Leaderboard

Popular Content

Showing content with the highest reputation on 04/10/25 in Posts

-

I really like this old tool. They are still made (Horia makes one), but this one has seen some serious use and still works great. It's a filing block; the center portion can be adjusted in height with the knob at the bottom, and the rim is glass hard. It lets you file small parts very flat and parallel quickly. The frame goes in a vise and allows it to pivot to further help keep the file flat. I don't use it often, and when I do I never use the frame, I just hold it in my hand.5 points

-

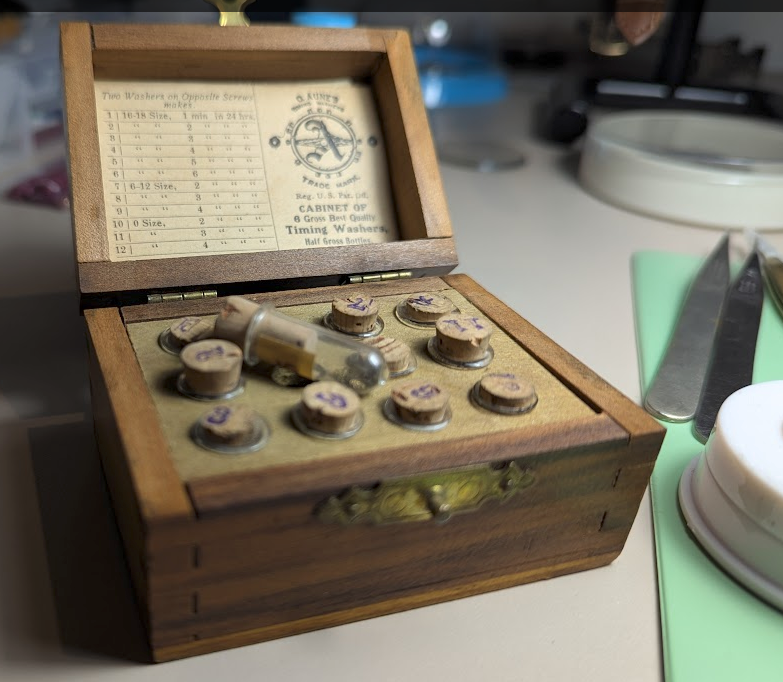

Last week I won an auction on some pocket watch timing washers for American watch sizes - I have a few sets already, but tend to buy them when I see a good set up for sale that I can get cheap because the sizes I'd use most are usually running low. I won these for just two dollars, and the one blurry photo didn't show the box. I am delighted that they came in this beautiful little wooden box, and how many watchmakers have owned this box over the past 80 or 100 years, keeping it together and in nice condition. What are your favorite antique tools or materials?3 points

-

3 points

-

3 points

-

I was trying to work out the age of this. Tbh I dont think it's really old. The card inside does say Cabinet . The finger jointing and simple round over moulding on the lid is quite a modern combination, also the light colour wood, looks like pine. Look at the streaks patterns on the base, looks like Parana pine, there were loads of that stuff around when I started work, it's like rocking horse shit now. Also the nailed clasp, I've seen that clasp on Bergeon boxes. If I had to guess it would be 60s or 70s era. No I take the pine back, looking inside the lid the grain is more visible. Looks like Sepele , which is a cheap mahogany. Still say 60s ish. I want to say homemade, but I can't make up my mind. I used to make lots of little jewellery boxes like this, I still have the finger jointing jig that I used. I either did a round over mould like this or a stepped ovolo. Mostly made from Mahogany and oak. If this was oak, you would know from the weight of it. Old stuff was nearly always oak, back in the day it was a solid almost indestructible and relatively cheap hardwood compared to the expensive, hard to work decorative woods like Elm and Walnut. What I really really love about this Michael, not so much the box because of my trade I've seen some beautifully made things over the years, but the glass tubes. Miniture test-tubes with that rim to hold them in place, I love em Here's my contribution of antique tools that I bought. I didn't make the 4 piece self assembly stand, but I thought it was quite a clever little idea for holding the arbor vices and screw lanterns. I thought this fitted in with your suggested idea of antique tools, it's probably one of the best things I've bought from Ebay and wasn't even an auction. I actually bought these plug gauges for just the boxes.....typical joiner3 points

-

Here’s a tip for those of you who occasionally use a smoothing broach—for example, to smooth out the bearing for the barrel arbor in the barrel bridge. Mount the smoothing broach in a pin vise. It greatly increases efficiency, ease of use, and control. I was genuinely surprised by how much of a difference it made. So much so that I felt I had to share it.2 points

-

I looked at several videos about disassembling Seiko 6139s, and from that it is not clear to me how I could remove the dial from the front. That's what I thought earlier, that I will have to cut the stem then. What is visible from the stem inside the movement looks so corroded that it will have to be replaced anyway. Thanks for all the advice! I will report my progress after I have acquired a cutting wire and after cutting the stem.2 points

-

The modern ones are graduated in 0.01mm on the knob, this one not. You learn quickly how much to turn by feel and can hit the thickness wanted- and yes, I use a vertical mic to check the thickness often.2 points

-

I think the oring is to press the movement ring down firmly to prevent any wiggle room. A wave washer might do a better job than the oring as the rubber will eventually deform.2 points

-

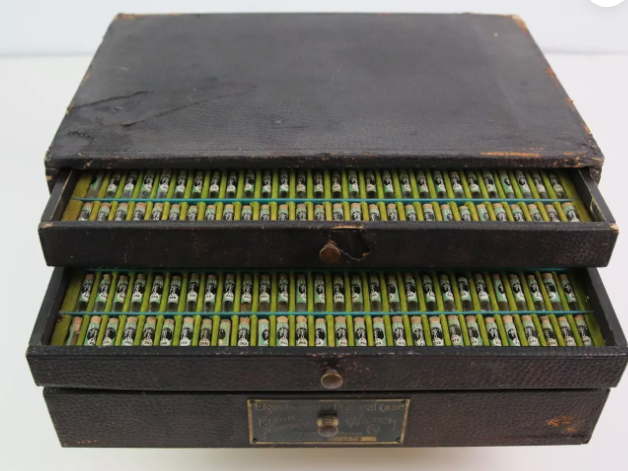

Plastic box at best. I'd expect an envelope of smaller envelopes or sleeves like my O-ring assortments. That's interesting, because to me the little test tubes are unremarkable. Material cabinets for American watch parts were always packaged as rows and rows of glass tubes. So I have various sets of little tubes already (including all my other timing washer kits). Example Elgin balance staffs cabinet: Your plug gauge box is really nice, Rich. Maybe I'll take it apart and look for the "Made in Taiwan" stamp in the bottom of the box.2 points

-

Pop into your nearest yuppy bar and ask for a handful. Chucking the case onto a cork gives you full access to all of it. You don't need a vice as it's so easy to hold the cork between your fingers. One of my friends was throwing away some kids playmats that were never used. They were made of a medium density foam and the pieces squeeze up enough to push a domed crystal onto and hold it in place. Again the addition of the cork means you can pick it up and work at eye level with it, if you need to inspect it at different angles under better lighting.2 points

-

But that was the time that quality and craftsmanship triumphed over profit. Today it would be a mass produced plastic box which would likley crack up in five years.2 points

-

If you did cut the stem, there still some stem sticking out of the winding crown, thats how you want the crown. Next remove balance+ cock assembly + fork, and throw the rest of the movement + the crown in Coca Cola for a 30 hrs soak. Coca Cola dissolves oil & grease. ( much better than WD40 oil ) Then start to disassemble before Coke dries out. If dial plate doesn't come out from back of the case, then it must have been loaded from the front, so bezel must be removed. Good luck Coca cola doesn't damage base metals, penetrate better than any oil base solution, dissolves oil/ grease. WD40 is water base and breaks rust bonds, not oil. Try coca cola , you be surprised how well it works.1 point

-

1 point

-

Longines have a service where you can send the serial number and they will tell you the date and name of the agent the watch was sent to. I'm not sure about the case, but I would expect "Longines" on the dial1 point

-

1 point

-

I see - I have some materials in tubes with rims and some without. But none of my other stuff is arranged vertically like this, always laying in some sort of tray. The insert feels like it is probably like thick balsa wood, glued in. It is not stained or finished in any way, supporting your theory. Which changes my thesis from "Wow old materials were so well packaged" (they still were) to "Wow someone loved these timing washers enough and kept them close enough at hand to make a custom box"1 point

-

1 point

-

I recently started using a smoothing broach on mainspring barrel arbor holes as well as the pivot holes of the plates. Then use a small bit of brasso on a pegwood to polish the walls of the holes until they shine. I think it increases the amplitude significantly but don't go crazy until there is excessive sideshake.1 point

-

Could try sticking the back down with double sided tape and pulling on the case.1 point

-

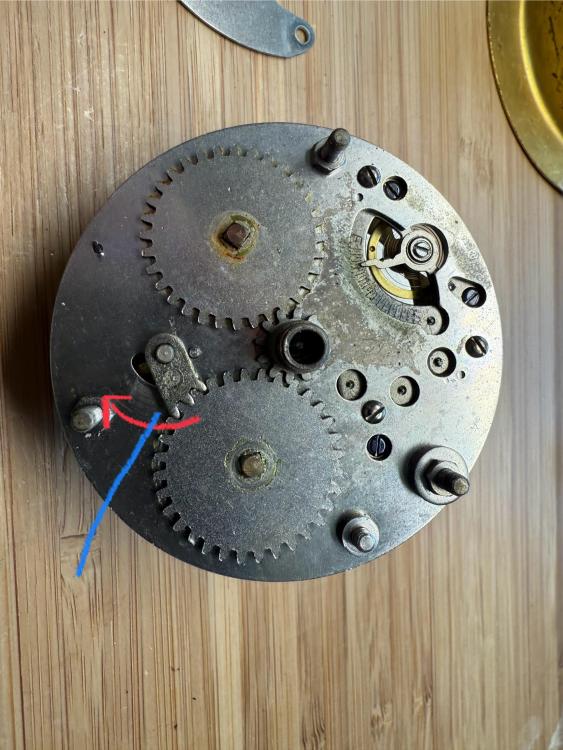

Of course. OH did comment what needed to be done using a stiff wire or similar. The following procedure needed to be done while the half plate was in position, as this is what prevents the click components falling apart and self-destructing the clock. Every clock with a mainspring will have some sort of ‘click’ arrangement to prevent the spring from simply unwinding as you wind it. On your clock there are two mainspring barrels allowing it to run for 8 days or so with relatively small mainsprings. The barrel ratchet wheels both engage with a shared intermediate gear attached to the winder. You can see the click in the picture (see red), which is held between the main plate and half-plate (removed in this pic), and is itself spring loaded from the other side of the main plate to keep its teeth engaged. To release the main spring power you need to securely hold the movement as you’ll need both hands free, or find a helper. Fit the winder and apply just enough wind to lift the click (see red arrow), then insert a slim screwdriver or stiff wire to hold the click away from the ratchet wheels (see blue line). This is the risky part where you mustn’t let the winder go. Gently unwind as much as you are able to do safely, probably only a single turn of the winder key if you are lucky, then remove the wire allowing the click to re-engage. Rinse and repeat until no more power remains. I discovered quite a few issues that needed to be sorted. Obviously the wheel had been destroyed when the click let go, but there were also damaged teeth on both barrels. I simply replaced these from a donor movement we were lucky to find. The center wheel arbour was bent, and most of the brass bushings had cracked and come loose, along with the cracked center wheel pinion/gear that had the crack in the earlier pictures. I think this is a design flaw in the clock, they really should have used steel for those parts. I used the replacement center wheel with good bushings, then for the pinion/gear I opened up the crack with a fine file and soft-soldered it up. Finally I closed up the central hole of the gear with a staking set to get a good friction fit on the shaft. The other problem was I think there was a missing dial washer, which allowed the hour wheel to lift out of position, preventing the hour hand from turning. I replaced that with a domed washer. All that and a thorough clean and service, and she’s up and running. I’ll upload more pictures when home at the weekend, the internet connection is crap in the hotel I’m in.1 point

-

There are a couple of sites where you can find the mainspring size. Emmy also shows a list of possible GR references. https://www.emmywatch.com/db/mainspring/1_5-0_18-450-15-man/unitas--285/ Ranfft confirms the original size as 1.50 x 15.0 x 0.18 x 450mm. https://ranfft.org/caliber/10192-Unitas-285 Here in the UK I buy from Cousins which lists the GR43071 being one of the alternatives also shown on Emmy. https://www.cousinsuk.com/category/filter/unitas-ut The only real difference is the thickness between the original 0.18mm and the GR 0.175mm which is best practice as you don't want to use a thicker (stronger) spring in an old movement.1 point

-

Welcome to the forum. Once the screws are removed the back should just lift off but I expect the gasket has turned to glue and that's what's holding it in place. You'll need to try and lever it from the top between the lugs but take it slowly and don't push anything too far in.1 point

-

Good pictures will help us to help you, close ups of the edges of the case and back please. Tom1 point

-

1 point

-

As I understand it, the main reason for a copper strike is that copper plates better over most surfaces than nickel and provides better adhesion for the nickel. Not for showing defects, though it would do that. As the layer is very thin it doesn't require further work before further plating. If plating on well prepared brass, I don't think a copper strike would be worth the effort. I usually do a much thicker copper layer to fill defects. This does need refinishing back to shape. If doing this you may need to protect some parts such as threads, as too much copper build up can block them (as I know from experience ) You can grind the nickel away but it's hard work. I use a nickel removing solution and reverse electrolysis - takes a minute or two. I like the cork idea Rich. I have lots of corks around (as I do drink ) and will be doing that in future1 point

-

Some might find this idea useful. My son owns a bar, which is handy. If you have lots of different cork sizes like me ( I don't drink ) you can usually find one thats a good tight fit inside the case. If not , find one that's close undersize and bang a wedge down the middle of the cork to expand it, like wedging a handle for something. I also use corks for sittings domed acrylics on when polishing them. Stick a sponge on the cork end and squeeze the crystal over it. Like so.1 point

-

It's called a copper strike and has a few different functions. Depending on what the base metal is, and it's condition, a copper strike can improve the top nickel plate adhesion and gives the base metal an overall better finish to start the nickel plating process. It's main reason is help visually check that the plating process is working ok, to find surface defects before the nickel plate is added. If something isn't right, the copper undercoat is easier to remove than the nickel. If the copper strike looks good and is adhering then all should be fine to carry on with the top nickel coating.1 point

-

A little note to add if I may. This is really handy with larger broaches, if you notice, smoothing broaches have a directional cut to them. The ones I have draw the taper deeper into a hole when turning them anticlockwise. This cut can be quite aggressive, and a hole can grab tight hold of a broach. With the extra leverage from a pinvice it's easier to wind the broach back out. Lol, if I tell you all my secrets H you might never talk to me again1 point

-

1 point

-

I do actually use a silicone cushion, though a cheap (£12) Chinese version. It has it's uses - e.g. I'm just about to use it to support a watch while I fit the strap spring bars.1 point

-

1 point

-

Thanks, useful to know, I will buy some Autosol acrylic when my Polywatch runs out - which may be several years. Funny how people worry about a few £ over some polishing compound and yet are willing to pay £56 on a silicone cushion just because it says 'Bergeon'1 point

-

If I were you I'd be very pleased with the result so far, and quit while I'm ahead.1 point

-

1 point

-

Normal WD40 is not a good penetrating oil; it's solvent based and thickens as that evaporates. (There is a WD40 branded penetrating oil, but that is very different to the original stuff). You need something to break down the rust. Evaporust or EDTA solution should do that - if you can remove enough WD40 residue with a solvent for it to get to the actual metal surface. Try and work with the watch on edge & angled towards the back, so any excess liquids run out rather than getting to the dial. dd small drops of whichever liquid to the setting lever hole at regular intervals until the rust has visibly reduced? (The EDTA based rust remover is five grams of EDTA powder per 100ml deionised water, then a trace of citric acid to bring it nearer neutral ph, and a few drops of washing up liquid/dish soap to help it get through any traces of oil. It works extremely well, with next to no effect on good metal).1 point