Leaderboard

Popular Content

Showing content with the highest reputation on 03/28/25 in Posts

-

5 points

-

I have a 50E that is about the same size and weight as the 230E , 40 grams lighter. It uses a separate transformer. Mine is 20 years old, daily use, running great. I think the current equivalent is the 60E. These smaller models are nice for really fine work, which is what I do 99% of the time.4 points

-

3 points

-

60E 12V, 40W, weight 230g, diameter 35mm, speed 5,000-20,000 rpm 230/E 240V, 80W, weight 270g, diameter 37mm, speed 6,000 - 22,000 rpm Very similar in size, weight and price (about £70). I use mine mostly for case polishing as I don't have a bench polisher, so the extra power of the 230/E might be better.3 points

-

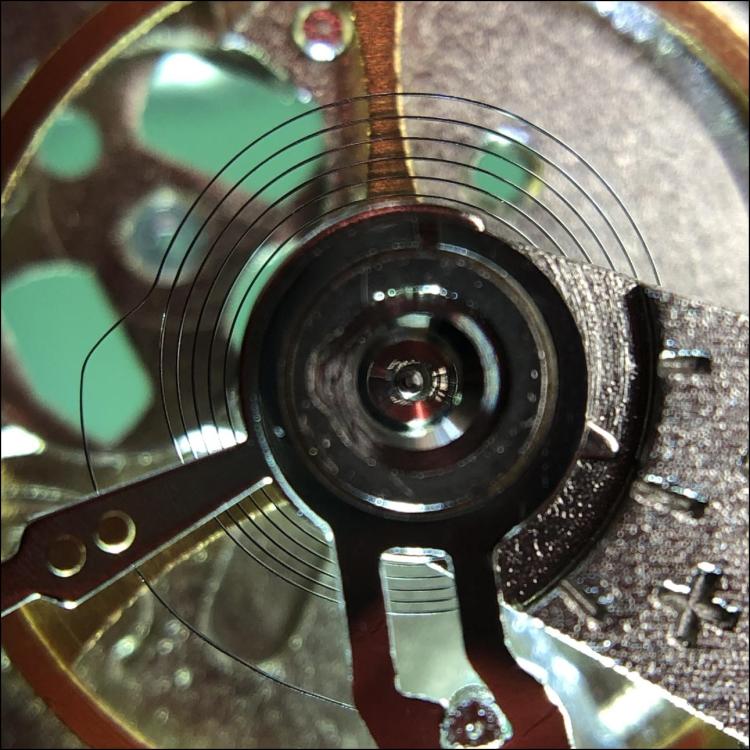

Ah no that's probably the old model, this is the one I have, as said above the run-out is very low, tbh i cant see it all. I've used my other rotary tools with the cheap carbide drills you can buy ( UK £5, Aliexpress £1 ) . They snap easy because of the run-out , but with the Proxon they will drill through anything3 points

-

Being labeled as a senior citizen just because you're over 55 years of age is quite confronting. That alone might just be a reason not enroll.3 points

-

After eight years in this hobby, I still—somewhat embarrassingly—find myself utterly at a loss, almost paralyzed, whenever I need to manipulate a hairspring. Where should I apply pressure, and in which direction, to get it back in shape? Last time, @nickelsilver and @nevenbekriev helped me out. Thank you! Would you be willing to lend a hand again? As I said, it feels embarrassing to keep asking for help with the same thing over and over, but right now, I don’t see any other option. The background to this is that I was trying to pry off the balance cock on this Vostok 2414 that was extremely tight. At that moment, the careful side of me said, "Remember @Nucejoe's advice—only loosen the screw slightly so the balance cock doesn’t launch itself into the Russian space program." Meanwhile, the lazy side of me said, "Don’t waste your time on unnecessary precautions. Just go for it! No one remembers a coward!" Unfortunately, I listened to my lazy side, and the balance cock shot up at least a decimeter into the air before landing on its back—damage done. The irony is that this happens just as I've explained to @ChrisInOz that the seasoned among us have developed strategies to minimize risks! Gosh!2 points

-

2 points

-

2 points

-

2 points

-

2 points

-

I’m super happy with my Proxxon 230/E Micromot rotary tool. I tried some cheaper options first, but the Proxxon is night and day—quiet and precise! I also got the Flexishaft for it. Not really necessary, but great quality and nice to have. Pictures of my set-up in this thread:2 points

-

2 points

-

2 points

-

On the upper right lug when looking at rhe movement I see brass plate wear. An original dial hands and movement might be worth that asking but if he says solid gold and it's plate, that reason alone to say no.2 points

-

I am working in two locations every other week. As luck would have it, a part I need is at the other location. I do ha e some clips at the other place. I wanted to wrap up this clock (my personal clock) so I just fabricated one to get it off the bench!! I have tons of old electronics...so yeah, that is a treasure trove of screws. Clips and stuff.2 points

-

I did a very quick check without my loop, the stem appears to not wobble at all having done presses in all directions twice. I'll pull off the glass then report back with more pictures. If it's not a split stem, it's either a lever by the dial or screw off crown. I'm doing this hobby to relax?2 points

-

Hello all, Just moved from US to Europe and brought some of my tools, well most of them. A friend gave me his Ikea desk that goes up or down. I told myself for the next few months it would be good enough. I didnt feel so safe not having borders around the desk to make sure parts to roll of fall off. Went to the hardware store to buy either thin pieces of wood or plastic or something to glue/stick around the edges. Ended up seeing a 120cm X 60cm wood top for 30 euros and was like... 30cm longer.. lets do it ! so bought it and came back home and intalled it. Feels so much bigger and better ! Eventually ill get one that i can cut off a little bit and add some space for my arms with a jigsaw but for now this is great ! Will get some clear silicone tomorrow to put around the edges where the top table and side panel meet to make sure there is no crevices. I have to add smaller pieces of wood in the front so when I work screws don't roll off on my side or at least help prevent anything from falling there, which happened a few times ! Would love to get a groove in but dont have the tools. Ill add a photo of a bench i think looks great ! here is a photo of before and after and if any of you have suggestions or Ideas to add to it feel free1 point

-

@RichardHarris123 I am guessing he means something like the inverse of this one, which was a "Swiss-Anglo Watch Co" dollar watch. The dial had threaded holes to screw onto these case bosses and I can imagine it being done the opposite way too. Oh here is the back side of a Reliance dial on an auction... And yet another which is probably the type in question1 point

-

Top wheel is the center seconds, the long pivot runs through the center wheel. It's probably just stuck with old oil. Warm it uo or stick thevparts in some paraffin for a hour. Top wheel.....second photo.1 point

-

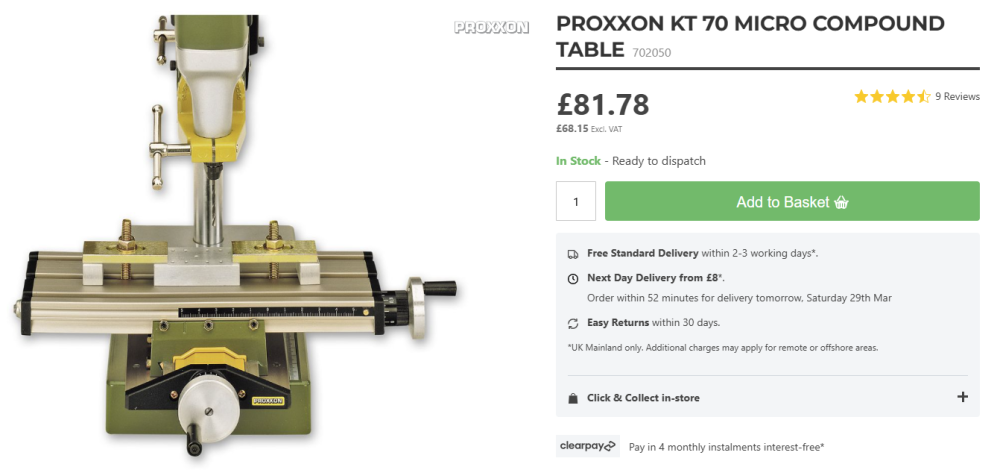

Hi Cees, this is simple clock, and You are anything but a newbie. Even if You are doing it for the first time, You already know a lot. You don't need spring winder for this clock. The spring winder will be needed when the springs are in barrels. There are many different opinions about the ways of rebushing. I will advice to drill the holes for the bushings through a conductor. This is steel plate with hole that is drilled with the drill bit that will be used for drilling the holes in the plate. You position the conductor with it's hole centered above the pivot hole in the plate and then clamp it on the plate, then drill the hole in the plate through the conductor. This way shifting of the holes is avoided no matter how elongated by the wear they are. Then You can prepare bushes on the lathe with the proper size for the holes. What is the condition of the pivots? In cheap clocks, the arbors are soft and burnishing doesn't help much when pivots are worn. Then repivoting with pivot wire is practiced rather than reshaping the worn pivots.1 point

-

Hi Richard. A handful of miyota 0S10 sheets for you. Miyota 0S10 instruction sheet.pdf 0s10 miyota sheet.pdf Miyota spec sheet.pdf1 point

-

Yes, we need to see what happened to the spring. I may guess it has stretched like a funnel, is it the case? If so, then You will need to remove the balance from the cock and show picture of the spring where the deformation is seen.1 point

-

Welcome to the forum. @Neverenoughwatches is the person to answer your question.1 point

-

1 point

-

Have a look at Tommy Jobson he knows what he is at , plenty of his videos not just this link.1 point

-

I have the ultra but I purchased it for the lathe course but it has a Hermle course included.1 point

-

1 point

-

I use a Foredom flextool which has a range of 0-18,000 RPMs, has foot control, and can also be run through a voltage regulator to set the speed. I got rid of my dremel style rotary tool as it was too fast, too loud, and too much runout. The flextool motors are very quiet as they are DC, plus the motor is not in the handpiece, which reduces vibration and runout. Plus there are a ton of attachments for then, like belt sanders, hammer handpieces, ect. Very versatile tool that gets a ton of use in my shop.1 point

-

What's the model and movement from the case back? Is it a 3S10? Edit1 point

-

Should have added that for that price I would have expected them to use a proper fitting strap.1 point

-

Indeed - the Reliance model was Ingersoll's "real" watch with 7 jewels. The Yankee, Midget, and I can't think of which other name are the true dollar watches with pin pallets and basically scaled down clock movements. It looks like you have real balance screws too, whereas the dollar balances are just stamped brass with metal protrusions that give the appearance of balance timing screws. I suppose you could shave them to poise but you can't add weight. Did this one have "lantern pinions" on the train? I just learned this term today and was eager to use it. I guess I would be pretty surprised if they used such a low end feature on their "good" watch. And did you determine its BPH? Their dollar watches are slow, 14400 if I recall.1 point

-

1 point

-

What is it like inside Rich, I used to wear an accurist chrono many years ago, i still have it .1 point

-

These movements are a copy of American movements such as Ansonia, New Haven just to name two. The springs are of the open type so not in mainspring barrels and they are very strong. You need s set of https://maddisonsofdurham.co.uk/value-range-round-mainspring-clamps-set-of-4-p1430 You can get them for good clock suppliers. The pinons are know as lantern pinons so the pivot holes can be a bit slack. It has been bodged up, so you have to make the best of what you have. Those clock bushing tools are a waste of money. Get yourself some clock makers broaches and some wooden handles for the big ones, don't buy cheap brooches as the cutting edges soon get blunt a good set will last you a lifetime. Here is a photo of what is called a lantern pinion. Just ask if you need more help / advice.1 point

-

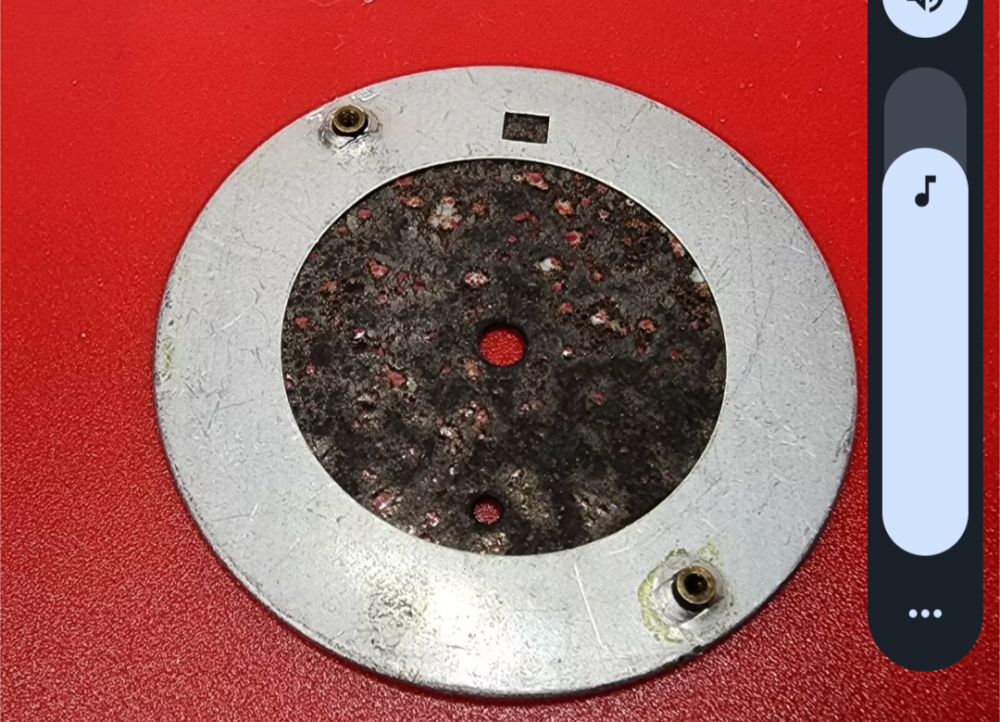

HWGIKE#53 Newmark 10.5 ligne 5 jewel pin pallet movement My only one customer Stephen sent me 5 watches, three mechanicals and two children coming from a marriage of a mechanical and an electrical watch. I started with 3 of the mechanicals and managed to quickly ruin 2 of them. This one is one of those, I managed to brake off the curb pin which is really a wire hook replacing the curb pin and the boot effectively. I luckily found a replacement in one of my drawer, my alternative was to machine another pin on the lathe and rivet it back to its place but there was no need for it. The donor movement also provided a "new" set of hands which I re-lumed. The boss of the original minute hand was damaged anyway. Had to replace the mainspring as it was set. Polished the non original crystal which actually looks funky. (not entirely sure about the meaning of funky but it seemed to be appropriate.) Also had to work on the HS which I have surprisingly not ruined as I went slow and methodologically inside out one step at the time. Still need to regulate it started with more than 10 mins a day slowness, might need to shorten the HS and re-regulate it set the beat error again. I first could not identify the movement but this helped: https://17jewels.info/movements/n/newmark/newmark-10-1-2/ This is also interesting: https://www.watchuseek.com/threads/newmark-watch-co-info-please.612406/ I usually dont do before and after pics but now I put two of them about the main plate to see whats the difference before and after cleaning and removing some surface rust. Stephen, I am going to send the original strap back to you just in case you dont like the yellow.1 point

-

1 point

-

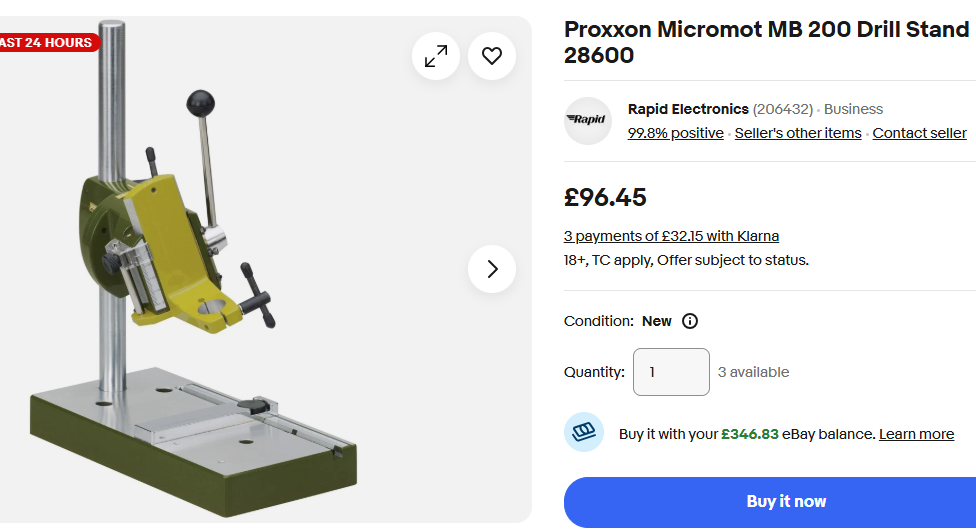

From what I read, all Proxxon tools have a 20mm tip, so it should work with all of them. Clamp+230/E about £110 from Amazon or Chronos Engineering (ebay)1 point

-

1 point

-

I can live with 5000 rpm. The one I have is 10,000 rpm minimum and some of the mini cotton wheels fall apart at that speed They have a good range of stuff, and good prices - £73 for just the 230/E drill and collets.1 point

-

I only have personal experience with the 230/E, and as I mentioned, I’m extremely satisfied with it. I wouldn’t describe the 230/E as small, but it does appear lighter and more compact than the alternatives you listed. The "Flexishaft" accessory is available for the 230/E and possibly for the models you mentioned as well, in case you find the tool too bulky. There’s a picture of the "Flexishaft" accessory in the post I linked. Had I known how easy it was to mount the multitool directly in my vise, I probably wouldn’t have bought the "Flexishaft" at all. Regarding speed, as mentioned, the lowest setting is 5,000 RPM, and the highest is 20,000 RPM. Personally, I’ve never felt the need for a lower speed, but I don’t know what your specific requirements are. For those who are less experienced (a category you don’t belong to), it may be useful to know that the final result isn’t just determined by speed. The type of polishing wheel, polishing compound, pressure, angle, and the duration of contact with the material all play a crucial role.1 point

-

Interesting. On deeper investigation it seems that there is a free content page, which is essentially a series of links to videos on Youtube, which we can all access anyway. The so-called 'ultra horology course' is a paid-for course ($97). Also, there doesn't appear to be any sort of age check to determine whether you are 55 or not. 'Silver seniors'..... pffftt, I'd rather pay, ha ha.1 point

-

Did you check the tool tag I posted Mike ? Mine came from chronos engineering, great company to deal with. The Proxon as with most rotary tools you are limited to the minimum speed which is around 5,000. Have a look at the minicraft gear, its German, or was. You can get a speed controler with them . I just made my own power and control up with a 12 volt transformer from a car boot and a voltage regulator, you can those from Aliex. 5 for a fiver. Minicraft comes up on ebay , some new and some old, I picked up a joblot of 3 drills and a stand for 30 quid. I'll pull the contoller apart if you want to have a look, very simple to knock up . The DC speed controller brings the rpm down to around 300 for the minicraft so nice and steady. Don't think you can lower the speed on the Proxon, it has a built in speed dial, adding another 230 voltage regulator interferes and makes 240 tools already adjustable, run rough.1 point

-

1 point

-

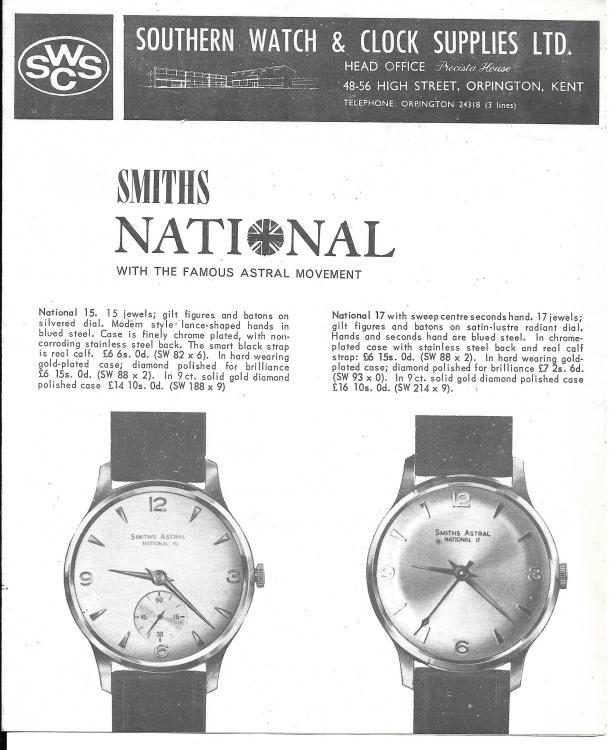

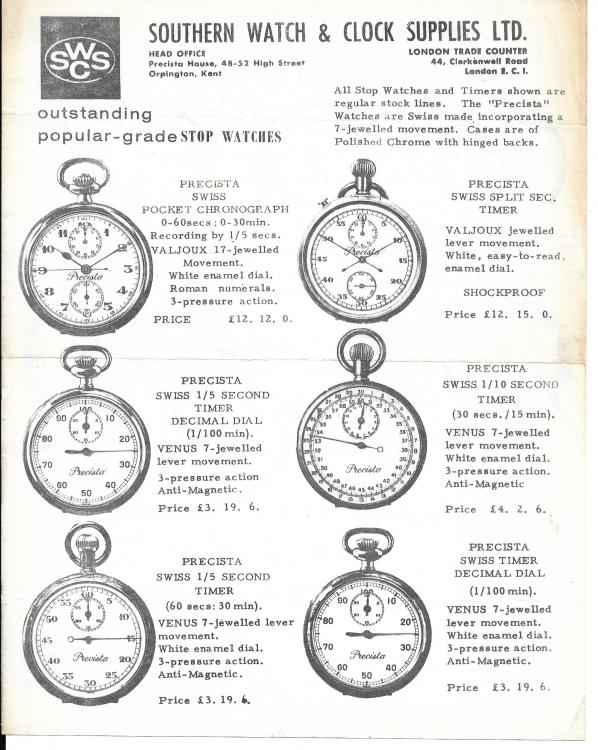

Hi All, I came across this thread while doing some family research. I'm the granddaughter of Paul and Emily Louisa Schick— my grandfather, Paul Schick, founded Southern Watch & Clock Supplies LTD. He was a Jewish refugee who fled the Nazi occupation of former Czechoslovakia. He arrived in England with nothing but his car, and met my English grandmother during the war. He ran SWCS with my grandmother and they created a lot of local jobs in Orpington and beyond. He passed away in 1991, and is survived by his two children (my father and his sister), 4 grandchildren, and 6 great grandchildren. It is heartening to see that their local business still inspires watchmakers and enthusiasts today1 point

-

You were always going to be up against this project, but you had the guts to go for it. Determination will see you through and you certainly have that. Good luck with the rest of the work1 point

-

So after filing a claim with eBay the seller still blames me for the parcel going missing as I didn't check the tracking and change the date of delivery but has still agreed to refund my money.1 point

-

After reading about the delivery guys you have, it makes me feel like I've been taking the delivery guys I have for granted. For parcels too big to fit into my dropbox, some of them would even open my front gate, leave it on my bench and ring my doorbell. Looks like I have to get them some Christmas presents in appreciation. For your horrid delivery guys, you can leave a lump of coal for them at their usual dropoff. PS My latest big value item was an Atmos clock from the US. The delivery actually rang my doorbell and handed it over to me persnally.1 point

-

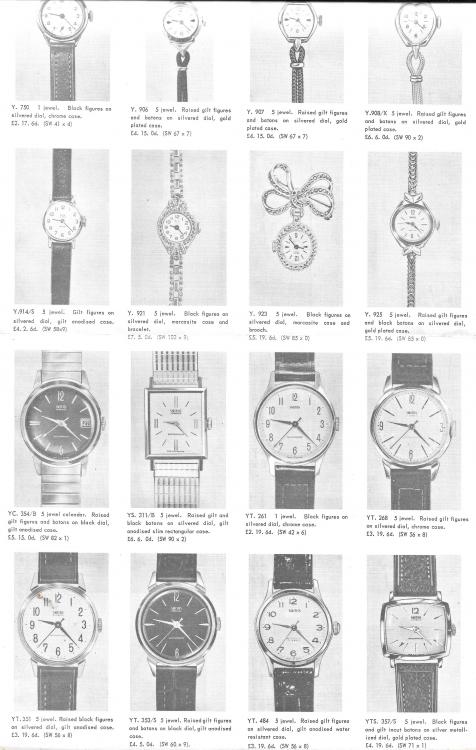

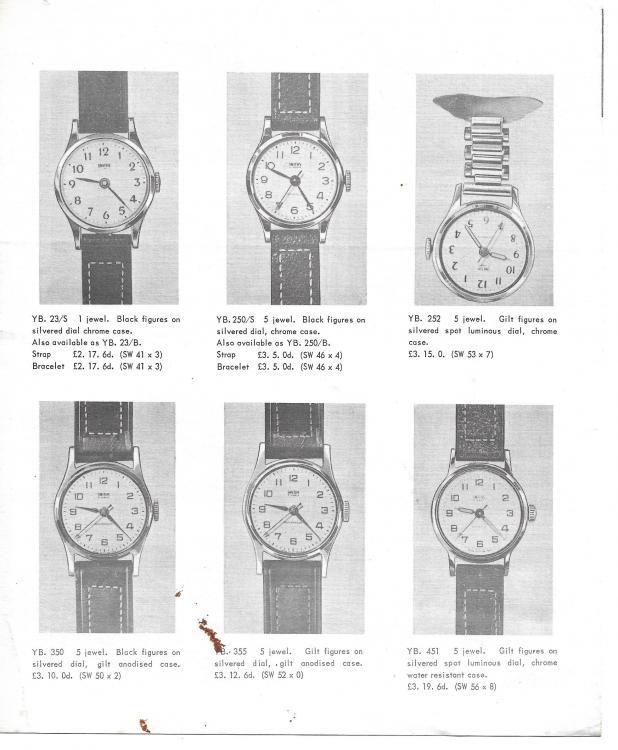

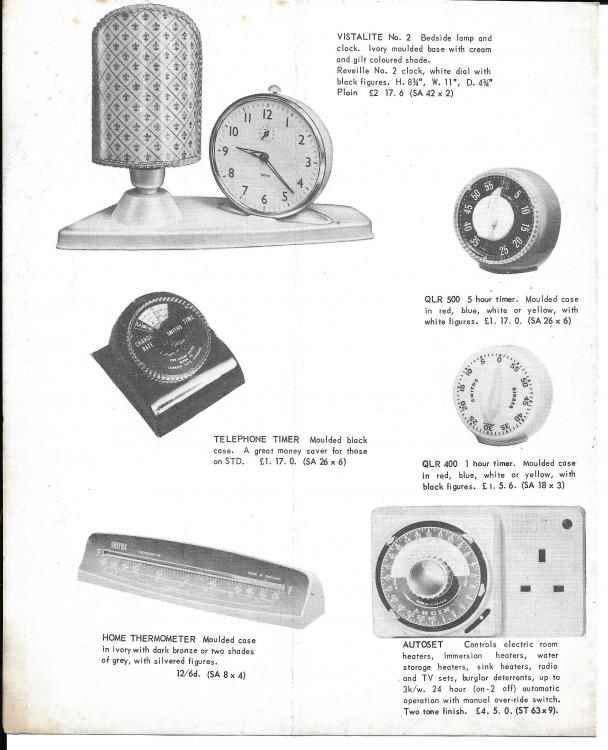

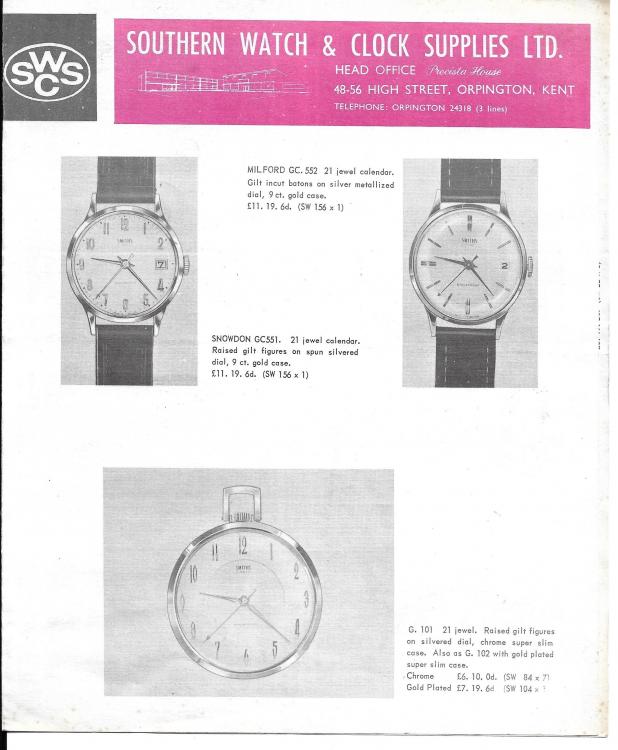

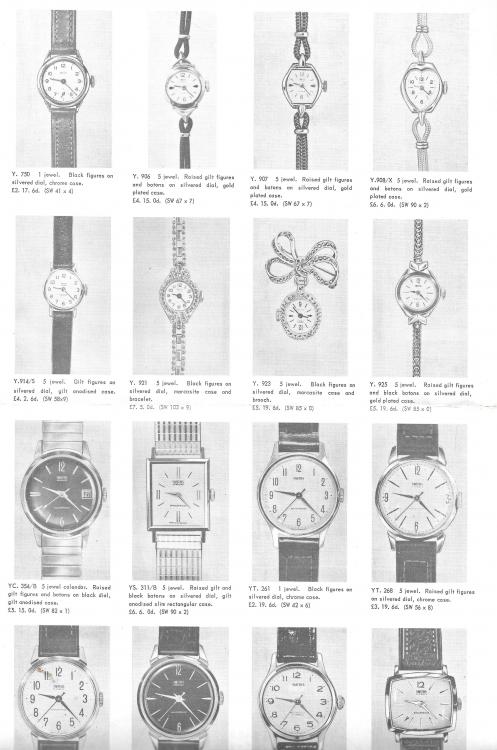

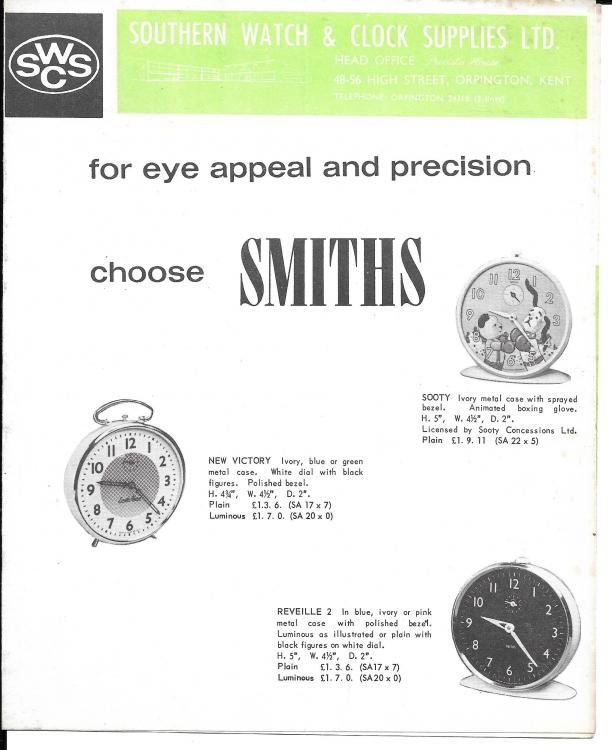

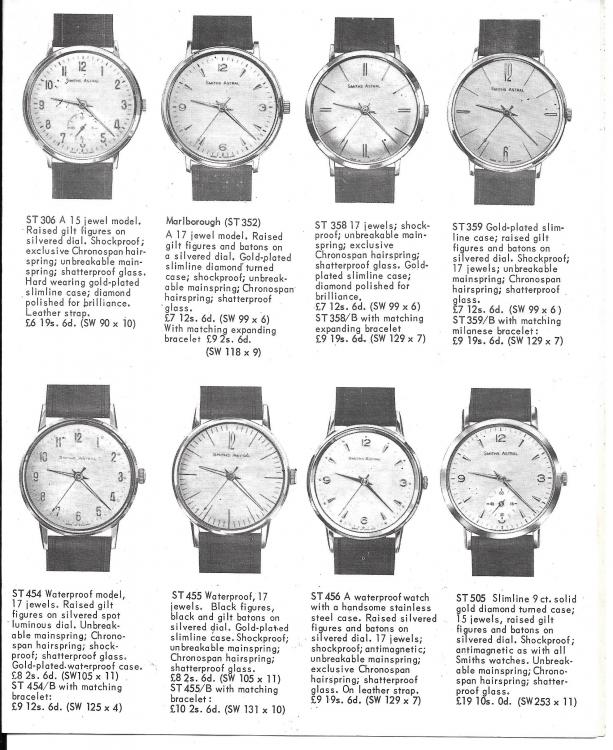

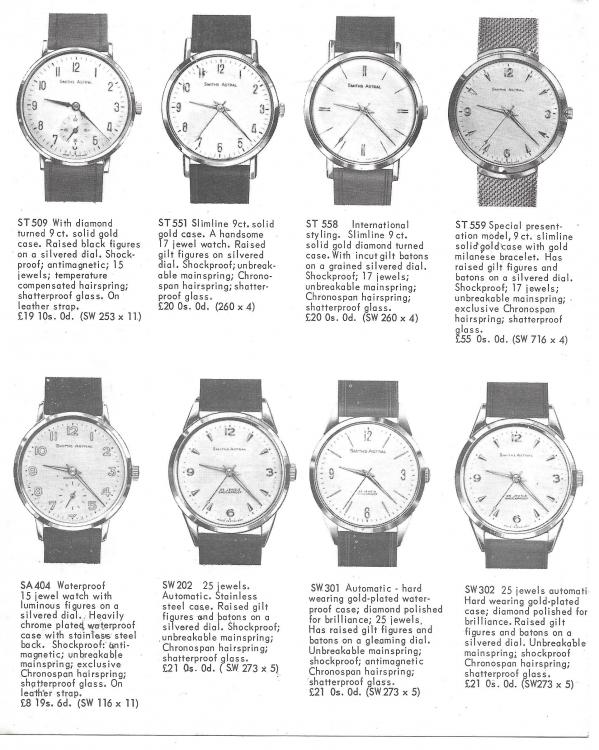

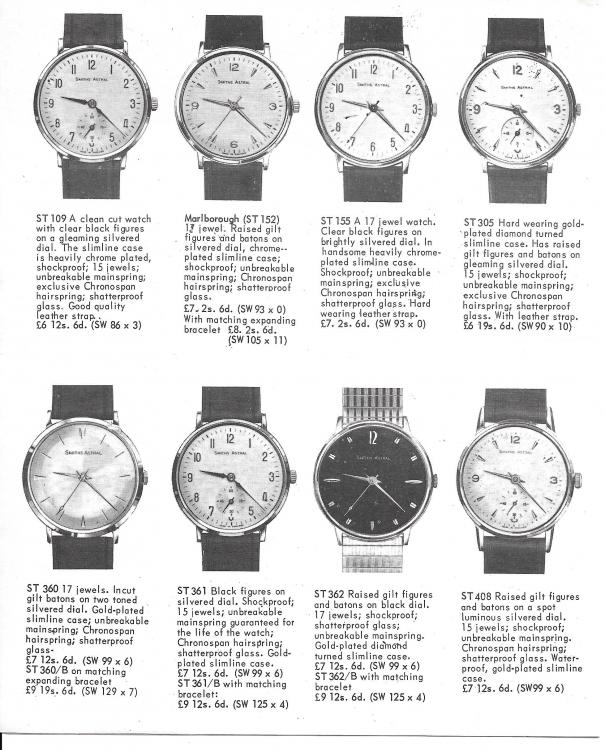

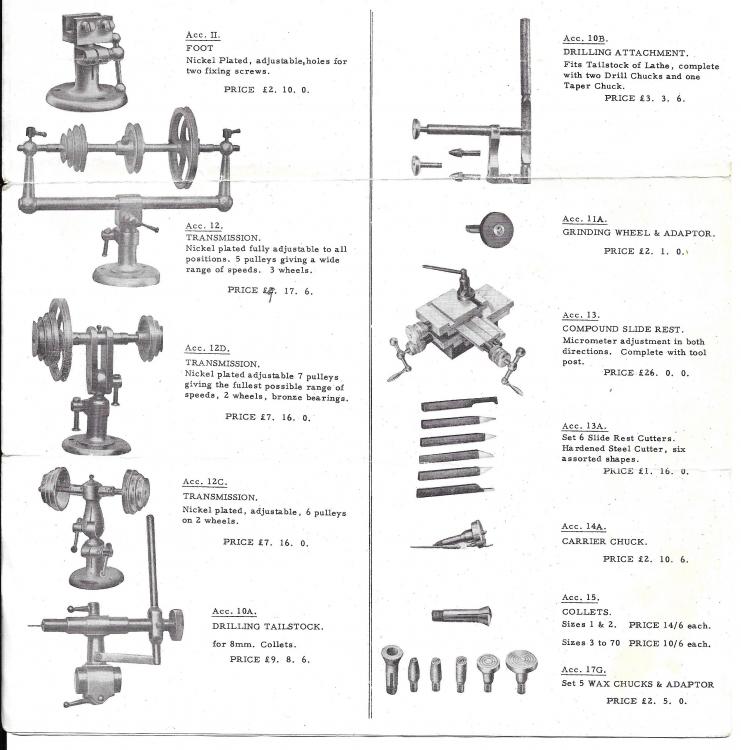

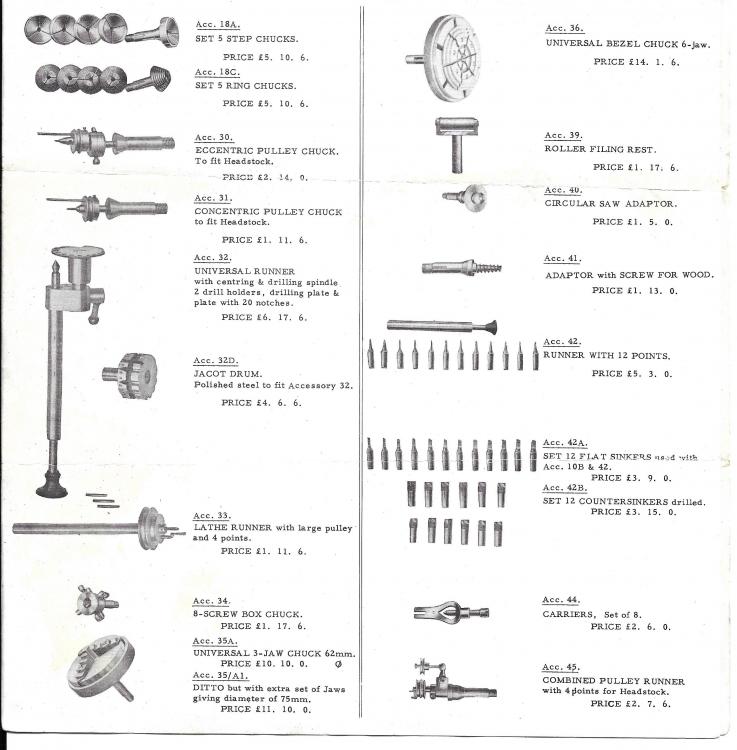

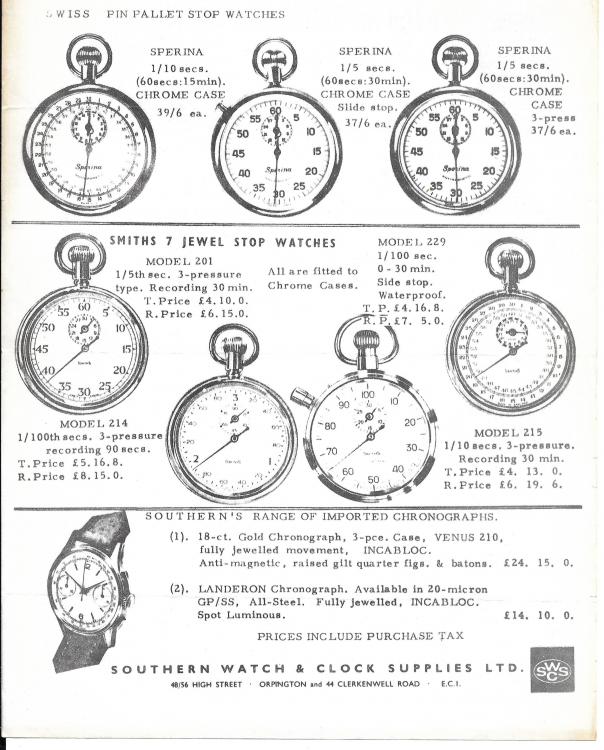

Smiths watches and clocks from SWCS (my scanner can do only A4s as max and some pages did not fit hence i scanned them twice, bottom and top) I have a question for you. Where does the Precista brand come from? Is this SWCS own brand? Have they bought the name? Or is it a 3rd party? Here is a Precista lathe with SWCS sign on the box and their HQ is in the Precista house, 48-52 High Street, Orpington, Kent1 point