Leaderboard

Popular Content

Showing content with the highest reputation on 04/03/25 in Posts

-

Not quite true and more is involved but a decent rule of thumb is for every 10 C rise in temperature, the reaction rate doubles.3 points

-

Got mine on Tuesday, but they were out of clamps (has everyone been ordering them from here?), so will have to wait for that. I'm very happy with it : much more compact and smoother running than my cheapo version.3 points

-

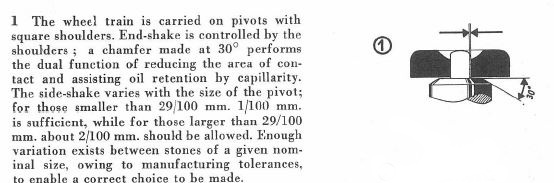

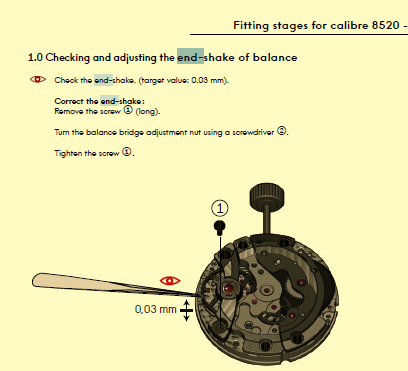

I agree and that is what I would do and as I screwed the bridge down and it jammed I would check the endshake of the wheels at that point and instantly I would see the problem, but @tonydageesaid as he screws down it jams, so as I understood it he is inferring he hasn't managed to fully screw the bridge down before the wheels jam and if there is less than zero endshake on one of the wheels it might crack or damage one of those jewels on the bridge or mainplate. Unlikely, but it could happen. If only the offending wheel is in place and he screws down the bridge, he'll know instantly it is that wheel, which I reckon it is either the 4th or escape wheel by what he has said. @tonydageewas the watch movement working before you worked on it? Jewels can move whilst being cleaned. I have had this happen a couple of times and when assembling a movement that previously worked well before cleaning, I found that there was zero endshake of a wheel when I screwed down the bridge. By telling us that he has a donor bridge, strongly suggests that he might not be adept or confident at moving jewels to suit the correct endshake rather than reaching for a different bridge. I would leave the donor bridge alone for now and work on the endshake issue, if that is what it is. Have you replaced any of the wheels from a donor movement? @tonydageedo you know how to set jewels to the correct endshake? If you are going to set the jewels on the escape wheel, remember that the endshake of the escape wheel and pallet fork has to be roughly the same, because the escape wheel tooth should ideally make contact with the same spot on the impulse face of the pallet jewel in both dial up and dial down positions.3 points

-

3 points

-

2 points

-

This would mean that if the reaction doubles then I guess we reduce the time by the opposite? Or simplistically in the case of watch cleaning fluids nothing it is really achieved by elevating the temperature other then bad things happening. The only place I know of and watch cleaning were elevated temperatures works is cleaning the band and/or bracelet. It's amazing how much biological material gets caked on the bands and elevating temperature with ultrasonic works well of course you using a proper cleaning product which is different than what you're using the clean your watch movement.2 points

-

I'd say just keep everything but I'm probably classed as a hoarder. If you come to work on either of these movements again the parts could come in handy.2 points

-

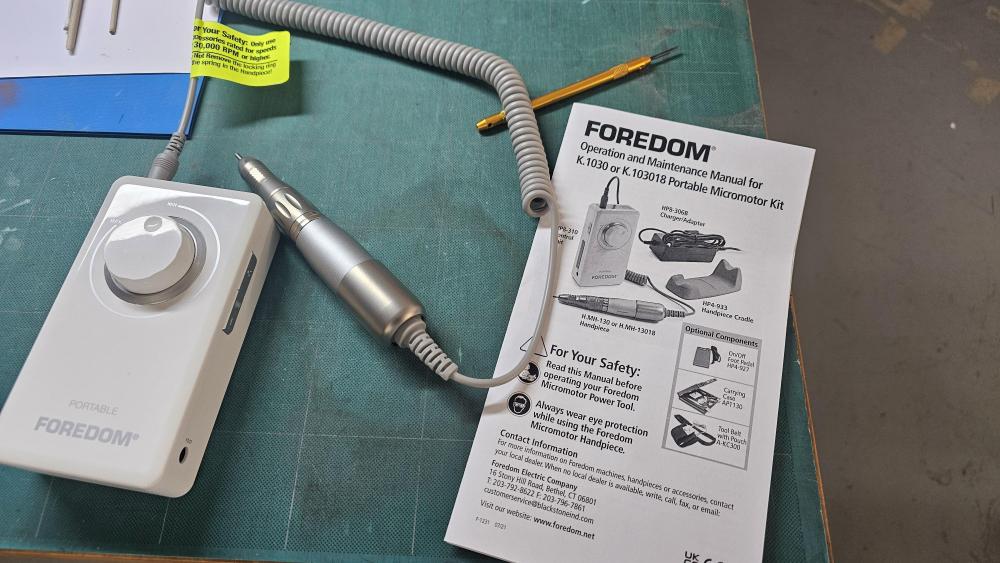

I'm going to use it with some felt bobs and micro mops for polishing scratches out of acrylic crystals. A FBHI friend of mine said he grinds down a 0.2mm carbide burr with a diamond wheel and uses it to grind a small slot in the shank of a broken screw to be able to remove the offending screw, but also it would be great for removing the best part of material (tool steel sheet) when making keyless work before I start to hand file to a precise size/shape. I might even perform a bit of home dentistry. If Bob Mortimer does it, I can't see why not... Only joking! But, Bob Mortimer does his own dentistry!!2 points

-

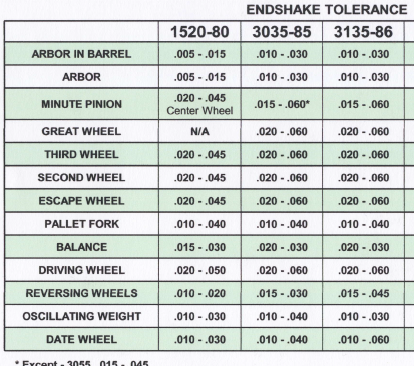

Are you sure about that? In my limited experience, end-shake < .02mm hasn't worked well at all, affecting the overall performance to become more or less erratic. If we're talking Rolex movements, I guess .01mm would work well, but a Vostok movement would more than likely jam. Here is a thread I started about it three years ago: https://www.watchrepairtalk.com/topic/23280-can-end-shake-and-or-side-shake-ever-be-too-small I just re-read the thread I linked to, and in a picture published by @JohnR725 not even Rolex would accept an end-shake < .02mm for any of the train wheels.2 points

-

That's an F1 Mclaren Jon " Bad boy " tools for a bad boy or "Bad boy" tools for a bad boy ? What've you been up to Jon ?2 points

-

2 points

-

I would just oil two of them opposite from each other, but that's just what I do. Some might do more. On a side note I use V105 for rotor bearings as well and don't buy into using V106. Just more money for pretty much the same stuff. If you don't have V105 for the bearing, a small drop of 9010 on just one of the ball bearings, unless they're ceramic bearings that don't need to get lubricated at all2 points

-

2 points

-

Another source of baskets if you're going to do a DIY spinning machine would be to go to eBay and purchase something like this By hairspring I assume you mean balance complete? Then if you had baskets like in the above image You can place the balance wheel in one section and the pallet fork in another.2 points

-

I think I can answer that. Yes! In Russian, "movement" is called "mechanism". @Leonid, if you google "cleaning" on this site you'll find many posts about it. For example, type the following on Google and press enter: site:watchrepairtalk.com cleaning Happy reading!2 points

-

Wow. There's a blast from the past. I saw Limp Bizkit ca 2003 at the Summer Sanitarium Tour. Wasn't who I was there to see (Metallica!), and I wasn't a big fan, but they put on one of the better shows for sure. It was right after Fred Durst broke up with Brittany Spears for a cultural touchstone/point of reference! Brian Johnson lives four doors up from me. Unfortunately, it's the wrong Brian Johnson. Also into cars, which is fun, but at least as into Trump, which is not. Limp Bizkit is probably best enjoyed in an ultrasonic machine.2 points

-

Gone for it, didn't buy the clamp as I have a bench polisher. Proxxon owes this site some discount. Hehe.2 points

-

Tool collection, yes, hording no, I have an aversion to anything not being used. In future, reassemble the movement as far as possible, bag and label what it is and what's missing.1 point

-

Never ask anyone into watchmaking what to keep! As Andy points out we probably all have an aversion to getting rid of potentially “useful “ things natural born hoarders and tool collectors, every single one of us Tom1 point

-

It doesn't matter when you remove them, the ratio of the various wheels are the same, replace them at 12 o'clock.1 point

-

Typically for most watch cleaning products and probably all the solvent-based ones elevating the temperature is not desirable. My experiences been if you elevate the temperature it becomes more aggressive at removing tarnish. For which we are time-limited in the cleaning solutions because beyond a certain point when the tarnish is gone it will start dissolving the metal into the solution which will turn a really pretty blue green color. Or simplistically cleaning is good etching the metal is not. I'm currently reading the Elma red specification use sheet and there is zero mention of elevating the temperature? Then based on the recommended cleaning machines one of them are capable of heating the cleaning products at all be used at room temperature. I placed the cleaning machine 70 elevated temperature at all is for the drying cycle.1 point

-

Always best in watch repair to diagnose and determine the problem or problems before implementing a solution. Versus mixing and matching hoping to somehow the problem will go away. Because often times mixing and matching from donor movements will introduce new problems especially if it was a vintage watch. Yes always one of my favorite questions are we fixing a pre-existing condition or are we dealing with a new problem after servicing? Why don't you try putting the fourth wheel and escape wheel in only and see what happens. Are you sure about that? In my limited experience, end-shake < .02mm hasn't worked well at all, affecting the overall performance to become more or less erratic. If we're talking Rolex movements, I guess .01mm would work well, but a Vostok movement would more than likely jam. Here is a thread I started about it three years ago: interesting I wonder if there is a confusion of terminology here? For instance from the Swiss watch repair manual it appears to be end shake of 0.01 might actually be side shake specification? which if you notice changes with the diameter of the pivot typically the only place I've ever seen end shake is with Rolex. Although I'm doing a quick search on something here's something interesting Omega watch and they'll accept a worse case of 0.03 for the balance wheel. Continuing down my search results I see another Omega watch with the same specification. I wonder if that means Omega is making poor quality watches if the tolerance is greater than a what I find interesting is looking at various books on watch repair and digest really isn't any specifications for end shake. Even though when I was in school we spent a lot of time adjusting it don't actually remember what it was at all. Of course some of that's because I typically work on American pocket watches where it cannot be adjusted it is what it is. Which seems to be the philosophy for just about all the watches out there except Rolex. Then even Rolex based on the tolerances of so apparently anything worse than 0.02 mm would be horrible but I'm not finding that specification out there may be you can find be the reference book? then Rolex the only company that seems to really get obsessed about it and actually published numbers based on this discussion apparently sucks for tolerances. Which suggests there must be a confusion over specifications in this discussion1 point

-

Mmm that’s a good idea but mine it’s just the tip so no threads at all, I will try to remove the stem first without tearing the whole thing first see if I can get it out, thanks for the tips1 point

-

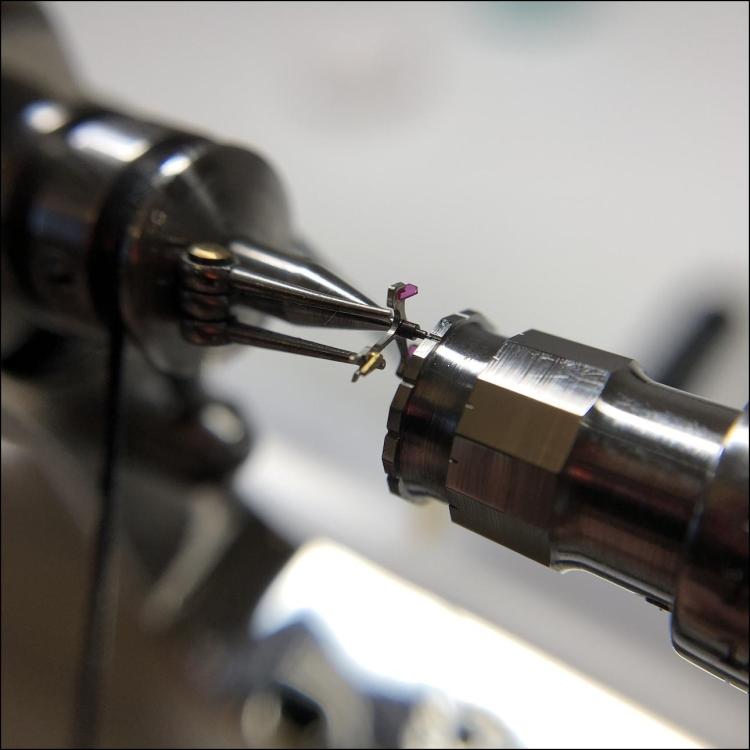

While taking my daily walk yesterday, I was thinking about a pallet fork pivot that didn’t seem in great condition and what I could do about it. My next thought—incorrect, as it would turn out—was how unfortunate it was that you couldn't burnish pallet pivots using a Jacot tool. But then I took the thought one step further and realized that a pallet fork is just as symmetrical as a wheel and that it might be possible to use the pallet fork's arm as if it were a wheel spoke. It felt a bit of a long shot, especially since I had never seen anyone do it or talk about it. But when I got home, I figured it was worth a try—and to my astonishment, it worked perfectly! I was so thrilled that I felt I had to share this, what was for me, a groundbreaking discovery. It’s probably nothing new to many of you, especially not to the professionals, but I hope those of you who, like me, thought it couldn’t be done, now know that it absolutely can1 point

-

I'm a mad man and burnish from underneath freehand. I get great results this way, using a steel burnisher and diamond paste1 point

-

Its great when you discover a new procedure to do something! I usually just chuck it in a collet, as my spindle is very true.1 point

-

Ive thought about getting a micromotor, but they are so expensive! what are your plans for it?1 point

-

It certainly is a Dutch clock. How many bells has it got because proper dutch striking should have two. Looking at the hands its an alarm. Do you have the hood if so can I see it please, at the moment I don't know if it's Frisian, if so it should have a pendulum with a long tail and 3 ornaments on top.1 point

-

As pointed out above, it's usually the reverser wheels. I've had this problem, and re-cleaning the wheels has fixed it. Or they could just be too worn1 point

-

I haven't tried them in US machine since I use a rotary cleaner. The glass is actually a bit thicker than my jam jars, by about 0,1-0,15mm. The cap lining doesn't like acetone too much, it has swollen a bit but otherwise feels normal to touch.1 point

-

Usually washing painted dials is not a desirable thing to do. I assume you mean how do you wash the watch movement?1 point

-

Again not something I do very often just doing torsion clocks ( usually) but the odd times I have done it I found it easier to take a picture of the wheels & pinions expand to count the teeth , it’s much easier for me to do that at my age. Dell1 point

-

I'm not 100% sure what you are saying. You made sure the train is free. How, if when you screw down the bridge and everything jams? If that is the case that when the 4th and escape wheel are not there you can screw down the bridge and you get the freedom of the train, then try only the escape wheel in place and fit the bridge. If this isn't the problem, then just fit the 4th wheel and try with the bridge. It's about finding out what works and slowly adding more wheels until you find the offending part. Try checking the endshake of every wheel as well1 point

-

Could be an end shake problem, as @AndyGSisaid, was it running before?1 point

-

1 point

-

I‘d want to mention that even Mark does not oil the Rolex reversers correctly…1 point

-

1 point

-

This is how the hairspring looks now after I manipulated it according to @nickelsilver's instructions. It once again looks just like it did before the accident. A huge thank you to all of you, but a special and heartfelt thanks to nickelsilver for the illustration and the accompanying pedagogical explanation, which—just like always—is world-class! The first thing I attempted was to adjust the slight indentation in the terminal curve just below the curb pins. I probably didn’t succeed completely, but I also didn’t want to tamper with it unnecessarily, as every adjustment carries a certain risk. Here are the tools I used. I held the spring in place with the tweezers right at the bend (at the blue arrow in nickelsilver's illustration) and then gently stroked the part of the spring that lies between the terminal curve and the main body of the hairspring, using the oiler, repeatedly in the direction of the arrow. I did this in stages, checking the shape of the spring after each step. I took my time and continuously monitored my breathing, and kept my shoulders relaxed. After eight years of working on watches, I know that when things go wrong, it’s usually because you feel stressed and tense. I also had to manipulate the hairspring slightly at the stud in the direction of the green arrow (in nickelsilver's illustration), as the spring was making slight contact with the curb pin. However, I made this adjustment as close to the stud as possible. Fortunately, things were not as bad as I initially feared. In my first post, I mentioned that the balance cock jumped at least ten centimeters into the air. In reality, it was probably no more than two or three centimeters—but it felt like a meter. And like my heart stopped. What likely saved the situation was that the only part mounted on the main plate at the time was the balance cock—no other components. In other words, there were no other parts for the balance wheel to get caught on. Before I begin assembling a movement, I always install the balance assembly, chatons, and cap jewels first to check the free movement of the balance wheel. It was right after doing this, when I was about to remove the balance cock, that the accident happened. I must say, I feel very encouraged and inspired after this “little” operation, so once again, a huge thank you!1 point

-

I find that the most airtight bottles for volatile solvents those with ground glass stoppers. I got some for my clinic over 30 yrs ago. Somehow over the years, I am left with only two. But it keeps acetone and xylene very well. Maybe I should go down to that quaint little dental supply shop and see if they have any hiding in some forgotten corner.1 point

-

1 point

-

On an automatic watch, I always time it at totally full-wind and not wait up to an hour, which I would if it is a manually wound movement, because the movement is going to spend most of its time when worn with the maximum amount of torque in the mainspring, thus being at its fullest wind. If it is a watch movement such as a Rolex 3135, the isochronism that has been designed into the movement makes no real difference if it is timed at full wind or an hour off that, as the rate is going to be pretty much the same even hours off a full wind. I have found, especially on vintage automatic watches, such as Omega 500 and 700 series autos, that if you fully wind the watch by hand just before the mainspring slips you may see a reading of 260 degrees, for example. Once the auto module and rotor is fitted and you give the rotor a bit of a spin on top of the full wind, so the watch movement is always at its fullest wind, you might be surprised to see a jump of 20 to 30 degrees, bringing it to 280 to 290 degrees, which in my experience is more a real world reading, as the watch is going to remain there more than being just off full wind, even by a few minutes. I'm not disputing what you are saying about leaving it 15 minutes to an hour before timing it, I'm just giving my experience of working primarily on vintage automatic watches and seeing this idiosyncrasy many times. In fact, if you fully wind an automatic watch and put it on a timegrapher at full wind and then turn the winding stem to put a bit more torque on the mainspring, you will probably see the same phenomena of the increase of amplitude as I have described. I have an Omega 751 on my bench at the moment which this is happening to. Full wind gives me 250 amplitude. Full wind with the rotor on and turned gives me 270 degrees1 point

-

@VWatchie, I was more concern if the spring has deformation in flat. This little out of center pictures show nothing to worry as it is easy to correct. But such flight of the balance with the cock may have stretched the spring as to make it look as a funnel. Do You have something similar? Does the movement work normally now? Does the spring look flat and parallel to the cock/balance when balance with the cock is in the movement?1 point

-

I use a Foredom flextool which has a range of 0-18,000 RPMs, has foot control, and can also be run through a voltage regulator to set the speed. I got rid of my dremel style rotary tool as it was too fast, too loud, and too much runout. The flextool motors are very quiet as they are DC, plus the motor is not in the handpiece, which reduces vibration and runout. Plus there are a ton of attachments for then, like belt sanders, hammer handpieces, ect. Very versatile tool that gets a ton of use in my shop.1 point

-

Please can we go back to the cap jewel oiling, so what is the preferred method for these, as you say, the pivot rests on the cap jewel so that could do with a bit of oil, I must admit that I oil the cap and assumed the capillary action sorted the jewel. If the correct method is to oil the jewel and allow the capillary action to oil the pivot end on the cap, I'm ready to change my ways as of now, oiling the cap jewel is a pain in the rear.1 point

-

I noticed in his video, he had to move the rate adjuster all the way to the end of its adjustment, and that is caused by a regulator pin resting on the hairspring. He needs to adjust the pins, and then the regulator put back in the center. He also installed the lower balance hole jewel in upside down, with the oil reservoir facing the balance. His videos are so incorrect, and he has such a wide audience that its frustrating that he doesn't do the repairs correctly. His oiling of cap jewels is probably the most frustrating. Most books ive read are against placing the oil on the cap jewel, and then placing them together, as it doesn't always have the capillary action to lubricate the jewel hole. He also said cap jewels are for keeping dust out, but they are what the pivot rests on. the tool is on aliexpress and is called a number of things, but usually movement base fixing seat or something along those lines. $130-ish. Seems unnecessary, but also cool.1 point

-

The typical reason for stiff winding (when no wear or defects of the parts) is not proper lubrication of the reverse wheels1 point

-

Okay What was Seiko's recommendation for their wheel? This is because each of the various automatic watches have different recommendations. Well I would agree with that it's oil mixed in a solvent. I suppose if you put a microscopic quantity of oil you can get it to look dry but you're still going to have a thin film of oil. My interpretation of what they were trying to do was to apply a very thin coating of oil but not so much as to being sticky exactly what you're finding. You do realize who originally came up with the formula for the alternative don't you? It may have been in the Omega document but somewhere around here I have a paper copy of something from ETA who originally came up with the V105 formula and they were only recommending it as an alternative if You could not purchase the v105. So what we have interesting here is based on your samples we have a 100% failure rate. I have a suspicion that if the entire world was having a 100% failure rate of this we would've heard about it by now. Then I'm not sure in the group that anyone would embrace if the alternative fails the preferred would also fail. On the other hand this is a group of people would like to use lighter fluid and sometimes DIY mixing their own watch cleaning products rather than purchasing a cleaning products so knows maybe they would feel that way. https://www.moebius-lubricants.ch/en/products/specialities1 point

-

Yes, benzine, I tried that too, mixing 9010 with benzine exactly like the Omega guide said. For testing I used it on ETA 2824's double reverser wheels and an vintage Seiko's differential wheel. The movements are known to be working fine before testing cause I serviced them myself and the automatic winding all worked flameless as they was treated with V105 in the service. Now, reverser wheels and differential would get removed, cleaned then treated with 9010/benzine mixture. - On the 2824 I notice the rotor does not move freely in both directions as it should, and the rotor does actually spins when handwinding slowly with the movement lying down flat. - On the Seiko it was so worse that handwing becomes extremely stiff, very bad helicopter effect on the rotor, and very bad automatic winding performance. It was so bad with the Seiko I thought I somehow broke the wheel but after clean and treated with V105 everything returns to normal. Flaweless working automatic winding system and silky smooth handwinding. This was written in AWCI article August 2012 about V105: As the article described Lubeta V105 is a dry lubricant, and notice the waxy film it leaves behind on the reverser wheel. This thing and the 9010/benzine mixture are TOTALLY different. This is what I really want to point out. V105 leaves a dry coated layer on the wheel, while in my experiment, I can't get the wheels to dry at all, eventhough it's just 3% of 9010 it is, still, conventional oil, that's why it leaves an oily liquid on the wheel which I can't get it to dry no matter how long I waited or how hard I try to blow it with an air blower. Now I'm not sponsored by ETA by anymean and you guys are clearly not buying V105 from me. In fact, all my efforts are to look for an alternative that can replace the unique V105. I just don't want people to assume that, because the 9010 mixture didn't work, means V105 won't work either. They are assuming V105 and the 9010 mixture are the same while they are not. Just think about it, if you could achieve the same good result with 9010, why bother developed something different?1 point

-

Just to add another data point, I've just serviced my 5206, and with that differential wheel, and also a spare from a 5216, function was correct when used unlubricated from the cleaning machine, but once dipped in 3% 9010 97% IPA and dried I couldn't handwind without the rotor rotating. Rinsing out the 9010 in 100%IPA in the ultrasonic and they were back to full function. It seems unintuitive, and I don't like the idea of bare metal either, especially not at this level of torque, but my vote is to follow the tech guide and run the differential wheel's internals dry.1 point

.thumb.jpg.9385550d228113fa7b67d93c68b52d12.jpg)

.thumb.jpg.a6131757362d38af302ef12fe9e0e3f2.jpg)