Leaderboard

Popular Content

Showing content with the highest reputation on 03/22/25 in Posts

-

What is the crystal made off? Acetone is the best solvent for superglue, but it will dissolve acrylic.3 points

-

I talked to Jim Lubic on the telephone back in 2004-2005 when I was first interested in going to watch school. I was asking him about the pros and cons of going to a WOSTEP school vs not. I believe he was AWI president back then. I attempted to attend Gem City College back then, but couldn’t stay there due to financial complications. I also tried to attend Lititz Watch Technicum and went through the interview process, but they were concerned that since I was married and had a small child, I wouldn’t be able to concentrate on my work or financially survive. That almost ended my desire to to become a watchmaker. Fast forward about 15 years, now my kids are grown and I decided to persue watchmaking again as a career. Becoming a watchmaker has been a lifelong dream and my next goal is getting the CW21 certification. I have also looked for opportunities to do an apprenticeship with a more experienced watchmaker, but haven’t been able to find anyone who is willing to take me on.3 points

-

Are you talking about opening the pins on an older watch having just two pins and no regulator boot? I would not recommend touching them at all when removing the balance complete. It should come free of them without interference. And when reinstalling the balance complete, a good hairspring should drop right between them without issue. Maybe land beside but lifting the spring over the pins should cause it to snap into place. The pins must be parallel to each other and should usually be perpendicular to the balance cock. If they are too far apart, you will have rate issues in vertical positions and wild rate variance at low amplitudes. And if they are not parallel, rates will vary between horizontal positions.3 points

-

3 points

-

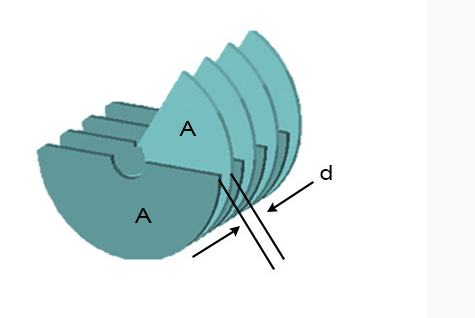

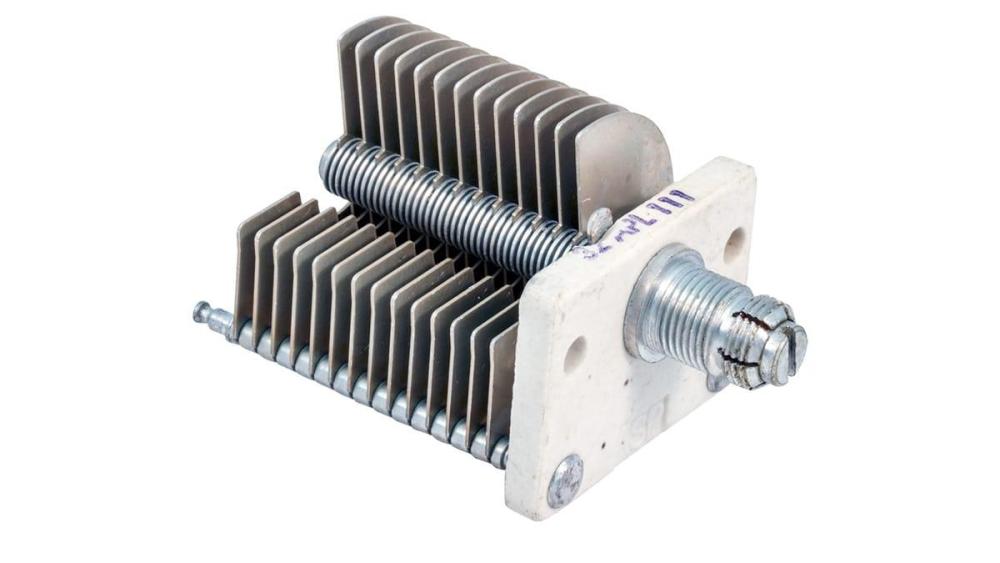

trimmer capacitors are quite interesting how they work. Unlike a variable resistor which might start off at zero and adjust to a maximum and stop. Trimmer capacitors typically do not have stops some of them might but in a watch they do not. The examples below have way more plates than you would have been a watch so basically you have two half round circles. When their maximum together you have your maximum capacitance. When there turned the opposites then you will have the least amount of capacitance. So turning it as you have done may not actually have the desired results. Typically you would have a timing machine for quartz watches and you would turn them very tiny quantities. Then yes even with a trimmer you can get down to a few seconds per day is happy really patient when you're adjusting and you also want to be careful not to press down on them as that tends to bring the plates together and then they have to readjust back to wherever they were plus if you push hard enough you can actually break the capacitor to visit uses ceramic for its construction.2 points

-

As far as I'm aware the off-gassing is only while in the uncured state, and the level of that depends on temperature. (eg. heating it causes the liquid stuff to give off vast amounts of vapour - as used to develop latent fingerprints). The simple way to avoid any stray vapour around a joint is to mist the area with cyanoacrylate accelerator spray, which makes it cure almost instantly. I use mostly "Mitre bond" kits - 50ml of fairly viscous adhesive and a can of accelerator for far less than many places charge for just a small tube or 20m bottle. The last ones I got were about £4 each kit.2 points

-

With both hour and minute hands affected, I'd first look at the cannon pinion.2 points

-

...as it happens, I am the superglue king lol. I've been using it for nearly 40 years, since it was introduced into the double glazing industry, which was my bread and butter in the late 80s. It's used almost exclusively in sticking trims to upvc frames. The stuff I use has two setting times....thick slow and thin fast. I use it mostly for gluing upvc trims together also timber,rubber leather, clothes, metal sometimes and skin but that's usually accidentally. Good for holding minor wounds together. The only thing I've known it to deteriorate over time is cloth materials but that is mostly due to its hardening affect which stops the material having any flexibility. It doesn't stick metal very well at all without compression, something we know by the glued caseback/nut trick.2 points

-

D'oh. After all the years I've been on here, I didn't know you could do that Rich I just selected 'Quote' at the bottom, and edited out what I didn't want. Anything else you hiding from me ?2 points

-

Hi. The modern day clocks are built from different levels of brass and steel in order to cut costs and increase the profit margin , I have said before the buying public are wowed by the look of it aka fashion watches selling at 100 s of pounds all swish and nice powered by a Hattori plastic movement costing a few quid at most. Modern clocks are no better. You could put the best movement possible in a crappy case and it wouldn’t sell well. Unfortunately it is the modern way, don’t like it but we have to accept it .2 points

-

For me the rate adjustment elements are secondary to having the hairspring set correctly with the balance. Things to check beforehand would be that the hairspring is centered with the balance jewel, and that the regulator arm tracks the hairspring's terminal curve through the arm's arc movements when adjusting the rate. Hairspring centering is quite easy to see, looking down on the balance, the coils will have nice even spaces, so no bunching up of them, if there is then that needs to be delt with first. If the terminal curve is good and the rate arm tracks it well then its ok to start adjusting the regulation pins. Setting them close, with the spring at rest sitting in the middle with a very small gap at each side of it, with the gaps adding up to a total of about the hairspring thickness ( half thickness at each side ).2 points

-

I'm really confused by this watch. The minute/hour hands are conventional, while the bridge with Pooh and gang doesn't move, and is actually the dial? So, how does the second hand pivot power the Eeyore disk? It this a specially customized movement for Disney? Would a replacement movement be found easily?2 points

-

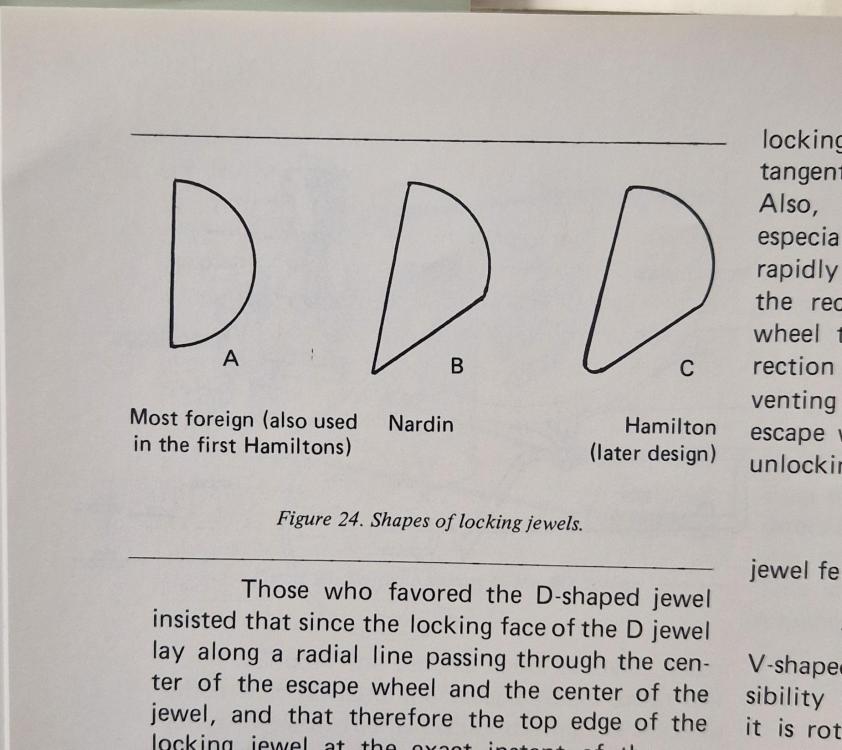

Just some info which you quite likely already know The locking stone is held in by a brass wedge, which can be undersized on diameter as the locking stone can be too. "Too precise" can be counterproductive here, there's a lot of margin. Ruby/sapphire does well in compression, the wedge serves well and only needs a small amount of force- a little shellac and all is well.2 points

-

2 points

-

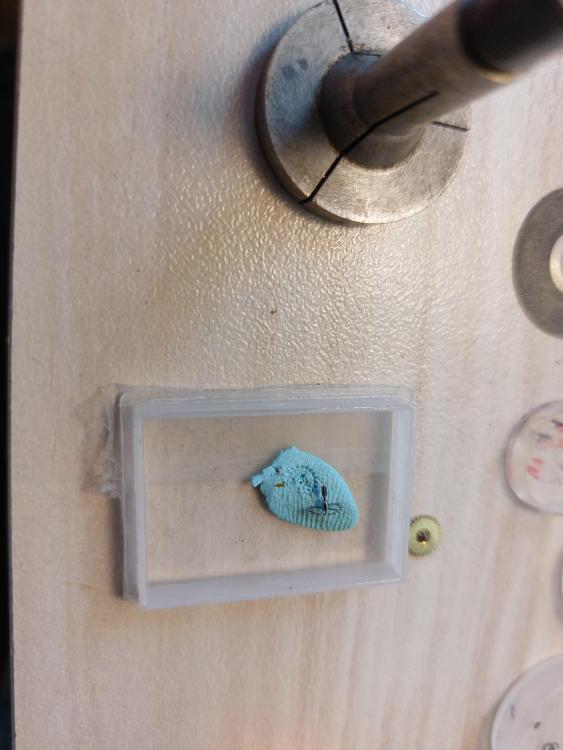

This is great idea about the sapphire glass. Thanks a lot, I have never tried to shape sapphire, but this is what I will try to do. The other stones (on the balance rollers) are white color too. Today i made several unsuccessful attempts to make glass 'stone', but the glass is too brittle for the way I try to make it. Interesting, I have made many impulse jewels of glass, but here the part that enters the hole in the spring is round and the glass breaks right on the border between the round and flat part when I try to lapp. But anyway, the glass seems to be not firm enough for this place. The way I repaired the broken part of the spring is rather ugly, but think it is reliable and I try to avoid making new spring.2 points

-

https://www.esslinger.com/isa-3-hand-quartz-watch-movement-isa1198-106-small-second-hand-at-12-00-overall-height-5-5mm/ Here is the link to the movement. It says the seconds hand is at the 12. Not sure how that would rotate eeyore. The seconds hand ticks back and forth. Not sure if the coil is damaged or if someone had done some work to it prior but there is a blemish on it. As far as I could find, they don't make just a coil for that movement. Maybe if I sourced it from eBay, but I haven't done any modifying to quartz movements. Only replaced them. That gold piece is solid. There is a shadow at the bottom left that makes it look like a space or an indent, but it is not. AndyGSi, I could dismantle it that way but what if I can't get the seconds hand on the new movement? Yes, I looked it up as well and this is why I am being cautious. I would rather admit defeat than empty my pockets1 point

-

Yes, it has a cutout for the Breguet spring (photo), the screw hole and the steady pins but no spring. The pinion on the bottom of the Third Winding Wheel on the Bulova is solid with the wheel and engages with the Ratchet Wheel. On the AS1320 it has a clutch wheel that can slip and disengage from turning the wheel when the watch is manually wound and it needs the spring to keep it engaged with the wheel. I'm not sure why this is necessary as the the auto works will also disengage from winding the rotor when the movement is wound because when it is wound the alternating disc rotates away from the rotor. That Technical Bulletin I posted above doesn't come out and say it but it sounds like this setup with the Bulova might be a design issue: Perhaps not having that slipping clutch (a cost saving measure?) leads to problems with the Third Winding Wheel breaking.1 point

-

In my experience it isn't after the full cure has taken place. With plastic on plastic it forms a melted bond, impossible to seperate without damage. I honestly don't think it's corrosive once it is fully set. When the accelerator is used often a weaker bond forms, but it's invaluable in winter and helps when gluing porous surfaces. Superglue has an antidote...a debonder solution but that's usually acetone. Interesting but irrelevant with the ops situation.1 point

-

Yes I do, plan to look through my watch scraps parts tomorrow, will look for samples to show. Regs1 point

-

I saw that and thought the same. I believe it's an error. I have two of the 10BRC and neither have that spring. I've looked at a number of the 10BRC movements on the web and can't see the spring. The Bulova parts list and description of how the automatic works functions does not mention the spring either in the parts list or when describing how the automatic works functions. The lubrication recommendation does not mention lubricating that spring, while the AS 1320 technical documentation does. I believe that the different construction of the Third Winding Wheel in the 10BRC compared to the AS 1320 is why Bulova did not include the spring.1 point

-

1 point

-

Google, "" is super glue corrosive "" Worst glue: Don't use cyanoacrylate glue! Also known as Super Glue, it is terrible for most electronic products. It's filled with corrosive chemicals that will off-gas, leaving a thin white haze on plastics, PCBs, and other OVER TIME , corrodes metal too. Regs1 point

-

1 point

-

I think I might well do the latter... I have, though didn't want to go too tight with it for fear of breaking the crystal. Ah, that's interesting - hadn't realised that. I realise there's some irony that I don't want to repair a precious item thats had superglue thrown at it! I'll take some later tonight - I can see superglue dial side so I think I'm going to just take the easy option and leave it for now, and if he ever breaks the clouded crystal have a go at it then... It's not a valuable item other than for sentimental reasons as far as I know, so I'm probably better trying to fix it when/if it's actually broken, rather than risk making it worse now when it's usable.1 point

-

Hi first we need good picture’s othe crystal and movement in order to determine the amount of the application of the super glue. Secondly as @mikepilk said acetone is the best dissolver of superglue so careful application with a cotton bud might suffice depending on amount and location.1 point

-

Also, nobody on reddit knows anything! (or the few who do are not good communicators) You will get vastly better advice here.1 point

-

Yes I've looked but couldn't find anything even similar.1 point

-

I've been down the same route with no joy. @Arigato says it's 35mm but that sounds too big to me.1 point

-

1 point

-

If the dial is original to the watch, I'd be surprised if the movement wasn't made Cyma ( Tavannes) . When I got stuck for how something fitted or worked....I would start further up in the component sequence of that function group, to where I'd understand an operation, then work backwards from there to where I was stuck, figuring out each connection and interaction on the way. When you get back to the original confusion,things " click " into place mentally . The piece might be wrong or damaged,but you should see that more clearly now.1 point

-

Hello and welcome to the forum, plenty of help offered .1 point

-

Are you sure there's no hole. It was what I was suggesting. If there's no hole, it's the wrong spring.1 point

-

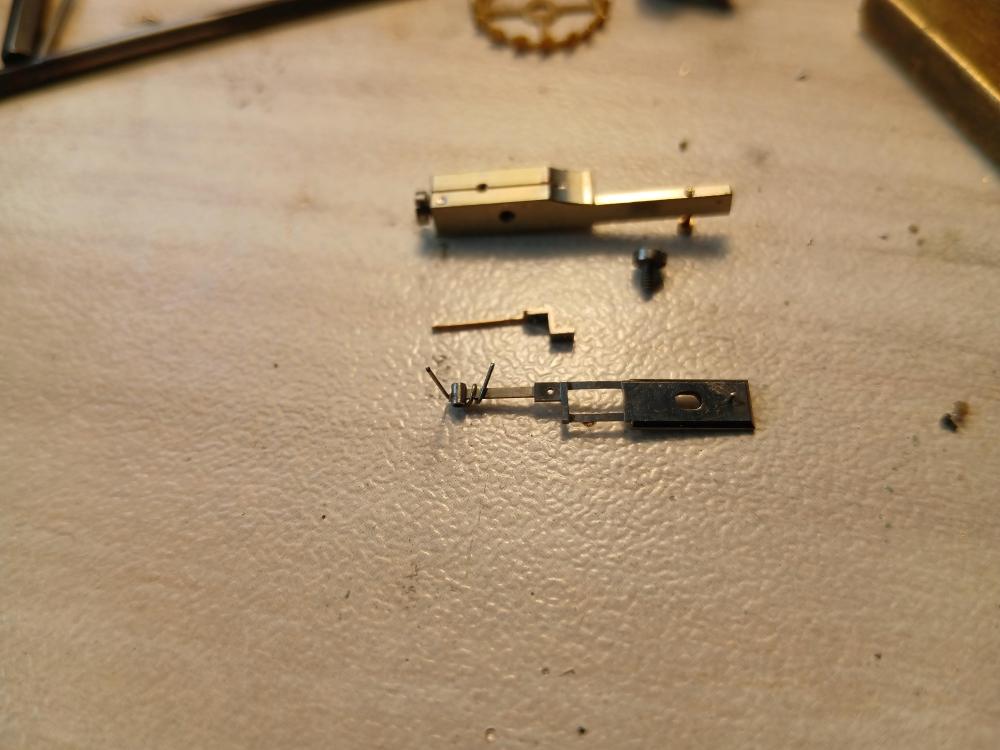

I am also realizing how this click needs to be put, and both legs needs to be in contact with the Ratchet whell, something I wasnt sure, so thats a step forward at least1 point

-

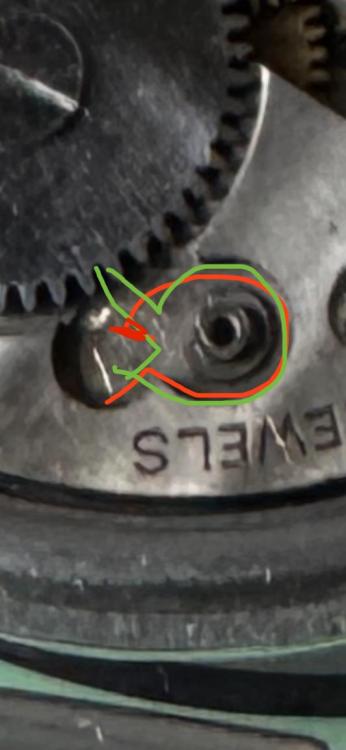

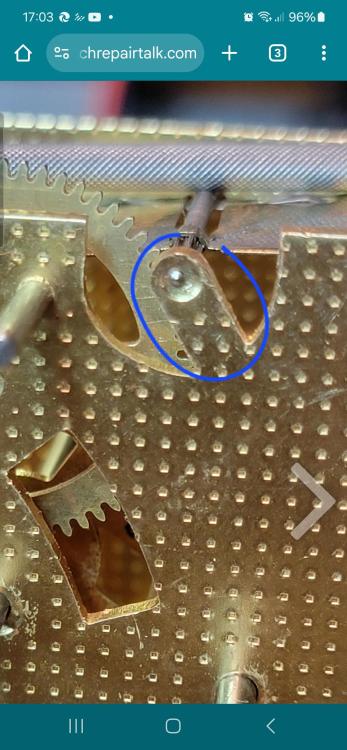

Wow so much help. Thank you everyone. Reddit can be nasty sometimes and I am glad I found this Forum. Mikepilk: Thats a great Idea, I assume it wont be that difficult with a delicate pair of pliers and its part of the hobby. RichardHarris123: Thank you and Hello from Germany. So on other movements I worked on the blue circle part normally goes in a small hole in the plate but this plate doesn't have a hole, was that what you were suggesting? Towards the end, before the click decided to fly away, i thought I had figured it out and the green part needed to be following the right side of the plate and the upward side needed to be between the two legs of the click if that makes any sense. I attached a terrible handmade drawing from my phone but im sure you will understand what I mean. Nucejoe: Thank you I will check this out right now.1 point

-

Do you have a depthing gauge if you have then check with it first before moving because that will not only tell you if depthing is correct & if not it will tell you how far & what direction.1 point

-

If the rates difference DU and DD are inbetween 5 seconds leave it alone.1 point

-

Looks more like a Cortebert. Though Malnija 362 & 363 , copied Cortebert, I doubt if Cyma sourced parts from Malnija.1 point

-

I've always wondered why there was this little finger. But shouldn't the meshing distances been pre-determined before locating the holes on the plates? And why only the fly has this adjustment and not every wheel?1 point

-

1 point

-

Welcome to the forum. What size is it?1 point

-

If you're just looking at replacing the movement then dismantle the old one from the back and pull it out that way.1 point

-

Actually, this 'peninsula' is made exactly for depthing regulation, simply by bending it. Only one correction - no heating is needed. This is silly idea. Guys, have You never worker on alarm clocks? This is traditional way for depthing the escapement there and the verge for the bell hammer too. Be brave and bend it a little. The main idea of this regulation here is to obtain depthing where the noise is smallest, but use it to obtain correct interaction without hesitation1 point

-

I've got a bench mounted one like a Bergeon, just a good quality Chinese version that has never let me down. I just don't have a 14-sided 30mm Breitling specific die to go with it. Got a set of Rolex (knock off) ones but the Breitling sets are quite expensive and incomplete anyway. And some feedback - it's off! Superglue, when allowed more than 30 seconds to fully cure, combined with a bigger nut, did the job. inside the watch is a standard ETA base calibre with a chronograph module. I think it's the same as the Omega I tackled, so should be good from here1 point

-

What's interesting is that they didn't just upgrade the entire circuit board. I was curious about cross referencing to a newer movement that would not show the trimmer capacitor. Then I noticed something very peculiar the 955 xx2 series of movements at least as far as the circuit goes does not cross reference with the 955 xx4 watch. Even though as far as I can tell they look identical. I'm attaching the 955.114 technical. ETA 955.114.pdf1 point

-

1 point

-

Have saved scrap watch case stem tubes. Put one of the right diameter on housing, push on tube till housing starts to move, next put a balance wheel and cock back on mainplate to assess what you have and which way ( in or out) housing needs moving to achieve the right end shake. A good end shake is one that a slight push on the cock, stops the balance. I do all that with one eye shut. There are folks who can do the same with one eye shut while smoking cigarettes . Regs To search for a family, say 581 ! add 582 , 583, 584, so on, to your key words. A cal of the family or its base cal might be hiding somewhere there. Regs1 point

-

Yes, I have found the info on this forum to have a ton of great resources and to be a really amazing community, which is why I finally moved from just lurking to joining and posting. (I believe I know who the "highly experienced/knowledgeable" person is, and I've been waiting for them them to chime in as well ). IMHO, time spent working on these vintage Timexes is well spent - and not everything has to be about $$. They are a real piece of Americana (dating back to pre-Civil War years!), and the hit of nostalgia I get when I get one running and restored cosmetically is immense.1 point

-

1 point

-

1 point

-

My lucky trick worked , I added a couple of drops of lighter fluid and it started working. Thanks everyone for all the support , I was nervous to open this one it's so complicated and I am still not good at opening movement1 point

.thumb.jpg.19a9c4ff164d78d516aa9f05a063752b.jpg)