Leaderboard

Popular Content

Showing content with the highest reputation on 04/04/25 in Posts

-

4 points

-

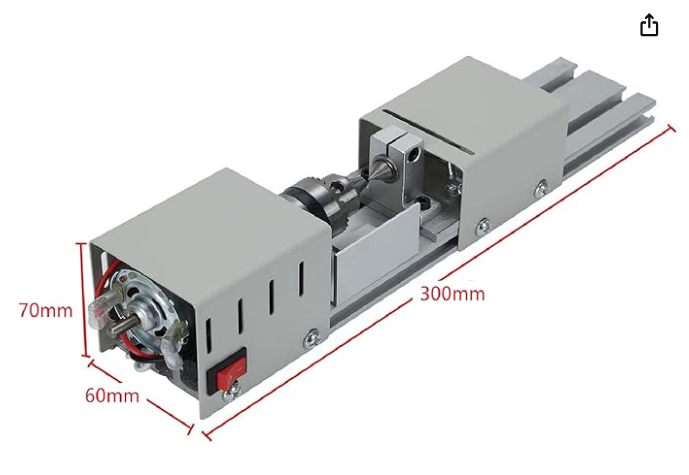

If you wish to use a polishing mop on a micromotor, you'll need a motor with a good torque output. I'm not sure if the Foredom is capable of such torque. I miss my lab micromotor. I gave it away to my dental lab guy when I retired. It came with an integrated dust extraction system. The moment the motor is activated, the vacuum starts and continues for awhile more to clear away any dust in the air. A good micromotor has torque feedback, meaning that when a load is applied to it, it increases power to the motor to maintain a constant speed. It should also have current overload protection and thermal protection. It don't like using rotary tools for polishing acrylic crystals, it tends to leave striations which are visible when light hits it at an angle. I prefer wet sanding and a final buff with a wool mop and polishing compound on my bench polishing machine. I have a Foredom hanging motor, an Osada micromotor, a homemade micromotor and a cordless nail spa motor. The cordless motor has very poor torque but it's really handy when working under a microscope. I didn't buy it, I just found it in my letterbox, without a name but with my address. It didn't have a return address either.4 points

-

That's what I do. Saliva works well (at least mine does but that might be due to the alcohol content ) Then I would try naphtha (lighter fluid) , then IPA - but only the tiniest amount on the very edge to start with to see the effect.3 points

-

Brilliant advice! It worked a treat after finding the right sized pin vise. Like a lot of things, it’s knowing the tips to make the job a bit easier. Thank you!3 points

-

Never throw away anything with good jewels. Odd wheels? You can practice pivot burnishing in the future.3 points

-

Keep everything !!! It's all usable. Reassemble it and zip lock it whole. A plate, a bridge or a cock might hold a jewel that you will want one day.3 points

-

It only takes me a minute or two using wet and dry then Polywatch to polish a crystal, I don't see the need to use a rotary tool. Indeed, the only time I tried to use a rotary tool to polish an acrylic crystal, it was far too aggressive and burnt the acrylic - but that was my old tool with a minimum speed of 10,000 rpm3 points

-

Never ask anyone into watchmaking what to keep! As Andy points out we probably all have an aversion to getting rid of potentially “useful “ things natural born hoarders and tool collectors, every single one of us Tom3 points

-

I'd say just keep everything but I'm probably classed as a hoarder. If you come to work on either of these movements again the parts could come in handy.3 points

-

I would suggest for the drill use a size 58=1.07mm then turn the pivot to the size you need after fitting the part that way you can be certain that the pivot is concentric with the rest of the arbor. Dell2 points

-

2 points

-

2 points

-

I threw some watch parts from a pin pallet movement away yesterday and whilst it was hovering over the bin ready to go in I had a strange feeling of 'What are you doing!' I overcame it thankfully and in they went, but I did keep the screws and jewels. Always keep screws and jewels! Incidentally, this was the very first time I've thrown watch parts away, because I have 'the hoard'. It can be a nasty little affliction2 points

-

I would try a winding stem extender that is oversized. Ream out the extender to get rid of the thread so it able to go over the broken stem like a sheath. Once that is reamed accordingly, put some superglue inside the stem extender and onto the broken stem.2 points

-

2 points

-

I'd check first if the movement is working then just leave it alone. If it does need a new movement then you'd be able to get it with a black crown and replacement lens from here in the UK including delivery for not much different than the $21. Possibly cheaper from US but I'm not up on prices or who deals with the public over their.1 point

-

The hope is once the crown is off you lift the movement at the nine position tilting the movement up to clear the case then slide out.1 point

-

Hi. Replacing the movement is the easiest option, if that’s the way you go then by all means utilise the old one for practice. You can get an assortment of crowns via Amz or Cousins which ever you find the most convenient1 point

-

1 point

-

Still not sure what you mean about the oil as this is only used to lubricate old movements. If you're getting a replacement movement then as mentioned above there are variations of the Ronda 515 so you need to make sure you get the correct one. The crown that comes with the movement would be plastic and no good to use.1 point

-

Hi. Sooner than hacking the gasket off try gripping the stem between the dial and case with some fine nosed pliers, or even grind a pair down to fit. I have used this method before when stubborn crowns and stems refuse to budge.1 point

-

Just bought some from these guys https://www.infinitywax.com/search?type=product&options[prefix]=last&options[unavailable_products]=show&q=autosol Cheaper the Amazon1 point

-

I've been using it ever since, never even considered using poly watch. Autosol have quite a few different types1 point

-

1 point

-

The holder the blued steel is in looks like a gun shell, and it looks old so probably good quality blue steel, some of the new stuff is rubbish. Dell This video maybe of help to you to give you an idea of what’s involved. https://youtu.be/-eYvYYc-8dc?si=K_6dU2PifHeuT7An needless to say it’s not how I would do it or suggest you do it but it’s just to give you an idea of what’s involved.1 point

-

1 point

-

As nothing apart from the Swiss Made appears to be painted, as you say I don't think you've got a lot to loose. I'd start with saliva on a cotton bud and go from their.1 point

-

When the crystal starts to rotate you know that you are on your way. Always rotate it, just pulling it upwards rarely works unless the crystal is a slight fit. With each little nip on the clamp the rotation gets a bit easier. I have cranked down hard on the clamp sometimes and was convinced the crystal would shatter. Like most materials,you push them to their limits in one attempt and they are liable to break, but small increments of pressure allows them to acclimatise to a situation.1 point

-

Does anything appear when you pull the crown to the setting position? Maybe it was a split stem that was damaged and someone's replaced it and the marks on the dial are where they held the stem while screwing the crown on?1 point

-

Sounds like corrosion has spread to mechanical elements of your watch or has ruined an electrical part. Picture only helps to identify the movement, I trust its the caliber Jon said.1 point

-

1 point

-

One can only concur with the previous posts, I have quite a lot of redundant watch and clock bits. Never know when you might need them.1 point

-

That is what I was expecting to see regarding ornaments it's Atlas carrying the globe and two Pheme Goddess at sides. Dutch striking is a hammer striking one of the bells on the hour and another hammer striking another bell on the half hour being a different tone. It certainly look as if parts are missing, be careful as many of these clocks are not as old as you think.1 point

-

Hi, it looks like the 18s Hamilton 940 double roller movement....1 point

-

That's how I do them, though I'd see what other more experienced people advise as well? I have been using Trichloroethylene (the original stuff in one-dip) which should not really be used without good ventilation. I've recently got some Hexane to try as that is apparently not as dangerous. (I won't pay for a tiny branded bottle when a 1L unbranded bottle of the same stuff is cheaper). One-dip has now been replaced by B-Dip, which is slightly less dangerous apparently. (A generic industrial solvent, Washcleaner 6090).1 point

-

That's a sensible policy, if the wheels are available, but they are becoming hard/impossible to find.1 point

-

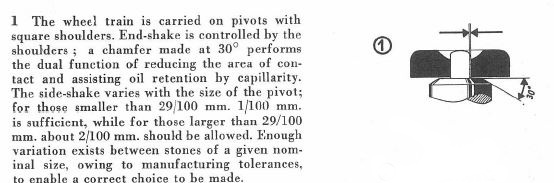

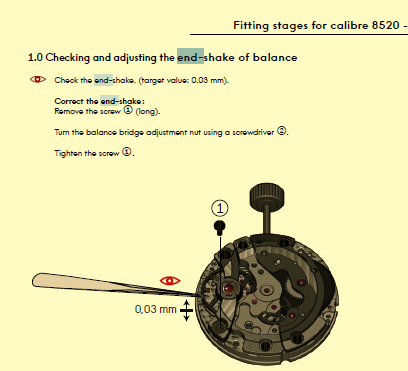

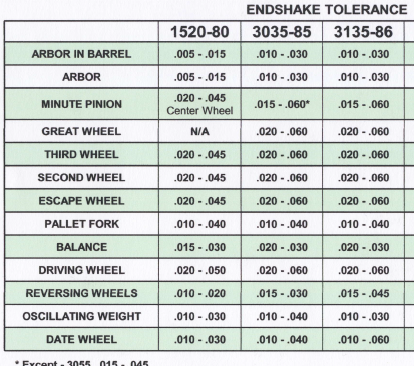

Always best in watch repair to diagnose and determine the problem or problems before implementing a solution. Versus mixing and matching hoping to somehow the problem will go away. Because often times mixing and matching from donor movements will introduce new problems especially if it was a vintage watch. Yes always one of my favorite questions are we fixing a pre-existing condition or are we dealing with a new problem after servicing? Why don't you try putting the fourth wheel and escape wheel in only and see what happens. Are you sure about that? In my limited experience, end-shake < .02mm hasn't worked well at all, affecting the overall performance to become more or less erratic. If we're talking Rolex movements, I guess .01mm would work well, but a Vostok movement would more than likely jam. Here is a thread I started about it three years ago: interesting I wonder if there is a confusion of terminology here? For instance from the Swiss watch repair manual it appears to be end shake of 0.01 might actually be side shake specification? which if you notice changes with the diameter of the pivot typically the only place I've ever seen end shake is with Rolex. Although I'm doing a quick search on something here's something interesting Omega watch and they'll accept a worse case of 0.03 for the balance wheel. Continuing down my search results I see another Omega watch with the same specification. I wonder if that means Omega is making poor quality watches if the tolerance is greater than a what I find interesting is looking at various books on watch repair and digest really isn't any specifications for end shake. Even though when I was in school we spent a lot of time adjusting it don't actually remember what it was at all. Of course some of that's because I typically work on American pocket watches where it cannot be adjusted it is what it is. Which seems to be the philosophy for just about all the watches out there except Rolex. Then even Rolex based on the tolerances of so apparently anything worse than 0.02 mm would be horrible but I'm not finding that specification out there may be you can find be the reference book? then Rolex the only company that seems to really get obsessed about it and actually published numbers based on this discussion apparently sucks for tolerances. Which suggests there must be a confusion over specifications in this discussion1 point

-

Anyone who has serviced a Rolex to find a part needs replacing finding it is difficult to say the least. A few years ago I needed a part for a GMT Rolex and after a world wide search found the part in Australia.. In the April edition of the BHI magazine there is a advertisement offering genuine Rolex parts.. Not sure if they have vintage parts but nothing wrong and contacting them. If you need a genuine part, then you need a genuine part. www. perpetual-time.com Contact: 0151 205 0776 Discount rate for BHI members1 point

-

The typical reason for stiff winding (when no wear or defects of the parts) is not proper lubrication of the reverse wheels1 point

-

I've attached a lesson I wrote on the BFG 866, which includes refitting the hairspring. Just make sure to turn the boot 90 degrees with a screwdriver of appropriate size to enable the hairspring to sit between the boot and curb pin. Fit the stud, then close the boot. If your hairspring needs refitting to the stud, you'll need a small brass pin shown in the photo. I prefer to fit the HS when it is clear of the balnace Lesson 15. The Baumgartner 866 continued.ppt1 point

-

In my perusals of eBay I became aware of the watch brand Sicura. I also learned that they were the company that rescued Breitling from oblivion in 1979. I came across the Sicura Satellite with it's large chrome plated case, metallic blue dial and its enormous seconds hand. I was able to acquire one that needed attention on eBay for a reasonable price. When it arrived I discovered the crystal was trash, they date wouldn't change and the watch would stall after a few hours. Inside beats a Swiss, Baumgartner, BFG 158 31/7. This is a manufacturer I personally never heard of but I would become very intimate with over the next few weeks. I stripped the movement down and during disassembly of the date mechanism I discovered the Day/Date advance wheel pivot shaft had worked itself loose and the day advance wheel itself had dislodged and was wedged under the cover plate. I continued the complete disassembly and found no further issues other than general filthiness with oil everywhere. While disassembling the mainspring to clean and lubricate it, the arbor popped up and caused the spring to exit the barrel in a knot. Thankfully, no mainsprings were harmed in the restoration of this watch, although my nerves definitely were tattered. During reassembly I pulled the Novodiac shock springs to clean and lubricate the balance jewels and the lower spring pinged off. Thankfully I found it a week later. I ordered and installed a new crystal because the original shattered when removing it I assembled and tested , disassembled, cleaned reassembled, rinse, and repeat no less than 5 times trying to get it to run correctly. I used the wrong oil and it was stalling the movement. It is currently running without any lube which I will correct after I take delivery of some Moebius, but at least it's running and keeping excellent time! I took delivery of a silicone strap last night with blue accent stitching and I really think it looks the Business. Thank you for taking the time to read this long winded story.1 point

-

On this watch the inner bezel/chapter ring sits in a shoulder in the crystal itself. I had to order one of those crystals with a tension ring inside the opening to accommodate the bezel. Because the original crystal was so stuck inside the case it crumbled while trying to press it out. I poked around with a screwdriver trying to pry out the remaining lip. You can see a scratch I made at the "55" position when the screwdriver slipped. Just another page added to this watches story.1 point