Leaderboard

Popular Content

Showing content with the highest reputation on 03/21/25 in Posts

-

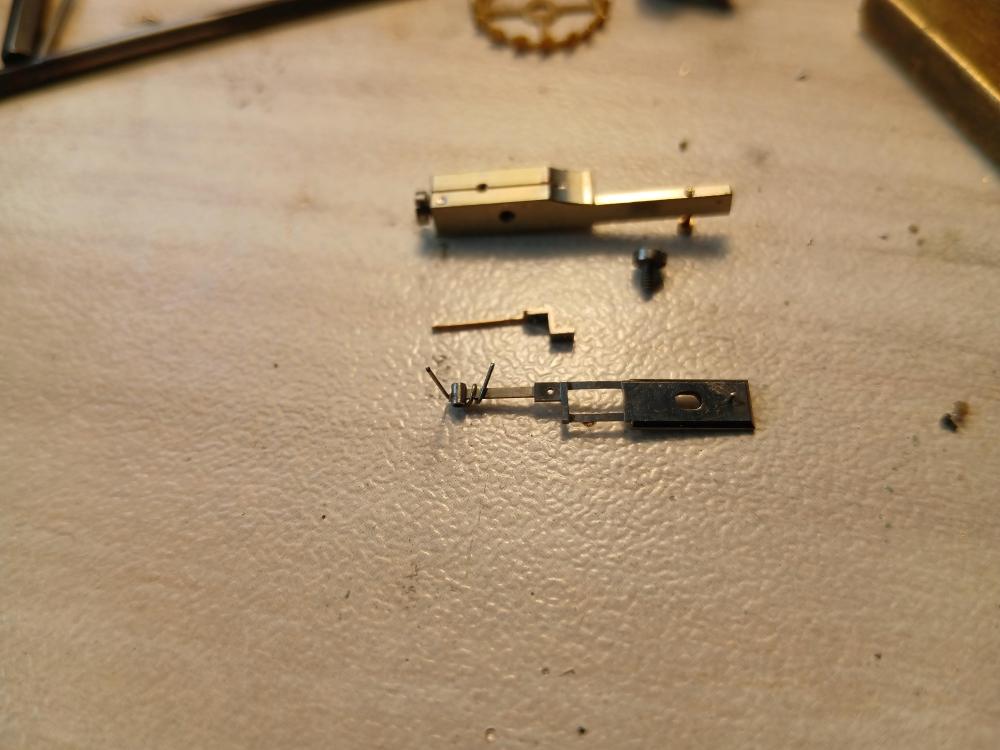

I've got a bench mounted one like a Bergeon, just a good quality Chinese version that has never let me down. I just don't have a 14-sided 30mm Breitling specific die to go with it. Got a set of Rolex (knock off) ones but the Breitling sets are quite expensive and incomplete anyway. And some feedback - it's off! Superglue, when allowed more than 30 seconds to fully cure, combined with a bigger nut, did the job. inside the watch is a standard ETA base calibre with a chronograph module. I think it's the same as the Omega I tackled, so should be good from here4 points

-

$500 USD what a complete rip off. I could have restored your movement to the finish of the example that I posted with all the screws blued better then in the picture for less than that. This is what I used to do. Once everything is apart and that means if it comes apart it is taken apart, remove the springs from there barrels. All of the brass would be covered in Horolene and left to soak, depending on condition for as long as it takes. Scrub with a brush you can by washout brushes at any good clock suppliers, dry in an old rag. Brasso is used to polish all the parts using a brush and your own elbow grease, you need clean soft rag and by hand polish all brass parts to a high finish. Wash out in petrol making sure all the brasso has been removed. Place and cover all parts in sawdust this will soak up any petrol., remove from sawdust and with another clean rag polish all the parts to a bright shine, then French chalk all brass parts with a clean chalk brush it must be very soft. The chalk brush most only be used for this type of work. French chalking prevents tarnish. All screws are cleaned and polished in a lathe using needle files and emery sticks, screws are cleaned in and old watch cleaned, when cleaned and dried, screws are then blued making sure they are all the same colour blue, dropped in oil, removed from oil and washed again in the old cleaner. Don’t forget to clean the barrel arbours remove bur and polish with emery sticks ending with the finest, arbour ends can be polished in the lathe. The fine adjuster square to be cleaned and polished with emery sticks. Pendulum rod can be polished in the lathe. I haven’t gone into pivot polishing or re-bushing as you just wanted to know how polishing was achieved. Clock makers have their own ways of doing things. This is what I was taught by my master and it is an old fashioned way.4 points

-

It’s possibly catered for within the chip using the inhibition method whereby it monitors the pulse rate and adds or drop pulses to reach stability. Used on a lot of the modern quartz watches. It’s a bit more complicated than my explanation , but that’s the gist of it.3 points

-

This is good advice. What you could use to better hear what is going on in/with the movement is using one of these: They're called "tickoprint". They have a microphone like timegraphers have and are (or in fact were..) used for regulating watches. They have a printing mechanism. Very outdated now, and so they come up for sale regurarly and are dirt cheap. In most cases the printing mechanism doesn't work anymore, but that’s not an issue. The reason why you might want one (and why I have one) is that it has a speaker connection. Works great. Another option (less fun if you like more tools..) would be to modify your timegrapher (if you have one). There is info online that shows how to hook up a loudspeaker to one of those. For instance:3 points

-

I have done several of these clocks and as @oldhippy says the prime mover is elbow grease. Plates polished with brasso and in my case very fine wire wool as the brass was almost black . I have seen plates look like that on professional y cleaned clocks , as dull as dishwater. I don’t achieve as classic a finish as the example that @oldhippy showed but way better than the one you received. The price was a bit steep but he has overheads etc to pay for. It has taken me all day to clean some plates some times longer.2 points

-

How would that level of high shine be acheived? Does brushing with French chalk produce this kind of shine or would a metal polish, like Brasso, been used. I know @oldhippy is against the use of rotary polishing machines, how long would it take to polish brass to this level of shine? And what would be used to protect the brass from tarnish after that? The brass of the OP's movement looks orangey. Is that due to dezincfication caused by soaking the brass in an acid?2 points

-

2 points

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement. If there is anything we can help you with don’t be afraid to ask. Nice clear photos can help a lot.2 points

-

2 points

-

2 points

-

2 points

-

2 points

-

1 point

-

Hello, my name is Thomas and I’m a watchmaker from Michigan. I am a long time lurker here, lol. I’ve only been repairing watches for about 5 years, but have tinkered on watches a bit longer I guess. I attended Gem City College studying under Jim Hush, and I have learned quite a bit from this forum, particularly posts by Al of Archer watches. I am trying to up my game and the quality of my work and this forum has helped me quite a bit. I am currently honing my skills in preparation for the CW21 certification.1 point

-

1 point

-

1 point

-

Yes absolutely no power at all. This is a controlled test. Using the hairspring to supply the energy. Turn the balance wheel exactly 180° Then it would be ideal if you in a watch with a second hand C get tell us how many seconds it took before it came to a stop in each of the three positions1 point

-

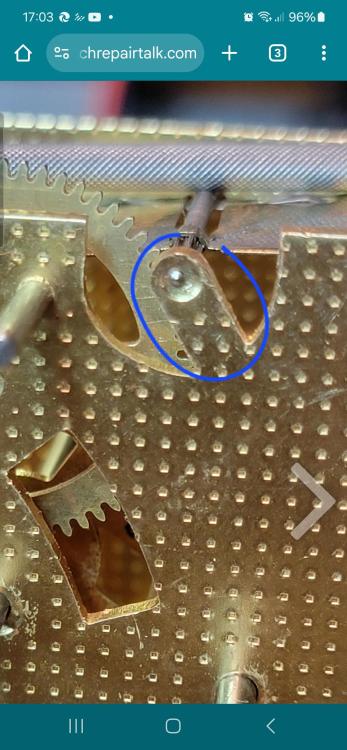

Actually, this 'peninsula' is made exactly for depthing regulation, simply by bending it. Only one correction - no heating is needed. This is silly idea. Guys, have You never worker on alarm clocks? This is traditional way for depthing the escapement there and the verge for the bell hammer too. Be brave and bend it a little. The main idea of this regulation here is to obtain depthing where the noise is smallest, but use it to obtain correct interaction without hesitation1 point

-

OK, You have balance related problems and until they are not solved, no point to check how the watch runs. First, when doing the free oscillations test, do not use puff with air. The test is meant for comparative measurement and needs to be precise. Turn the balance (use You finger) exactly to 180 degr and release it, then count the oscillations to full stop. Do the test DU and DD to be sure there is no significant difference. No point to go ahead with watch testing before result of at least 150 oscillations, which is 60 sec. The axial free play can not be 0.5mm. If more than 0.2mm, the pivots will be probably able to get out of the pivot holes and the balance will wobble. The free play needs to be small, but to exist. If You have such big free play, than this is serious problem. But for sure, the balance doesn't rub on the cock. The first candidate for where the balance rubs is the central wheel. You need to check if the balance cock is not bent up. If it is not the case, then the staff is not the correct one OR the stone settings are wrong. To compensate for big free play, You can bent the cock down, but no more than 0.1mm. If more bending is needed, then something is wrong (staff or settings).1 point

-

No, this is not a dumb question. It is something I have checked and it appears OK. During my research, I saw where someone suggested heating that pensula where the fly is, and then bending it to the left a tad. This seems drastic to me.1 point

-

1 point

-

It is possible that the problem is further back in the train and exhibits only at the fly and warning wheel. In such cases I usually dismantle the clock and re build ths strike side wheel by wheel , without the barrel and checking as each wheel is fitted back out to the fly. Laborious I know but whan chasing rainbows some times necessary.1 point

-

As with a lot of thing#. +lock# watches cars etc the visual bit is what the client sees and if what he sees looks good they accept that the rest is also good, not necessarily the case, but as long as you have done your level best on the internals according to the clients wishes all well and good.To achieve the level of restoration @oldhippy is advocating and the price you paid I would expect that standard. Normal service work requires the instrument to be clean and serviceable. Restoration is at a different level and cost regarding time involved.1 point

-

1 point

-

1 point

-

Oh one other thing to look at if it won't run dial up - I can't remember if this was anywhere earlier in the thread. Take the balance off and check the end shake on the pallet fork, as well as examine if the pallet fork arbor pivots are worn or broken, and check the pallet arbor jewels. If when you flip it dial up the pallet fork has too much end shake, it "falls" down and may then rub against the double roller. It should have very little up/down motion and obviously if you find a broken jewel that is a problem. I had no idea these could be bought under $100 USD.1 point

-

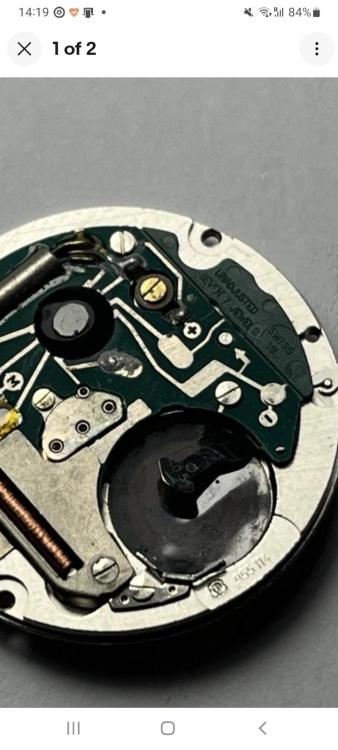

Hi. Judging from the outline I would say you are right, the trimmer capacitor is missing attached service sheet / parts list 612_ETA955.102,955.112,955.122,955.132,955.402,955.412,955.422,955.432.pdf1 point

-

Renaissance wax. I never used it. But I know quite famous clock maker who uses it , so it must be good. I was not just a clock repair but most of my work was restoring which means getting the clock to its originality I worked on high grade clocks, but I had to cut my teeth on cheap movements.1 point

-

1 point

-

hmmm, I'm not so sure. The price seems high for a basic clean overhaul, but I dont see it necessary to do a full museum-quality restoration on the movement unless thats what the customer has asked for. I certainly wouldnt be re-blueing screws in a basic service, especially for a movement thats likely to be hidden in a case. But, it should be clean and well-lubricated. Totally depends on the client and what they want I suppose.1 point

-

Have saved scrap watch case stem tubes. Put one of the right diameter on housing, push on tube till housing starts to move, next put a balance wheel and cock back on mainplate to assess what you have and which way ( in or out) housing needs moving to achieve the right end shake. A good end shake is one that a slight push on the cock, stops the balance. I do all that with one eye shut. There are folks who can do the same with one eye shut while smoking cigarettes . Regs To search for a family, say 581 ! add 582 , 583, 584, so on, to your key words. A cal of the family or its base cal might be hiding somewhere there. Regs1 point

-

Hi everyone! I’m TimepieceTinkerer, and although I’m a bit late to introduce myself, I didn’t want to skip it and come off as rude. I’m from Leicestershire, and I’ve been into watchmaking as a hobby for some time now. I enjoy working with vintage movements and learning more about the craft as I go. While I’m still very much an amateur, I’m excited to be here and to learn from the wealth of knowledge that this watchmaking community has to offer. Looking forward to sharing in the experience with all of you. Regards, TimepieceTinkerer1 point

-

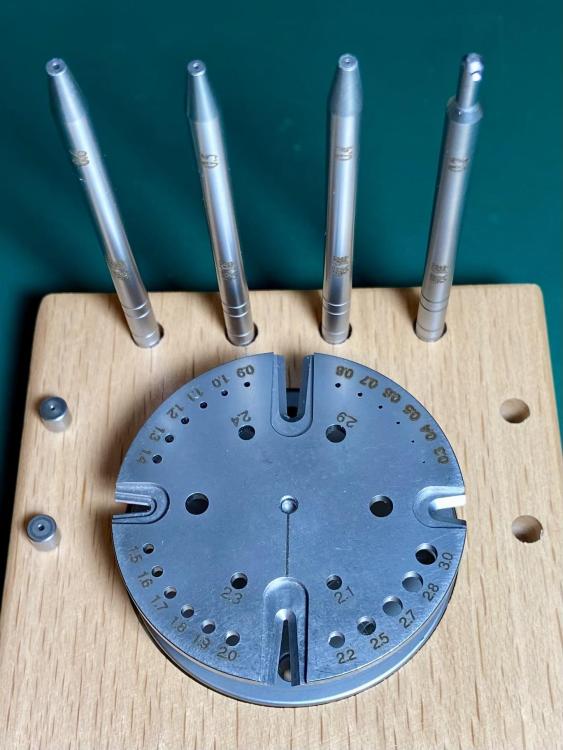

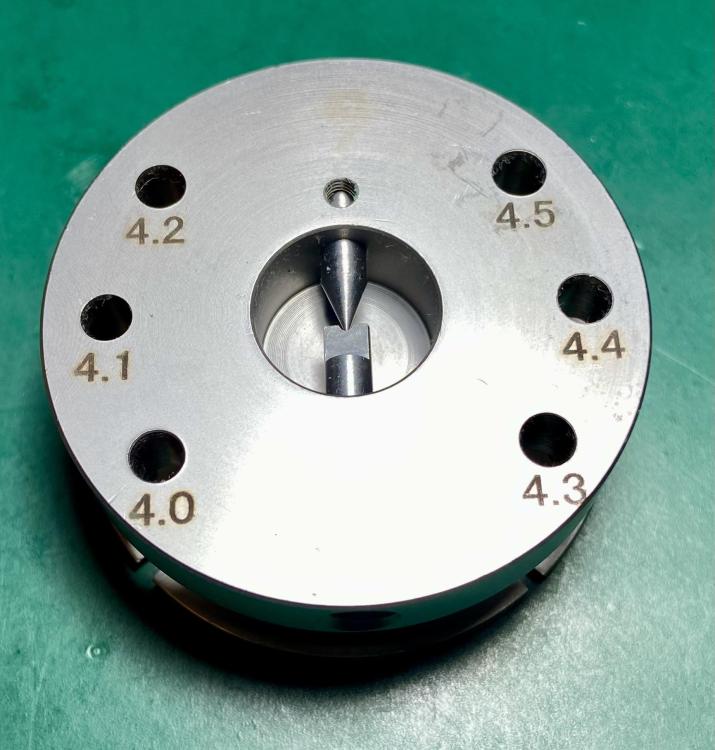

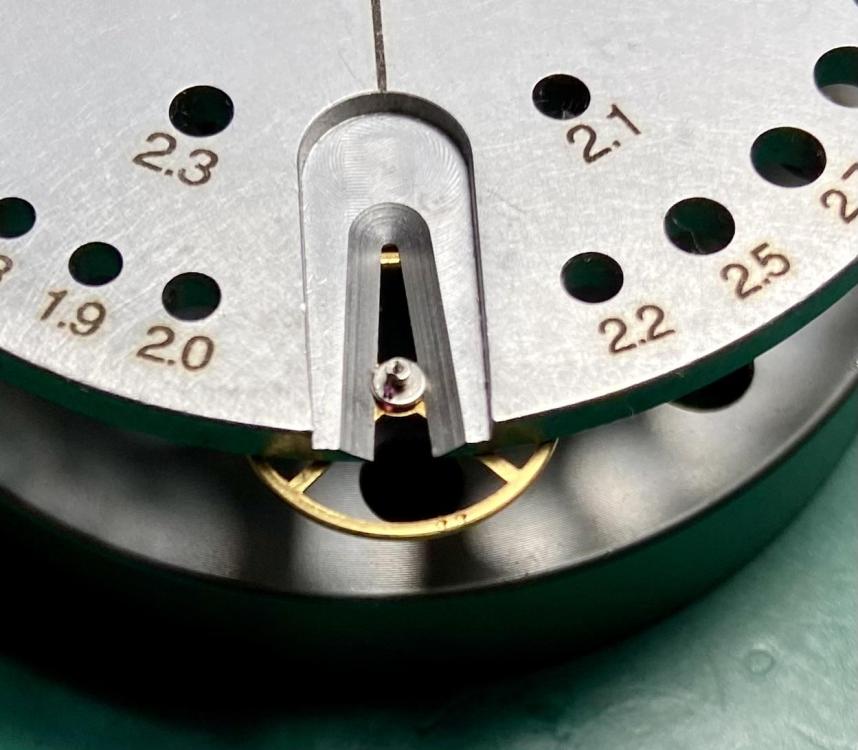

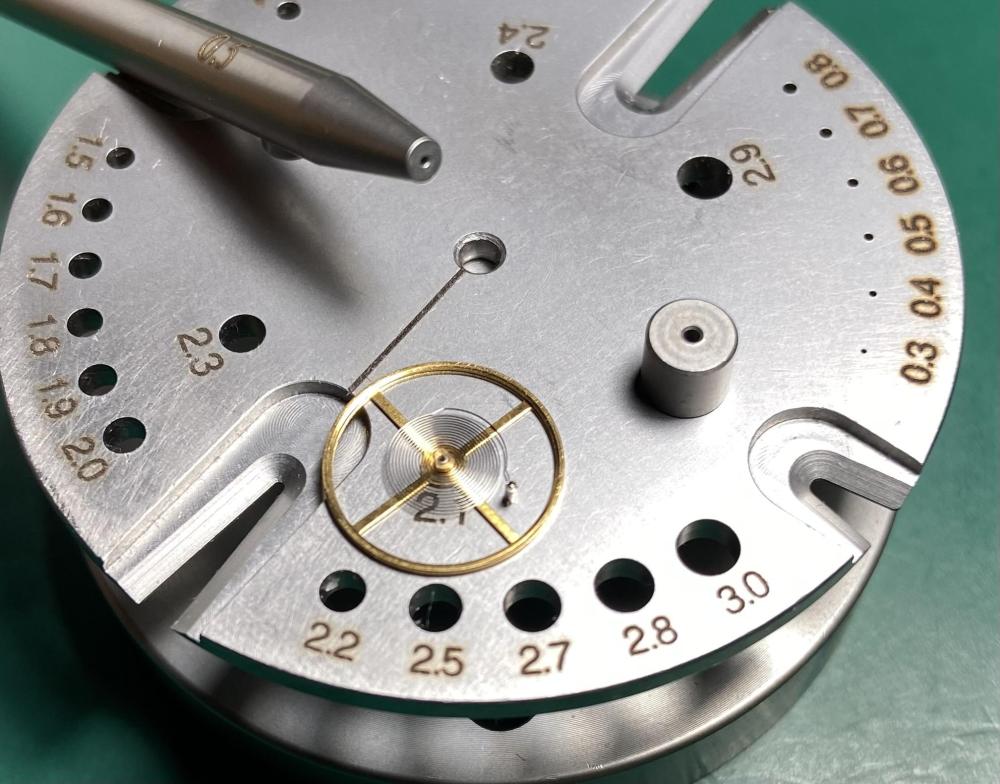

Funnily enough, I made a lesson on this subject for my third year students. As @nickelsilverhas already pointed out, that there is no magical fix just using a reamer in a jewelling tool, especially if you have to use several to open up the hole to the correct diameter for the bush. The hole will wander on a badly ovaled hole, no matter how good you think you are! Btw, what a lovely set-up you've made for your faceplate @nickelsilver. It's a pity you can't post videos on here, as a couple of slides have them. The slide with the crosshair on the centering microscope picks up the outside of the hole as it is turned whilst centering the work with light taps on the side of the bridge or mainplate. That's the hardest part of the job, really. Once the hole is centred, or what is left of it, the hole is bored open just a tad smaller than the reamer which is 0.01 smaller than the bush you make. You can bore it to 0.01 undersize by measuring the hole with a plug gauge then fit the bush that is 0.01 mm bigger than the bored/reamed hole. I do like this kind of work, as it's so satisfying when it all comes together1 point

-

This is great idea about the sapphire glass. Thanks a lot, I have never tried to shape sapphire, but this is what I will try to do. The other stones (on the balance rollers) are white color too. Today i made several unsuccessful attempts to make glass 'stone', but the glass is too brittle for the way I try to make it. Interesting, I have made many impulse jewels of glass, but here the part that enters the hole in the spring is round and the glass breaks right on the border between the round and flat part when I try to lapp. But anyway, the glass seems to be not firm enough for this place. The way I repaired the broken part of the spring is rather ugly, but think it is reliable and I try to avoid making new spring.1 point

-

1 point

-

Long time since I was in Chester, used to visit Astra Zenica In Macclesfield to doo some work .1 point

-

Takigen is a hardware manufacturer - hinges, handles, latches etc.1 point

-

Hi Nath, My answer will differ from the others. As one who has built several lathes (not complicatet ones, but well working), I think i have this right. Making own lathe is possible, at least I did my first one when I was 15 years old. Watchmaking was different before 150 years, one aprentice would never be proclamed 'watchmaker' untill he built by himself several different size and style clock and watch movements. And, learning the craft always started by lesons for filing, cutting, heat treatment, building simple tools, then more complicated ones... At that time the watch parts were not interchangeable at all and even repairing watches ment making parts when needed to replace. Yes, buying lathe is easier and faster, but making one will make You eyes and mind much more open and You will obtain skills that others will only dream for. There is a Bulgarian fairy tail with wisdom inside that says about the Fox - She was hungry and tried to reach the grapes in a vineyard, but the grapes were too high for her to reach, so the Fox said they are too sour for her and went away... Now, for making own movement... I will quote a Bulgarian Writer, one of his heroes said: ‘One is to WANT, another is to CAN, and 3th and 4th is to DO IT’. I will continue this thought with my own experience. When one is young, he WANTS, but he CAN'T. Then, when growing older, he gradually gathers experience and abilities, but when he is already experienced and able enough and he has proved that he CAN, he would probably has forgotten what he WANTed when he was young... See, making movement is different if one will copy existing movement, or even only the escapement, than if he will design everything by himself. Designing will need many knowledge and experience... Now, for the lathe design: You will need one more bearing for the spindle. One on front, and one on the back. Single bearing, even if it is with two rows of balls, will not support the spindle stable enough. What are this rails? What is planned to move on them? What is this thing on the front rail? Is it rail bearing? Unless I will know the answers, I will be not able to say if it will work well or not.1 point

-

If you are getting orange peel I assume you are spraying your lacquer, yes. Orange peel is the result of an incorrect spraying technique, often the result from too much distance between gun/airbrush and subject, so the paint starts drying before it hits the subject, or you are putting too heavy a coat of lacquer down and it's drying at different rates. Try lighter coats with more dry time between coats, or try a less hot thinner so it slows the dry time a little.1 point

-

I have recently used a jacot tool to successfully re-polish a badly worn pivot in a pocket watch the first time in my life. I have watched Richard's videos about it and I also went to a book printed in the same year I was born in 1976. This book is written in Hungarian and was one of the book used by the state sponsored and only one watchmaker school as far as I understand. (To my knowledge you cannot learn watchmaking any longer in Hungary as of now.) I scanned the corresponding pages as how to re-finish a pivot including the usage of a jacot tool. It was a great help to me so I thought I share these pages with you. After scanning the pages i sent the pdf through a pdf to txt engine then sentence by sentence I translated the Hungarian text to English. I learnt watchmaking in English and it might sound strange but the Hungarian name of the parts and methods were unknown to me. This added some more difficulty on top of the fact that my English is far from perfect. I am writing this because I am not sure how good the end result is. If anyone feels that could correct the text so it would be more readable or would make better sense please do so. Enjoy if you can. jacot_tool.pdf jacot_tool_Kopasok_javitasa_magyar.txt jacot_tool_repairing_wear.txt1 point

-

I have a link below that you might find helpful. Scroll down until you get to Joseph School of Watch Making. Then you want to download unit four. at the bottom of PDF page 7 you going to find something of interest. notice there is a reference to the shape because the shape of the curvature of the burnisher has to correspond the shape of your pivot. Then notice and they follow up with a reference to refinishing. Unfortunately just because something is called a burnisher doesn't mean there is a universal standard of what the finish should be. I've noticed they range from being very course to basically shiny smooth. Elgin watch company made a sapphire burnisher one and was slightly frosted and the other was really really smooth and shiny. then with your nifty new tool at find something to practice with before jumping in with a good watch. It's an interesting tool to learn how to use and requires a lot of practice if you want to be good with it. But if you know what you're doing you can produce some incredibly beautiful finish on the pivot. https://mybulova.com/vintage-bulova-catalogs1 point

.thumb.jpg.19a9c4ff164d78d516aa9f05a063752b.jpg)