Leaderboard

Popular Content

Showing content with the highest reputation on 04/15/25 in all areas

-

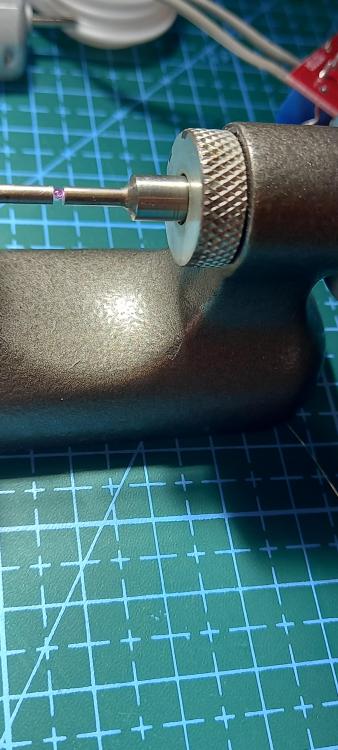

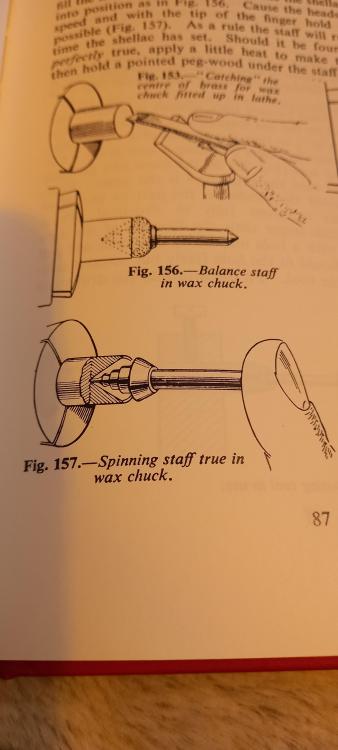

If you dont mind me tagging something onto this thread of modifying jewels Cole. I had a little play at changing the outside diameter of one, no lathe required. I used a very small dc motor, the type that were used in Scalextric cars. I turned the very end of the 2mm spindle down to 0.8mm, then shellaced a 1.2 mm jewel and centred it while heating and running. Using the spindle directly minimises any run-out, that can also be futher improved by shortening the spindle, but for the 8mm sticking out, I couldn't see any at x40. Once mounted I used a 2000 diamond file on the side of the jewel , which quickly ground down the size. In the pictures you can see the outside edge is a little rough and chipped from the file. The jewel did polish up much better with some diamond dental strips. But as I was finishing up, I got a bit heavy handed.... the shellac gave way and the jewel flew . You'll have to take my word for the finish, though it did need some diamond paste ( on its way from AliExpress) to complete the job. The initial diameter reduction was rapid, at the last measure before it disappeared the OD was 1.13mm, which took less than 2 minutes. Now I just need to check in a mirror, I seem to have something in my eye7 points

-

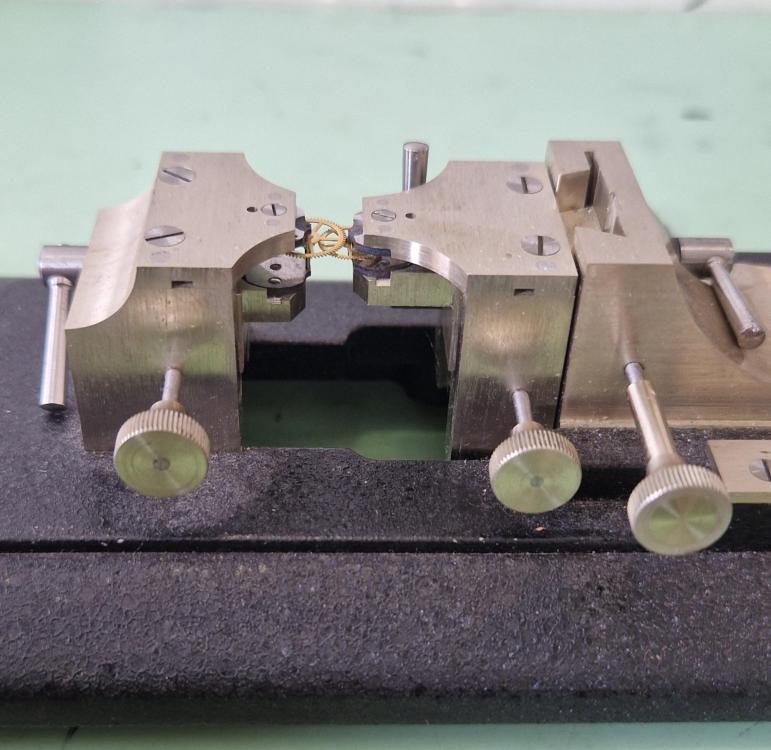

Here's another old tool that doesn't get used much, but has saved me many hours and headaches when it has been. This is a depthing tool, but quite special. The depth can be set (or measured) very precisely with the micrometer to the right, with a direct reading of the actual center distance between the wheel and pinion. It originally came with a set of the little plates in the slots to the right that take the pivots (first pic), most of mine are missing but they can be made when needed. The section that takes the right hand wheel can be adjusted in height. And it can be set on a profile projector if needed to check things. This one is marked Tripet, but most I have seen are marked Hauser. All of them were made by a small company in La Chaux de Fonds (can't think of the name now).5 points

-

4 points

-

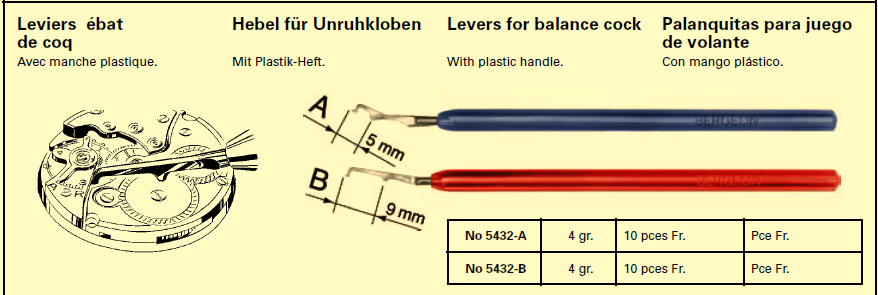

Personally I prefer to bend the balance bridge when it's out of the watch. Although typically I'm doing American pocket watches and it actually takes quite a lot of force to bend the bridge. But if you would like a lever and it's a wristwatch or something smaller than a pocket watch the Swiss have you covered as they have a lever or two. I remember somebody pointed this out to me and I looked at the tool and can't remember why but I was not impressed. I suppose the real question is why do we either method? In other words the watch left the factory without a shim unless of course it's a Russian watch and then it definitely had one plus a few other companies also had them but typically the watch doesn't need them at all. But with anything of vintage things have happened things have well things aren't always where there supposed to be. Then people change balance staffs and don't realize that pivots can be shortened. I saw a picture of a Russian balance staff and noticed they have extremely long pivots but apparently nobody has a lathe Or fail to grasp why the pivots are so long and shimming. But it would really be best if you didn't have to. Then for doing any of the things like we talk about you really should be practicing on a practice watch. Or even pieces of watches you don't even need a complete watch you just need the balance wheel on the bridge in the main plate see them practice bending things and see how much worse it takes to break etc. As everything requires practice and practicing on a watch you want to keep when you have no experience isn't necessarily what you want to do as it will lead to probably what were seeing where things are going to get much much worse before they hopefully get better hopefully Then I'm attaching a PDF on balance wheel truing. If you work on American pocket watches with bimetallic balance wheels your destiny will be to always have to true them. Typically there almost always out of flat or they been squeezed which has undesirable timing consequences and really screws up the poise. Plus typically American pocket watches have just had a lot of undesirable repairers over the years. Joseph Bulova School of Watch Making - Unit 2 balance wheel truing.pdf3 points

-

Yes, I understand. But one has to try, only this way the fear of the unknown disappears. I promise it will be not so hard to do and of course, if bending is too much, then lift it with some lever (bend it up) and with several iterations everything will be perfect. Never try to lift or bend down when the balance is in place, this is the important rule. If you have some useless movement, try and exercise on it.3 points

-

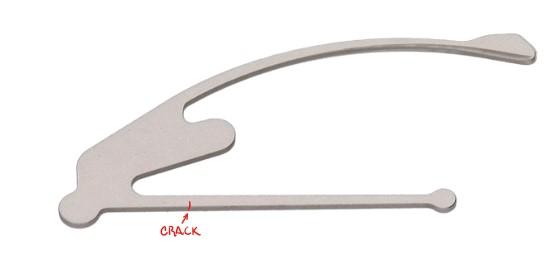

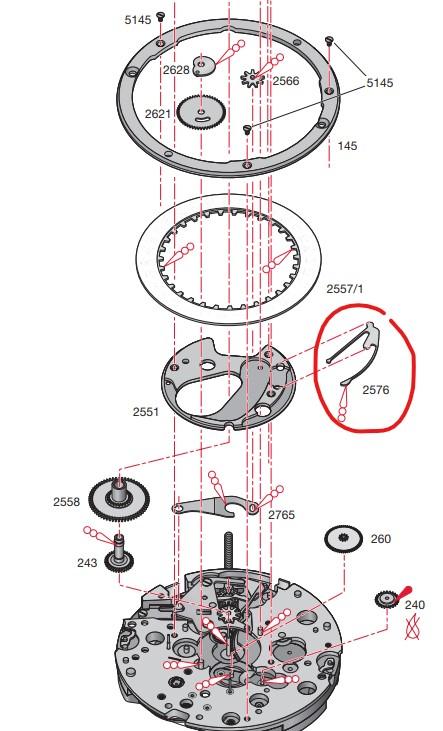

I was able to diagnose an odd issue with my Panerai and thought I would share in case anyone ever experiences it also. After I performed a full service on my pam00091, which uses the OPIII movement. The OPIII is a modified Valjoux 7750/7765. After reassembly I noticed the date wheel would only advance half a day. Showing half of the previous day and next day. After verifying everything was properly lubricated I studied in more depth the way the date advance operated. Noticing something a bit strange I put it under the microscope. Low and behold there was a tiny microscopic crack in the date jumper. It appears as if it was in the original part as the chrome plating follows the crack and may have been just enough to hold it together. Cleaning or bending it to reinstall looks to have been more than it could take. I have to imagine a fault in a part of this type is rare, but maybe not. Hope this helps someone in their search for a similar fault.3 points

-

Basically what you have here is a very very cheap wax chuck lathe. De Carle shows turning a staff in a hollowed out spindle. Straight off the motor Michael, the graver needs to be sharp , I used a carbide tooth removed from a tungsten bench saw blade. What do mean ? This is a real lathe !!! So these motors are incredibly cheap, cheap enough to dispose of after each use,but it will be interesting to see how long one will last. I got a keyless chuck from Ali that fits the spindle, so I'll be ramping its workload up to 6"3 points

-

3 points

-

Just ordered a cantilever toolbox to keep my polishing items in. Photos to follow. Used mops etc are going to be bagged and labeled with the compound used.3 points

-

I want to show others how you can modify the inner diameter of a hole jewel. For this movement, I have a high grade Waltham that has it's pallet fork jewel broken. Sure, I could order a new jewel, but I have a large assortment on hand. To start, you'll need to remove the old jewel, if yours is broken. Find a jewel that is the required thickness and OD, and one that has an ID that is smaller than the pivot it will match with. Now there is a few ways to modify the jewel. You can place it in a jewel chuck, or you can mount it in it's plate, and then center the hole on the lathe. I for some reason have never purchased jewel chucks, so I have it mounted in its cock, and that is mounted in a face plate. For widening the hole, you also have a few options there. You can use a piece of thin wire that is charged with diamond paste, or you can turn a piece of hardened steel to fit the pivot. I have done it both ways, and I haven't had much luck with the wire method that Daniels demonstrates. When making the steel burnisher, turn it on a slight taper. The end of the rod should protrude just past the back of the jewel. Then, with the rod mounted in you tailstock, add some diamond paste to it. I purchase diamond powder of varying micro size, and then mix it with a bit of oil to make the paste. With the headstock turning roughly 1-200 rpms, advance the diamond charged steel rod into the jewels hole. Retract it every second or so to keep it even. Little pressure is needed, but the paste will work its way off the steel rod, so it needs to be reapplied often. I like to rotate the tailstock spindle while I do this as well, advancing and retracting the spindle to continue cutting the jewel. This isn't a fast process, but should only take you 5 minutes or so. You'll notice in the beginning, that it seems like the steel rod is advancing quick quickly, but this is due to it also being polished and shaped by the diamond paste. It will eventually confirm itself to the jewel hole shape, and it will be less noticeable that it's diameter is being reduced. You may be thinking, isn't the steel much softer than the sapphire jewel? Won't the steel be the only thing that's being removed? And you'd be right to a point. But the steel becomes charged with the diamond paste, embedding it into the surface. After you reach the point of the steel rod conforming to the jewels hole, little diamond paste is added from then on. Below are some pictures of how I have it set up. Here is the setup with wire. I don't really like this method. And here is the setup with a hardened steel rod2 points

-

Your approach limits your adjusting to integer number of folds. One fold Two folds, ......so on. You don't have 1.3 or 1.3758 folds. Just insert one fold under the cock, then moving the foil with respect to cock screw, gives you infinite slopes of the cock, and shoot for the smallest end shake. In practice, smallest end shake is, one that, if cock screw is 99% tightened !! balance is not free to turn. But When fully 100% tightened, balance frees up to turn. It is a very practical approach. Mark teaches it in one of his videos. Regs2 points

-

He just wanted to show off his fancy mill-lathe, it’s got nothing on my lextric motor mod2 points

-

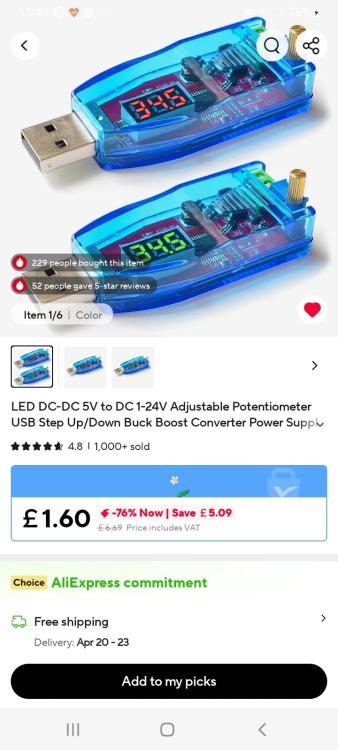

Oh and the dc motors are an eye-watering £3.29 for 10. So this is the cheapest adjustable speed spindle for practising small turning, no excuse for not having a lathe now people2 points

-

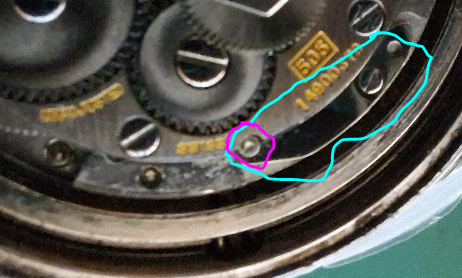

just to be clear here there are two dimples and this one in the circle I think is the wrong one even though it looks right unfortunately I don't know how to make nifty symbols like pretty circles so I will just freehand draw I think this is the dimple that needs to be pushed notice I circled two separate things? The pink thing which looks like a button appears to have a piece of steel underneath it that's the larger thing I circled its held in place by a screw. I'm guessing that's holding the button up and that you can push it down as it does look like a dimple for pushing.2 points

-

yes that is actually the way you're supposed to hold the watch on the holder. something that I've often wondered about was the Chinese loosely cloned a witschi timing machine. Then they sort of cloned the microphone but that outer a notch in the metal isn't very good and it's come up before on the group yes watches have a habit of popping out. So yes it is a problem but how is wondered why they didn't do a better job of cloning and a while back I got an answer. This is because when which she made their first version of the watch expert timing machine microphone has a really pathetic a notch in the metal just like the Chinese. Where later versions it's at least twice as deep and is extremely good at holding a watch movement. So it looks like a witschi grasp the problem and fixed it at all the later generations of their microphone. then yes it's an outstanding idea to always hold onto the watch when you're adjusting it just in case.2 points

-

This is not riveted but just tight fit, the arbor must be slightly tapered where the wheel fits. If it is not enough firm now, the hole can be slightly closed by round tip punch.2 points

-

@JohnR725 I really appreciate your help, I just started using Elma Red after some years of solvent based solutions. I would use the solution for one or two cycles a week, and I really don't mind changing the fluid often since I have a local supplier who sells it, and the volume needed is not big. I should have read the guide of the product before asking, somehow I didn't even think about that. So, I guess that: 1.- I can reuse the solution as long as It does look clean and bright and I change it regularly, lest say 3-4 watches and no longer that lest say a month. 2.- I should add at least one more rinse with distilled water. 3.- It seems safe to clean balance and pallet fork in ultrasonic bath with Elma Red. 4.- Final rinse just 30 seconds in IPA. 5.- Better dissolve Elma Red with distilled water. I hope I understood right. Thank you a lot.2 points

-

2 points

-

It's quite a lot of work to get it back to brass and replate with nickel. The finish you get on the nickel will be the brass finish you achieve - nickel does not fill any defects. So you need a polished finish with no defects. I plate with copper before nickel as it can be plated thick enough to fill pits and defects. But then I have to polish again before the nickel. You can do home plating quite cheaply, there are plenty of Youtube videos showing DIY nickel plating.2 points

-

Mostly, and to maintain a constant pressure on the hole, and to keep the rod aligned Yes I use the same technique on balance pivot holes as well. This is just what is currently on the bench for this type of repair. The smallest I've done is 0.09, but It should scale down, although I haven't done a 0.07 hole yet. I have some sapphire rod, maybe ill cut a slice off and see how small of a hole I can make someday. I would someday like to start a YouTube series on lathe work, from basic gravers, to making your own jewels and threading attachments. But I'm swamped, have roughly 35 watches in the backlog.2 points

-

I have progressed beyond my practice movements (though I continue to practice) and am in the middle of my first scrap movement from EBay. Advertised as a non runner for restoration. Totally misrepresented, but that has been the fun of it. Crystal glued in. Dial glued on. Glue got into the keyless works and I had to cut the winding stem to remove it. Gasket missing. Case screws missing. Crown tube broken. What could possibly go wrong. But at no time did I feel unprepared thanks to Mark’s courses and my other go-to Alex Hamilton and Marshal Sutclif. So I just wanted to say thanks. Totally disassembled and cleaned. Just waiting for a few parts. And we will take it from there.1 point

-

I don't know when I will need this information, but thanks to this strange story I guess I will always remember this solution. Thanks Andy.1 point

-

Get a piece of brass plate stock and mark on it where the indicating pins on the balance cock are, and drill them out. Then mark out where the screw would go, then drill and tap it. Then do as nev said, and bend the cock gently. In my opinion, shimming is an unacceptable repair, as its only a timesaving method. Too many bad previous repairs I've seen, I'd rather do it right the first time. Maybe that's why I have the clients watch now, and not the repairman who shimmed the balance.1 point

-

mike your skill have constantly improved from the start. Manipulating tiny coils is just another level of improvement, must say its painstaking. When you feel ready to attack the next tiny coil, be confident your dexterity is practically on the improve and you will get proficient at it, and come to give good advice. Best regards.1 point

-

Hello WRT members in my last post I mentioned about maybe try doing 3m22-0d39 straps. I got a request for this model so gave it a try. We kept the openings closed and we found out the strap would be much stronger. Gonna show you the result with the metal armor mounted on the strap. I fixed 2 3m22’s on request. A earlier project was a 5j22-0a70 with a broken rubber strap insert.1 point

-

1 point

-

The run-out is on my mind, but very unlikely a spec would be available for such a cheap thing. I'm going completely by eye, x40 magnification is the highest I have, that I can get it under. I can't detect any run-out at all on the slowest speed, which is where it's most visible, i had thoughts of cutting the spindle tight back to the bearing, but as it was so good with the 8mm length I decided against it. At the moment it's just a play thing, but this might have an application yet. The good bit is the chance for someone to experience a little lathe work for practically nothing. The motors are 33p, the speed controller 50p and if you have a spare 5v usb adapter plug, another potentiometer as a usb plug-in power supply £1.60p or an old 6v plug in transformer as the motors are 6v rated...8,000 rpm. Who remembers whizzing their Scalextrics cars through figures of 8 under mum and dad's dining room table at xmas . I did use some 9010 with the dental strips and it was coming along great. Then I caught the back of the jewel ....it must have removed the remaining shellac holding the jewel in place, then used my eyeball as a vertical trampoline1 point

-

Good Stuff! Try it again, this time having a bit of water on the file, that should minimize chipping. The only issue I could see with this method, is just how true the spindle runs. Even a few hundredths of a mm could cause issues once you install the jewel, causing it to not line up with the opposite jewel. Let me know how this ends up on the second attempt!1 point

-

1 point

-

1 point

-

The end of the month is our 5 year anniversary so the wife surprised me with a new watch with a wood inlay (wood is the traditional 5 year gift) Ive become a fan of the affordability of Sea Gulls automatic movements, and always loved the skeleton design (this will be my 3rd skeleton automatic). This has the Sea Gull ST1701 20 jewel automatic movement, which apparently is a Venus 175 clone.1 point

-

the ammonia product for cleaning your brushes you know what the chemical properties are or have a material safety sheets? As far as I know ammonia or I believe ammonium hydroxide but I'm not a chemist here I might be wrong as been used for watch and clock cleaning for a very very long time. The only experiences or knowledge I have a bit being bad is it will frost brass if left on long enough and frosting means dissolving the copper into the solution which turns are pretty blue-green color. Or on one professional discussion group somebody went on vacation with the watch in the solution and came back and needed an entire new watch and it was a very expensive watch. The claim was that only the jewels were left but I found that unlikely I suspect some of the metal was left but not in a functional state what I was cleaning watches at home and had a problem with the l&r rants not evaporating at all no matter how much heat and blowing from a hairdryer that I was using it just wasn't going to evaporate. A friend suggested alcohol. Going to the local hardware store I purchased a gallon of the same alcohol that's used to dissolve shellac it actually says that on the label. But the purpose of the final alcohol rinse is only to rinse off the prior rinses and I don't even think I was in their 15 seconds it didn't seem to be a problem at all we do end up with other interesting problems like shellac is not necessarily one substance it can be a whole bunch of substances. Then of course alcohol you need to specify which one it is. I did see on a woodworking discussion group the referenced isopropyl alcohol as to whether it dissolves shellac or not and? I think some people said it did but it took a really long time and we do end up with lots of variables so rinsing in the alcohol is fine just don't leave it in there very long just enough to rinse off the rim's and then you can dry as far as the cleaning goes I don't know how many times you can use it. I think somewhere I have documentation of what Swatch group recommends for cleaning but I don't think the using the water base and unfortunately Swatch group has infinitely deep pockets so their cleaning procedures will not match ours. Although I do know that other people that are using the solvent-based cleaners will use them until well they use him much longer than I would I've even known a people to filter them except that stupid because you Filter out oil that's dissolved in the solution. So I guess what shall have to do is just keep an eye on the cleaning fluid of it starts to look dirty or it's not cleaning then replace it I think if you look at the water-based cleaner it does have ammonia. But I think the key to cleaning with anything that makes things bright and shiny is minimalistic time is preferred versus something longer that will start to do bad things. Then typically anything other than the cleaner with the ammonia I don't know enough about the water-based but any of the solvent-based you can go much longer in the rinse because it's relatively harmless it's not dissolving or brightening things. Oh and they even do make a non-ammonia non-water-based cleaning product but in another discussion group somebody said it's still have a smelled too much of course all solvents are going to have some level of smell and it still contained chemicals to make things bright and shiny so I assume ammonia or not anything that makes things bright and shiny you basically have a time limit of bright and shiny and then it will start basically dissolving things like typically copper out of the brass. here's interesting video something dreadfully expensive. This is the cleaning machine that I use when I go to work. Let's look at all the things that we know for instance alcohol is bad but as per Elma's recommendation the last rinse is alcohol as the normal rents will not evaporate. Ultrasonic there's people out there that say that's bad this machine actually has two separate frequencies. Then just to make sure the fluid gets everywhere it even uses vacuum and yes the cleaning fluid really does go places that normally might have to disassemble. So we have alcohol to the frequencies of ultrasonic and vacuum that lets the fluid literally get every place and we clean all of our balance wheels pallet forks in this machine and cleans really beautifully is just a shame it costs such a huge sum of money.1 point

-

OK, now I see You believe the balance got out of flat while removing the hairspring. It is not probable, but not impossible. But no matter, You need to true You balance. After riveting the balance staff, this is normal to expect the balance will need truing. Actually, we don't have idea how bad the balance is out of true, we only know the balance touches the center wheel and thus we can suppose as one of the reasons for it is balance out of true. You can use truing calipers of whatever type You have. The 8-type I prefer is easier to use as it takes no time to open and close it. It can not be used for the truing itself, as the pivots will immediately break. The other type can be used for the truing as the pivots do not contact with the tool and are thus preserved, but the riveting of the staff this way is subjected to significant pressure and if it is not riveted so firmly, the joint can move and it is very bad when trying to true the balance as every little move there will strongly affect truing. If the staff is not riveted properly, then for sure removing or placing the hairspring can easily bring the rim out of true We need to see some video that shows how the balance turns in the movement and how it is positioned against the central wheel. Shimming the cock is OK, but You have to check end shake every time You put the cock in the movement. The way You put the foil can not be the same every time and the foil itself will get thinner and flattened with every tightening of the screw. Regulating by bending the cock gives reliable result that doesn't depend on chance. Why do You think that bending the cock will be irreversible? Of course, You can decide which way to use, both are possible.1 point

-

Not in the mail, but I happened to be at my local jeweler, who lets me rummage around in his case of estate sale and broken watches. Found a few nice little guys to play with. First this Waltham. Missing the crystal and looks like it may have a broken balance pivot, but gorgeous otherwise. S/N 19182492 puts it at 1913. The case is marked Dueber, 9096616. Then this lovely little Elgin. S/N 14422258, dating it to 1909! Officially the oldest watch I own. Case is also Dueber, 7614612. The balance seems okay on this one, but it's sluggish. Hopefully just needs a service. I had to throw in this stopwatch and sweet Deco watch fob while I was at it.1 point

-

1 point

-

There are numerous posts on the forum about not using a holder and placing it directly on the microphone as intended. Not sure how you've put enough pressure on the movement to get it to ping out as should only need the lightest of pressure to make the adjustment. Edit (Phone rang and clicked save) Was going to add what are you using to move the lever with and have you thought about holding the movement while you're making the adjustments.1 point

-

Good find. This movement is a Swiss ETA 2472 selfwinder, which Hamilton has rebranded with it's own calib designation. Go on to Dr ranfft site to see all variants of the family this calib belongs to. Though there probably is a walkthrough on same or its variants calibers posted on WRT, yet for ready reference take lots of pictures as you disassemble. Regs1 point

-

I have this tool as well - just bought it - and want to use it for hairspring comets and a friction pinion from an as1900 so glad it works well for that. Can I ask though what is the centre part in the bottom picture used for? I thought maybe it was for tightening canon pinions somehow but it doesn’t really seem right for that. Grateful if you can share any info. Thanks.1 point

-

1 point

-

Using wheels on the Dremel, the problem is nickel is hard and brass soft, so you need to be quite aggressive to remove the nickel, but be careful not to damage the brass. I've done it, but it's a lot of work. Much easier to use reverse electrolysis. If in the UK I buy Nickel Stripping Solution from https://youplate.co.uk/products/nickel-stripping-solution It's a mixture of mainly strong sulphuric acid - you can find the recipe online to make your own. This guy uses vinegar, seems to work. You need to keep checking as too long and the brass will be pitted1 point

-

Some might find this idea useful. My son owns a bar, which is handy. If you have lots of different cork sizes like me ( I don't drink ) you can usually find one thats a good tight fit inside the case. If not , find one that's close undersize and bang a wedge down the middle of the cork to expand it, like wedging a handle for something. I also use corks for sittings domed acrylics on when polishing them. Stick a sponge on the cork end and squeeze the crystal over it. Like so.1 point

-

Polywatch is approximately 0.66 GBP per ml (incl. tax), and Autosol Acrylic Polish is approximately 0.07 GBP per ml (incl. tax). So, Polywatch is almost ten times as expensive as Autosol Acrylic Polish. In either case, it is not much money, but if you use a lot, why not choose the cheaper and possibly better option!? Yes, branding is the single most important factor when making purchase decisions. It goes to show how rational we are as human beings1 point

-

If I were you I'd be very pleased with the result so far, and quit while I'm ahead.1 point

-

I think for the age of the watch and considering what it looked like previously I'd just leave it as is.1 point

-

1 point

-

We have a thread where hairspring tweezers were discussed. I cannot imagine doing hairspring adjustments without curve tweezers, but I often see „adjusted“ hairsprings in fora with a series of small kinks instead of a curve. You should practice your skills with an intact hairspring, best of an alarm clock, make determined distortions and try to remove again. And make yourself familiar with the few rules for such adjustments. Frank1 point

-

Aren't you worried about damaging the pivot when you press onto it? Besides, I'm quite curious about that tool. I saw the link, but can you elaborate on it's functioning?1 point

-

It's possible you have a stump in your staking set that could be used too. Do you have one with a deep V groove, or perhaps some of the old fashioned roller remover stumps that have like a cross opening cut in them?1 point

-

If you search for "offset cannon" on this site you will find some other WRT threads that discuss this type of cannon pinion and how to service and/or repair them.1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)