Leaderboard

Popular Content

Showing content with the highest reputation on 04/12/25 in Posts

-

As a retired dentist, I've drilled into a lot of stuff, including elastomeric substances. I had drills that turn as fast as 400,000 rpm and as slow as 1 rpm. Rubbers don't drill very well. They tend to distort under pressure and the hole will end up... not very nice. Watch this video first. Rubber is better cut with a blade than drilled with a twist drill or abrasive like a diamond drill. In the above video, a brass rod was used but your case, I think a large bore stainless steel hypodermic needle would work better. Maybe a 1.5mm needle. Cut off the sharp tip and file the inside surface of the tube until a sharp, cutting edge is obtained. Then mount the needle in pin vise and bore the rubber by hand, constantly checking that the bore hasn't drifted. You might need several straps as guinea pigs before succeeding. Hope this helps. And please treat everyone with respect and dignity. Shalom.6 points

-

Update: The dimensions of the original grinding disc: Hole diameter: 4mm Outside diameter: 24mm Thickness ~ 0.49 mm I have received 3 discs advertised on eBay as Molfres disks but they are not original just borrowed from a rotary set or ordered from aliexpress (I can see that the hole is drilled by somebody not in the factory), also they are thicker than the original about ~0.65 mm which does matter unless you cut trough the retaining plate with the thicker disk. I went out to the garage and I checked two of my rotary sets bought from Lidl - brand name: Parkside and found a red set with ~ 0.65 thickness and a black set with ~ 0.52 mm thickness. Both sets have smaller hole diameter than the required 4mm so I drilled a 4 mm hole into a black one. From left to right: eBay ~ 0.65mm, original (broken) ~0.49mm, red set from rotary tool (identical to the one got from eBay) ~0.65mm, black set from rotary tool ~0.52mm. I simply drilled a 4mm hole with my bench drill into one of the black ones installed it and went for the first step of my first attempt of balance staff replacement. The black disk installed: So this FEF 190 was in my cabinet and was waiting for me as this movement is the Holy Grail of my 100 challenge, it cannot be complete without a balance staff replacement. I quote from the manual: "The balance staff will be sufficiently ground when its projecting portion measures 0.02-0.03 mm. If it is not the case adjust the retaining plate to the correct position." As you can see on the pics I went a bit too deep the balance wheel should not be touched. The grinding operation can be done in matter of seconds, however as a new disk was installed i adjusted the retaining plate a number of times and turned the adjusting screw too much at the end. I used the riveting tool came with the grinding tool to drive the staff out of the balance, unfortunately the smallest one is broken.3 points

-

It make no sense for it to have such a large diameter screw-on back and have the movement come out front ways. I'm of the opinion that this ring sits to a lip on the case inner and the clamps pull the movement back to its position. The clamps are holding the ring, pulling the ring.....you are trying to take the ring, the movement and the dial all together....it's probably jamming .3 points

-

Firstly i think you need calm down, and secondly you need to understand that Andy is trying to help you. A picture tells a thousand words, supplying us with a photo explains more than you can tell and is standard practice. I can't ever remember anyone arguing over it.3 points

-

2 points

-

Yes we want to see pictures. Anything that's a interesting repair we want to see that also we are visually oriented on this group. The problem is the original posting person has a very clear idea of exactly what they're doing exactly what the problem is and totally cannot comprehend at all why we would question anything at all related to the question. So the concept that we might want to see the actual watch is beyond their comprehension even though it is a watch repair discussion group and we always want to see the watch we like seeing pictures especially if their watches and clocks. Even better if the watches and clocks are naked as I really like seeing the mechanisms of clocks and watches.2 points

-

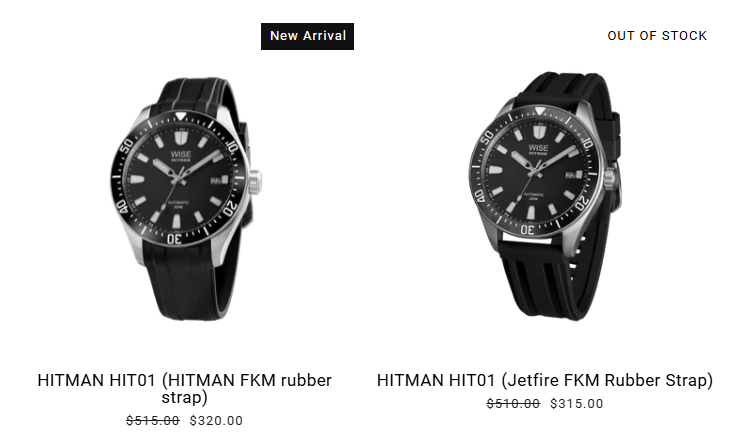

It wasn't clear to me on the first read if he was even using a curved end strap, maybe I should have read it more throughly but never expected that response. I did go afterwards and look at the offending watch and noticed how far the spring bar is from the case. I've had similar issues in the past and on most occasion found a strap that worked. On the occasions that I couldn't I used a heated syringe needle in a drill press to melt a new hole through the strap and then used a spring bar tube to fill the old hole. The thing I find strange is to pay $300+ for a watch and then say the strap is cheap which I think says a lot about the brand. My pet hate about these micro brands is how they always show inflated prices with large discounts to make people think they're getting a bargain.2 points

-

This is like how long is a piece of string. Without pictures how can we help you.2 points

-

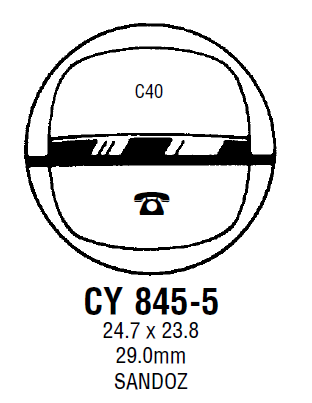

Got it! I put a tiny amount of evaporust around the seal ring using a thin wire and left it ten minutes or so. I could see it wicking in to the gap in places, so went around it with micro swabs - and it pulled a load of crud out. The ring then moved quite easily and could lift it out by prying alternate sides. The crystal is weirder than I thought - round inside, with a pressure ring as well!2 points

-

The docs I promised: https://drive.google.com/drive/folders/1MTQV60zWhV5h0SP5OdnusZZx5E24HhTs?usp=drive_link2 points

-

2 points

-

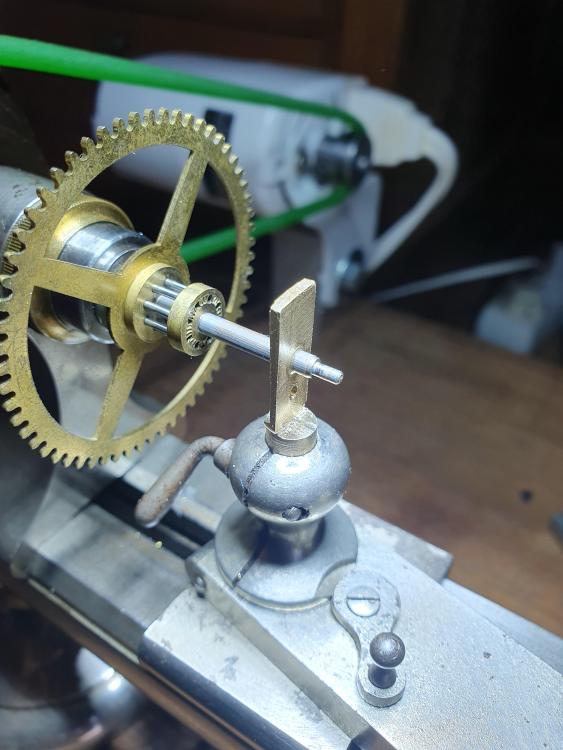

I posted about this on NAWCC but thought I would give the clock folks over something to see. This clock came in a beautiful marble case, but the movement is a cheesy open-spring pin-lever design. I cleaned it (the efficient way), and it would not run at all. I realized that the spring was giving almost no power to the train. I was sure it was a weak mainspring. Last year, I donated to the local watch and clock museum by buying everything that came up for auction at the local guild meeting. I dropped $450 for a good cause. Part of the haul was a bag of mainsprings for clocks. LOL...what will I ever do with them. Today, I fished out a mongo spring that would fit in this clock. The balance wheel took off like a rocket. I had to collect it in the yard next door . Well, I decided it was too strong, so I dug through the bag again and found something more appropriate. The clock is running and keeping time so far.2 points

-

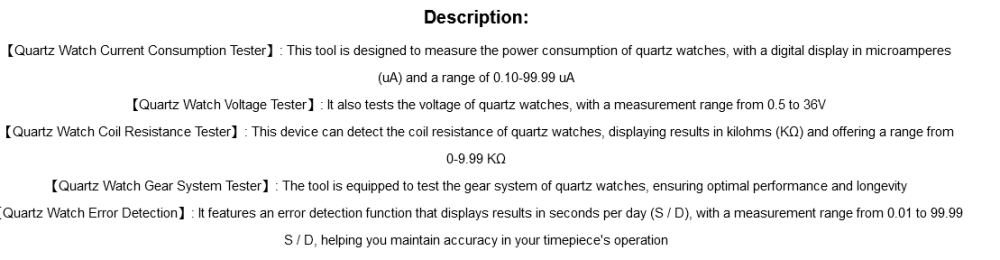

I noticed now there is a new quartz testing devices out looks interesting https://www.aliexpress.us/item/3256808087625641.html2 points

-

A fellow human being would realise, OK, I'm new here, asking more experienced members for help. Maybe it would be a good idea to provide them what they are asking for, so that they can understand the problem better. After all's said and done, you might be disappointed with the help we can offer, but don't lash out because the first answer you get isn't the easy solution you were expecting.2 points

-

I suggest if you don't like a simple response from someone trying to offer help then you go elsewhere.2 points

-

I definitely haven’t drilled a hole in a strap of any kind before and doubt it can be done, these are made during the moulding process. people are asking for photos so they can see what you are dealing with and if they can figure out a way to help you. you have been treated politely and with respect, unlike your response here. I suggest you take a deep breath and try to moderate your frustration talking to us here. regards Tom2 points

-

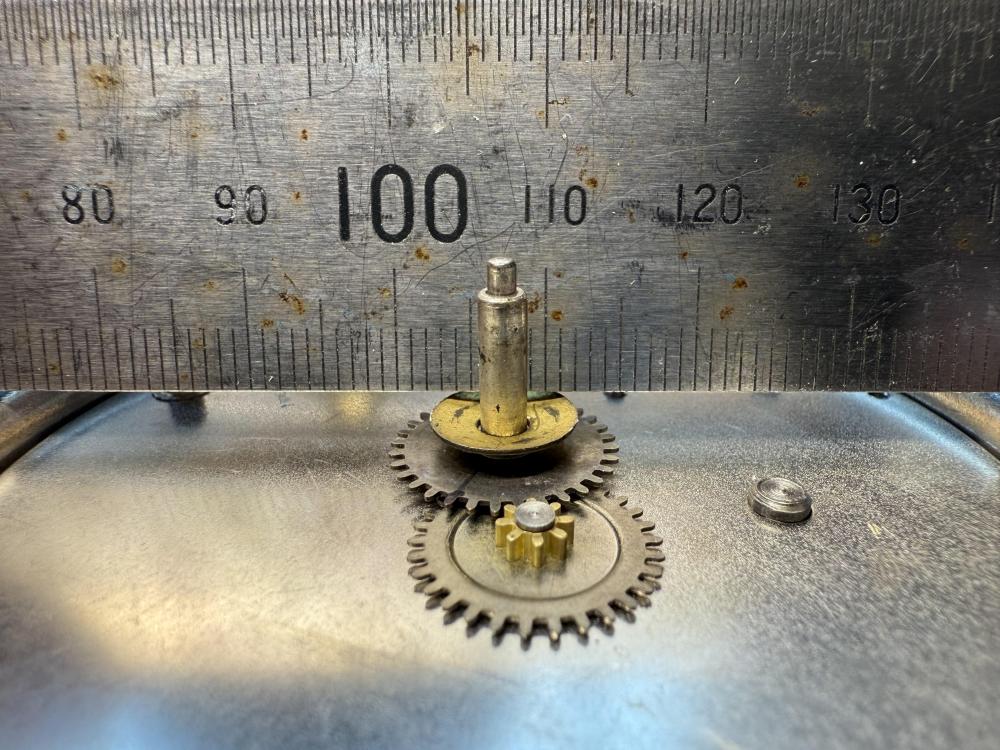

A few more pics…. The steel rule shows the position of the dial when fitted to the clock case. You can see the dial washer I’ve added. Without that you can see how the hour wheel could move excessively allowing its teeth to disengage. That’s one of the reasons the hour hand wouldn’t turn. The cracked gear from the minute wheel, opened up with a file and soldered… the central bore was closed up a little with a staking set to give it a good friction fit. Stripped, ready to clean.1 point

-

Not sure what you mean about the shape being different, do you mean the new one is an S with integrated bridle, can you post photos.1 point

-

1 point

-

1 point

-

It was so easy in my time I would send the case away to one of my suppliers and get it back in a few days with a new glass. These days this country is bloody useless.1 point

-

Normally it does, but it doesn't look like the movement would fit through the front. Had a quick Google and found a few Sandoz with that movement and similar screws, but the movement rings had cut-outs so they could be grabbed. I wonder if that movement ring has been fitted inverted?1 point

-

1 point

-

1 point

-

1 point

-

The listing doesn't say a great deal but would be interested to know more about it.1 point

-

Lets start over, with better co-operation please. It's an unusual question, help us to help you. Our needs are small, just oblige/humor us with a picture. Kind of like a long hole punch.1 point

-

I have the guard and a large assortment of springs. I'm sure I can find one that works. Thanks for your help.1 point

-

1 point

-

No! Naptha is not paint thinner! Naptha is lighter fuel, like Ronsonol or Zippo. It's a good degreaser while being relatively safe on plastics. Paint thinner is xylene. A strong solvent that can damage many types of plastics and finishes.1 point

-

This guy can do anything. Prepare to pay. No No, we don't want to date you. But, thanks Grok has your answer. Should have asked him first. Modifying a rubber watch strap to fit your Wise Hitman snugly without spring bars is doable, but it requires precision to avoid ruining the strap. Since the replacement strap fits well without spring bars but leaves a gap with them, punching a new hole closer to the watch case sounds like a solid plan. Here’s how to approach it, addressing your ideas and concerns: Freezing the strap: Freezing can make rubber slightly more rigid, which might help stabilize it for punching or drilling, but it’s not strictly necessary and could make the material brittle if overdone. If you try this, wrap the strap in a cloth, place it in a sealed bag, and freeze for 30–60 minutes. Let it warm up slightly before working to avoid cracking. Drilling with a vise and 1mm bit: Drilling can work, but it’s overkill and risky for a rubber strap. A 1mm drill bit might tear the material or create an uneven hole, especially if the strap is thick. Holding it in a vise could also deform the rubber unless you pad it carefully. I’d avoid this unless you’re confident in your setup and have a steady hand. Heated metal rod: This method—using a heated rod to melt a hole—can work for rubber but is messy and hard to control. It risks burning the strap, leaving jagged edges, or releasing unpleasant fumes. Finding a rod (like a thin nail or wire) isn’t the issue; the technique is just less precise than punching. If you go this route, heat a clean metal rod over a flame until red-hot, work in a ventilated area, and practice on scrap rubber first. But I don’t recommend it here. Best approach—using a leather punch or watch strap punch: The cleanest, most reliable way to add a hole is with a dedicated tool designed for straps, like a handheld leather punch or a watch strap hole punch. These are inexpensive (around $10–20 online), and they create smooth, professional-looking holes without tearing. Here’s a step-by-step: Mark the spot: Put the strap on the watch without spring bars, position it exactly where it hugs the case, and mark where the new hole should go with a fine-tip permanent marker or a pin. Double-check the alignment to ensure it’s centered and will pull the strap snugly against the lugs. Stabilize the strap: Place the strap on a firm, flat surface like a cutting board or a block of wood. If it’s thick, you can sandwich it between two pieces of scrap leather or cardboard to keep it steady, but don’t clamp it too tightly to avoid deforming the rubber. Punch the hole: Use a 1.5mm or 2mm punch (match the size of the existing spring bar holes). Press the punch straight down with steady pressure, twisting slightly if needed. A quality punch will cut through thick rubber cleanly. If the strap is frozen, it might punch more easily, but room temperature usually works fine. Test and clean: Check the hole’s fit with the spring bar. If it’s slightly off, you can carefully widen it with the punch. Clean any debris with a damp cloth, and test the strap on the watch to confirm it sits flush with no gap. Why this works: A punch is designed for materials like leather and rubber, giving you control and a clean result. It’s safer than drilling (no tearing) and cleaner than a heated rod (no burning). You can find these tools on sites like Amazon, eBay, or watch-specific retailers like Esslinger or Strapcode. Alternative: If punching feels daunting or you don’t want to buy a tool, take the strap to a watchmaker or cobbler. They can punch a precise hole for a few bucks, saving you the hassle. Since you’ve already got toothpicks shimming the spring bars, you know the fit is close—getting that hole right should eliminate the gap and flipping issue. Final tip: If the strap still doesn’t feel right after this, consider a higher-quality rubber strap from a reputable brand like Everest or RubberB. Some straps are just poorly designed for certain lug shapes, and the Hitman’s case might be picky. But punching a new hole should do the trick for now. Let me know if you need help finding a punch or sourcing a strap!1 point

-

No, I have never drilled a hole for spring bars through a rubber strap before. There...done.1 point

-

So you didn't find this then? http://www.hamiltonchronicles.com/2018/02/there-are-66-dateline-models-in.html Edit And this from the same site. http://www.hamiltonchronicles.com/2017/02/1966-mystery-watch.html Also not sure what you mean about the dial as every other A-279 I've seen has the same dial?1 point

-

1 point

-

Unless of historical importance or very expensive, I'm in favour of Upcycling. Furniture and watches included.1 point

-

Not sacrilegious at all. Repurposing redundant objects I always consider a good thing , somthing that may well have been put in the tip has another useful life. May I suggest maintaining the horological theme use it for displaying your watch collection . Somewhat fitting for the old clock case.1 point

-

Being a joiner , I shudder at some of the things people do to old furniture. An example my sister wants my french polished Elm Ercol table and chairs that was bought by my parents when I was born....and paint it !!!. Saying that re-purposing can bring an unused unwanted piece back up life. What you've done Andy looks great . It depends entirely what you are covering over, once done there's no going back.1 point

-

LRxxx batteries should never be used in watches. They are alkaline batteries and very prone to leakage.1 point

-

1 point

-

1 point

-

£0.88, I used to be able to get, 10 pints, fish and chips, and sexy Sarah, to do unspeakable thing's for that.1 point

-

If I were you I'd be very pleased with the result so far, and quit while I'm ahead.1 point

-

OK, today I visited a friend who is watchmaker and asked him if he has useless old sapphire crystal. He took out one from an old Seiko Kinetic for parts and gave it to me. I came home and started work. The first I did was to break the crystal with the hope some small piece will have suitable shape to work on. For my surprise, appears there is thin (0.35mm) sapphire layer on top of a thick glass piece. I first was disappointed, as the stone I need is with diam 0.65mm (and then ground to half to obtain D cross-section) but then figured that it may be actually better for me. Realized that I can use one of the flat and polished faces as locking face of the jewel and thus there is still enough meat in thickness of the sapphire. So, I ground small rectangle piece and glued it with shellac on the side of a 0.6mm steel plate, then filed it round and lapped it to form the 'back' of the stone. I think the stone is good enough and will do the job it is meant for. I cleaned all the parts of the movement as there was gummed oil everywhere. The spring is very strong and it was challenge to get it wound while holding the barrel and collect it in the winder barrel to extract it. It left for tomorrow to test everything1 point

-

This came as a 'NOS" watch, which the case is. On the other hand, the ETA 2789-1 on the inside was anything but. The movement looked like it had been sitting in pieces in a drawer banging about for a few decades before being reassembled. It runs fine, just a lot of wear and tear on the parts. This is the "youngest" watch I've serviced (1980's?) and the first watch I serviced that had both a quickset day and date, which sure is a joy to use. The instant change day/date is pretty cool too. I do love the look!1 point

-

Do you need a photo to tell me if you have ever drilled a hole for spring bars through a rubber strap before? I don't understand why everything has to become a fight. I'm asking questions that do not require photos. If I did provide photos, I don't know what information they would provide you with. I cannot provide a photo that illustrates this issue properly. The strap is a normal strap that fits most watches. It seems this watch, the name of which I've already provided, does not have the same depth on its spring bar lugs as is typical. With the strap on, there is a gap between it and the watch. Do you want to see that gap? I can show you a photo of that gap - but what would that prove? I can show you a photo of the strap off the watch - but I am not sure what that would prove. It's a standard flared strap. It's going to look like any number of straps look. I can show you where I would drill the hole - but you have not asked for that photo. "Give me photos" is not clear enough instructions. I've explained to you what is not working. I can go take 20 photos, but you're going to need to explain what you are looking for. This is a specific issue regarding millimeter discrepancies. And none of the questions I've asked - which I outlined in my last post - require photographic evidence. Simple - have you drilled a hole in a strap before, do you recommend any business to drill spring bar holes into the lugs, and is there a strap measurement system I'm not aware of for straps that are not the standard size? I can provide photos, I can provide measurements, I can break out the calipers - but I need better direction that ignoring everything I write and saying "send photos" like a dating site. Treat me like a fellow human being. That's all I ask.0 points