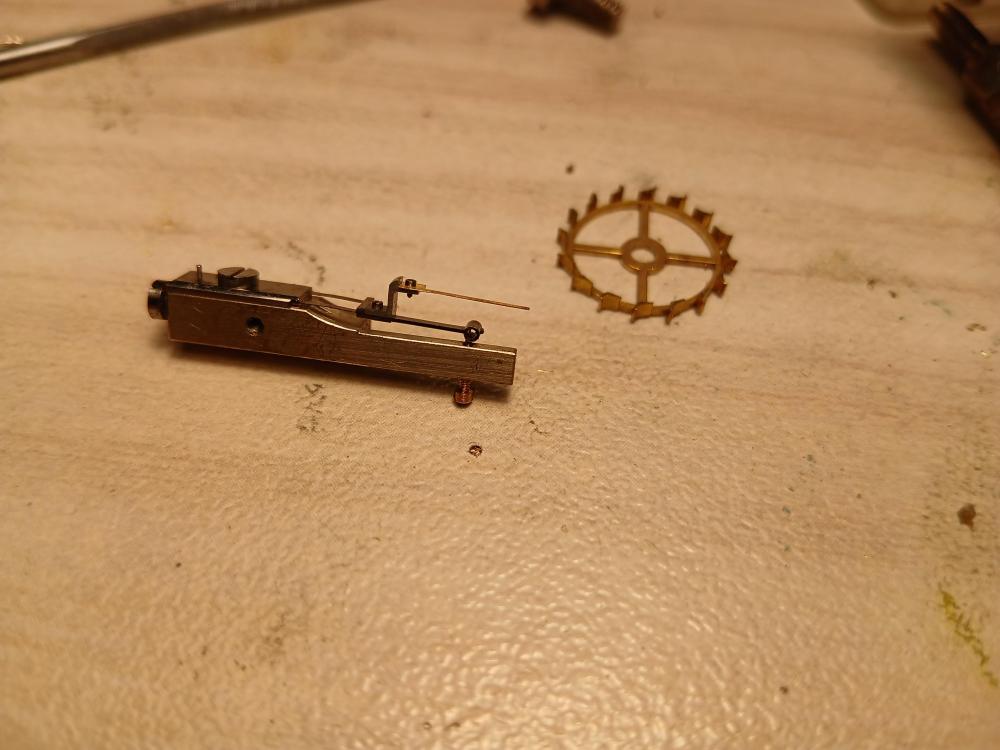

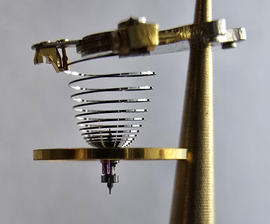

Man, when these guys fail it's usually dramatically! 25 years ago one could still find (some) spare parts for the UN chronometers, but not anymore. There's a fellow in the U.S. who had some locking stones made for Hamilton chronometers and sells them for a fair price. I bet they would work on a UN. Hope the detent survives; can't remember if the spring on these is a separate part? Great looking escape wheel there!3 points

-

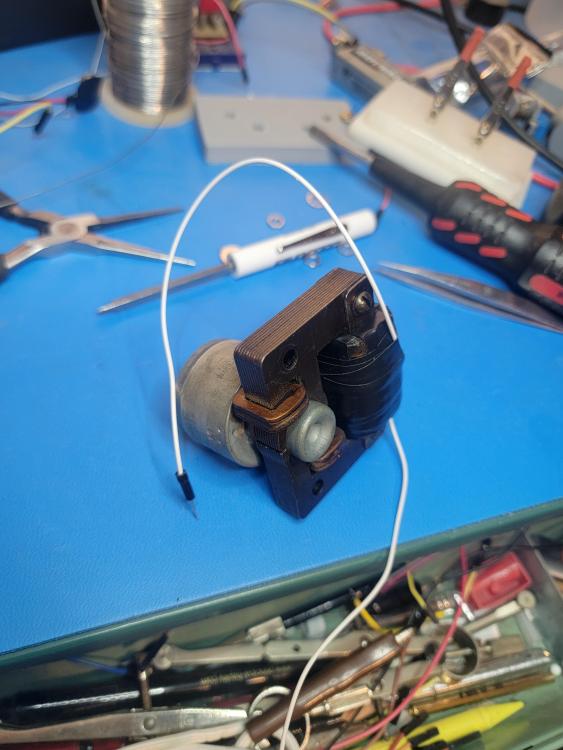

Today I had only time to repivot the balance staff (piece of cake), the detent spring left for tomorrow (i hope) Here is a picture of the detent spring. The stone is missing, that's how I received it. The part that supports the little golden spring is sheared and missing I have to decide if to make the missing locking stone out of glass or of tungsten carbide. Glass - will look more authentic, but carbide I guess will be firmer... Ideas? Well, with brass the things are easy to do, but there are different types of brass. The hard brass is easier to work with. Anyway, the higher revolutions are - the better. The most important thing is the cutter to be sharp and to have proper chamfer (to be backed off - hope to use correct terminology as looking at the dictionary), then the cutting will be clean and easy2 points

-

2 points

-

2 points

-

Real - because why would Rich stake his reputation on a superfake. I think he is just trolling you all to show off his Seamaster.2 points

-

I agree @watchweasol. I regularly buy and restore clocks to sell. There is a definite shift in fashion, with some clocks being in demand and others not. I do come across people wanting to buy a nice nostalgic peice that reminds them of their childhood, or matching the decor on a restored period house, but there arent many. I did visit an old lady recently who found she couldnt reach her clock to wind it properly. I refitted it lower down the wall.2 points

-

Hi V.Watchie. Another smart idea well produced. I used to use the machine sewing needles bent at about 30 degrees , now having to give up watches because of cataracts but may get back to it. Well done nd thanks for the post.2 points

-

Right so Andy, I had the same again 6 weeks ago. Ebay will still step in....but they have moved more towards looking after the seller now. And a buyer's protection fee is included in the purchase price. What I had to do.....it was evri again...was ask them to investigate the delivery, it is their legal obligation to do that. They then have to give you a report on the outcome, you can then use that as evidence for ebay to refund you. I actually managed to speak on the phone to high level ebay operative that talked me through the process. In the past the seller used to request a certificate of failed delivery from the delivery company. Evri would never do that for me, apparently they dont have such a thing. But they must email you an investigation report , that will detail that the item was left in an unsafe place, they can't deny that the driver made an error delivery. Ebay also told me that there is some sort of ombudsman that investigates delivery company performance. Not individual cases as such, i think its about collecting data to form an investigation to force companies to change their proceedures and policies.2 points

-

I paid 130 inc. Shipping 3 years ago, good quality steel and the spindle is quiet accurate, not perfect but very usable. If you have a lathe and experience, the quality of the stumps and pushers are not so much of a problem, easy to knock out spares.2 points

-

Jes John, You are right. Both balance pivots are broken, the EW pivot of the side where the wheel is was broken, the down side hole jewel of EW is broken, the detent spring stone is broken, a part of the detent spring is broken and needs attention. Still some work to do... The cutter is simple flying cutter, and some hand filing to form the spokes. The teeth surface is good enough I think, but soon will check how it works in real and will show here.2 points

-

2 points

-

I guess You can use bent oiler, but be careful with the hairspring. But, do You know that the main thing to do when restoring such movement is to sharpen the balance pivot tips (cones)? This is what actually wears in this movements and without the sharpening, the watch will never work as it should.1 point

-

1 point

-

Omega does do that hour hand just not on what this model is supposed to be. The missus said the shop had rows of draws full of expensive looking watches. He gave her a proper business card, I'm curious to have a look but I think I'd be too tempted to buy something. Apparently his top end fakes sell for 2 grand. Well spotted Andy.1 point

-

My (not particularly expert) thoughts would be: The outer bore for the ratchet wheel should be concentric with the original hole position. And possibly simpler but a bit crude - The arbour only turns while the watch is being wound, so look which way the arbour is pushed by the action of the crown wheel while winding it? It looks like to the right by torque and down by the angle of the wheel teeth? From that I'd guess that the lower right in the photo is the badly worn area and the upper left is the nearest untouched area, that could be used as a reference for a close fitting stake or drill to locate the plate before opening the hole for the bush. That's what I'd try - though on a junk movement first to be sure it worked!1 point

-

Hello and welcome from Leeds, England. I've learnt something new, didn't know left handed watches existed.1 point

-

I'm not sure as there's so many variations with this model. I'm erring on the side of real, but I'd have to hold it and have the back off before I buy it That's one thing I spotted, most are hollow triangles, but then I found a solid one.1 point

-

They look crooked and 6 O'clock looks off too. Its probably the angle/pixles. You've sold me. I'll give you $9001 point

-

1 point

-

The other day, I was on the OTHER watch forum (NAWCC), and was just reading new posts and I got on to one where someone mentioned using a hot-air workstation for tempering steel. Holy smokes! I have a hot-air workstation for electronic rework that goes up to 480 degrees C. This is well within the temperature needed to temper steel. Not only that it is also in the range for blueing steel. I struggle with metallurgy...annealing, hardening, etc. Now, having a tool that gives somewhat precise temperatures is going to help me along the learning curve.1 point

-

I don't use a soldering iron for melting shellac. I think the BTU isn't enough. And I have a 70W temperature controlled iron. Not one of those pookie 25W toys. A spirit lamp seems to be the best tool for this job. A dental microtorch is a tad too hot. There is a new kind of wick for spirit lamps. It has a core of glass fibres, a copper wire to help hold its shape and a wrapping of some fabric. It doesn't burn off and shorten. I love it.1 point

-

Yes, a favorite show. Well, regarding the other caveats, I was not thinking of hardening using the HA station...just the tempering. I did blue a screw this morning. It seemed to work. I held it in a copper ladle.1 point

-

Anyway, 480°C can't harden or anneal any steel. That needs about 700°C. I just go by the color of the heated part. Cherry red for annealing and orange for hardening. Although a hot air tip and solder table can reach tempering temperatures, at those temperatures, it requires a long soak time of up to an hour. I just use my microtorch with a soft flame and heat it till the steel turns the color I want. Blue for a softer hardened steel and straw color for a harder temper. It's still a lot of guesswork and luck. Just watch the show "Forged in Fire". Even seasoned bladesmiths can get it wrong.1 point

-

I have a hot air station too but I find that it doesn't seem to work that well for some jobs. Like bluing small screws. They just get blown around. I prefer to use use my solder hotplate for that kind of work. I've also tried using my hot air tip for melting shellac but again, the soldering table works better. And recently, I discovered an interesting tool for tempering the innermost coil of a mainspring, the dial foot soldering machine. Just use the carbon rod and touch the part you wish to soften with it until it becomes red hot.1 point

-

Sorry I didn't mean it was down to the rotors and lack of power but down to the movements themselves in general.1 point

-

Is that still the same with the new one? Is the rotor bridge secured correctly?1 point

-

Hi. Mine is just hanging on the wall not running , it had no weights bit I used a pair fron a Dutch zandaam clock they are heavy (large) I think I have the original weights written some where if I find it I will post it. The original ones were heavy lead weights aka grandfather clock type.1 point

-

The seller does not have a clue about how the law works! In English law, the item is the responsibility of the seller/sender until it has been properly delivered. Any postal or delivery service is acting as a subcontractor for the sender, and the sender has total responsibility for their failure to correctly deliver the item. See here: https://www.citizensadvice.org.uk/consumer/somethings-gone-wrong-with-a-purchase/if-something-you-ordered-hasnt-been-delivered/ ps. That applies to UK sellers, not overseas ones.1 point

-

So back to an earlier question, what's the case and what spacer are you using?1 point

-

At least it has an actual mechanical movement - Seagull ST6 series, possibly? Very unlike this object a friend from Malaysia gave me some years back. (He initially showed me his & tried to convince me it was genuine! - It weighs a fraction of what a real one should, never mind other details). Even the quartz movement looks to be a cut-price version with a fixed capacitor where the trimmer cap should be.1 point

-

the photos are nice but you missed a few steps and maybe a few words describing things would be nice. I assume you made your own cutter? I would be curious about how exactly worked out the profile etc. plus did you flawlessly faces after your cutting or was the cutting good enough for the finished then the crossing out of the wheel here it's rough and in the final product is perfect but we didn't get to see the pictures of how that was done then unless you posted it someplace else which I did not look for what did the rest of the clock look like? Because usually when this happens the balance staff pivots get broken jewels get broken and I'm amazed escape wheel still has its pivots. This is where those not familiar the detent escapement is really a thing of beauty until it has a problem then it's a thing of extreme destruction.1 point

-

Watch Chronoglide Watchmakers Hammer time videos on youtube. As @RichardHarris123 said you need a staking set though, if it is oval then it is a bit more trickier, hopefully can be saved. Its almost an everyday business with old movements, i recently posted two videos with the before and after state:1 point

-

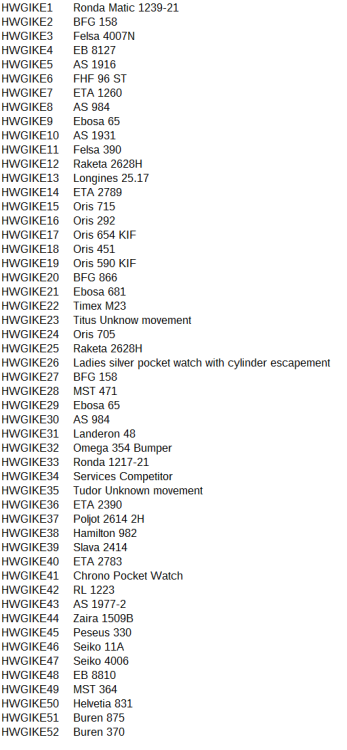

Milestone: Halfway in my Here We Go I Know Everything (HWGIKE) challenge. Halfway with 52 because I had two duplicates. The list so far: I learnt a lot, it took 8 months to complete and I invested a LOT of time in it after the normal working hours mainly when the family has fallen already asleep. It was a lot more difficult than I originally thought and I put so much effort into it that I was actually risking my health, I am still struggling with both of my arms and I have a back ache which I possibly developed spending 8 hours with IT work sitting and then the watchmaker stuff sitting again... probably my posture is not 100% right.. no wonder every watchmaker book starts with the environment and with the right posture. I tried to record my mistakes and successes as accurate as I could.. as you can imagine even recording this took a bit of time, taking pictures trying to remember what went wrong and what went right with what movement. Consistency is key, but if you dont have the time it is difficult to keep it up. I finished the Buren 875 last night and this morning I already had a few missed calls from Tompion, Graham and Breguet. Just saying..1 point

-

1 point

-

Bought a GE Westminster mantle clock for $15 the other day. I expected to find an issue with the Telechron motor. Turns out, one of the wires coming off the coil had broken right at the inside coil. The only way to save it was to remove the paper insulation from the inside and unwind a few turns of the coil. Then re-insulate the inside with electrical tape. Here is the final result with new leads to attach to the AC cord. As far is the sealed unit, it seems to work, but I am going to heat it up and oil atbthe bushing as it cools. Once complete, I will show a picture.1 point

-

An old book I was reading recently mentions Harrison building his H1 in Barton. I got curious so reasearched him more. Turns out he grew up in Barton not far from me. And tested his first chronometer clock on the river Humber, about 4 miles from my house. I courted my missus on the shores of the Humber estuary, watching the tides come and go 250 years later lol.1 point

-

For a long time, I have been using 3mm TPU 3D printer filament on all (8) of my WW lathes.1 point

-

Just enough tension that if you were turning a piece of rod, the band won't slip. I use a counter pulley with my set up, so I adjust the tension as little as possible for the work I'm doing. I find the counter pulley keeps up the torque when turning at quite low speeds. when not using the lathe move the band so there is no tension, so when you start her up next time there is lubricant all around the spindle. Personally, I turn the pulley by hand to begin with and add the oil then, also on my counter-shaft. I use ISO 22 Airline oil from Toolstation. It's about 8 quid for a litre. Pretty much the same viscosity as really thin engine oil. I found this oil hits the sweet spot on my WW bed 8 mm Boley and Leinen lathe I use the same oil when honing screwdrivers and the like1 point

-

At Derek's memorial service, if someone had dropped a bomb 99% of the best watchmakers in the world would have disappeared. Amazing watchmaker and amazing guy.1 point

-

1 point

-

I just learned out of nowhere that my own sister has been sitting on a Disco Mickey watch for who knows how many years.1 point

-

1 point

-

I assume this is what you mean by a better picture and you can't spot anything wrong in this picture? Yes I know the tool was made specifically to do this but some hairsprings really do not like to be stretched in this method. Then the place where you are having a problem with your balance wheel is in the watch not here which is why you won't see a problem typically. What was the watch doing before you serviced it? I suppose we need a definition of what perfectly aligned means and let me quote something down below to help with that. Usually one of the biggest problems for everyone in watch repair is the hairspring. Is truly amazing how much energy is lost when the hairspring is not where it's supposed to be.1 point

-

What You need to check is if the hairspring, when the balance is in the movement, is not resting on the balance arms. So You need to look at the spring from a side and it must be parallel to the balance/cock, there must be safe distance between it and the balance arms and the cock.1 point

-

Tricky one. The earlier 10L has the cock inverted so the pinion would be supported by the jewel… If you could invert the pinion cock you’d be home free…but could you make a little ‘jig’ out of pithwood or something soft in the shape of the cock that would support the pinion, either curved like a C to avoid the 4th wheel, or a stick with a hole and countersink to let the pinion drop a bit and let you avoid putting pressure on the wheel? I have one of those Bergeon delrin tools with nice countersunk holes but I think it would be too wide to avoid the plate for the 4th wheel…1 point

-

That’s nice to know. You can never stop learning. The internet was not around when I was an apprentice. I learned from my master. It just goes to show I’m an old fart. I enjoy the forum so much in helping others with knowledge that I have gained over the years.1 point