Leaderboard

Popular Content

Showing content with the highest reputation on 04/13/25 in all areas

-

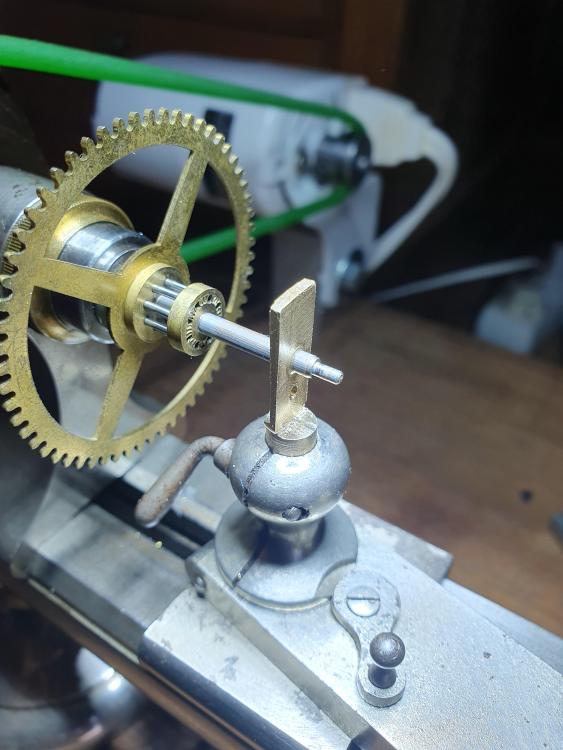

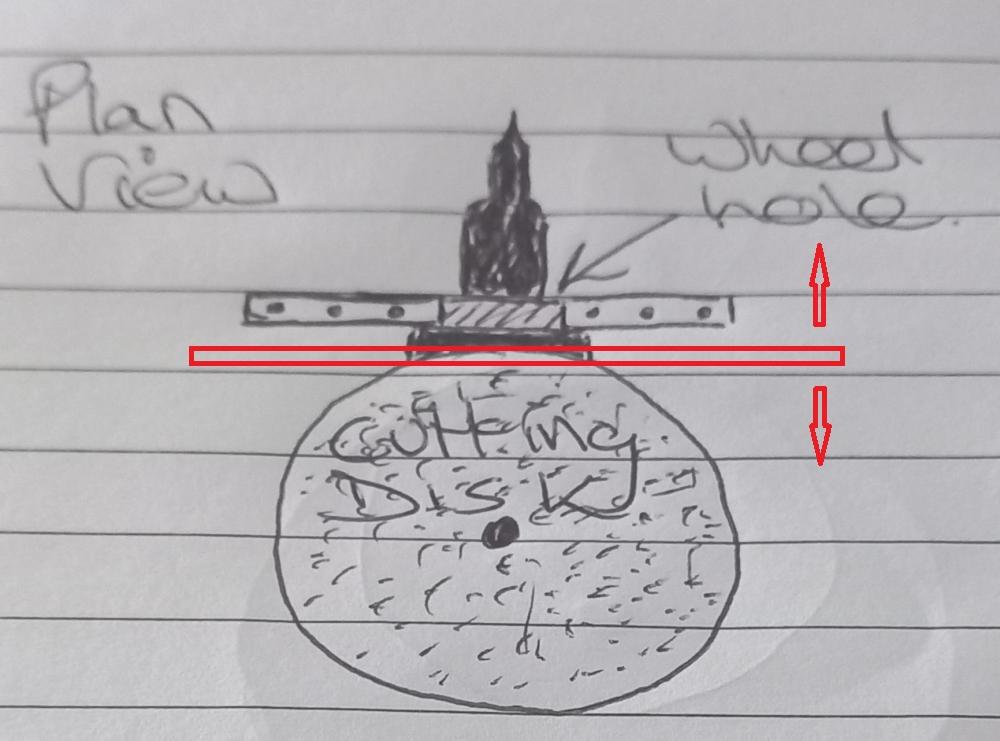

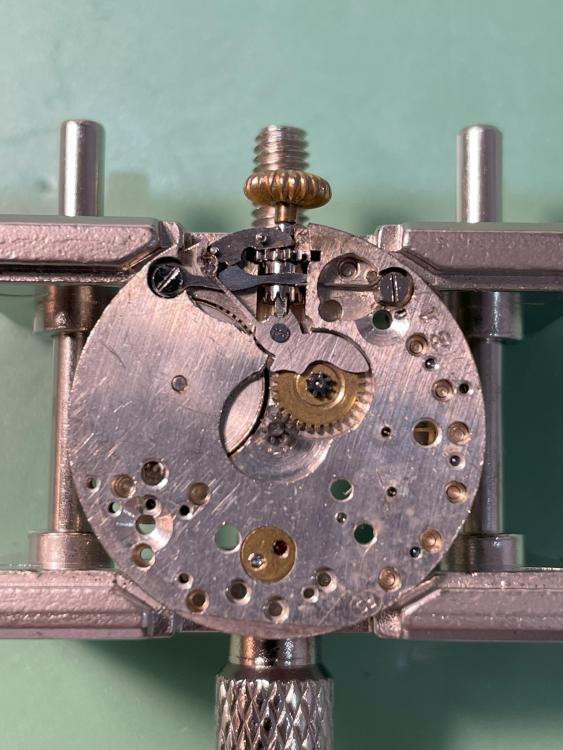

Maybe pics are better to explain, but if you read the manual I scanned above it becomes all clear. Its not a lengthy text as you only need to read the English part. You grind off the entire length of the balance staff till the arms by gently pressing it to the rotating disk while slowly turning the collet, to adjust the machine you move the retaining plate closer or further away from the disk. As the disk wears out you slowly need to move the retaining plate towards the disk by the means of turning the adjusting screw. The machine is correctly set I quote again: "The balance staff will be sufficiently ground when its projecting portion measures 0.02-0.03 mm. If it is not the case adjust the retaining plate to the correct position." This 0.02-0.03 mm wafer can be ignored / easily removed. I went too close with my final adjustment and marked the wheel but it should not happen cannot happen if the machine is correctly set.3 points

-

Can you do a little drawing of how the disk cuts across the staff please.2 points

-

How about a thick nato strap, any gap would be less obvious, as the wrist wouldn't be visible.2 points

-

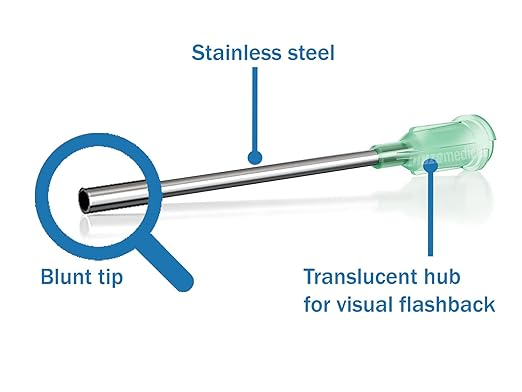

This is the type you need in either 15Gauge or 16Gauge which should be 1.6mm O/D so you can use a 1.5mm Spring Bar. You need to sharpen the tip slightly and I heated with a mini lighter blowtorch. I think there are better options from the strap you're starting with but I'm out most of the day so will see what other people suggest. This was solved as mentioned above by using a spring bar tube to fill the existing hole. Edit Just found you can get 16Gauge Hypodermics which would possibly go through better. And body piercing ones maybe even better.2 points

-

@Xonax thank you for posting photos. They were well taken and helped us to understand the problem more easily. We have never seen such long lugs in modern watches and would have had a hard time visualizing what you put in words. Many of us in the watch repair circle are a bit dyslexic. So pictures are really a help.2 points

-

Caseback I am like you I like making something to repair something especially if the tool I make makes life easier & even better if it’s available commercially as it saves me money. Dell2 points

-

The problem is everybody approaches problem solving differently. While it seems crystal clear to you because you're holding the watch in your hand and you can see the problem. Unfortunately everybody in the world is different for some of us one picture's worth 1000 words and Once we look at the picture we can grasp the problem. Actually that's clever marketing because you're forced to purchase their straps. A lot of watch companies do clever things to force you into only purchasing their items.2 points

-

I will have to do that as well. My first setup won't let me support close to a larger wheel. No problem. I enjoy making tools as much as working on watches.2 points

-

2 points

-

2 points

-

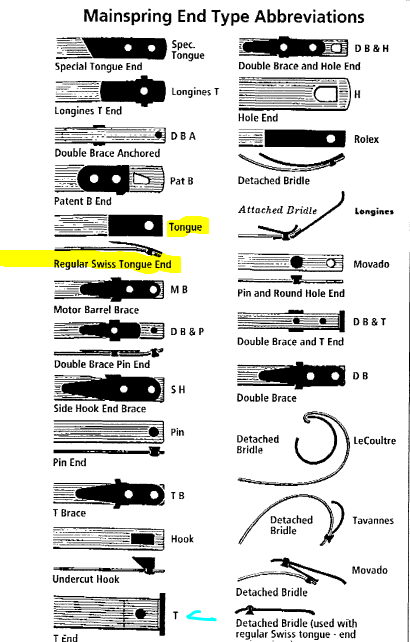

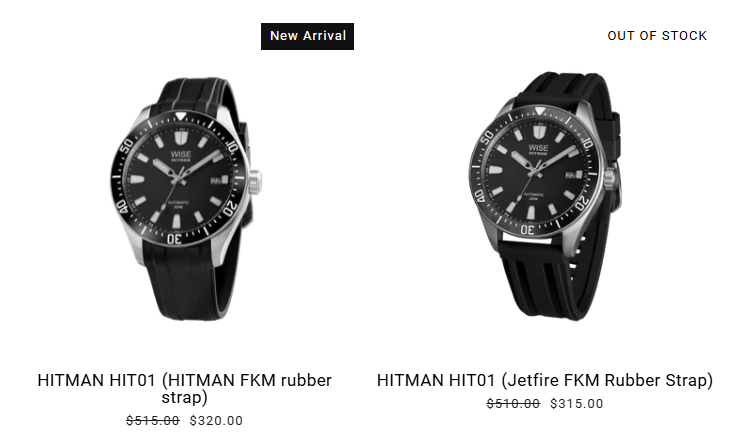

I think we need a clarification here. The alarm watch has two separate mainsprings. the picture you show it appears to be a standard automatic mainspring end which should be identical to whatever Seiko has on the end of their spring for running the watch. Because the watches an automatic it does require an automatic mainspring so that the end can slip. Then there's a separate mainspring for the alarm and it's been such an incredible quantity of time since I've ever service to one and I have zero idea what that would look like. It should probably have a tongue end as a guess because it doesn't need to slip1 point

-

1 point

-

1 point

-

Extra drain on the battery due to needing a service.....friction1 point

-

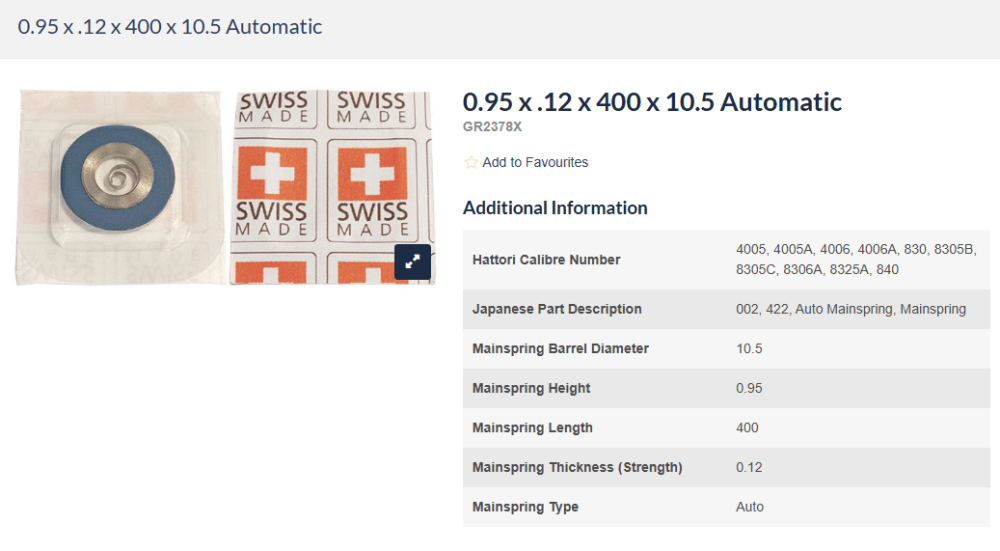

For completeness, this build had a happy ending. As nevenbekriev said, once the pressure was off and I finally gleaned that it was a left-hand thread I was able to remove the sheared-off bit of screw in the barrel arbor. Found another left-hand screw in one of my old movements, and hey-presto, the mainspring was all back together. As for the broken setting lever spring, I couldn't find any movement parts for the AS 415 family, or the AS 521 specifically as this appears to be. However it turns out that this is the same setting lever spring used in the AS 340 (I was also doing up one of these at the same time so it was a completely lucky coincidence). I was able to source another battered old AS 340, got the setting lever spring out of it, fitted it to my AS 521, and happy days. Pictures show it in place. A little tarnished but working fine. Movement is now all back together and running very sweetly. Thank you all for your help. Appreciated.1 point

-

Hi in the center of the movement there is a bridge with three perhaps four small indents , these are the pivot holes of the wheels . its there you place an tiny drop before spinning up on the line release. if it frees up and runs it means sticky bearing pivots and could do with service and clean / oil.1 point

-

Based on the video clip, it looks like pivot end of the balance staff must be pressed into the edge of the rotating disc, progressively ground away completely rather than cut. And with the ability to rotate the balance to grind off the hub if its diameter is greater than the thickness of the disc? I was puzzling over the "sunburst finish" left on the balance arms but realize that is from slight finger rotation of the balance while it is chucked in. This is a really neat tool - incredible how fast it is. I'm about to begin learning to cut off a staff on the lathe.1 point

-

1 point

-

I don't think there is an easy solution here. If you do manage to make a new hole through the strap, it will be so close to the original hole and tear through eventually. Drilling new holes in the lugs to reduce the gap might be an viable alternative. Why not buy original straps from the manufacturer?1 point

-

Always nice if you would give a picture so we know exactly what we're talking about. But in the absence of a picture I did a quick search and found this https://www.hps1source.com/products/eta-804-124 Zero idea anything about the company but based on the price of basically it's a throwaway watch I would just replace the movement. QuickLook looks like they're also for sale on eBay1 point

-

1 point

-

I restored a 4006 a couple of years ago, I broke the original mainspring trying to fit it on a mainspring winder arbour that was too small (was the largest one I had) I then purchased the GR mainspring that Andy has posted, but found the arbour hole in the GR2378X is too large for the 4006 arbour, I tried to make the spring arbour hole smaller but broke it too, that was before I learned on this site and others how to close it up properly without breaking it. The only problem then is you still have to find an appropriate winder to suit. In desperation I used a mainspring from a 7019 movement that I had plenty of with only minor dimensional differences but the arbour hole is correct, worked okay with decent amplitude and is still functioning to this day.1 point

-

When it comes to replacement screws, we usually get a few lots of assorted screws, either from Cousins or eBay. If you are lucky, you'll find an exact match, if not, a similar thread but different head design or length. Sometimes I modify screws by rethreading a close match and reshaping the head and screw length. So far I've not made a screw from scratch yet but that's another possibility.1 point

-

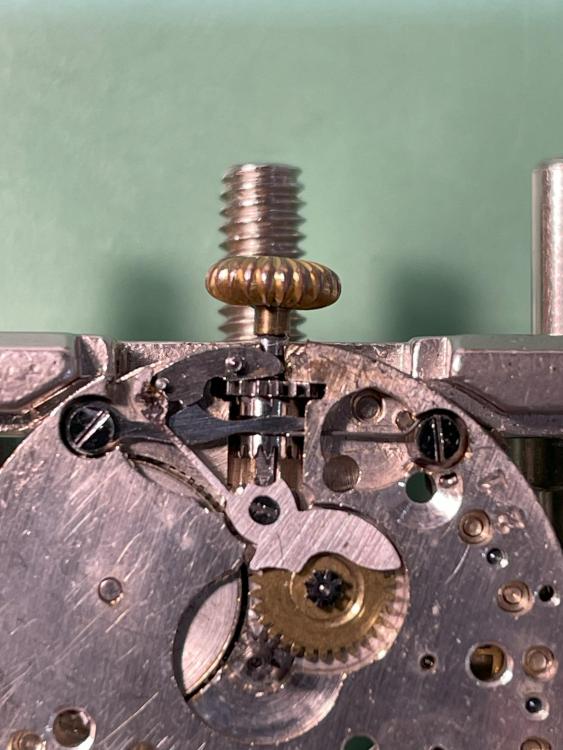

It wasn't clear to me on the first read if he was even using a curved end strap, maybe I should have read it more throughly but never expected that response. I did go afterwards and look at the offending watch and noticed how far the spring bar is from the case. I've had similar issues in the past and on most occasion found a strap that worked. On the occasions that I couldn't I used a heated syringe needle in a drill press to melt a new hole through the strap and then used a spring bar tube to fill the old hole. The thing I find strange is to pay $300+ for a watch and then say the strap is cheap which I think says a lot about the brand. My pet hate about these micro brands is how they always show inflated prices with large discounts to make people think they're getting a bargain.1 point

-

1 point

-

No! Naptha is not paint thinner! Naptha is lighter fuel, like Ronsonol or Zippo. It's a good degreaser while being relatively safe on plastics. Paint thinner is xylene. A strong solvent that can damage many types of plastics and finishes.1 point

-

Firstly i think you need calm down, and secondly you need to understand that Andy is trying to help you. A picture tells a thousand words, supplying us with a photo explains more than you can tell and is standard practice. I can't ever remember anyone arguing over it.1 point

-

Thats not enough. Is this the battery that it left the repar shop with. Try a new silver oxide battery. If it left the shop with this battery, you've assumed they put in a new one...it might not be ! besides that it's crap. Pop it out, is the bottom of it bulging , use a knife blade as straight edge if you're not sure. Check the simplest things first , then move on.1 point

-

Perhaps a stupid question.... but when you do the case up tightly are you pushing the seconds hand into the crystal?1 point