Leaderboard

Popular Content

Showing content with the highest reputation on 03/31/25 in Posts

-

4 points

-

On an automatic watch, I always time it at totally full-wind and not wait up to an hour, which I would if it is a manually wound movement, because the movement is going to spend most of its time when worn with the maximum amount of torque in the mainspring, thus being at its fullest wind. If it is a watch movement such as a Rolex 3135, the isochronism that has been designed into the movement makes no real difference if it is timed at full wind or an hour off that, as the rate is going to be pretty much the same even hours off a full wind. I have found, especially on vintage automatic watches, such as Omega 500 and 700 series autos, that if you fully wind the watch by hand just before the mainspring slips you may see a reading of 260 degrees, for example. Once the auto module and rotor is fitted and you give the rotor a bit of a spin on top of the full wind, so the watch movement is always at its fullest wind, you might be surprised to see a jump of 20 to 30 degrees, bringing it to 280 to 290 degrees, which in my experience is more a real world reading, as the watch is going to remain there more than being just off full wind, even by a few minutes. I'm not disputing what you are saying about leaving it 15 minutes to an hour before timing it, I'm just giving my experience of working primarily on vintage automatic watches and seeing this idiosyncrasy many times. In fact, if you fully wind an automatic watch and put it on a timegrapher at full wind and then turn the winding stem to put a bit more torque on the mainspring, you will probably see the same phenomena of the increase of amplitude as I have described. I have an Omega 751 on my bench at the moment which this is happening to. Full wind gives me 250 amplitude. Full wind with the rotor on and turned gives me 270 degrees4 points

-

As rehajm said straighten it carefully. The tricky bit will be keeping the head still while manipulating the hand back to its original position. Don't be tempted to stick anything in the hole to grip it , you'll risk deforming or enlarging it. Find the best fitting hole in a staking block and clamp it down with something like a lollipop stick under finger pressure. If you can warm the position where it's bent that would make it a little more malleable. Not a flame, for a heat source I use a plug in wax melt warmer. Just some rubbing action at the point of the bend with a tiny piece of soft leather will introduce some heat to it. Then tease it slowly back with a piece of pegwoog, nudging it back a bit at a time, don't go for it in one. The metal will adapt more readily to small adjustments ( bend and then relax ) rather than a big one that will surpass its shear point. Pencil hands, no idea what the originals might be And my first cuppa and toast are more important to me at this moment in time to even try to find out....4 points

-

Have in mind that the thread in the barrel arbor is most probably left-hand thread. And, now that the head of the screw is sheared, the screw is no tightened any more and thus easy to unscrew. If still using sharp pointed tool doesn't help, then the easiest solution is to cut a slot in the remain of the screw. You can safely cut it through the square part of the arbor until reach the bearing pivot. I mean cutting with dremel-like tool with dental separator disk 0.2mm wide.4 points

-

3 points

-

He’s a genuinely nice guy, if you bang his door with your head he’ll likely offer you a cup of tea and an aspirin Tom3 points

-

Oh my, electronic equipment, all the way from china on a DC10 Decota. You're braver than me Andy. it's better not to, then you won't need to buy more....because that's a.... Now turn that dial up to 10 ! Now tell the truth ....who didn't bang their head to that ? If not then you're not completely alive and kicking.3 points

-

I've just bought another microscope with a double boom arm. So that makes 9 microscopes so far. In fact, I'm just about to open the box. With AliExpress everyday feels like Christmas day! I've bought probably close to x 100 ST36 movement and watches from various sellers and only a couple have had a broken screw or missing case clamp.3 points

-

I think I must have 50+ browser tabs open there for all sorts of bits and pieces, I don’t buy often but have a few things that I will be ordering soon. The rest will need to wait a bit till my “round tuit” pile goes down a bit Tom3 points

-

3 points

-

there is a interesting word associated with timepieces isochronism. In an ideal perfect world amplitude will have zero effect on timekeeping. Unfortunately we do not live in a ideal world an amplitude will affect timekeeping but usually at much lower amplitudes. This is why the watch companies will specify a minimum amplitude the watch should run at 24 hours. Because anything below that timekeeping will suffer https://en.wikipedia.org/wiki/Isochronous_timing when you do this put it on the timing machine and tell us what the numbers are in three positions dial-up, dial down and crowned. This is because whether you shake the watch or hand wind the watch both actions will wind up the watch. Shaking though typically requires way way more than winding by the crown I don't think Rolex actually publishes how many times you to shake the watch to wind it up the full but it would be quite a bit.3 points

-

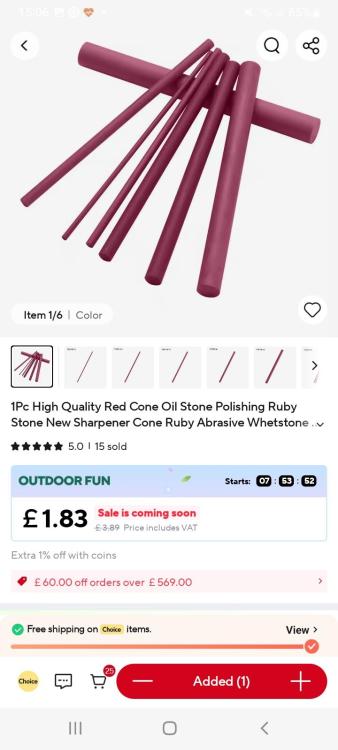

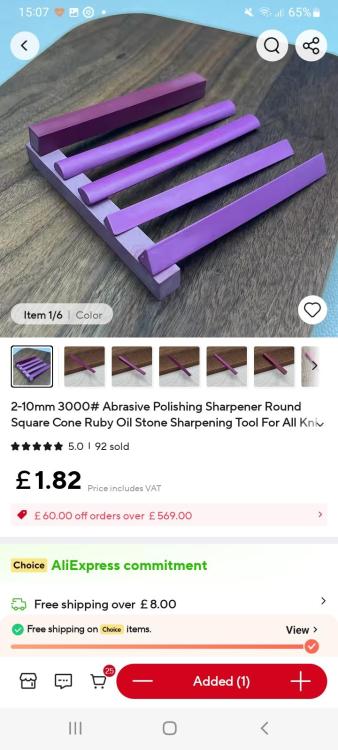

Finding all of these, I have ordered about a half dozen round, square, and triangular types all for around the price of one 100mm length stone of any type from Cousins. Can't wait to use them to anglage a Timex.2 points

-

Well it was going to be vodka but have you seen the price of that nowadays?2 points

-

I use Ali a lot as well. Some decent tools on there. Havent purchased any consumables yet. I usually get those from startimesupply or somewhere similar in the US.2 points

-

No, they can be between 1.2mm and 1.4mm but will be the same size throughout the strap. I have no idea what size is required for each strap.2 points

-

That hairspring is at least bent and possibly tangled. The stud is sitting over the next coil when it should be a terminal curve on the outside. At the lower left part of the photo, the coils are bunched up to the degree that they almost look like one crosses over another. It is possible the hairspring is sticking together with oil or magnetism. Start by demagnetizing it and putting it into a strong solvent (not IPA) to see if it becomes round and concentric again. If not, your next step is to start learning to fix the hairspring or order a new balance complete. This is a picture from AliExpress and may not be a genuine balance, but does illustrate what the hairspring should look like2 points

-

It's one of these AS 415 family. https://watch-movements-archive.com/watch-movement/as-529/2 points

-

when doing timing machine diagnostics the minimum would be three positions you always want to have one crown position typically crown down. The dial up and down amplitudes should be almost identical and so should the timekeeping. I have a suspicion if we saw the crown down position fully wound up it would be below the minimum of 200° at 24 hours this watch desperately needs to be serviced. then your outside of the range of regulation which is a maximum of ± 150 seconds or basically it's a waste of time to try to regulate if you're having a issue because the watch hasn't been serviced properly in a very long time. then your timing machine does it have a graphical display that we could get a picture of when the Rolex is on it? Graphical displays are nice for diagnostic purposes.2 points

-

Hey watch guys, I've recently got into a bad habit of trolling through Aliexpress' site. Random search inputs but mostly watchmaker's tools. Just the cheaper consumables stuff, I'm addicted lol. All those little bits and pieces that normally I would pay 3,4 and 5 x as much for to seller that bought their stock from the same place. 2 lots up to now and another on the way, this 3rd lot brings my total to only around 40 quid for 30 items. I'll wait for this lot to arrive then chuck it all on my bench and post some pictures. The majority comprises of drills, diamond burrs, degussit stones, sharpening stones, disks and brushes, pkus a few random hand tools and dc electronics. This kind of stuff is a fraction of what we'd pay in the uk. The bigger stuff isn't and sometimes even more. All free delivery ( evri if you can deal with their shite service ) and Ali must have a warehouse here in the UK as it arrived in 3 days. Don't know if anyone has noticed but Ali have 2 baskets , a main and a separate 10 item only basket that has a minimum item order for free shipping and added discounts for extra item orders. What's your ethics on buying all this usable crap from China and not paying ebay sellers the 400+ % mark up ?1 point

-

Hi all, my name is Richard and I am a set of screwdrivers, a case cushion and a pair of tweezers into hobby watchmaking. I was brought to it by inheriting a Tissot Seastar Sonorous, and I am learning on a Velona with an ASST 1950 movement, and an Ingersoll with a Smiths cal 637 movement. The latter may be more of an issue…1 point

-

Thats an interesting seconds hand, you could fill the tip with some lume, they usually red paint inside. See inside the back please for a look at the case clamp. I don't buy new spares usually just donor watches, you might be able to knock something up that will work.1 point

-

1 point

-

I'd say these are questions on which the search function will provide you with all the info you need.1 point

-

Guilty. Supposedly Brian Johnson lives a few minites from my neice in Florida. I’ve threatend to go bang on his door…1 point

-

1 point

-

1 point

-

1 point

-

...waiting for the gasp when realising the cost of Horolene....1 point

-

Hello and welcome from Leeds, England. All the Richards I know are idiots. Hehe.1 point

-

1 point

-

Will do! The ASST 1950 has gone from not running at all to modest amplitude and stopping altogether in some positions - I’ll post some photos later. I have very limited magnification at the moment but a digital microscope is on the way…1 point

-

1 point

-

1 point

-

The previous delivery guy assigned to my area was excellent. For big packages, he would open my gate and leave it on my porch bench. But alas, he has returned to China because he can't stand the weather in Singapore. The new delivery guy is cr*p. He just throws packages over my gate and onto the driveway. I have a proper parcel dropbox installed on my boundary wall. It's big enough to take a shoebox sized package but this new delivery guy probably doesn't even know what it is. I just sent a nasty complaint to the delivery company a couple of days ago. And they actually replied and apologized and promised to look into the matter. We shall see. My addiction is worse, I buy kitchen gadgets, cat toys, apparel, electronic spare parts, gardening tools and supplies, welding supplies, etc. I was thinking of ordering laboratory glassware for distilling my IPA. But with this new delivery guy.... I'm not going to risk it.1 point

-

Haha I understand where you're coming from Hector, but you never know, its stuff that you might actually use one day....possibly Most of the stuff i bought were tools for making parts , setting levers and such, so tiny files , stones, diamond burrs and diamond disks. I was really surprised how cheap they were for the quality. The difficult bit is making sure that evri don't mess up the delivery....again1 point

-

Hehe. Aliexpress just me a summary of all my purchases last year. It's shocking.1 point

-

I've done them in the past but no idea what the cost would be here in the UK or who would attempt it these days. Pin size depends on the strap but they're normally between 1.2mm & 1.4mm.1 point

-

Well, I looked back at my files to see what pictures I took and what I posted here is all I have. Odd, because back then, I was taking lots of pictures. Show us pictures of the springs and your current status and maybe we can figure it out. I still have the watch.1 point

-

1 point

-

..verrrry carefully. …and only if I know there’s replacements about… ..I’m placing the pivot end in a snug hole on my anvil holding that end and slowly and gradually rocking the hand back into place with tiny presses. Brass tweezers or equivalent…this is about as ambitious I’ve been with that technique..1 point

-

The tool is well made an helps with balance work. I would purchase it again even though I own a staking set. The tool is not usable for riveting new balance staffs. Karl1 point

-

It is my bedtime so I'll add my view tomorrow. I will just say the movement is certainly French. Us old buggers need our sleep.1 point

-

HWGIKE#53 Newmark 10.5 ligne 5 jewel pin pallet movement My only one customer Stephen sent me 5 watches, three mechanicals and two children coming from a marriage of a mechanical and an electrical watch. I started with 3 of the mechanicals and managed to quickly ruin 2 of them. This one is one of those, I managed to brake off the curb pin which is really a wire hook replacing the curb pin and the boot effectively. I luckily found a replacement in one of my drawer, my alternative was to machine another pin on the lathe and rivet it back to its place but there was no need for it. The donor movement also provided a "new" set of hands which I re-lumed. The boss of the original minute hand was damaged anyway. Had to replace the mainspring as it was set. Polished the non original crystal which actually looks funky. (not entirely sure about the meaning of funky but it seemed to be appropriate.) Also had to work on the HS which I have surprisingly not ruined as I went slow and methodologically inside out one step at the time. Still need to regulate it started with more than 10 mins a day slowness, might need to shorten the HS and re-regulate it set the beat error again. I first could not identify the movement but this helped: https://17jewels.info/movements/n/newmark/newmark-10-1-2/ This is also interesting: https://www.watchuseek.com/threads/newmark-watch-co-info-please.612406/ I usually dont do before and after pics but now I put two of them about the main plate to see whats the difference before and after cleaning and removing some surface rust. Stephen, I am going to send the original strap back to you just in case you dont like the yellow.1 point

-

1 point

-

I finally also had the chance/need to regulate a Rolex balance (cal 3035). I also arranged the ergonomic setup like you, @VWatchie. That really helps. Thanks also to @Jon for your guidance. As you said, in the end, it wasn't as scary as expected. Quite fiddly to get it onto the star-screw, but turning precisely was easy - the screw had just the right resistance. And well, one has to give it to Rolex... the precision is just incredible with these free-sprung balances. I'll have to wear it a few days to see real-life precision, but I think it's going to be 0 to +1. At almost full wind, across all positions, the delta is only 3 (-1 to +2).1 point

-

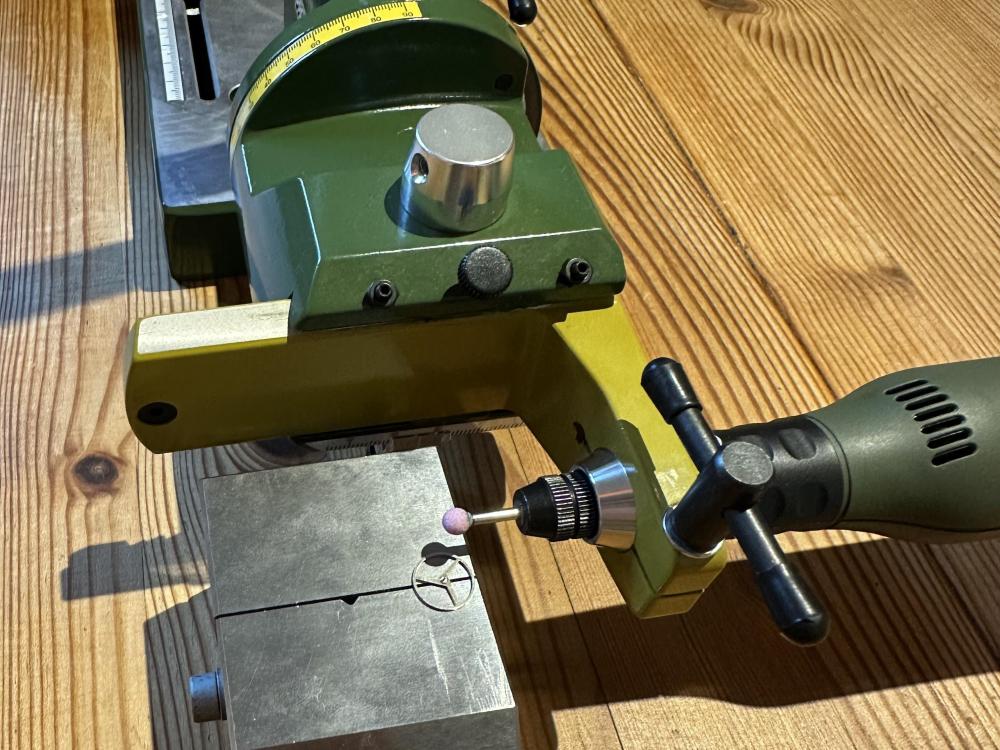

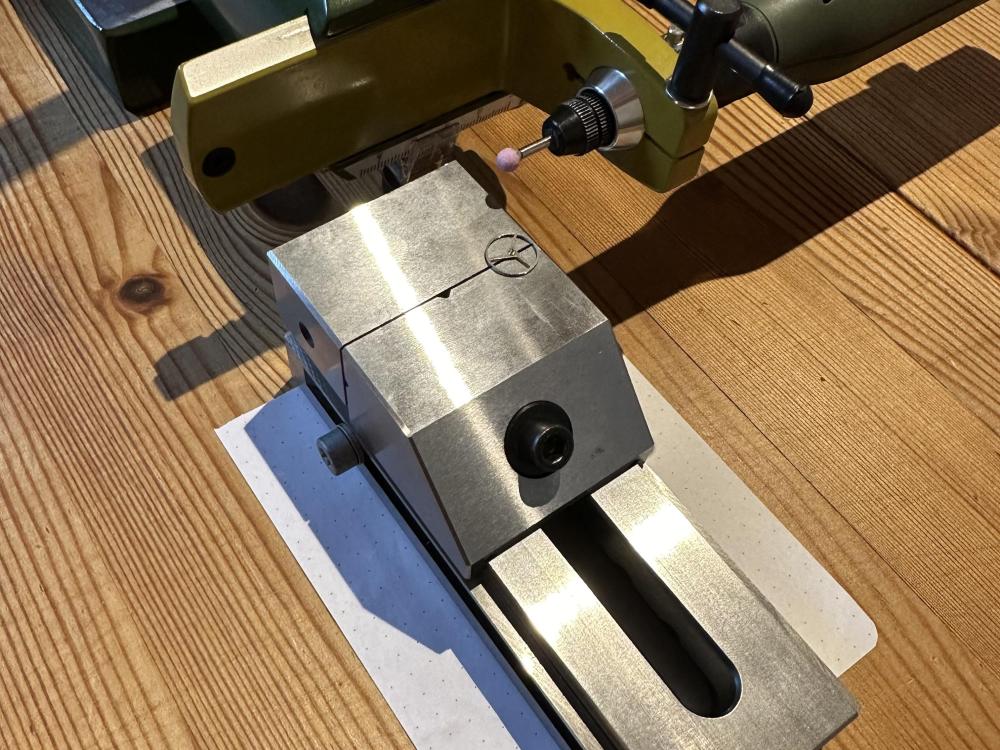

Sorry, no native speaker, will do my very best. The table is the fixed ground level. The stand with the micromot and the grinding attachment is standing on the table, so the grinding ball has a fixed distance to the table. I lift up the vice with the balance in steps of 0.05 mm by putting sheets of paper beneath it. 1 sheet, grind away hub material by moving the vice around under the rotating ball, put next sheet so vice goes 0.05 mm higher, grind away hub material, next sheet and so on.1 point

-

I don‘t have to do this task (replace balance staff) often, maybe one time in a year. As I ruined a Valjoux 72 balance wheel by pushing the staff out without any work on the staff before, I became a fan of the „grind the hub away“ method. So here is a description of my amateur without lathe setup. I put the balance in a vice, hub side up. I use my micromot with a ball grinding attachment. Then I grind the staff away freehand until the rest of the hub is maybe 0.5 mm. Then I put the micromot in a stand and adjust the height roughly. Now I grind away the hub step by step by putting sheets of paper (0.05 mm thickness) under the vice. Stand and vice have to be placed on a very flat table of course. When the hub is grinded down to about 0.05 - 0.1 mm you can punch it out in the staking set (correct support from the downside!), the thin rest of the hub will just break off, no damage to the hole, as many others already mentioned. As always you should first try this with a balance from the scrap box.1 point

-

Let's take this one step further and say that surely Hamilton/Elgin/Rolex wouldn't have not only developed, but bragged about the -- for want of a better term -- breakaway rivet if there was not a problem with watchmakers deforming balances. This isn't a discussion of best practices, but trying to address a mindset of either taking shortcuts or not having the proper skill or equipment. There are watchmakers without a lathe to cut the rivet, so they must seek less recommended methods to get the job done. There are watchmakers who learned from a teacher to punch rather than cut and in deference to a mentor will continue that tradition even when shown a better way. Then there are watchmakers who see a single purpose tool and determine that if the tool exists it must be because it's the proper way to perform a task. In other words, it's much easier to limit the damage with tools and redesign of parts than it is to change peoples' minds. Let me give you another example from the IT world. Everyone agrees that data needs to be backed up. Best practices suggest that it be performed at least daily and a copy is stored locally and off-site for both security and disaster recovery. And that backup needs to be tested and verified periodically. Whole industries have sprung up around data recovery specifically because best practices are either disregarded, debated or not known. And many operating systems now have auto reminders (aka nagware) that won't go away until some sort of backup is enabled specifically because people just don't do it. I consider myself educated and will most likely be cutting rivets going forward. Thanks to all.1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)