Leaderboard

Popular Content

Showing content with the highest reputation on 04/05/25 in Posts

-

The classic - Practical over Theory - A book doesn't cover every situation.3 points

-

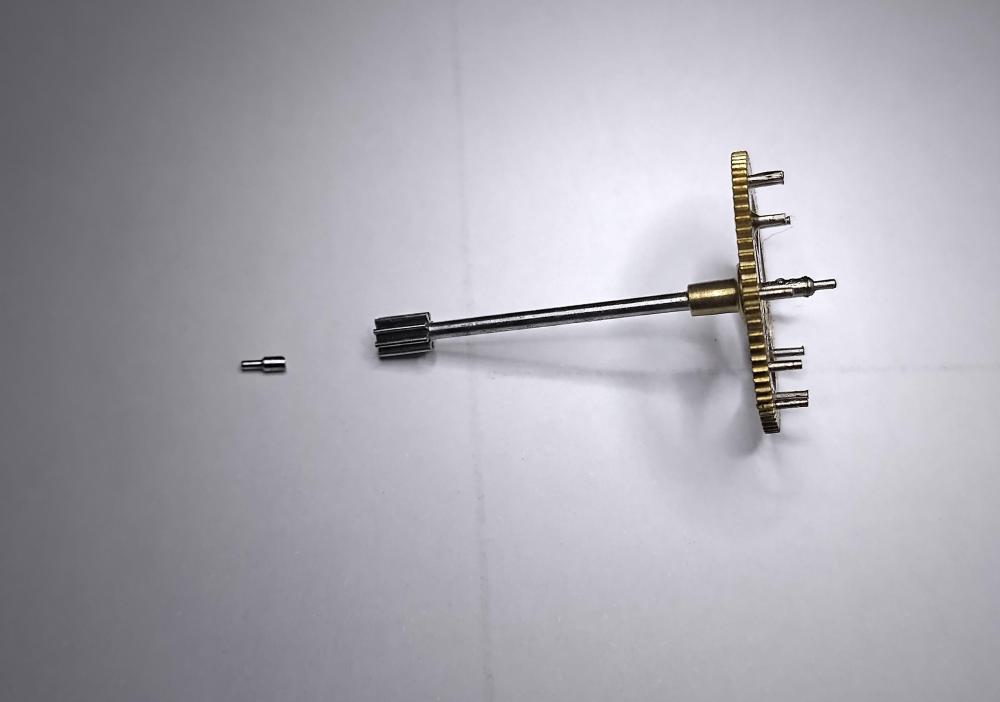

Yes just turn down the part to the required diameter heat the pinion but not cherry red press fit part quench before heat transfers to new bit then turn pivot and shoulder to correct length for end shake. I would recommend doing a test piece before doing the arbor, drill a hole in a bit of round bar of approximately same diameter as the pinion turn a bit of steel to required size heat and press fit then quench, that will tell you if the hole size is correct & roughly how long to heat & most importantly give you confidence to do the proper part especially if you do it more than once. Dell3 points

-

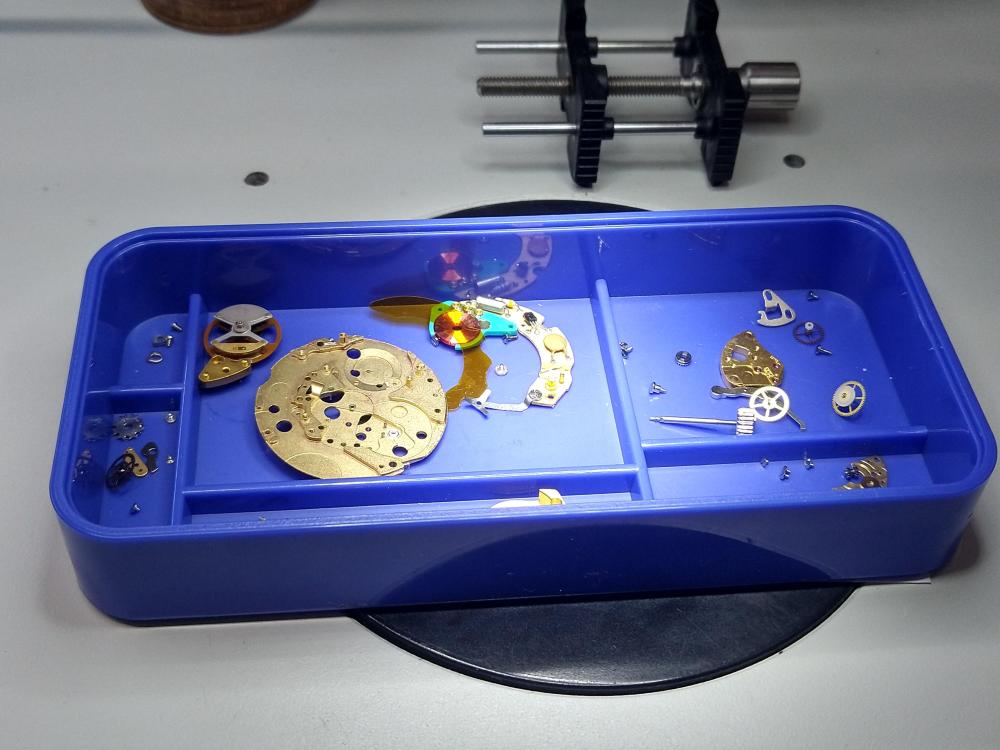

I agree with the advice above, everything you have there looks to be worth keeping. There is the possibility of using the parts, screws and jewels in future repairs. Wheels are useful when learning to use the Jacot tool. You will inevitably snap some pivots, so it’s best to learn on wheels you can afford to damage. You can also practice other new techniques on these parts, such as reaming out a hole and fitting a friction fit jewel. Best Regards, Mark3 points

-

3 points

-

HWGIKE#56 AVIA ESA 9154 love child of an electric and a mechanical Could not resist... I still had 2 nights and a couple of hours today to service this one before travelling. I have 9158s but this one is a 9154, pallet fork has a built in magnet. This is a real miracle, a bit tricky to get out from the case, but didn't take long to figure it out. Was very very fast after the service, didnt check it before though. Had no choice but to re-lume the hands.2 points

-

2 points

-

2 points

-

Dell it is a cardboard tube. My blue steel was in something very much like it and yes the steel is as hard as hell.2 points

-

Thanks for posting your solution. It's posts like this which make this forum such a uniquely valuable resource for us hobbyists. That's clever and well executed. The part you made looks just as good as the original.2 points

-

2 points

-

2 points

-

Hi. First impressions is that it’s a good serviceable set with all of the required bits. It has a base aka K&D inverto so as to be able to use the punches as stakes if fitted to the bottom. All the text is in German which would imply it’s of European origin but not necessarily so as it could have been made for the European market. All in all a good set.2 points

-

I hold the arbor down with some tweezers, then using an old oiler, run it between the coil and the arbor, so that the coil opens and lets the arbor slip in.2 points

-

Let me rephrase my previous response to VWatchie's findings. As far as I am concerned ; " whatever end shake you get best overall performance with, is the ideal end shake " which mainly applies to balance shake and entire escapement. Though VWatchie only mentions erratic graphical display ! I presume the word "overall includes , timekeeping, minimum amp drop after 24 hrs run, smallest delta " positional amplitude drop" etc. When we get optimum performance, I can't care less what books recommend. The issue OP is facing is a problem in gear train, which I think this thread will well cover all possible faults and approaches to correct the problem. Regs2 points

-

Never throw away anything with good jewels. Odd wheels? You can practice pivot burnishing in the future.2 points

-

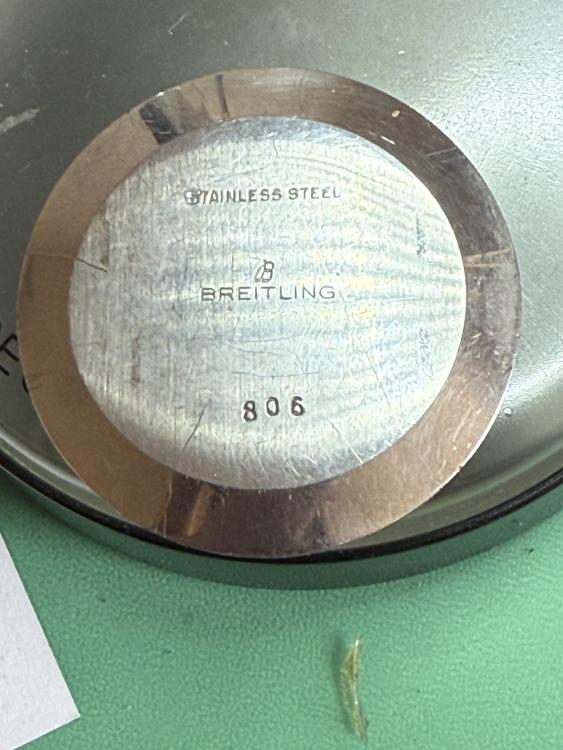

A friend of a friend has entrusted me with the service/restoration of what was his grandfather's Breitling Navitimer 806. It was just lying around in a drawer, missing its glass and two of the hands, but incredibly it runs and the Chrono seems to function. I've started dismantling it and have learned that I'm not the worst amateur watch fixer in the world - the dial had been glued down! I'm planning to strip down and clean the movement - I should be competent to do that. Clean and re-lume the hands. Source a new glass - acrylic I think - and do very little to the dial apart from maybe a cotton bud and water. Any advice from the good people here before I crack on? I did tell him the potential value of this and suggest he might get a proper watch maker to sort it. I've offered no guarantees apart from I shouldn't make it worse.1 point

-

The Poljot Sturmanskie Chronograph: The Soviet-Era Pilot’s Watch You Didn’t Know You Needed When you think of legendary pilot’s watches, your mind probably drifts toward the likes of the Rolex GMT-Master, the Breitling Navitimer, or perhaps even the IWC Big Pilot. But if you’re here, chances are you’re the kind of person who enjoys veering off the well-trodden horological runway and landing somewhere a little more... Soviet. Enter the Poljot Sturmanskie Chronograph—an exquisite piece of Cold War-era timekeeping that blends rugged functionality with just the right amount of vintage charm. Also, I accidentally bought one. But we’ll get to that later. A Brief History Lesson (or: How the Soviets Decided They Needed Chronographs Too) The Sturmanskie name has long been associated with Soviet aviation and space exploration. Famously, Yuri Gagarin wore a Sturmanskie when he became the first human in space in 1961—though that was a simpler, time-only model. By the 1970s, the Soviet Union decided that their air force pilots needed something more complex: a proper chronograph. Enter the Poljot 3133 movement, a robust and slightly “borrowed” (read: reverse-engineered) take on the Swiss Valjoux 7734. In true Soviet style, they took a reliable Western idea and made it their own, producing a movement that has since developed a cult following. The Sturmanskie Chronograph became standard-issue for Soviet pilots, cosmonauts, and, I assume, the occasional KGB agent who needed to precisely time how long it took to shake a tail in a black Volga. First Impressions: Rugged, Functional, and Gloriously Soviet When my Sturmanskie arrived, I’ll admit, it wasn’t planned. I was dabbling in the fine art of eBay late at night, bidding on a job lot of watch parts, when—whoops—I also won this. But fate works in mysterious ways, and honestly, I couldn’t be happier. The moment I unboxed it, I knew this was something special. The dial is a masterclass in military functionality—no-nonsense, crisp Arabic numerals, and subdials positioned in a way that suggests this thing means business. There’s a tachymeter scale around the outer rim, which, if I’m being honest, I will never actually use unless I suddenly find myself timing a MiG fighter’s landing approach. And then there’s the case. At around 38mm, it’s smaller than many modern pilot’s watches, but let’s be real: if you need a 44mm wrist-clad dinner plate to feel like a real man, you may have other issues to address. The domed acrylic crystal only adds to the vintage charm, with just enough distortion to make you feel like you’re reading your watch through a Cold War-era submarine periscope. The Movement: A Soviet Workhorse with a Swiss Accent Inside the Sturmanskie ticks the Poljot 3133, a movement that started its life in the 1970s and is still revered today for its durability. It’s a manual-wind chronograph, which means you have to give it a daily wind—an act that adds to the whole experience. There’s something satisfying about winding a mechanical watch, knowing that you’re directly interacting with decades-old engineering. Accuracy? Let’s just say that it’s probably not COSC-certified, but that’s part of the charm. If you wanted pinpoint precision, you’d buy a quartz Casio and call it a day. Instead, the 3133 offers a pleasingly anachronistic experience, reminding you that timekeeping is as much about the journey as it is about the destination. How Does It Wear? Despite its military roots, the Sturmanskie is surprisingly comfortable. The case sits nicely on the wrist, and while the original strap was probably made from surplus Soviet tank leather, swapping it out for a leather band transforms the watch entirely. It’s one of those rare timepieces that looks equally at home in a bomber jacket or peeking out from under a dress cuff—assuming your workplace is cool with you showing up in Cold War-era memorabilia. Comparisons: How Does It Stack Up? Now, let’s put the Sturmanskie up against some of its contemporaries. Compared to the iconic Seiko 6139 “Pogue,” the Sturmanskie has a more traditional layout but lacks the automatic convenience of the Seiko. The Omega Speedmaster, its better-known spacefaring cousin, is undeniably a superior watch in terms of finishing and precision, but you’re also paying an entirely different price bracket for that privilege. And against something like the Heuer Bundeswehr Chronograph? The Sturmanskie holds its own with its military pedigree, even if the Heuer has that undeniable Swiss allure. Final Thoughts: A Piece of History for Your Wrist The Poljot Sturmanskie Chronograph isn’t just a watch—it’s a piece of Cold War history that you can wear. It’s functional, it’s charmingly imperfect, and it’s a fantastic conversation starter. While it may not have the cachet of a Rolex or the refinement of an Omega, it offers something arguably better: character. And, if you’re anything like me, it might just be the best accidental eBay purchase you’ll ever make.1 point

-

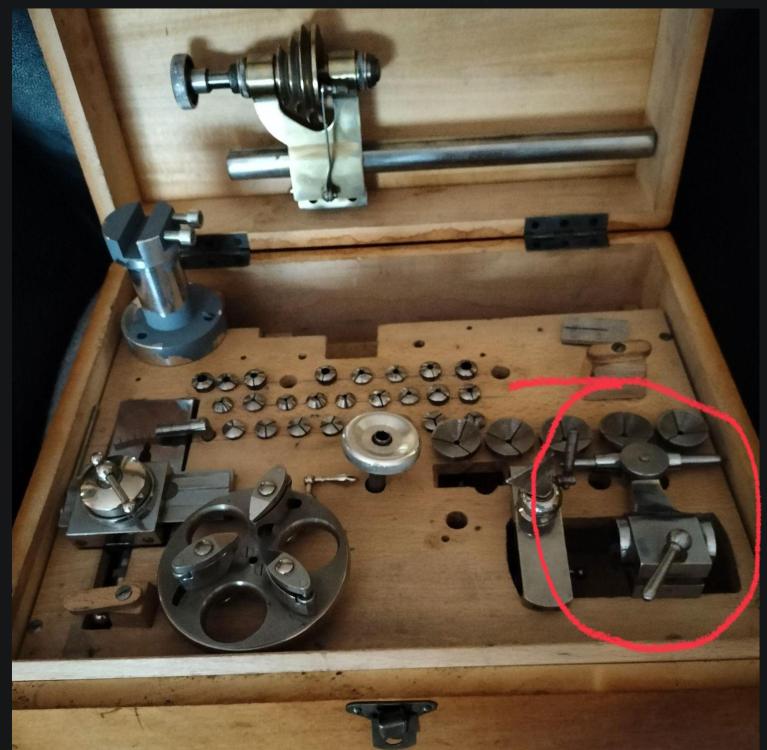

Hi all, I'm in the position to take over a Boley lathe. It's 8mm with a cross-slide and faceplate I wanted. Apart from making balance staffs and winding stems, an important goal would be repivotting and drilling out worn pivot holes to rebush (oval ones making round again). There is however no tailstock included with drillchuck or even just one with simple collets. What are my options? As it's also no WW, finding compatible tailstock will be next to impossible (and then there is the problem with alignment). I know there are people doing it freehand but as a novice with not to steady hands (understatement) this seems extremely difficult. It would be used for wristwatches and clocks. Kind regards1 point

-

Let us know how you get on, not price obviously but just if you purchase & any help with using it if you are unsure about anything1 point

-

1 point

-

As Jon said your best bet is google it & eBay is a good sauce of price guide but some things go cheap so don’t take it as gospel, it looks to be a complete kit in good condition so something like that won’t be cheap.1 point

-

1 point

-

Personally, I would be a bit wary of asking valuations on any forum. Without sounding obtuse, something is only worth what someone is willing to pay for it and what the other party is willing to take, so I'm sure you'll have an idea of what to offer by looking on Bay what something like this has gone for in the past. Someone might tell you that the lathe is worth £2000 and someone else might tell you £200, so you still don't have any idea what it is worth to you.1 point

-

1 point

-

…I’ve done a couple 6309s and invested the 10 quid on model specific gasket sets…how about this posted earlier today if you want to diy?1 point

-

I use a Bergeon barrel arbor holder 30610 (1.0mm and 1.5mm), which is one of my favourite tools, but I can imagine running an oiler between the coil and the arbor could ease the process even more for those really stubborn situations1 point

-

On a Pultra 10 8mm lathe the the drilling is done by a tapered brass collet to fit the runner with a hole in to take the drill bit with a sleeve over to squeeze the collet to grip the drill bit , as carbide drill bits have all the same size shank you would only need to make one. Dell This is the tailstock1 point

-

That is a nice lathe with a really good set of attachments! You can use a hand guided runner through the existing tailstock. There are various collet adapters for runners that take a taper insert, and there are also runners of different sizes with mounted chucks on ebay. https://www.ebay.co.uk/itm/266810651953 https://www.ebay.co.uk/itm/405687866138 It should be reasonably easy (if not quick) to find a drilling tailstock on ebay - Original Boley parts for the same type bed do appear regularly. There are two fixed tailstocks on at present, but not a drilling one. I'd set up a search so you get notified when one is listed. (And from experience, WW ones are far less likely to be interchangeable! I've been trying to find matching WW parts for months; I have multiples headstocks, tailstocks & beds - and no combination that fits to make a complete lathe!).1 point

-

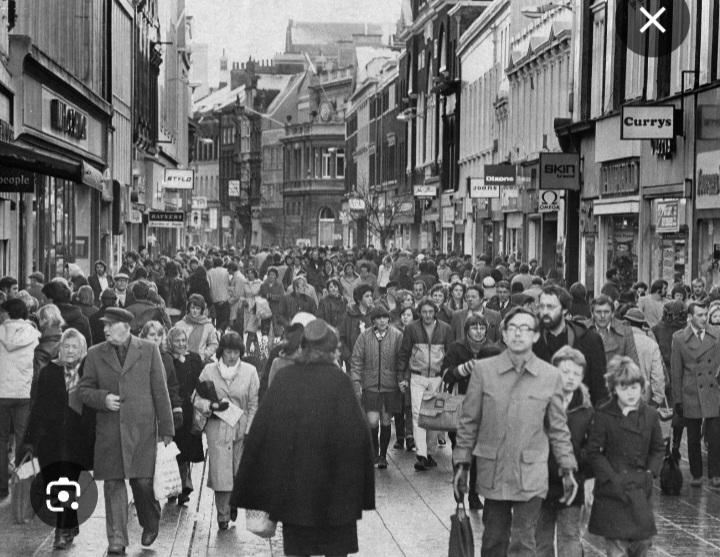

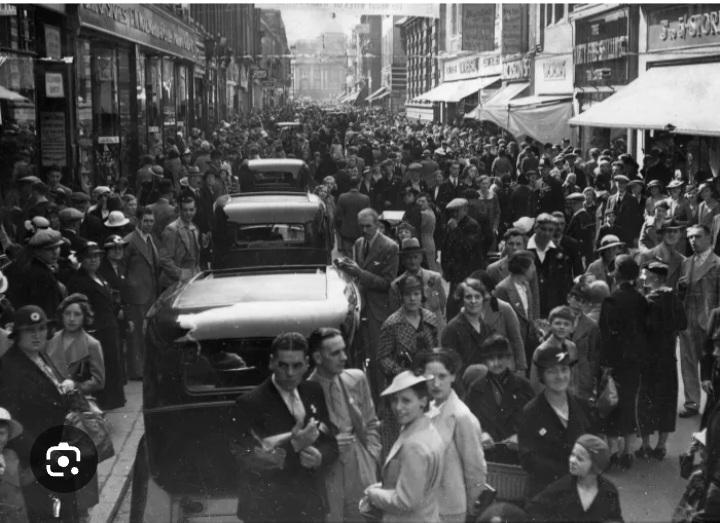

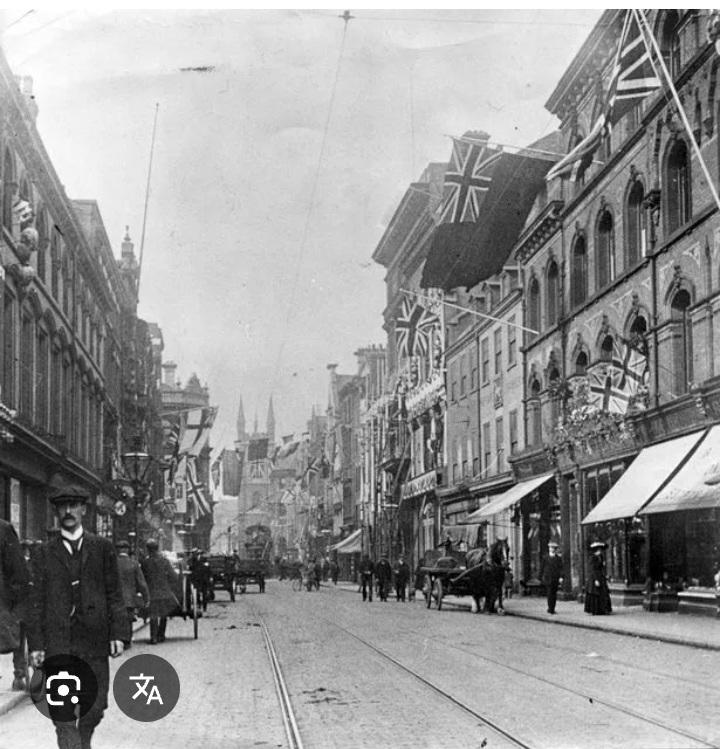

Made in my home town of Hull, 45 WhiteFriarGate. Which back then would have been the main shopping area, it had a shipping lane right at the top of the street. My son works just around the corner .I'll get you a photo of the shop next time I'm in town.1 point

-

You have a tailstock there and that is the basic thing you need for the type of drilling you want to do. Not having a drillchuck or collet chuck is no problem. Previously there have been several options mentioned. Check out this thread for instance: https://www.watchrepairtalk.com/topic/31637-tailstock-runner-specs-for-peerless-2/?do=findComment&comment=2718731 point

-

Just bought some from these guys https://www.infinitywax.com/search?type=product&options[prefix]=last&options[unavailable_products]=show&q=autosol Cheaper the Amazon1 point

-

1 point

-

Cousins has an aluminum case with a bunch of small circular aluminum canisters with glass tops. I keep dead movements in those. Like movements together. Assembled as far as they'll go. Jewels, screws, springs, and who knows if you'll come across another of the same movement needing attention, or a forum member needing a part.1 point

-

1 point

-

Hold the arbor in a pin vise, insert while turning in reverse of the direction of wind- in your case that would be clockwise- you might tilt a little to get it started, but it will go in.1 point

-

I threw some watch parts from a pin pallet movement away yesterday and whilst it was hovering over the bin ready to go in I had a strange feeling of 'What are you doing!' I overcame it thankfully and in they went, but I did keep the screws and jewels. Always keep screws and jewels! Incidentally, this was the very first time I've thrown watch parts away, because I have 'the hoard'. It can be a nasty little affliction1 point

-

One can only concur with the previous posts, I have quite a lot of redundant watch and clock bits. Never know when you might need them.1 point

-

Keep everything !!! It's all usable. Reassemble it and zip lock it whole. A plate, a bridge or a cock might hold a jewel that you will want one day.1 point

-

Never ask anyone into watchmaking what to keep! As Andy points out we probably all have an aversion to getting rid of potentially “useful “ things natural born hoarders and tool collectors, every single one of us Tom1 point

-

If it is a bolt type rotor bearing like in a modern ETA 7750 I would remove the bearing and dip it in. If it is a friction fit type, like on an old Valjoux 7750 then I use a pipette to put a very small drop on the bearing without getting on the rotor, because it will leave a bit of a waxy white mark otherwise. Try it, works a treat! If a client brings in an automatic that hasn't been service in 8 or 9 years plus, I replace the reversing wheel(s) as standard1 point

-

I'm going to use it with some felt bobs and micro mops for polishing scratches out of acrylic crystals. A FBHI friend of mine said he grinds down a 0.2mm carbide burr with a diamond wheel and uses it to grind a small slot in the shank of a broken screw to be able to remove the offending screw, but also it would be great for removing the best part of material (tool steel sheet) when making keyless work before I start to hand file to a precise size/shape. I might even perform a bit of home dentistry. If Bob Mortimer does it, I can't see why not... Only joking! But, Bob Mortimer does his own dentistry!!1 point

-

It could well just be dried up oil that's "set" whilst it's not been running, though some quartz movements need a couple of points shorting to reset the IC and start it working properly again. Have you tried setting the hands? If it is only just sticking, moving the hands back & forth may rock the gear train slightly and kick it back to life?1 point

-

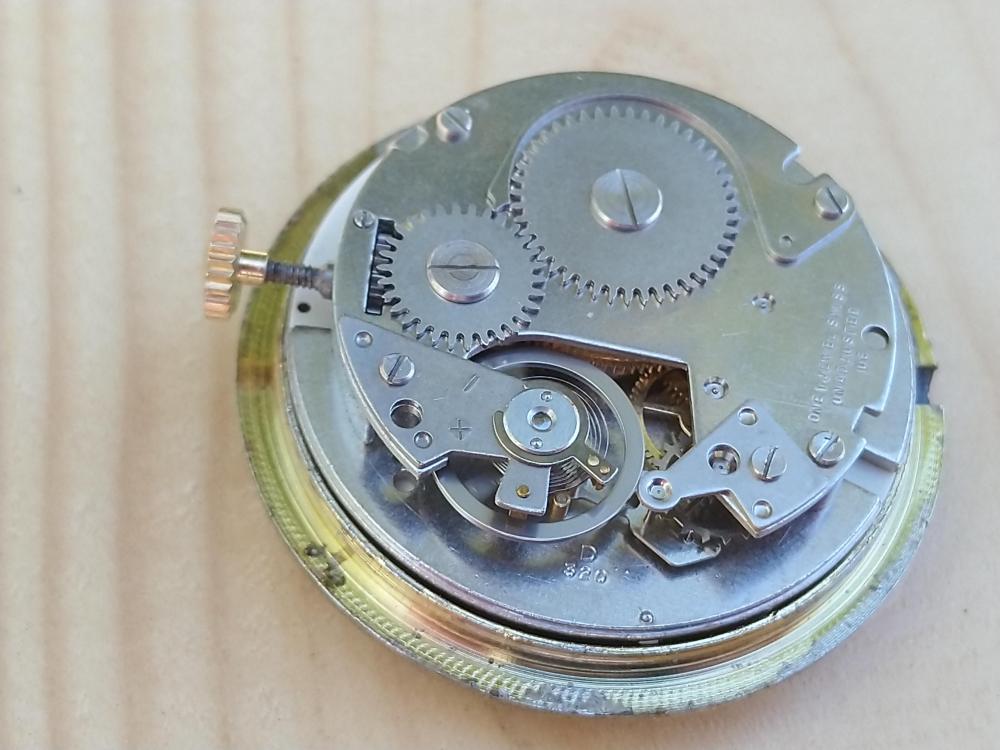

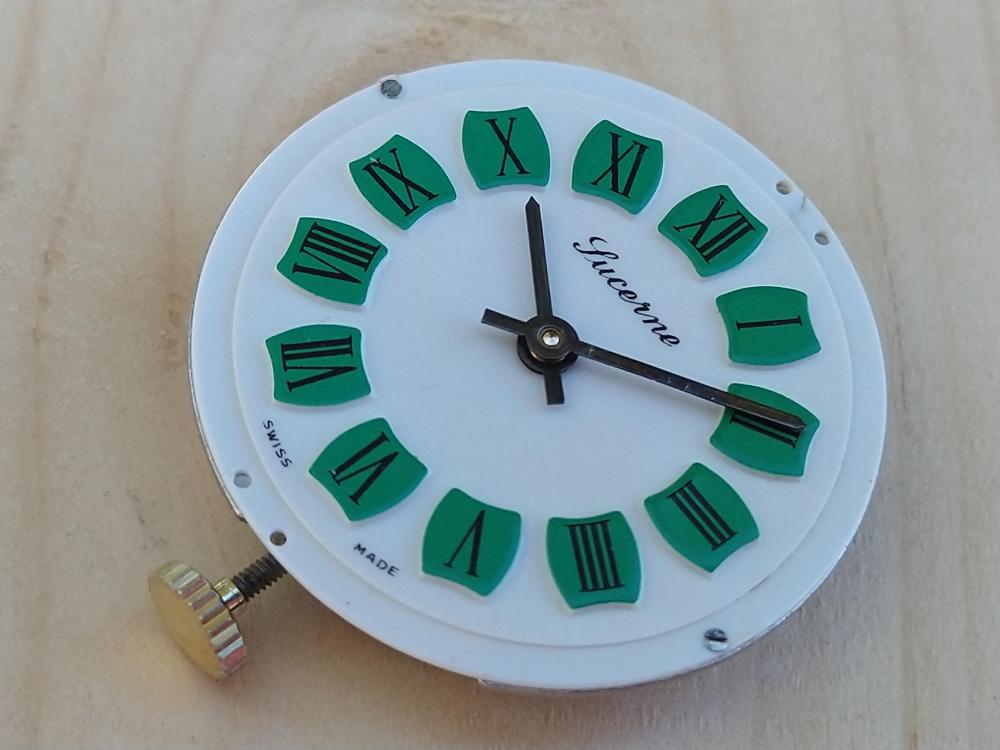

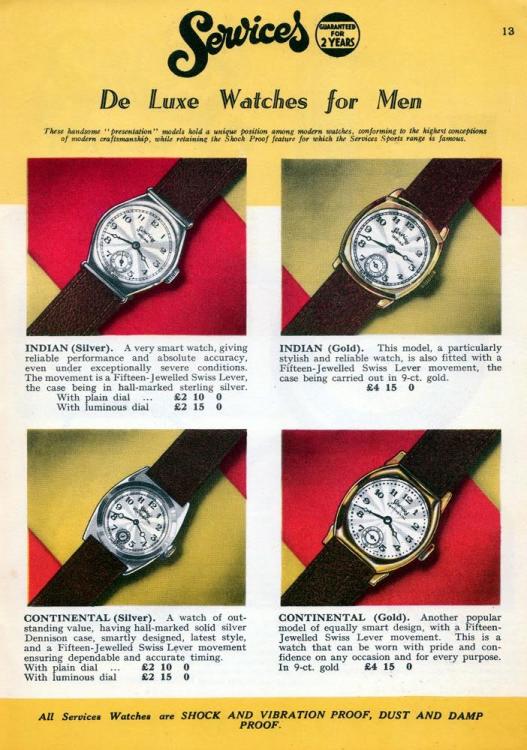

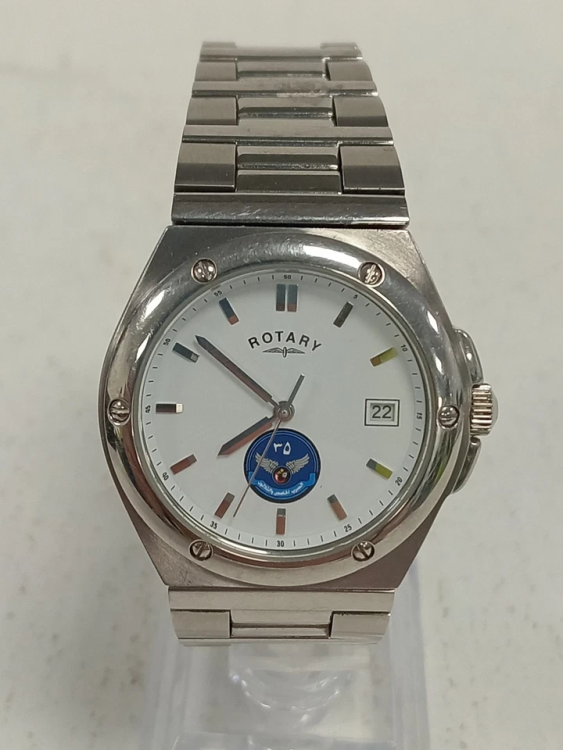

HWGIKE#54 Desa 320 Pin pallet While I was waiting for parts I thought I would do another pendant watch this time for my Mother in law. When I opened it up I had a BFG866 feeling but it said D 320 so it counts! No mistakes or anything to mention. HWGIKE#55 Services Continental Bifora 102 Swiss lever This is one of the Stephen's mechanical watch out of 3 i did not ruin. Service went well but when I put it on the time machine the graph was nonsense. Realized that the balance was wobbly as one of the pivot was worn and bent. Luckily eBay had a complete balance in mint condition for £12.90. When it arrived I installed it but the graph was still nonsense, I had three double parallel lines... I saw that the upper pivot was jumping in its jewel hole... realized that the jewel was replaced, hole diameter twice the size compared to the pivot diameter.. not just that but it was not secured either and was moving in its seat. Selected one from my stock, balance jewel not plate with correct outside diameter correct hole and rubbed it in securely. Also had to replace its mainspring... old one was very weak and set. Selected one from my stock but it was too strong, balance went over 360 so I had to order the proper one from cousinsuk. Even this weaker spring is very powerful now as the watch clean and lubricated half wound and amplitude is around 320-330. Beat error is around 1.1ms not sure why.. managed to change it from 0.6 to 1.1 after setting the impulse jewel exactly in the middle of the banking pins. Very strange. Regulated and keeps time. Case is made by Mr Aaron Lufkin Dennison and made out of silver.1 point

-

1 point

-

We are all living in a pond but you are a fish while i am a mole. I struggle with English as I am Hungarian but when it comes to watchmaker English it gets even more difficult for me. When I try to read something from George Daniels sometime it takes me a day or two to understand the meaning of a sentence or page. It is all down to the fact that as him and you feel natural in this pond but I am a bit new to it and a bit of strange to have water in my lungs. Now I am not sure how a grandma sucks on eggs either. I am going to re-read your post probably a hundred time and going to process it slowly. What is the meaning of "small pecks"? Going slowly just a bit at the time? I subscribed.1 point

-

1 point

-

1 point

-

1 point

-

Hello everyone, I'm sharing my latest project, the restoration of a 1944 Waltham A-11 watch. I'm also designing a custom case to store it, as I intend to start a collection of Type A-11 watches not only from Waltham, but also from Elgin and Bulova. Hope you enjoy the video. Bye. .1 point

-

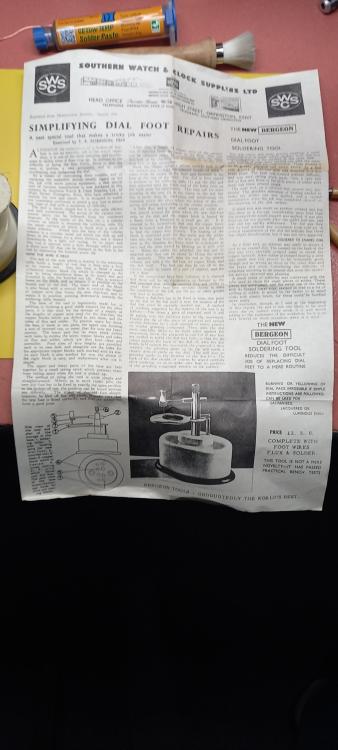

Eyup watch peeps, this is my first real restoration try with my dial foot soldering tool. This type is used with a micro blow torch and low melt soldering paste. Turned out rather well if i say so myself, as you can see from the pictures a piece of copper wire is fitted to the brass heat block at the top. The dial itself lays on a cloth pad, i added a few drops of water just to dampen it down to protect the dial. Marking up the dial foot's position is really important as the surrounding area needs to cleaned up with 400 emery paper to get a good weld, without marking you risk losing the foot's position. So just a small dot from a needle and a scratched in crosshair to sight you in with the foot. The copper wire is held on the dial's back surface by the spring loaded sliding post although you do need some finger pressure as well, as i found out when placing the solder the wire will come off its position. The soldering process is very quick, 30 seconds tops, the low melt bubbles up at 138 degrees and is pulled into the joint quickly, then a quick blast of compressed air helps to stop any heat transfer to the dial. Job done and feels well stuck. The tool was around £50 made by Bergeon, some nutter on ebay has one up at nearly £500. I did post one up last week on tools ebay has to offer, it went for £40, did anyone pay attention?1 point