Leaderboard

Popular Content

Showing content with the highest reputation on 03/29/25 in Posts

-

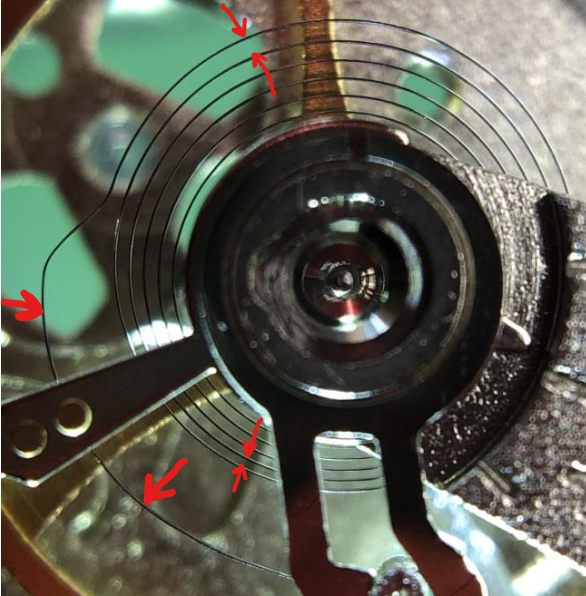

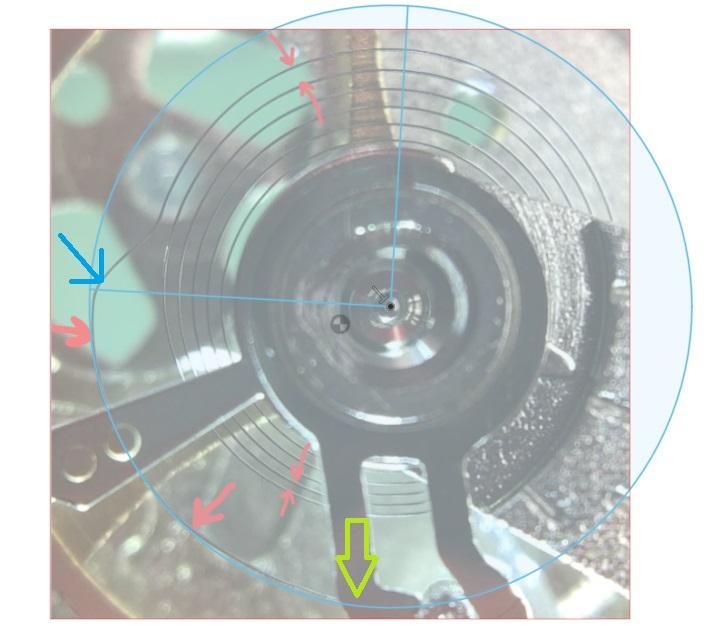

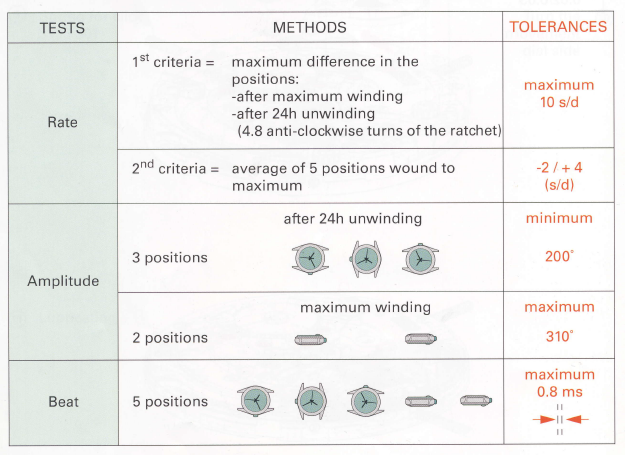

MIke's on the right track. For errors in the round, you make the correction at 90 degrees to the maximum error. You can see the regulator curve is pretty "on", but I would still push a little at the stud where the green arrow is. This will bring the hairspring a bit closer to center, but will also worsen the fact that the regulator curve is already favoring the inside of its perfect radius on the other side of the regulator pins. You could reform it, but you would reintroduce the out of round condition. For me the quickest and best fix would be to twist at the blue arrow, which happens to be at one of the bends that transition from regulator curve to hairspring body, and happens to be at 90 degrees to the max error.8 points

-

4 points

-

I would recommend looking at @Dell YouTube channel, no nonsense practical stuff there. He uses a pultra 10mm lathe so just a little smaller than your uni at 3 I think. he has a few of these or maybe he will be able to recommend something. Tom (not a clock guy, but listening to @OldHippy, @Dell and @MikeEll)3 points

-

3 points

-

I bought them from ebay, as I'd browsed the 230/E, I was sent an offer with £3 off, so I paid £69, and the bench clamp was £333 points

-

The bits that make up lantern pinions are top cap , bottom cap and trundles , the name given to the rods which form the lantern. These rods or trundles wear but can be removed and replaced individually to effect a repair. I have seen some almost worn through which have been turned round in the frame to present the unworn side as a repair. It works but not for long.3 points

-

2 points

-

Hello all, Just moved from US to Europe and brought some of my tools, well most of them. A friend gave me his Ikea desk that goes up or down. I told myself for the next few months it would be good enough. I didnt feel so safe not having borders around the desk to make sure parts to roll of fall off. Went to the hardware store to buy either thin pieces of wood or plastic or something to glue/stick around the edges. Ended up seeing a 120cm X 60cm wood top for 30 euros and was like... 30cm longer.. lets do it ! so bought it and came back home and intalled it. Feels so much bigger and better ! Eventually ill get one that i can cut off a little bit and add some space for my arms with a jigsaw but for now this is great ! Will get some clear silicone tomorrow to put around the edges where the top table and side panel meet to make sure there is no crevices. I have to add smaller pieces of wood in the front so when I work screws don't roll off on my side or at least help prevent anything from falling there, which happened a few times ! Would love to get a groove in but dont have the tools. Ill add a photo of a bench i think looks great ! here is a photo of before and after and if any of you have suggestions or Ideas to add to it feel free2 points

-

It is my bedtime so I'll add my view tomorrow. I will just say the movement is certainly French. Us old buggers need our sleep.2 points

-

2 points

-

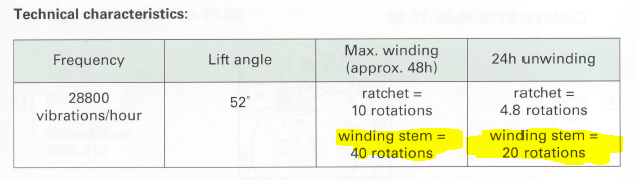

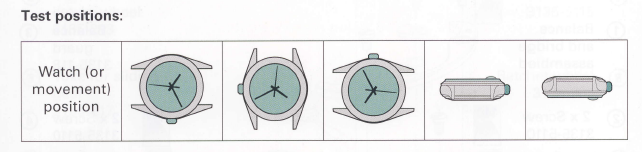

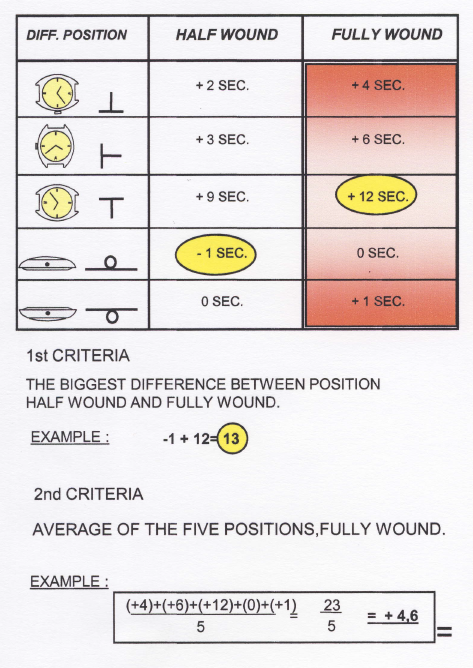

the answer for the question is no it will not help you. Adjusting the balance screw for regulation only works if you actually have a regulation problem. Attempting to regulate a watch for a problem that is not a regulation problem is not going to be helpful at all and will actually make things worse. not understanding how your Rolex works is going to lead to problems and confusions. let's look an example of a confusion and problem that you're having of lacking of understanding of what exactly are trying to do. Rolex has a procedure if you would like to evaluate your watch on the timing machine. notice in order to wind your watch all the way up to its maximum requires 40 turns complete turns of the crown. In order to reach the 50% minimum required for running of your watch it requires 20 turns. so basically you're not winding your watch up to get it to run at all and that's leading to confusions. you didn't say how fast the watch was two days later? In order to do a proper timing procedure you have to follow a procedure putting the watch on the timing machine and getting a result instantaneously is not a procedure. A timing machine shows what the watches doing at exact instant it's on the machine in that exact position wearing a watch means the watches moving around in a variety of positions which is why Rolex has a procedure. So in its procedure you're supposed to look at the watch on the timing machine in five positions then the procedure is to wind the watch all the way to the maximum. Do not place in the timing machine yet as the watch needs to run a little bit the settle down when it's wound to the maximum the numbers will not be quite right. So typically would wait anywhere from 15 minutes to about an hour. So basically 15 minutes would work well. then as you're rotating the watch around in the various tests positions you should allow about 20 to 30 seconds between rotating positions for the watch to stabilize and then let it sit on the timing machine for about 30 seconds to get your numbers. Down below is an example of the procedure. then the actual specifications for the 3135 is this2 points

-

Modern hairsprings like yours are much more robust than the old blued ones - they distort so easily and too much repeated bending can break them. Your spring doesn't look too bad, the terminal curve is a little flat where shown I was very gentle and cautious with hairsprings until I saw this video of Mr Fried - robust to say the least !2 points

-

These are not easy clocks the striking mechanism can be a bugger to sort and get right. That is if you decide to take the movement apart. This will help you to understand the strike. Never use motorized tools on any clock as you have very little control and before you know it the damage is done always use hand tool only you have full control. The movement is made up of brass and steel both are quite soft. Levers-2 (1).pdf2 points

-

2 points

-

Hi. I think a serving hatch in the door so food and drink can be passed through .2 points

-

i figured exactly the same Rob when saw them on the westclox, i think I remarked the same comment to MB who I was in discussion with at the time. Haha it was actually our conversation Rob. Haha another revelation WW. "trundles" .........- to trundle along - ....walk slowly. The forum is on fire today with the history of pinions .2 points

-

I thought it would need tension, so possibly the lateral forces between the pins and the sudden release of you prising upwards. Its caused ME a problem now though.....I can't stop watching the popping cork video2 points

-

I was curious when I was younger about why small gears were called "Pinions", until I saw the early pin or dowel style construction - probably in articles or documentaries about windmills, rather than clocks. Then it made sense that they were originally the small gears made with pins vs. teeth. Until I joined this site I'd not heard the name "Lantern pinion" though, which is very appropriate.2 points

-

Hi Cees, this is simple clock, and You are anything but a newbie. Even if You are doing it for the first time, You already know a lot. You don't need spring winder for this clock. The spring winder will be needed when the springs are in barrels. There are many different opinions about the ways of rebushing. I will advice to drill the holes for the bushings through a conductor. This is steel plate with hole that is drilled with the drill bit that will be used for drilling the holes in the plate. You position the conductor with it's hole centered above the pivot hole in the plate and then clamp it on the plate, then drill the hole in the plate through the conductor. This way shifting of the holes is avoided no matter how elongated by the wear they are. Then You can prepare bushes on the lathe with the proper size for the holes. What is the condition of the pivots? In cheap clocks, the arbors are soft and burnishing doesn't help much when pivots are worn. Then repivoting with pivot wire is practiced rather than reshaping the worn pivots.2 points

-

These movements are a copy of American movements such as Ansonia, New Haven just to name two. The springs are of the open type so not in mainspring barrels and they are very strong. You need s set of https://maddisonsofdurham.co.uk/value-range-round-mainspring-clamps-set-of-4-p1430 You can get them for good clock suppliers. The pinons are know as lantern pinons so the pivot holes can be a bit slack. It has been bodged up, so you have to make the best of what you have. Those clock bushing tools are a waste of money. Get yourself some clock makers broaches and some wooden handles for the big ones, don't buy cheap brooches as the cutting edges soon get blunt a good set will last you a lifetime. Here is a photo of what is called a lantern pinion. Just ask if you need more help / advice.2 points

-

Hello everyone, I would like to present to you my latest project, a Vulcain Cricket (yes, another Cricket), model S2315A. I always wanted a Cricket, and it looks to me that Vulcain has made a lot of different variations of dials, watches etc. Cannot really find much info on the one I have. Initial condition overall: is running, but definitely needs servicing. It has a lot of DNA allover the place. Also, the watch came with its original bracelet (I wonder how that will turn out). Movement: looks to be a cal.120. Not 100% sure as googling for this caliber brings different results. What do you think? Also had tested it on the timegrapher, results on the picture. Crystal: needs a new one, as the original is cracked and has oxidation on the tension ring. Dial: looks pretty clean. Case: gold plating has some ware. Honestly not sure what to do as I have no setup of my own yet. Is it worth sending for replating? I am a newbie in the trade so any thoughts or suggestions are super welcome! Thank you!1 point

-

Evening all, after many years of fascination with clocks and watches, and paying a lot of money to have them maintained, I have decided with retirement looming I would start a new hobby and look at repairing my own watches. I have spent 30 years restoring classic motorcycles, so I thought it was time to size down. I have purchased a number of project watches to start developing my skills, starting with a smiths 602 movement. I would be most appreciative for any advice. Mainly because if I get it working, it is a very nice simple retro watch. I have done a lot of study on the movement and disassembled it today, the only think that perplexed me was that the centre, 3rd and 4th wheel seem to be set together as a 'pressed assembly', i.e. I cant seem to separate them - am I missing something, or is this how these cheaper movements were designed? appreciative of any advice1 point

-

No way. Swatch would go bust. They need watch repaiers and fiddlers to break , bend or otherwise knacker balance springs to keep the industry going. Although the silicon ones they use on some watches today may come close.1 point

-

Best to remove the movement gaining better access to the area.1 point

-

Maybe for a tenner, Uri Geller could wave a hand over it and it will be perfect.1 point

-

I would start here and get the assortment of clamps and the same for screws https://www.cousinsuk.com/category/case-clamps https://www.cousinsuk.com/product/case-screws-wristwatch-movement-to-case-assorted Tom1 point

-

The balance cock is the part that these two screws hold (marked in Red) The movement looks filthy. Picture 1 is the suspension spring which look good. If the clock is just stopping then you need to look for wear like the pivot holes or even worn pivots. You could spend a long time fiddling around trying this and that and not getting any wear, I suggest you strip the movement down, get three plastic tubs and keep the three trains separate. I can help you put it all back to me it is easy.1 point

-

1 point

-

You've got to remove the circlips but from memory they're a nightmare due to lack of space.1 point

-

Yes, they should be, and you replied at the time to the topic saying as much; for which I was very grateful. Another balance from the same model in the family worked, so it was manufacturing issues.1 point

-

1 point

-

1 point

-

Because you aren't playing the recording of a vacuum you should have made so that you can work in peace I have been fiddling with watches for about 10 years and it's only the last year or so that I've felt confident in tweaking hairsprings (excluding overcoils which still give me the chills).1 point

-

Hello John, and welcome to the forum. Added some reading for you to get acquainted with the anatomy of watches and a bit of theory. Where in Aussie are you located it’s a BIG CONTINENT. witschi_training_course.pdf TZIllustratedGlossary.pdf TM 9-1575.pdf1 point

-

1 point

-

It looks like it might just need a slight tweak. The spacing is greater at the top than bottom. Could the stud have twisted slightly? I would start by pushing in just above the pins, or out just below them, until the spacing looks even. It looks like there could be a slight kink in the terminal curve just below the pins.1 point

-

I love the desk's position in the room , great when you dont want to be disturbed. A sign hung on the door knob outside can work , though not quite as effective as your idea.1 point

-

Me too, i was fascinated by them in the Wesclox Pocket Ben I did last year, just pins set into a round table.1 point

-

My go-to is paraffin, it has terrific wetting properties. Usual cleaning method for me for really gunky parts is to put them in a shallow tin of paraffin and warm it on top of wax melter. Gets the paraffin up to around 80 °1 point

-

I have the same issue with some older Bulova's. They have like 3 huge steady pins that feels like they need a crowbar to get them out of the mainplate. Loosening the bridge screw doesn't always work as the steady pins are so dang long that the screw needs to be totally removed to get all of the steady pins out of the plate.1 point

-

I eventually installed the pusher. I tried replacing the original pendant/tube on new one that came with the pusher, but couldn’t. It’s supposed to be driven out of the case by pushing/punching from the inside of the case. I didn’t know how and/or didn’t have the tool to do it, besides it wasn’t necessary, the original is in pristine condition. I was just curious and wanted to learn something along the way.1 point

-

I use a Foredom flextool which has a range of 0-18,000 RPMs, has foot control, and can also be run through a voltage regulator to set the speed. I got rid of my dremel style rotary tool as it was too fast, too loud, and too much runout. The flextool motors are very quiet as they are DC, plus the motor is not in the handpiece, which reduces vibration and runout. Plus there are a ton of attachments for then, like belt sanders, hammer handpieces, ect. Very versatile tool that gets a ton of use in my shop.1 point

-

Learned a new term! Thank you. I have seen these in American dollar pocket watches too, Ingersoll and Ingraham in particular, which are close relatives of small clocks and alarm clocks. It's good to have a name for them.1 point

-

1 point

-

is not really a Hamilton electric it was only sold by Hamilton it's really a Swiss watch. then more than likely it's never been serviced so it needs to be serviced. That means it has to be completely disassembled cleaned etc. I'm attaching the service manual. ESA 9150.pdf1 point

-

1 point

-

1 point

-

1 point

-

Since the weather has been freezing my outdoor time has been limited. What better way to pass the time than to work on a few projects. Here are three I completed in the last few days. left to right - a 1942 Kelton ( owned by US Time \ aka Timex) it features the model 20 movement and a non-radiolite dial. In the middle is the 1960 US Time '100' Wafer Thin that features the then newly introduced model 23 movement and split case. On the right is the 1967 Timex 'Marlin' currently nick named the "Dot - Dash'. It features the model 24 movement and is a grail watch for many Timex collectors. The SSQ is used to help me check the time keeping. No need for fancy time graph machines or devices. My philosophy is to wear a vintage watch as a reminder that time is best spent doing what one enjoys!1 point

.thumb.jpeg.cd6d20f3fd1f21747a43456b96dd785d.jpeg)

.thumb.jpg.3c2f9733fb41772df229e751fc1ce893.jpg)