Leaderboard

Popular Content

Showing content with the highest reputation on 04/01/25 in Posts

-

I want to show others how you can modify the inner diameter of a hole jewel. For this movement, I have a high grade Waltham that has it's pallet fork jewel broken. Sure, I could order a new jewel, but I have a large assortment on hand. To start, you'll need to remove the old jewel, if yours is broken. Find a jewel that is the required thickness and OD, and one that has an ID that is smaller than the pivot it will match with. Now there is a few ways to modify the jewel. You can place it in a jewel chuck, or you can mount it in it's plate, and then center the hole on the lathe. I for some reason have never purchased jewel chucks, so I have it mounted in its cock, and that is mounted in a face plate. For widening the hole, you also have a few options there. You can use a piece of thin wire that is charged with diamond paste, or you can turn a piece of hardened steel to fit the pivot. I have done it both ways, and I haven't had much luck with the wire method that Daniels demonstrates. When making the steel burnisher, turn it on a slight taper. The end of the rod should protrude just past the back of the jewel. Then, with the rod mounted in you tailstock, add some diamond paste to it. I purchase diamond powder of varying micro size, and then mix it with a bit of oil to make the paste. With the headstock turning roughly 1-200 rpms, advance the diamond charged steel rod into the jewels hole. Retract it every second or so to keep it even. Little pressure is needed, but the paste will work its way off the steel rod, so it needs to be reapplied often. I like to rotate the tailstock spindle while I do this as well, advancing and retracting the spindle to continue cutting the jewel. This isn't a fast process, but should only take you 5 minutes or so. You'll notice in the beginning, that it seems like the steel rod is advancing quick quickly, but this is due to it also being polished and shaped by the diamond paste. It will eventually confirm itself to the jewel hole shape, and it will be less noticeable that it's diameter is being reduced. You may be thinking, isn't the steel much softer than the sapphire jewel? Won't the steel be the only thing that's being removed? And you'd be right to a point. But the steel becomes charged with the diamond paste, embedding it into the surface. After you reach the point of the steel rod conforming to the jewels hole, little diamond paste is added from then on. Below are some pictures of how I have it set up. Here is the setup with wire. I don't really like this method. And here is the setup with a hardened steel rod4 points

-

Mostly, and to maintain a constant pressure on the hole, and to keep the rod aligned Yes I use the same technique on balance pivot holes as well. This is just what is currently on the bench for this type of repair. The smallest I've done is 0.09, but It should scale down, although I haven't done a 0.07 hole yet. I have some sapphire rod, maybe ill cut a slice off and see how small of a hole I can make someday. I would someday like to start a YouTube series on lathe work, from basic gravers, to making your own jewels and threading attachments. But I'm swamped, have roughly 35 watches in the backlog.3 points

-

3 points

-

Lathe? I wish . I made these with just a saw, files, drill and a tap. I needed some left handed, so I made some. I got the centre spindles down to size by putting in an electric drill and using a file, then wet and dry. For the hooks, I drilled a hole, hammered in a bit of steel ( I think I used a needle) then filed to shape.2 points

-

Some models have various holes in the case to set the spring in different positions to adjust the alignment of the bezel.2 points

-

Wow. There's a blast from the past. I saw Limp Bizkit ca 2003 at the Summer Sanitarium Tour. Wasn't who I was there to see (Metallica!), and I wasn't a big fan, but they put on one of the better shows for sure. It was right after Fred Durst broke up with Brittany Spears for a cultural touchstone/point of reference! Brian Johnson lives four doors up from me. Unfortunately, it's the wrong Brian Johnson. Also into cars, which is fun, but at least as into Trump, which is not. Limp Bizkit is probably best enjoyed in an ultrasonic machine.2 points

-

2 points

-

II agree and have noticed that I can’t do things like this when feeling stressed or tired, because there is a higher likelihood that I’ll feel impatient and rush the process. I’ll make sure to give an update!2 points

-

Sure, I should have posted it in the first place. Price was $25 / 4 pieces for me. https://a.aliexpress.com/_Ex1guy02 points

-

Hi all. Hope this is ok, I did search first but found no similar threads. Given that many of us are not blessed with high salaries or pensions and cannot afford to buy high value tools from the Swiss makers, we only have what China offers for our hobby and as many have found a lot of what is sold on the likes of eBay turn out to be just rubbish and not even worth the low prices asked. After buying a few useless tools I started to look at some of their better quality offering, which although quite a bit more expensive, were still miles cheaper than the Swiss tools, sofar the few I have tried turned out to be of excellent quality. So to help others less well of could we have this thread for people to post about their quality Chinese Tools, for others new to hobby but put off buy high prices might find a better tool at a more appropriate price. If this is OK I will start it off with some of my recent acquisitions. Thanks. Paul1 point

-

The taper is pretty negligible. You would reverse the jewel setting in the lathe, and grind again from the opposite side, to counter the taper if it was too much. I haven't tested as far as amplitude gains for either one, or if it's a detriment to not reverse the jewel and regrind from the other side. I'm usually taking off very little, and the burnisher conforms to the jewel surface, so I don't think it makes a ton of difference, but it's a very good point to bring up!1 point

-

1 point

-

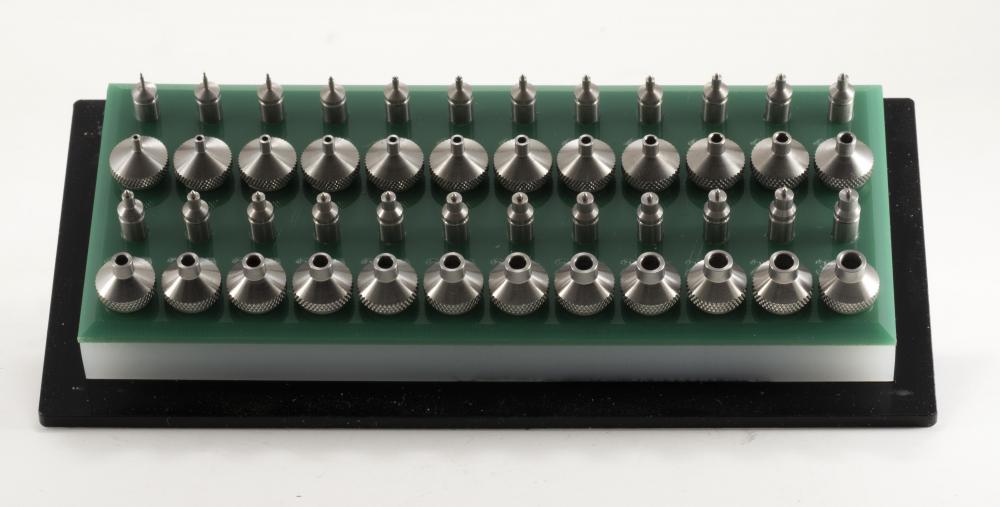

You can punch these out and make new ones. In fact, this is the preferred type of winder, in the sense that the arbors can be replaced when needed. A lathe, files, and stones are all that's needed to make a new one. Winders are much more basic than Bergeon would have you believe. If you're competent on a lathe, you can make quite a few in a weekend.1 point

-

Hello Steve you have already experienced the pangs of learning the craft but be reassured that we have all gone through that initiation at some time or another and come out th3 other side a wiser and more knowledgeable person so take heart you ar3 only treading where we have all trodden.1 point

-

That might be possible, but with the cone of a balance staff, it would eventually start to touch the jewel, possibly before you have reached your desired ID. Plus, I don't have balance staffs on hand, I generally make them. Its much faster for me to just turn a piece of steel the correct size. And the very slight taper is important, similar to a reamer. Absolutely. I don't think many people are aware you can do this, which is why I wanted to share. You arent going to be able to make huge changes in the size, but if you have a jewel that's very close, this is an excellent way to make it fit. You may also wonder why I dont just turn down the pivot of the part im making the jewel for, and thats because I dont want to alter the strength of the pivot.1 point

-

Yes you must completely wash brasso off not to hot water with some washing up liquid and dry, leave it for some time to make sure, if you can still see traces of brasso you will need to repeat until it has all gone. If the glass was packed by using cork you could try replacing cork or get a new glass but they can be expensive.1 point

-

I used to use those glass jars. As you said, the glass is thick and it blocks quite a bit of the ultrasonic energy. The plastic covers are ok with #111 and #3. But benzine makes the plastic swell and soften.1 point

-

I've heard of them but never bought anything. Ha Ha Ha Limp Bizkit. You poor sod.1 point

-

I'm not being 'nitpicky' I just gave my experience of servicing many vintage automatics and I also said 'I'm not disputing what you are saying', but it seems this has ruffled your feathers somewhat, so I shall say no more John1 point

-

Lots of folk here to help with that. Many are not keen on these low jewel count watches, as the plate bearings can wear quickly. I really like them, they're a bit of a challenge, especially the pin levers. But Smiths made endless models that have real character and the English made ones, not British are really good quality.1 point

-

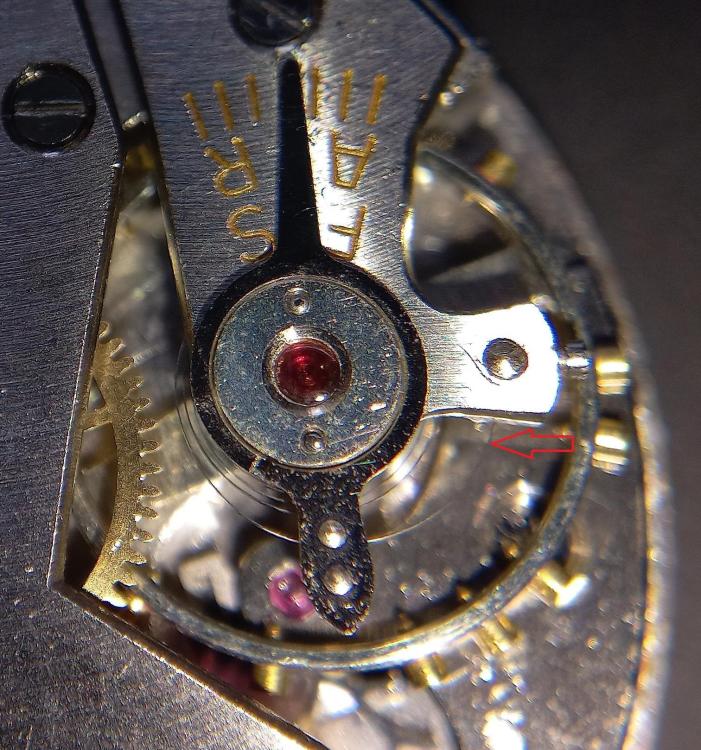

There are two types that I'm aware of, one with a red infill and the curved tip that follows the dial edge ( yours ). The other has a surface painted red arrow as the tip, not as aesthetically pleasing imo. So you'll be starting on your journey of modifing and making parts already ....good man1 point

-

1 point

-

1 point

-

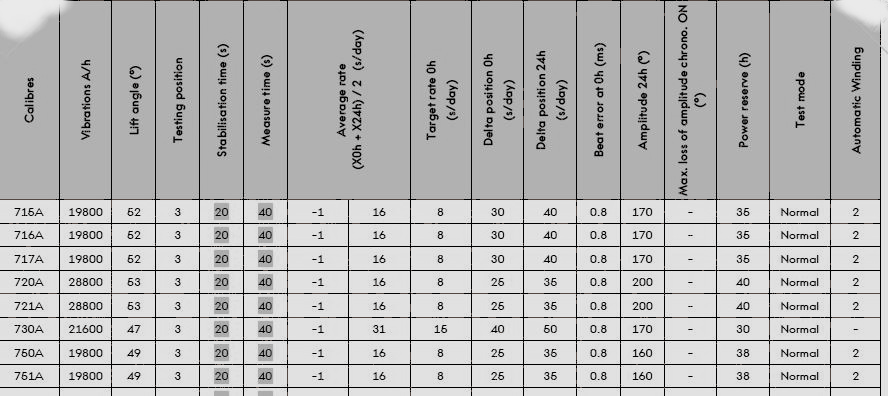

if you really want to get nitpicky about this I did have a concern because I can't find that actual specification in any of the Rolex information that I have. so for Rolex your correct there does not appear to be a specification of this. all I was trying to do was have people have a procedure whenever timing a watch. typically the enthusiastic watchmaker winds up their freshly serviced watch places it dial down on the timing machine is happy with the amplitude hopefully regulates the watch and that's it for timing machine. they never bother to check in any other positions and definitely never checked 24 hours later. This is actually quite common on YouTube one position if they even put it on a timing machine. So all I wanted was a procedure and having a common procedure for both automatic and manual wind seemed like a good thing? then the procedure of waiting is based upon the specifications I've found for other companies and the fully wound up timing specification does very with the shortest being 15 minutes and the longest was actually several hours but that was a unique escapement or something. In any case let me quote from Omega what they have and no they do not differentiate between automatic and manual watch. 0h Measures to be made between 30 and 90 minutes after fully winding. 24h Measures to be made between 23.5 and 25 hours after fully winding. then for your 751 a this is the timing specifications for the watch. You notice if you want to be nitpicky I think I was specifying 30 seconds stabilization and 30 seconds measuring and here they have 20 seconds to stabilize and 40 seconds to measure. then as far as amplitude goes all they care about is what it is it 24 hours. Which as you can see varies between the various calibers. with interestingly Omega watches will typically go at least some of them quite low in amplitude and still be acceptable at 24 hours. with an automatic watch it probably depends upon the breaking grease as to whether you can wind it up to just before it slips. Or whether somebody was enthusiastic with their breaking grease and it doesn't slip on a timely basis. But what I'm curious about is based on your expertise of the quote above what do you make of the quote I have down below for the current problem someone is having?1 point

-

1 point

-

I have assembled the three sections independently and dissembled and reassembled the two plates with each of the three sections. That has considerably settled my feelings about this.I have photos to allow me t repeat this process.1 point

-

Oh my, electronic equipment, all the way from china on a DC10 Decota. You're braver than me Andy. it's better not to, then you won't need to buy more....because that's a.... Now turn that dial up to 10 ! Now tell the truth ....who didn't bang their head to that ? If not then you're not completely alive and kicking.1 point

-

On an automatic watch, I always time it at totally full-wind and not wait up to an hour, which I would if it is a manually wound movement, because the movement is going to spend most of its time when worn with the maximum amount of torque in the mainspring, thus being at its fullest wind. If it is a watch movement such as a Rolex 3135, the isochronism that has been designed into the movement makes no real difference if it is timed at full wind or an hour off that, as the rate is going to be pretty much the same even hours off a full wind. I have found, especially on vintage automatic watches, such as Omega 500 and 700 series autos, that if you fully wind the watch by hand just before the mainspring slips you may see a reading of 260 degrees, for example. Once the auto module and rotor is fitted and you give the rotor a bit of a spin on top of the full wind, so the watch movement is always at its fullest wind, you might be surprised to see a jump of 20 to 30 degrees, bringing it to 280 to 290 degrees, which in my experience is more a real world reading, as the watch is going to remain there more than being just off full wind, even by a few minutes. I'm not disputing what you are saying about leaving it 15 minutes to an hour before timing it, I'm just giving my experience of working primarily on vintage automatic watches and seeing this idiosyncrasy many times. In fact, if you fully wind an automatic watch and put it on a timegrapher at full wind and then turn the winding stem to put a bit more torque on the mainspring, you will probably see the same phenomena of the increase of amplitude as I have described. I have an Omega 751 on my bench at the moment which this is happening to. Full wind gives me 250 amplitude. Full wind with the rotor on and turned gives me 270 degrees1 point

-

The hairspring isn't centered as it was originally. Press at the arrow to get the coil spacing even. The regulator pin gap should be 1.5-2x the hairspring thickness, and the spring should be centered in the gap when at rest. You will have to make gentle nudges at the stud to center it once you've centered the body (coils) by pressing at the arrow. The regulator curve should follow an arc centered on the balance center. It's also out of flat; manipulate it at the stud to bring the opposite side down, and you may still need to lower the stud. The current condition could have the hairspring touching the stud and/or the underside of the balance cock.1 point

-

Opinions are worth considering when they are offered with reason. Yours were not; All Chinese made tools are crap. End of story. You are telling us that all of the tools that I and others here have bought and used are garbage. Why? Because you say so. Well, you are wrong and you have shown that you are totally unwilling to listen to other viewpoints that contradict your own, viewpoints that are based in actual hands on experience with the tools mentioned in this thread. If you have actual experience with any of the products mentioned in this thread then please quote the original post and give your feedback. That is what this thread is for. But please don't come in hear and take a huge non-reasoned dump in the middle of the topic and then expect everyone to, for some reason, respect that. That's not how discourse works.1 point

-

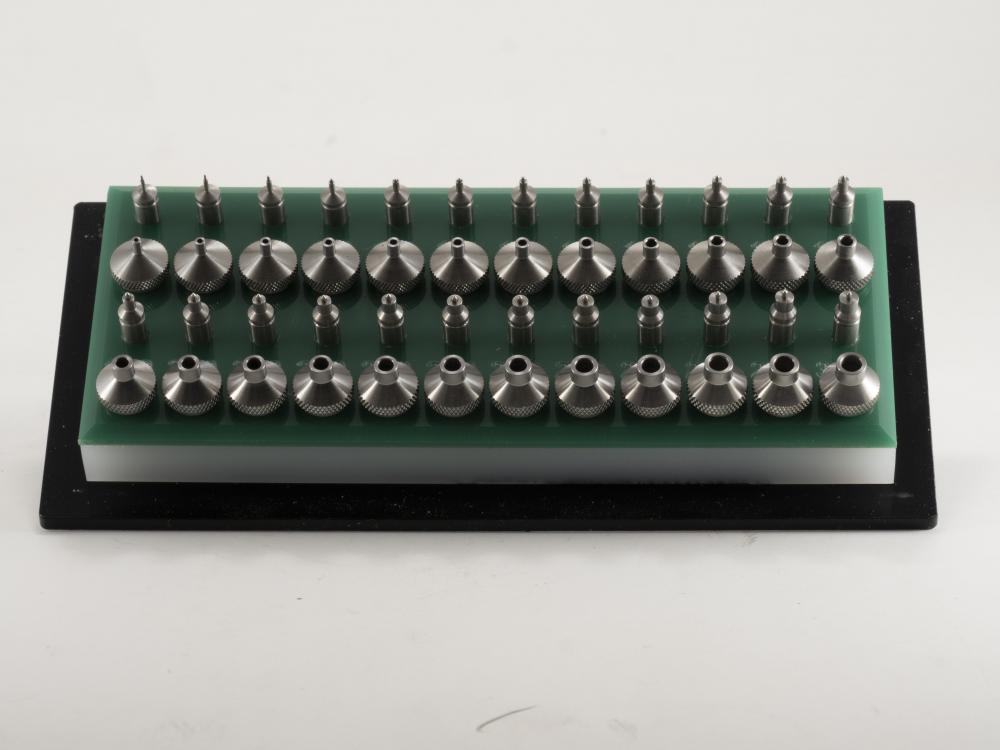

Hi all Time for the next tool in this series This time is the good old Jewelling tool Seen before on the forum but still well worth a second look here. Again from Aliexpress for £117 for the tool and a nice selection of 24 pushers and anvils which are all well made and seem to do what they are supposed to do, https://www.aliexpress.com/item/4000261581571.html?spm=a2g0o.order_list.0.0.119c1802OtQ8wu Obviously a clone of the well known Horia tool but a well made tool none the less and at a fraction of the originals asking price. Not used it in anger yet but have used it a couple of times to adjust end shake and that function was performed faultlessly so doubt a jewel replacement will be an issue for this tool either, once a replacement jewel has been found that is. Thanks for following this thread. Paul1 point