Leaderboard

Popular Content

Showing content with the highest reputation on 04/09/25 in Posts

-

I had another paragraph but I took it out. Basically my interpretation of the above quote would be conceivably someday in the future will come to the group they will go through this discussion and they will reach the? The problem wasn't solved as we don't get an answer to how was solved at all. So somebody's going to be unhappy someday in the future because they don't know what the problem was. Watch repair is a continuous lifelong learning process. Were unfortunately along the way we all make mistakes and with time we make less mistakes. Unfortunately we still from time to time make mistakes. But with time they become fewer and far between its part of learning and for those of us helping on the group we would like to know what the problem was it will help us to help somebody else in the future.4 points

-

Here’s a tip for those of you who occasionally use a smoothing broach—for example, to smooth out the bearing for the barrel arbor in the barrel bridge. Mount the smoothing broach in a pin vise. It greatly increases efficiency, ease of use, and control. I was genuinely surprised by how much of a difference it made. So much so that I felt I had to share it.3 points

-

The real option is to use a little bigger screw (0.8) and cut the thread for it.3 points

-

Some might find this idea useful. My son owns a bar, which is handy. If you have lots of different cork sizes like me ( I don't drink ) you can usually find one thats a good tight fit inside the case. If not , find one that's close undersize and bang a wedge down the middle of the cork to expand it, like wedging a handle for something. I also use corks for sittings domed acrylics on when polishing them. Stick a sponge on the cork end and squeeze the crystal over it. Like so.3 points

-

Success. I just received the clock from across the pond where it was expertly repaired by forum member known as MikeEll. After I so disastrously mangled the gears by failing to release the mainspring tension, this one was a goner. With forum help I attempted to straighten out several gear teeth only completely to break off a tooth. Mike came to my aid and we have been working together for about two months. The clock is absolutely beautiful and will be passed down to my grandson as coming finally from his great, great, great uncle. But now I intend to keep it a lot longer than originally planned. Thank you so much Mike for your expert work and willingness to help me out. Pic attached. (I love this forum.)3 points

-

3D-print is always an iterative process. Especially when trying to fit a new gadget A to an existing thingamabob B. Dunno if I'll aim for OE look. Since last, some 5 protos have been done, fitting better each time. Once fit is in place, form will be addressed. Prototype-sequence up till now (right-to-left): Non-functional. Non-fit. Bad fit. Better fit. Almost-there fit. I'm now here (that's '5'): I'm getting there...3 points

-

@Neverenoughwatches & @HectorLooi My point was a Joke by being high, even at $57.46 it's expensive and no way is that -68%3 points

-

It's quite a lot of work to get it back to brass and replate with nickel. The finish you get on the nickel will be the brass finish you achieve - nickel does not fill any defects. So you need a polished finish with no defects. I plate with copper before nickel as it can be plated thick enough to fill pits and defects. But then I have to polish again before the nickel. You can do home plating quite cheaply, there are plenty of Youtube videos showing DIY nickel plating.3 points

-

As I understand it, the main reason for a copper strike is that copper plates better over most surfaces than nickel and provides better adhesion for the nickel. Not for showing defects, though it would do that. As the layer is very thin it doesn't require further work before further plating. If plating on well prepared brass, I don't think a copper strike would be worth the effort. I usually do a much thicker copper layer to fill defects. This does need refinishing back to shape. If doing this you may need to protect some parts such as threads, as too much copper build up can block them (as I know from experience ) You can grind the nickel away but it's hard work. I use a nickel removing solution and reverse electrolysis - takes a minute or two. I like the cork idea Rich. I have lots of corks around (as I do drink ) and will be doing that in future2 points

-

Ah - the Bulova 10BC just has two vertical pins, no boot. I just finished a project with that movement too. This is what you will find on most movements from the 1940's and older. On larger pocket watch movements with stout hairsprings, as long as the spring is perfectly formed it will usually land directly between the pins when installed. But on a small movement like the 10BC with a small regulator, the hairspring may land outside of the pins. It is easy to put in once the balance is mounted. Take your finest oiler (clean!) and just push down VERY gently on the hairspring right beside the regulator. As soon as the spring reaches the ends of the regulator pins it should jump in between them and land where expected. But you have to be really gentle with this or you will bend the spring out of flat. It is much more delicate on a small movement like yours. If the hairspring is not correctly formed, it may not jump in between the pins and if it does, it still may be incorrectly placed and not centered between them. It is of course best to place the spring between the pins at the moment you are installing the stud into the balance cock, but that isn't always as easy as it sounds.2 points

-

2 points

-

You forgot one of the forum's golden rules, " no question is silly " . A matter of repositioning dial feet.....I'd rather not. The day date disk stepping may not then line up with the date window of the new case. I wouldn't mess, like Richard said you might ruin a perfectly good watch. Lets look at an example of the alignments. The crown positions of the two cases are 3.8 ( old case ) and 3 ( new case ) , that's 15 degrees of case position difference. In order for the date window to line back up at 3 the dial needs to be re-positioned on the movement 15° clockwise, thats the first obstacle. Now looking at just the date disk alone, it's divided into 31 days , each date number and disk tooth is approximately 11.6 ° of rotation from it's neighbouring number. So each date position is also approx. 11.6° apart, since the new dial position is 15 ° from its original position and the date mech is set to that position..... the jumper can't be repositioned ! ... the date numbering will be approx 3.4° out of alignment with the date window.2 points

-

Haha. You mean you discovered it? Obviously you haven't been doing clocks. I made handles for some of the smaller ones and glued the broaches in.2 points

-

I don't know... Diving in too fast and spending thousands of dollars on name brand Swiss tools after watching YouTube (even the Bergeon mainspring winders ) is more of a Reddit thing!2 points

-

2 points

-

Thanks, useful to know, I will buy some Autosol acrylic when my Polywatch runs out - which may be several years. Funny how people worry about a few £ over some polishing compound and yet are willing to pay £56 on a silicone cushion just because it says 'Bergeon'2 points

-

1 point

-

That is likely the most vital information and tip in this thread. I had a horrible experience with my smoothing broaches before I realized that. Because we are so influenced by how ordinary screws work, we assume that (all?) smoothing broaches are constructed in the same way. So, yes, we need to turn them clockwise if and when they get stuck.1 point

-

1 point

-

It was my pleasure to help. I took plenty of pics while I was working on it, will post those a little later for anyone interested.1 point

-

I think you've figured it and the above post explains far better than I will, but crown either side of 4 works (3.8/4.2), but bang on 4 needs a new day and date wheel. Day wheel can be realigned on some, date is a different disc.1 point

-

Use cheap emery sticks, half-round and flat, starting at about 220 grit. Hold the case firm in a vice between wood or plasic, best are those that you can swivel to all positions. Frank N.B. To strip the chrome, put the case for few minutes into hydrochloric acid. If it is still there after 30 minutes, it is most probably nickel.1 point

-

It's called a copper strike and has a few different functions. Depending on what the base metal is, and it's condition, a copper strike can improve the top nickel plate adhesion and gives the base metal an overall better finish to start the nickel plating process. It's main reason is help visually check that the plating process is working ok, to find surface defects before the nickel plate is added. If something isn't right, the copper undercoat is easier to remove than the nickel. If the copper strike looks good and is adhering then all should be fine to carry on with the top nickel coating.1 point

-

On movements with overcoil hairsprings there won't be a "boot", just the two pins. The Bulova 10BC has an overcoil, as I would imagine a vintage Hamilton would. Most of the time the spring stays in; if it doesn't it's simple enough to get back in place, just double check the spring is flat and centered.1 point

-

You won't believe some of the things that I admit to, it would make your toes curl. So you can imagine the sort of things that I don't admit to1 point

-

1 point

-

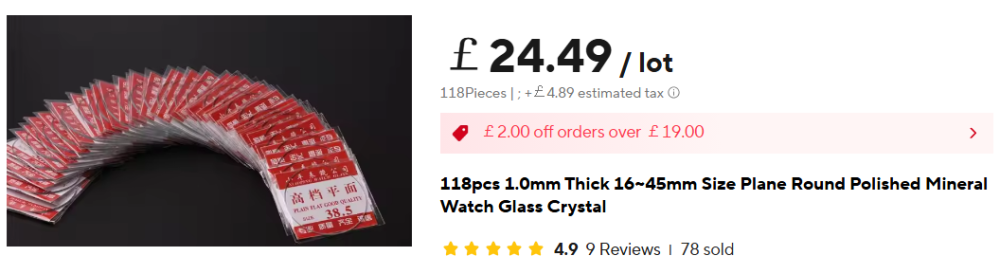

If you think the price is a joke, look at AliExpress. It's even cheaper. That's why I buy most of my stuff from AliExpress. Only stuff that I can't get from AliExpress then I'll check if Lazada has it.1 point

-

1 point

-

1 point

-

A little note to add if I may. This is really handy with larger broaches, if you notice, smoothing broaches have a directional cut to them. The ones I have draw the taper deeper into a hole when turning them anticlockwise. This cut can be quite aggressive, and a hole can grab tight hold of a broach. With the extra leverage from a pinvice it's easier to wind the broach back out. Lol, if I tell you all my secrets H you might never talk to me again1 point

-

Yes, you're right about that, but I'm still curious about what made the person who asked the question feel that the problem was solved—whether it was something technical, an oversight, a beginner's mistake, or something entirely different. And there's never anything to be ashamed of, even if it feels that way. We've all done or missed something that, once realized, felt almost unbelievably stupid (and we thought we'd never, over our dead body, admit it to anyone).1 point

-

I second what @mikepilk said about plating. Looks like you'll just have to cut that spring bar. Most of the time I'll just replace the acrylic unless it's a special or strange shape.1 point

-

Polywatch is approximately 0.66 GBP per ml (incl. tax), and Autosol Acrylic Polish is approximately 0.07 GBP per ml (incl. tax). So, Polywatch is almost ten times as expensive as Autosol Acrylic Polish. In either case, it is not much money, but if you use a lot, why not choose the cheaper and possibly better option!? Yes, branding is the single most important factor when making purchase decisions. It goes to show how rational we are as human beings1 point

-

I do actually use a silicone cushion, though a cheap (£12) Chinese version. It has it's uses - e.g. I'm just about to use it to support a watch while I fit the strap spring bars.1 point

-

Hey watch guys, I've recently got into a bad habit of trolling through Aliexpress' site. Random search inputs but mostly watchmaker's tools. Just the cheaper consumables stuff, I'm addicted lol. All those little bits and pieces that normally I would pay 3,4 and 5 x as much for to seller that bought their stock from the same place. 2 lots up to now and another on the way, this 3rd lot brings my total to only around 40 quid for 30 items. I'll wait for this lot to arrive then chuck it all on my bench and post some pictures. The majority comprises of drills, diamond burrs, degussit stones, sharpening stones, disks and brushes, pkus a few random hand tools and dc electronics. This kind of stuff is a fraction of what we'd pay in the uk. The bigger stuff isn't and sometimes even more. All free delivery ( evri if you can deal with their shite service ) and Ali must have a warehouse here in the UK as it arrived in 3 days. Don't know if anyone has noticed but Ali have 2 baskets , a main and a separate 10 item only basket that has a minimum item order for free shipping and added discounts for extra item orders. What's your ethics on buying all this usable crap from China and not paying ebay sellers the 400+ % mark up ?1 point

-

My name is Eduardo and i live in Spain. I love watches and love to repair things, so it was logical that I ended up here. I love to learn and love to share my knowledge, so here I am starting this exciting journey.1 point

-

I never bought one, but made a few. I use one only as far as de-casing a movement and removing hands and then to put back. The movement needs to be held stable while working on it in a holder and be able to pick it up and inspect it, through all angles. Get the bridging rig organised and set to work Richard. We'll catch up with you next year.1 point

-

1 point

-

Ah but this listing says in the description the seller was an overeager hobbyist who watched too much YouTube and gave up after a few months. Still waiting to see one in an old pro's vintage tools lot.1 point

-

My dad, a watchmaker from 1947 until 1992, never had one. I inherited everything. No case cushion.1 point

-

Yes I have. Because it says Bergeon on a few items, hence the ridiculous price. https://www.ebay.com/itm/176976592409?_skw=watchmaker+tool+lot&itmmeta=01JRBX9GSBYAD7KV6SCTP9R73D&hash=item2934a07e19:g:KYcAAOSwkFRn7a6D&itmprp=enc%3AAQAKAAAA8FkggFvd1GGDu0w3yXCmi1c331hc4QN0oVecY0BOs7i%2BFlHADIyC%2FsgWlL%2FfrjKaMP3YxllpUuxBl3cFqyYANNG4tP3cF6O5FQg1JQvYmTIHlVcj5%2BCCSDVE0foWVWPe1%2BukY9bC7YgnEtKcHM2HqHRyuVgQwrwxF4ElnYJ%2BA4I%2FH2%2BLz6OvvfOsM7JdiW8dE1LvTHjzCRpONG4g3QckwFy4fdMy%2BOtf6F7ieDXVwwTf9I0%2Fkr6mOkGVeUDpG4Jx1tU311qLNuS%2BeueQ%2FT04hCYvnkFBeExD9mo6FQyCGDkUs4RvHXO3xwZbx1X0caSM2A%3D%3D|tkp%3ABk9SR-KMpv3CZQ1 point

-

It occurrs to me that I don't think I have ever seen a casing cushion in any old-timer's vintage tool lot at auction. Every other tool imaginable, every type of movement holder, but never a cushion. Modern luxury?1 point

-

This tool provides a good base for securely resting the balance while lifting the hairspring collet with levers or installing it with one of the provided punches.1 point

-

Yes I think you’re right. I gave it one more go but it seemed barely to make a difference so I think it’s time to restrain myself and stop! @AndyGSi @Klassiker - stopping while I’m ahead is definitely the way to here! Now I need to figure out what to do with the case. Most of the chrome has flaked off and is showing the base metal - brass I think. Polishing wheel and electroplating à la Nekkid Watchmaker needed! Maybe one day. Final result:1 point

-

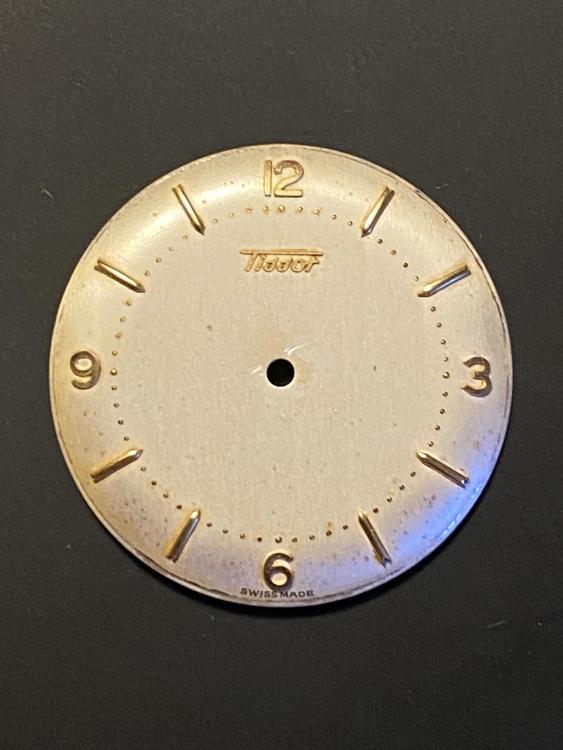

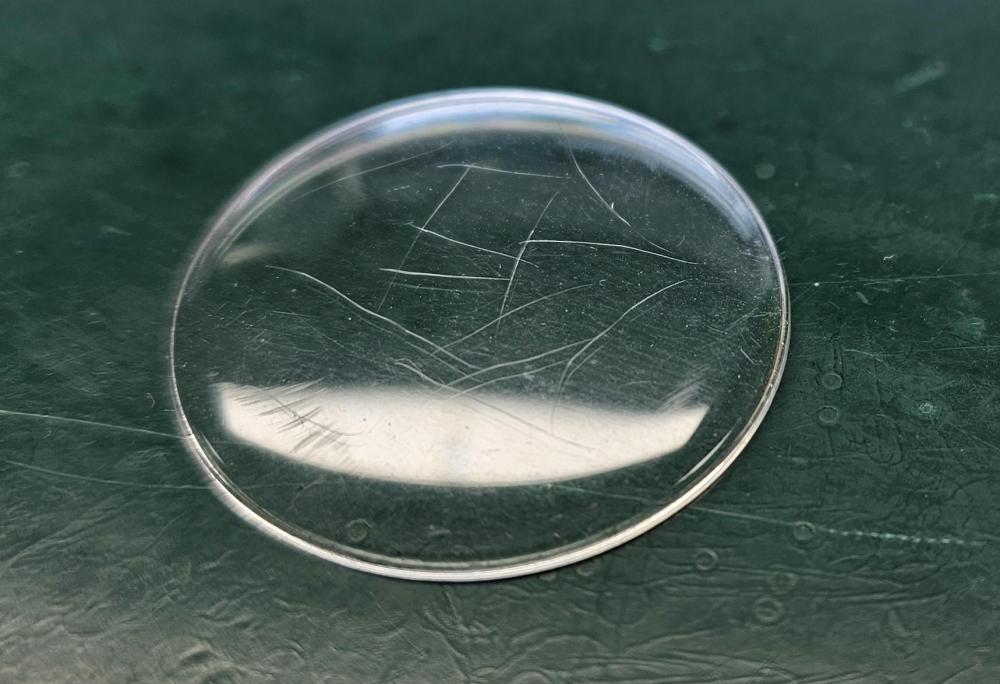

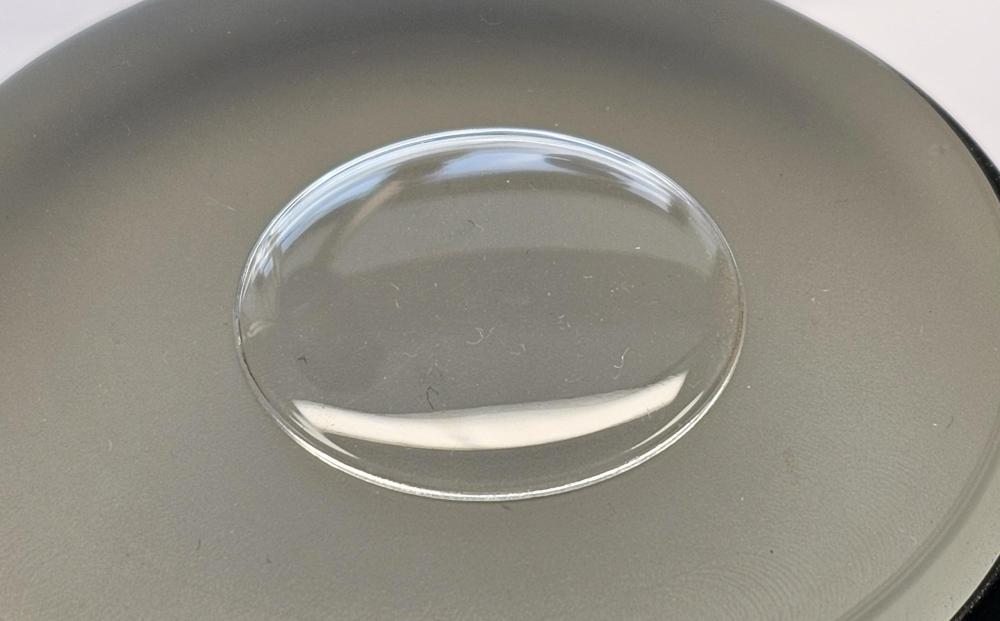

OK guys, This is a bold statement, but I think you all need to throw away your Polywatch! I've just scratched up an acrylic crystal with a blade, then gave it a good going over with 1200 grit wet and dry and finished it off with the Autosol acrylic polish by hand with a microfibre cloth. @RichardHarris123and @Neverenoughwatcheswere spot on suggesting using this stuff. The results are damn good as you can see from the before and after photos. Just in case some might think I put it on a watch cushion to make it look better1 point

-

If I were you I'd be very pleased with the result so far, and quit while I'm ahead.1 point

-

Polishing is as much an art as it is science. There are a lot of variables to consider. Like the type of material being polished, type of polishing agent used, type of polishing wheel, rotation speed, pressure applied. For a hard metal like stainless steel, I like to use a hard wheel like felt or even MDF particle board. It's less likely to round off a sharp edge. Actual polishing is very fast, usually taking less than a few minutes. Getting the surface prepped to take a polish, that's the killer.1 point

-

Some of those felt wheels are quite hard and take a bit of use before they wear and the Dialux covers all the surface. I use them with Dialux Green for scratches on stainless steel. For final polishing on all surfaces, I use the mini chamois wheels. They are excellent, robust, you can get them in to tight corners, and they will give a mirror finish.1 point

-

The felt wheel is not running true yet. As it wears down, it'll be ok. If you run at a low speed, the compound block will coat the surface better.1 point

-

1 point

.thumb.jpg.19a9c4ff164d78d516aa9f05a063752b.jpg)