Leaderboard

Popular Content

Showing content with the highest reputation on 03/26/25 in all areas

-

5 points

-

That's nothing, a rocking horse has just taken a S$%t in my garden.4 points

-

We've all done it Chris. The pivot looked bent anyway, so you would have needed to change it - I have heard rumours of people straightening pivots, but some have also claimed to have seen unicorns If you search Ebay for 'balance complete eta 1260' you will find some. Make sure you get the non-Incabloc version You will see some Renata balances, the number for the non-inca version is 1644 points

-

Some of these are intended for pocket watches. The two circlular ones with protruding bits - the one with 10 tips is a sleeve wrench, used for adjusting the stem sleeves in American negative-set pocket watch cases. The other with 6 tips is a jewel pusher, used for pushing out lightly friction fit jewels in brass settings which are mostly found on American pocket watches though some Swiss watches use them too. The Levin tool with the parallel ruby jaws is for poising a balance, getting it to run without any heavy spots which affect timekeeping, and the Levin tool with the thumbscrew between two halves is a truing caliper, used for verifying wheels are straight and true. The one you have happens to be the best type of this tool in my opinion. Eventually you will need the micrometers for something, but if they measure in inches rather than mm that is less useful. You won't need most of these for an ST36 or any modern movement, but the moment you pick up a pre-1950 pocket watch and want to make it run well a lot of these will become useful. If you do decide to sell some, I would expect the Levin truing caliper to be worth about $35 on ebay, and the Levin poising tool is pretty nice with an intact spirit level. If the ruby jaws are not chipped in the middle, that would be worth $50-$75 on ebay. The sleeve wrench and jewel pusher are harder to sell because there are tons of them available. It could bring $30 or it could only be $5 if you were unlucky. Movement holders of various types are always worth at least $15-$20 (some much more but I don't see those here), but I would keep those as you can use them today.4 points

-

Some of this you will already need like the movement holders. You've also got an adjustable mainspring winder in the lot. If it were me I would keep all of it, two very nice items are the complete Levin truing tool and the poising tool. If you really get into the hobby, within a year you might want these two, you'd be lucky to get something as good when the time comes. I thought that was a joiner's purpose , until I started repairing watches, then I thought it was just my purpose .4 points

-

There seems to be a general consenus/view that one of a watchmakers purposes in life is to collect tools..4 points

-

3 points

-

Thank you for the encouragement. I do have a staking set, but I have yet to learn how to use it. It is a K&D 18R set with a mixture of different brands of punches, some K&D and some Levin. I will look for a donor movement too. I was servicing this watch in order to give it to a friend who admired it, so I would like to repair it if possible.3 points

-

It's easy done chris, don't beat yourself up. You now have the opportunity to learn something new, an often required proceedure.3 points

-

Don't worry, Chris! We've all been there, and it's a part of the learning process. You never stop making mistakes, but gradually, you develop strategies to minimize the risks. The way out here will be to replace the balance staff. However, that's something that requires quite a few tools, such as a staking set and suitable punches. Perhaps the easiest way out will be to try to source a balance complete (balance wheel + balance staff + balance spring) from a donor movement if one can be found.3 points

-

Normally with the door you should have two small screws top and bottom on the brass part with the door knob on. When you have removed the base with the movement look inside at the top you should have two screws one each side that holds the handle unscrew those and not only will the handle be able to be removed but the glass should also be able to be removed. Just be careful when you take the case apart number them as some might look the same but might not fit quite right. Any trouble post photos of door top and bottom also in side the case with movement removed3 points

-

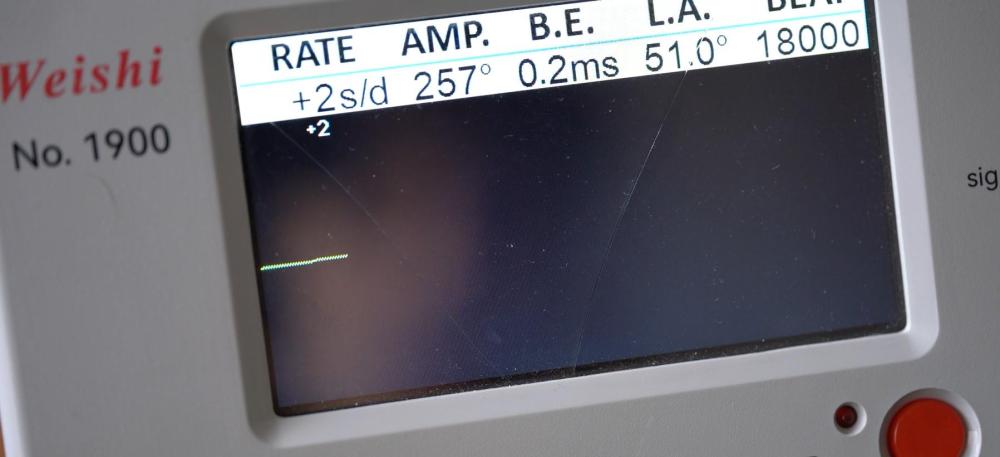

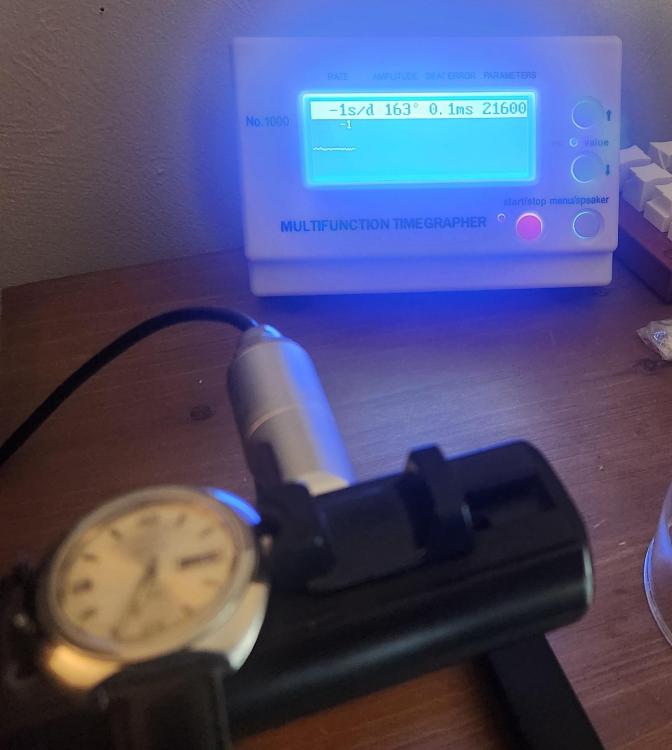

Hello watchbangers! I am back again with another walkthrough of a project which I completed almost two years ago already now! Wow does time fly, I would love to regulate that to go a bit haha xD. Now as I fixed up a watch for my younger brother a few posts ago, I decided that I would give my dad a pretty watch for his birthday aswell! Funnily enough, this watch came from the same lot of vintage Junghans non/runners that I surprisingly won on Ebay, from which my brother watch originated from! As always, for the ones to lazy to read or interested in a visual accompaniment the link to the 4k video: Now to the watch! It has a very nice curved rectangular case shape with ( what I assume ) is some sort of gold look a like. The caseback is stainless steel. The acrylic crystal is pretty scratched up and the dial does seem to have some sort of.. corrosion? Around the edges. I assume thta its either just wear from the dial edges rubbing against the case or that these used to be some sort of adhesive, which over time, just ripped of the finish or ate itself into the dial. Otherwise he obviously missing seconds hand is missing, the watch is a non runner and when shaken does have some clanking sound. I opened up to be surprised with a missing ratched wheel screw. So thats already one things less I have to worry about haha. The design in pretty simple, what I liked about this calibre is the crown wheel which is held down by its core, the huge balance wheel and the big cap jewel used in the shock system. What I do want to point out is that there is literally no method of movement fixation to this model. There are taps for screws which fixate the movement to some sort of holder but those are both missing. I came up with a pretty neat fix for that later on down the road. Now I removed the stem and de cased the watch from the back. You can steel see the ratchet wheel that I didnt remove at that point behind the movement haha. I removed the hands and the dial to completely free the movement from any outer parts. It reveled a pretty smooth looking movement! And again that fat cap jewel on the movement side aswell. Took of the cannon pinion, the hour wheel, the minute wheel and the setting wheel with its cover Removed the clutch wheels ( dont need them to remove the mainspring power as the ratchet wheel was nit attached) and the cover plate for the gearless works. Then took out the yoke and the yoke spring before turning the movement around. On the barrel bridge we see the caliber number for this watch „687“. This movement was made around the 1960s, however I cannot pin point the exact date as I do not rememeber and did not take a picture of the stamp under the balance cock which shows the manufactury date. Of course the balance comes off first as a precaution. This revealed the typical Junghans Star logo. As the incomplete click assembly system was smiling at us here, I immediatly took out the click and the click spring. Next, I removed the crown wheel and its core by unscrewing both screws. Then I took of the cap jewel from the escapement wheel and the pallet fork bridge and pallet fork. Off with the train wheel bridge. The brass from the second hand wheel is pretty stained , hopefully it will get its shine back after a good cleaning! Off with the second hand wheel and the third wheel. Then I removed the minute wheel bridge. What I found cool is that this bridge also had the number „1“ stamped into it. Maybe that would help for the reassemnnly or it could help pinpoint the production batch? Removing the last three components: the mainspring barrel, the minute wheel and the escapement wheel. Taking in the mainplate all naked shows the nicely sandblasted surface. Of course I cannot wash the watch without taking out the shock systems. Here picturs of the extremely empty looking blocs without their huge stones haha. A total overview of all the watch components including the unwound mainspring. Then another picture of the watch during the cleaning cycle. I think it just finished the first rising phase here. Now for the reassembly I literally just worked my way backwards from the step I just described and just lubricated aswell. Here the lubrication I used with the places: Moebius 9010 : Second hand wheel, escapement wheel pivots, Moebius HP 1300: Slower turning wheels such as the minute wheel, third wheel the the barrel arbor and the barrel pivots. Additionally I added some to the pivot swhere the transmission wheel and the setting wheel (in the front side) would run around. Moeius 9415 : The Pallet fork jewels Molykote DX : Friction points in the gearless works. As the crystal was a bit scratched up I worked it over with some polywatch and got some case shine back by using some jewelers cloth to polish the gold colour. Now regarding that movement fixation issue that I described before! After researching a bit online for donor holder rings or screws, I came up empty. I settled on designing and printing my own holder ring which would not hold the movement in place with the screws, but by the locking force when the case back would be wedges between the the case and the holder ring. Here are a few pictures of its creation. With the watch „complete“ again, I put it onto the timegrapher again! While the preregulation did have a slow rate, I was very happy with the amplitude of around 260! This is the regulation of the dial down side at the end: Here is the picture of after everything was done and it was ready to be packed away until my dads birthday! I also had a nice Junghans watch case which I received from the company itself when I sent in a watch long ago. I dont have picture with the box but I just wanted to say that haha. Now im conclusion, I had some fun with the watch! It was pleasantly surprised with the level of detail to such a simple watch. Of course nothing in comparison to modern counter parts but they definetly cared for the aesthetic quality aswell. A few things which spoke for this was the sandblasting, the polished crease around the train wheel jewels, the shape of the setting wheel. Of course the final result does show a lot of potential for improvement but I will just deal with that when the watch comes in for service in a few years. If anyone has any questions/ comments or anything to say in particular, you can always write a comment or hit me up privately!3 points

-

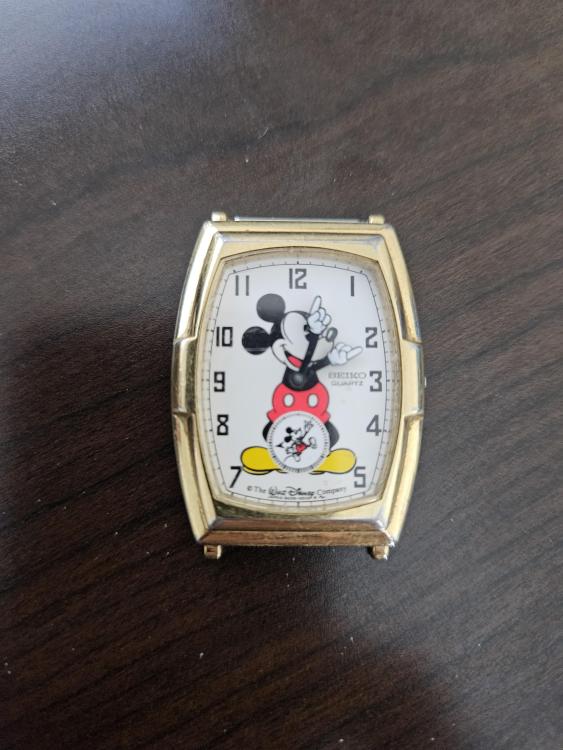

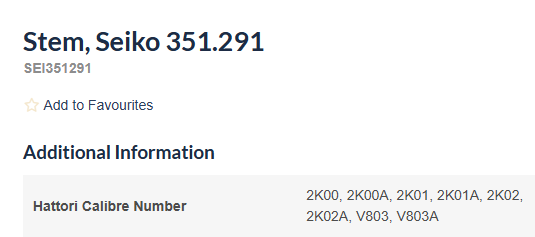

I have both but prefer the digi. I asume i need to test the coil for ohms somehow or if theres any voltage running thru Well I sorted it. I have a crown and new stem on order as the old crown is missing. The old stem is still in the case and movement. I thought maybe the stem wasn't pushed in and was in setting mode. Pushed the stem in and Mickey is off and running.2 points

-

Ah.. but there is only one,I have two going at it like..........unicorns. Bag it up Rich and slap the log on ebay.2 points

-

There are two grazing in my back garden right now Mike, one is looking kinda frisky, so I may be buying Swatch out when the offspring arrives.2 points

-

Don't be so hard on yourself. We've all been there! One slip and hours of work down the drain. It's in the nature of the job/hobby. A huge sense of satisfaction when you finally get the job done is the other side of the same coin. That top pivot was scrap anyway. And you will, even if it takes longer than you hoped. Now you are going to learn how to replace a balance staff. All good!2 points

-

You are indeed correct OH, I can see the screws, what a surprise and the top does come apart.2 points

-

Hobbyist to hobbyist - your 9010/1300/9415/8200/DX set is just fine for everything you will do and need. One often registered complaint about Molykote DX is that it is hard to clean away, and can get missed in the cleaning machine by some solvents. But as a hobbyist without a speed- and machine-dependent workflow where you will spend more time pre-cleaning parts or only do manual cleaning, the issue of getting the DX off is eliminated. I have 9501 and it suits all my needs fine, but there is no reason not to continue using the Molykote pretty much anywhere a service sheet calls for 9501 or 9504. The 8200 is best used as a mainspring lubricant. And I really advise against asking chatgpt for movement servicing advice. This thread should demonstrate why, especially the images near the end.2 points

-

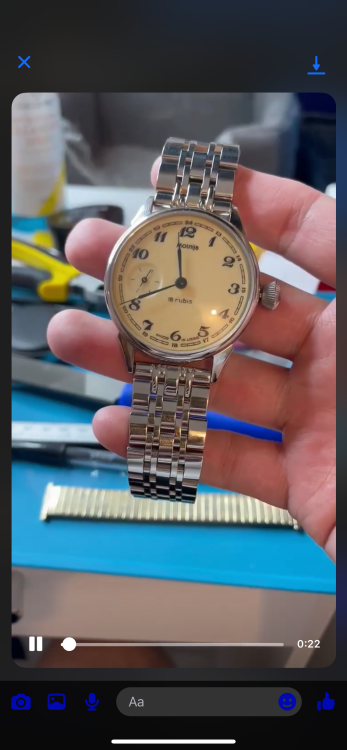

This is Record Watch Co movement, probably modification of Record 6 but with negative stem. And it has all the 17 jewels2 points

-

The pawl levers were worn and not working to wind the mainspring. Found a donor 7006a and replaced the trainbridge. Was clumsy and broke the escape wheel pivot but got the one off the donor movement which I won for $9.08 including tac and shipping. This case has seiko turtle DNA and is 41mm, 39.5mm lug to lug and 12mm thick. Wears very nice on the wrist.2 points

-

Frightening stuff above! Superglue and sulphuric in the eye does not sound at all pleasant. Very glad those were happy endings.2 points

-

It reminds me of my then 13-year-old daughter, who had been nagging me for days to drill a couple of holes in the ceiling of her room for screws to hang her curtains. Eventually, she got tired of waiting for me and decided to take matters into her own hands—by grabbing a bottle of super glue and attempting to attach some sort of contraption to the ceiling. Suddenly, I heard a desperate scream from her room, and 30 seconds later, I was on the phone with emergency services, trying to find out how dangerous it is to get super glue in your eye. She was in a terrible pain. I didn’t get a definitive answer, but they advised me to take her to the emergency room at one of Stockholm’s largest hospitals, Karolinska. A specialist ophthalmologist spent over an hour carefully removing the glue from her eye. Fortunately, everything turned out fine. Had her vision been permanently affected, I would have had a hard time forgiving myself. So nowadays, I make sure to drill holes in walls and ceilings before any serious accidents happen.2 points

-

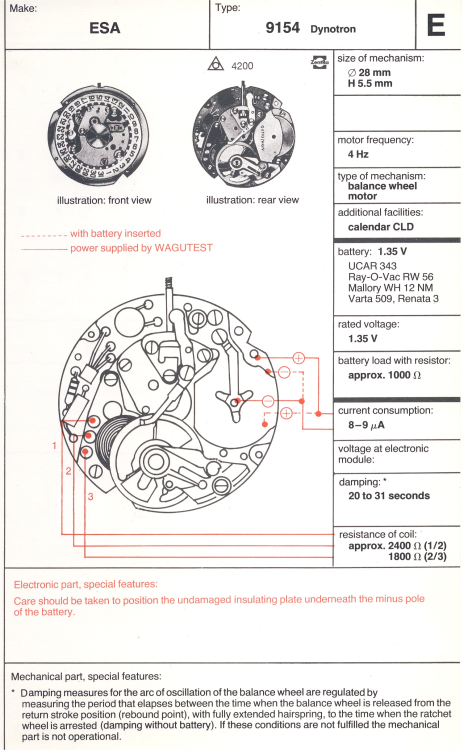

There a little mote here on the 9154 Circuit. 9154 Circuit.pdf1 point

-

1 point

-

Oops , had missed it. Thanks for informing me.1 point

-

1 point

-

1 point

-

interesting strategy for an electric watch which typically will have permanent magnets that really don't like to be demagnetized even if they are listed as permanent. typically I've given up with that question because it's wishful thinking that anyone would have test equipment beyond the DVM. Test equipment for electric watch would be a variable voltage power supply, some way of measuring microamp current and a DVM for resistance and voltage. while they look almost identical at least to the casual observer I don't think this is a 9154 which is why attached the technical up above for 9150. But to be thorough I will attach the technical for the 9154 and some images I found on the Internet so 9150 as for contacts for the coil assembly with one home attached to a screw. than the 9154 only has three contacts the 9154 as a different coil arrangement were now it only has three terminals none of which are attached to the screw. So the image down below of this watch is a 9150. Although not the same all of the cleaning procedures testing etc. will all be identical other than the coil resistances current consumption will probably be a little bit different. yes the joys of YouTube watch repair where nobody ever reads the tech sheet and is unaware of the impending doom that they typically never have but anyone following will. Yes you definitely want to look at the tech guide before you even begin the disassemble or it will be not a happy outcome. if you are hoping for a quick squirt of lighter fluid and the watch would run I think you're out of luck. Electric watches typically have very little power and require the gear train to be extremely free moving in other words no sticky oil at all. in addition to when people change batteries it's very bad to get anything like old battery corrosion or anything else into an electric watch. So basically no quick fix here. 3540_ETA 9154.pdf1 point

-

1 point

-

Looks as if it comes out from the front. you need crystal lift I suggest the bergeon one, cheap ones do not work well. It will be a two piece stem so so you pull it right out and the movement will come out.1 point

-

Which glass can't you remove? I always used https://www.johnwardle.co.uk/clear-brush-on-brass-lacquers-9-p.asp applied with a flat very fine artist brush.1 point

-

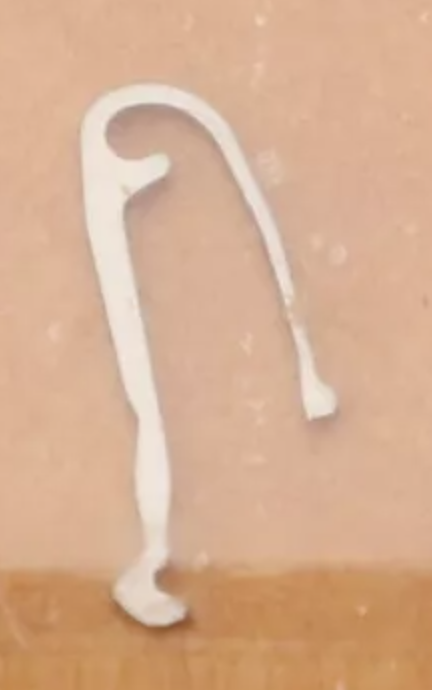

This is what it should look like so doesn't look that deformed From the literature it should be no where near the boss/hole but appears to go across the edge of the boss as if it's not sat low enough. Is this a raised pip that the spring should sit the other side of? Edit This alsl look different but could just be the position of the stem?1 point

-

1 point

-

If the balance oscillates (and the amplitude is good) and the train is not moving, this means some problem with the transmission of the balance movement to the train. I don't know this particular movement, the ones I have worked on are made with pallet fork and "escape wheel" which look like ones in mechanical movements, but actually act in reverse. There is an index wheel and ratchet for the escape wheel that need adjustment there. Of course, it is possible the train to be blocked somehow, but it will be not letting the balance to oscillate free. !!!Do not try to demagnetize this movement!!! Do not try to remove the balance, as the coils have to be removed first.1 point

-

Be careful doing that. There are a couple of videos on youtube of people servicing the 9154 and neither remove the balance correctly. It is very easy to damage the coils if you don't follow the exact procedure shown in the tech sheet, which requires the movement to be removed from the case.1 point

-

Welcome to the forum. All I can get details for at the moment is the Crystal 300T02ANS. How would that measure up compared to the original? I'm not sure there is a Crystal Gasket, can you post some photos.1 point

-

1 point

-

I splashed 98% sulphuric acid on my face, the safety googles protected my eye. I washed it off within seconds, strange thing, it didn't burn, just left a white crescent under the googles. Sucked all the moisture out of my skin.1 point

-

Good point H , 70 ° C Been there many, many times Jon, without it my job in double glazing used to be slow, unpredictable and not pretty...hence I love the stuff.1 point

-

Lol, that's funny Mike. When I visit places on holiday , I like to explore my surroundings, get my bearings. I probably did the same when I joined the forum, I just like to know where everything is and how it all works. If I think of anything else I'll let you know1 point

-

D'oh. After all the years I've been on here, I didn't know you could do that Rich I just selected 'Quote' at the bottom, and edited out what I didn't want. Anything else you hiding from me ?1 point

-

1 point

-

I used to think the length only effected reserve, but the length does effect strength, though probably not a lot. Imagine a spring only 25mm long, how strong that would be compared to a much longer one. The spring is effectively a beam in bending, so the moment of Inertia is (width x thickness³)/12. So the thickness is much more important than the width. With your spring choices (0.11/0.105)³ is a about 15% increase in strength. The lengths are so similar, I wouldn't worry about that1 point

-

1 point

-

1 point

-

1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement. If there is anything we can help you with don’t be afraid to ask. Nice clear photos can help a lot.1 point

-

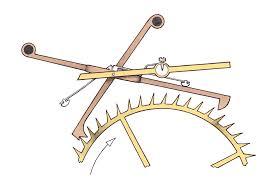

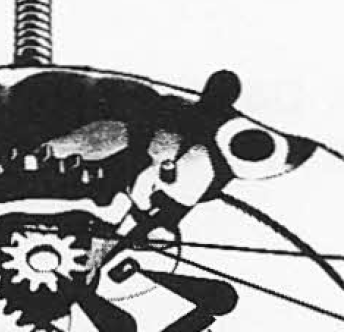

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement. If there is anything we can help you with don’t be afraid to ask. Nice clear photos can help a lot. Grasshopper escapement certainly not easy to make. For those that don't know what it is here is a picture.1 point

-

1 point

.thumb.jpg.19a9c4ff164d78d516aa9f05a063752b.jpg)

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)