Leaderboard

Popular Content

Showing content with the highest reputation on 04/08/25 in Posts

-

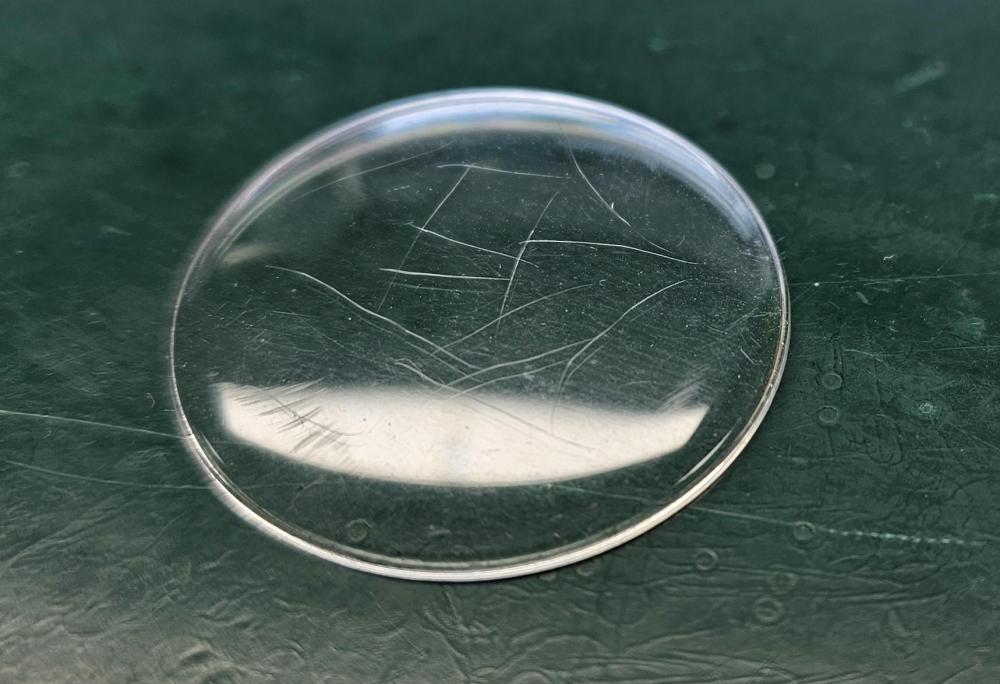

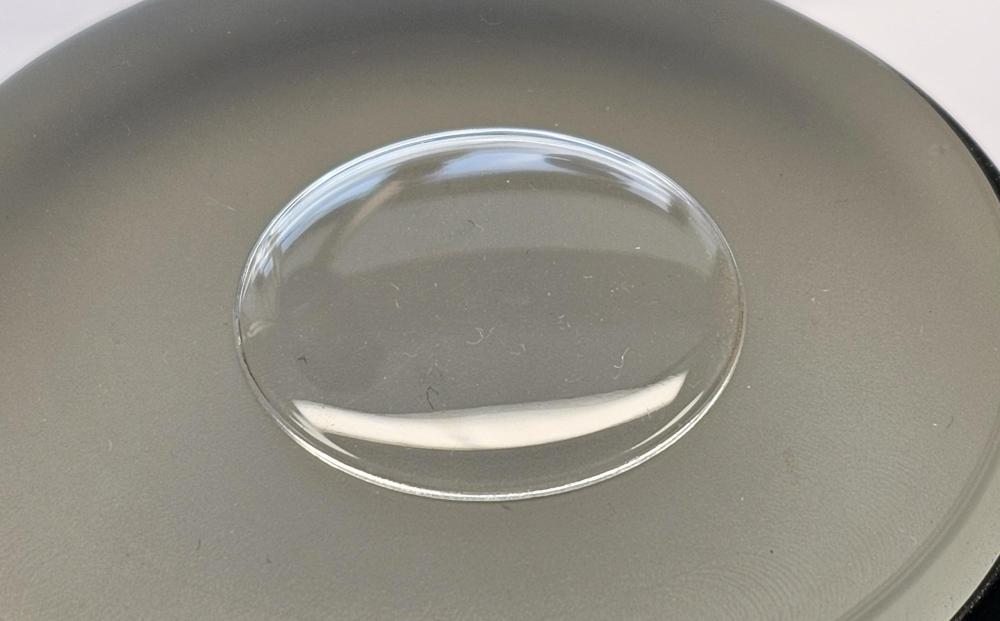

OK guys, This is a bold statement, but I think you all need to throw away your Polywatch! I've just scratched up an acrylic crystal with a blade, then gave it a good going over with 1200 grit wet and dry and finished it off with the Autosol acrylic polish by hand with a microfibre cloth. @RichardHarris123and @Neverenoughwatcheswere spot on suggesting using this stuff. The results are damn good as you can see from the before and after photos. Just in case some might think I put it on a watch cushion to make it look better7 points

-

The before and after photos I just posted were using this stuff, which is the Autosol acrylic polish https://www.infinitywax.com/products/autosol-acrylic-polish-75ml The regular Autosol metal polish, I find is too course4 points

-

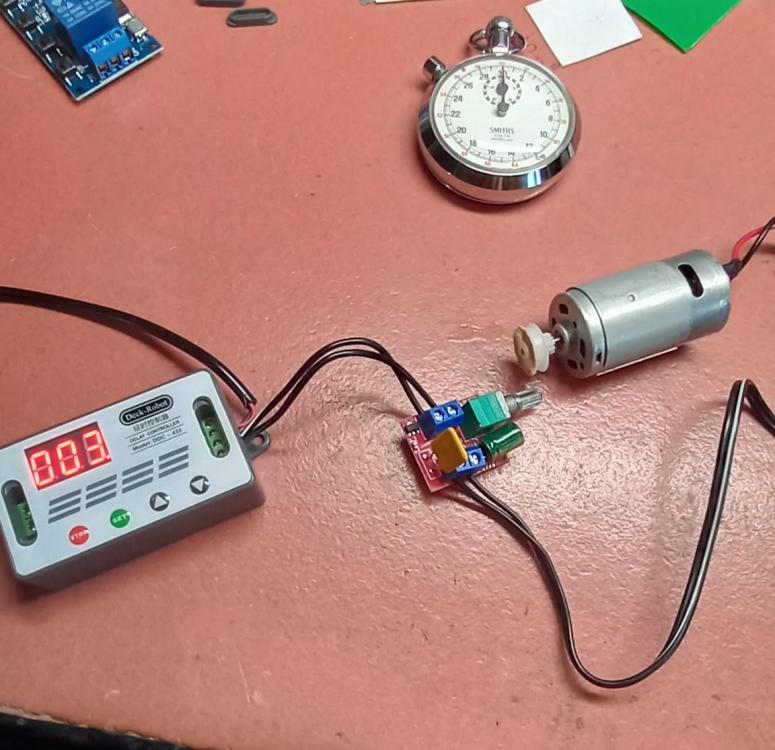

Aliexpress time delay switch for rotary cleaners, only one-way but fully programmable up to 999 minutes per on and off cycle and up to 999 repeat loops. A whopping £2.40 ! I even went to the the extravagance of throwing in a 50 pence voltage regulator . Beans and rice for me for the rest of this month.3 points

-

It's surprising how much you can improve a case's finish, with only a hand cloth polish and a small dab of autosol. I'm always wary of highly polished cases, I get suspicious of rectified damage. it's easy to over polish and lose sharp edges.3 points

-

3 points

-

Thank you one and all. I really appreciate your collective enthusiasm and experience. in the the end I decided not to second guess the more remote and improbable faults and trusted my own lack of skill and experience as the problem. So, forth wheel and escape wheel in together. That was fine. More patience and fiddlearsing about and… Problem solved! Much appreciated TonyG3 points

-

I think for the age of the watch and considering what it looked like previously I'd just leave it as is.3 points

-

One I just finished today, L. Audemars pocket minute repeater with chronograph. The case is in great shape, so I'm laying the destruction at the hands of the last watchmaker. I think they clamped it tightly in a movement holder and squeezed the hammers, but still kind of a mystery. Maybe the bare movement hit the floor? The damage: New arbors both hammers (both pivots gone on both- the plate pivots are like 0.60mm) New lift pin one hammer New bridge jewels both hammers New weight repeater escapement fork New banking pin for repeater escapement eccentric Repivot 4th wheel (3.70mm long) New staff I managed to get jewels in the original rub-in settings, so overall I doubt anyone down the line (except you guys) will ever know. Beautifully made watch.3 points

-

£0.88, I used to be able to get, 10 pints, fish and chips, and sexy Sarah, to do unspeakable thing's for that.2 points

-

Ill give a little update to this as well. The taper for a Moseley tailstock spindle is around 1.7 degrees. It took a lot of fiddling and testing with a dial indicator, but I got it set to accept some brass sockets.2 points

-

Here's a little update on this device. I have since purchased Archie Perkins book, The Modern Watchmakers Lathe and How to Use It, and also the Levin's book, Practical Benchwork for Horologists. They both demonstrate how this tool works, in great detail. I made a riser for this tool to bring it more on center with my lathe. The cutter that came with it is just a hair too wide, so I ground it down. Once that was done, I set the cutter in the center, adjusted one of the stops to be flush with the arm, then opened up the arm to accept the diameter of a small drill bit. And it works quite well! I unfortunately failed to get photos, but I'll get some tonight. I need to make an entirely new jewel setting for a pocket watch, so I'll document that for users here. I still have a bit of adjusting to do as far as setting the cutter height, and the angle of it is too shallow so I'll take that in a bit. Ill also need to make a few additional cutters for it, and they are unfortunately tapered to fit the spindle. I do wish there was a better system to prevent you from turning the lead screw the wrong way, accidentally widening the hole, but I'm sure Ill get used to it with time.2 points

-

Polywatch is £3.30 inc VAT from Cousins for 5ml excluding shipping. Autosol acrylic polish is £4.99 inc VAT excluding shipping for 75 ml. So, 75 ml of Polywatch works out as £49.50 (10 times more expensive) Polywatch is a lot thinner than Autosol as well, so it is also stamped on to begin with. I know Polywatch goes a long way, but the word 'shafted' springs to mind2 points

-

2 points

-

2 points

-

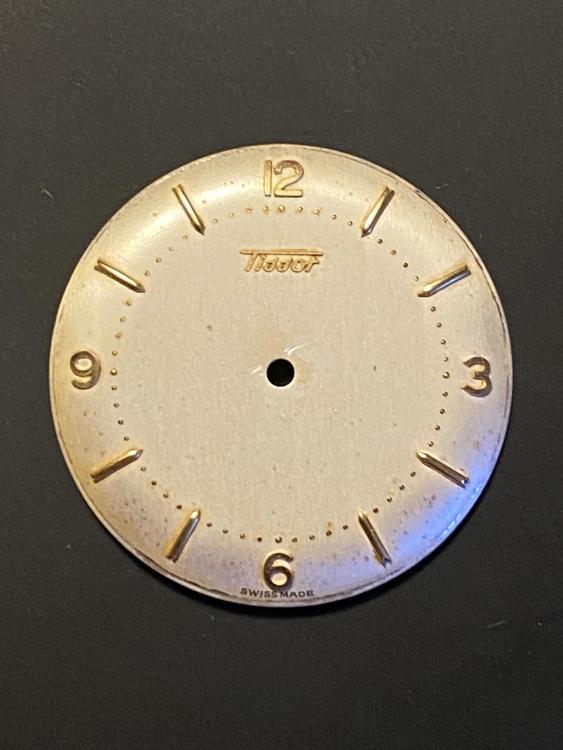

Typically with dials it's recommended not to do anything at all because typically they don't do well to anything especially if they're painted dials. If there are enameled dials like found in American pocket watches then they can go in water and all sorts of cleaning and will clean up quite nicely. Or some American pocket watches use engraved brass dials filled in with wax or something like they did with clock dials and then silvered. With fee is you can strip off the lacquer and dip them in one dip silver cleaning brightening solution. That actually works really well and then unfortunately you have to lacquer it again because with the silver exposed it will tarnish. Seeing as how you are able to clean up or dial the way you did you may build a try some of the liquid silver tarnish remover. But whatever you do you typically want to be careful as even if you think you know what you're doing bad things can still occur. Which would result in either finding a replacement dial or sending it out to be refinished after somebody on your part of the planet that does that kind of thing.2 points

-

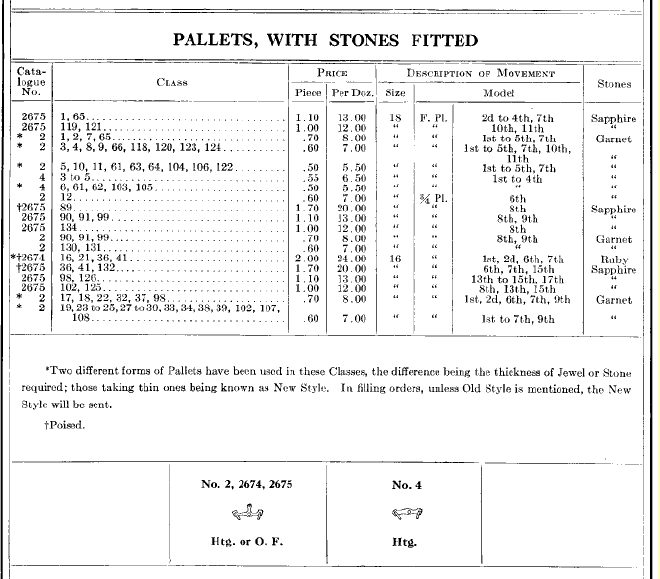

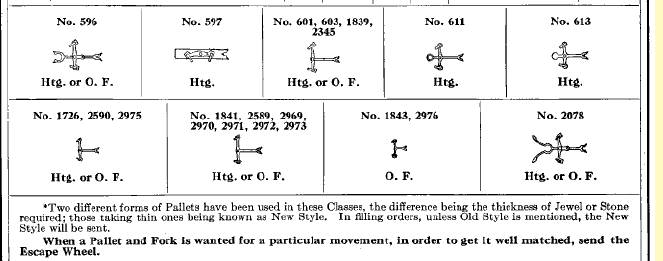

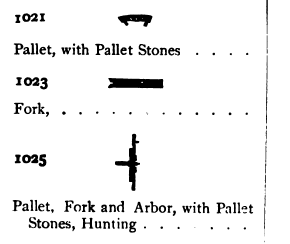

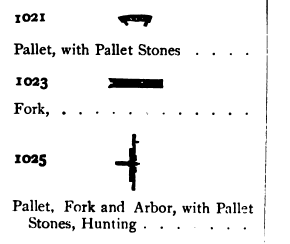

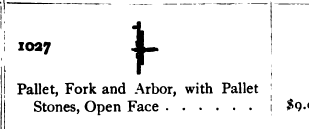

It's hard to help out when you get such a general description like this. Which is why I always ask for photographs model number is oh look we did get a number much much farther down. One of the problems with early American pocket watches will be lots of parts variations. Your pallet fork is a number four which on the parts list has an X indicating that it has variations. Then the parts book really sucks because it doesn't show the entire pallet fork and yes other than the modifications with file that does look like the right pallet fork. Oh and of minor confusion on the part book notice the reference to class? Sometime in the mid-20s Elgin change their entire parts system before this they used a class system. So in other words a 335 is equal to a class of 105. The pallet fork section actually covers several pages with lots and lots of drawings a pallet Forex. On the second page of the section we see another one of those forks were we can see a better example of the entire thing. Interesting description for a pallet fork the kindergarten design well I learn something new every day. Plus it could be worse like let's look what Waltham did with their kindergarten design pallet fork Yes this is one of the 18 size Waltham pocket watches notice how you get the pallet with stones and you get the separate fork? But for quantity a pallet forks there are two of them? That's because the open face in the hunting have the gears arranged in a different fashion and the pallet stones have to be on the right side. So even if you find a donor watch to steal a pallet fork from you may have to disassemble and reassemble it so the stones are in the right direction. Then I can't remember which company uses two screws to hold the assembly together and that allows you to adjust the depth of the pallet fork. If that wasn't enough things for somebody to screw around with like banking pins you can have more things to screw around with.2 points

-

Hello all. Going to Budapest next week only four nights, Monday to Friday. Looked at all the tourist stuff but any recommendations would be appreciated.1 point

-

Thanks, useful to know, I will buy some Autosol acrylic when my Polywatch runs out - which may be several years. Funny how people worry about a few £ over some polishing compound and yet are willing to pay £56 on a silicone cushion just because it says 'Bergeon'1 point

-

1 point

-

Unspeakable things ? Like gouging a mainplate to increase endshake and not removing a mainspring to fully service a watch. Why that harlot !!!1 point

-

This is an uncased version of a similar module, the wiring is a little different , not quite as simple. But it programs the same and works the same. At 88 pence I can afford an extra 4 pint milk pack to keep cuppas on the table. Now there is no excuse for anyone not to make a spinney thing cleaner with a little automation .1 point

-

1 point

-

I ordered the cheap one shown in my earlier post, I can do a review in a few weeks if there's interest.1 point

-

Yes I think you’re right. I gave it one more go but it seemed barely to make a difference so I think it’s time to restrain myself and stop! @AndyGSi @Klassiker - stopping while I’m ahead is definitely the way to here! Now I need to figure out what to do with the case. Most of the chrome has flaked off and is showing the base metal - brass I think. Polishing wheel and electroplating à la Nekkid Watchmaker needed! Maybe one day. Final result:1 point

-

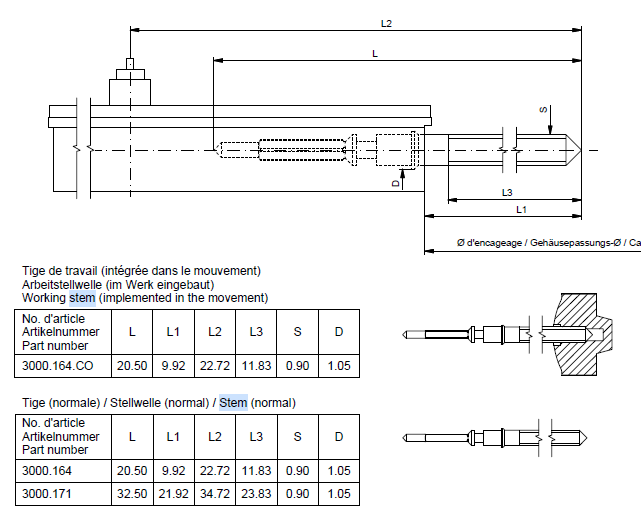

Not sure where you've got that stem part number from but the correct number is 3000.164 for 20mm long and 3000.171 for 32mm long. Also the TAP 10 is the old form of measurements so you'll be looking for a 0.9mm crown. Have a look here to give you an idea of what's available. https://www.cousinsuk.com/category/regular-including-japanese-style Edit Just had a look at your photos and think you'll be OK with the existing stem if you get a crown with a long tube.1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

Here there is another video from a Hungarian watchmaker: https://photos.app.goo.gl/4y1t7MmjcopZUHeM6 I hopefully will be able to record something similar soon. I am excited. Balance staff replacement one of the thing i must learn. Then the lathe.. both are very scary things.1 point

-

1 point

-

By the way they come up very rarely I was hunting one for the last two years and even the cosmetically and/or mechanically bad looking ones do sell around and above £300, a good one is about the double. There is one for sale at the moment on eBay and a tape holds it together for 400 euros. (I dont like to paste an eBay link into watchrepairtalk as the link wont work after the listing is closed.)1 point

-

1 point

-

1 point

-

Scanning is not an option. Shroud has utterly and completely disintegrated into little bits. I think I can 3D-print, altogether avoiding casting. Have both FDM and resin printers in-house. This is obviously a job for the resin-printer. An email is out to the local Seiko dealer. Not particularly high expectations on that one though. Being a 3D-print nerd I obviously had that in my mind, but - with the watch being a proper Seiko and not some homemade concoction, I would prefer OE spareparts. However the task of designing a replacement part of my own design was simply too exciting, so I've made a rough sketch that looks like this - for the moment it's a fitting-exercise: Either my email will get me an OE-part or my own design will end up fitting properly.1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

I have the extra fine, the medium, and 0.25 micron diamond powder. The medium works quite well. Ill try out some autosol as well1 point

-

1 point

-

So this is where I’m up to. Just using saliva and a piece of paper towel wrapped around a small plastic stick. It’s still not a thing of great beauty but better than it was! I’ll go over it again but it almost feels like all the staining is in the top layer of lacquer, so it might be interesting to try and remove that without destroying what’s underneath. Somehow .1 point

-

Well boys, it appears I have made a mistake! This appears to be the correct pallet fork! My experience with these older Elgin's, they always have an elegant pallet fork. This one appears to be from the factory this way, which is interesting considering its a 17 jewel movement. Hopefully I don't lose any reputation for this mistake. It just appeared very unlike Elgin to use such a pallet fork.1 point

-

1 point

-

1 point

-

As nothing apart from the Swiss Made appears to be painted, as you say I don't think you've got a lot to loose. I'd start with saliva on a cotton bud and go from their.1 point

-

1 point

-

I'm not 100% sure what you are saying. You made sure the train is free. How, if when you screw down the bridge and everything jams? If that is the case that when the 4th and escape wheel are not there you can screw down the bridge and you get the freedom of the train, then try only the escape wheel in place and fit the bridge. If this isn't the problem, then just fit the 4th wheel and try with the bridge. It's about finding out what works and slowly adding more wheels until you find the offending part. Try checking the endshake of every wheel as well1 point

-

No reason why a hairspring cant go through the machine. Just need to make sure its adequately isolated in the baskets. Follow up with a post-clean dip in hairspring cleaner before drying.1 point