Leaderboard

Popular Content

Showing content with the highest reputation on 04/18/25 in all areas

-

I made a brass object sort of approximating the shape of a balance staff on my lathe (obvs learning), cleaned and reassembled a Timex M24 from a late 60's watch the seller said "needs new battery" and installed a NOS Elgin mainspring that showed up in the mail into an 1890s 6 size that had been waiting on the bench. To find it runs ++++ on the timegrapher, at a wicked 100° amplitude.3 points

-

i think this is true, once the back has popped off the case seam, a repairer must develop a habit of lifting the back away carefully without inserting anything sharp inside. I use a fingernail at the very edge of the back before the lip starts.2 points

-

With these battery clips , what I do is with a finger cot on cover the coil and release the clip that way if you slip you finger guards the coil, If you use the hole in the clip to hold the tweezers/probe all is ok. I think more coils are damaged by removing the snap backs without due care and clipping the coil, whick always seems to bl located at the pry point.2 points

-

The terminal curve of your hairspring might be distorted. If the curve is perfect, the hairspring should remain in the centre if the gap of the regulator pins when the regulator arm is moved along the entire curve. And adjusting the rate should not affect the beat error. However, reshaping the terminal curve is not easy stuff. Maybe at this beginner's level, getting the watch running is already a commendable achievement.2 points

-

Heat from the wearer's wrist is causing internal moisture to settle on the glass. You could try putting it in a dehydrator for an hour with the back off1 point

-

1 point

-

It would be fine to try. Maybe start with a larger bezel and cut it down.1 point

-

Is it water moisture ? If so and you have good sunshine where you are, just put the watch under direct sun light ( Dial facing sun ) a few hours, sun light dries the moisture. Depending on the amount of moisture, lubricants in movement might have been ruined. No other source of heat is safe.1 point

-

The glass looks quite flat. The op could double- side tape it to something and pull it off.1 point

-

1 point

-

1 point

-

Ahh the DD modules. I havent done one of these for about a year, but when I did it, I followed the service guide and got it within spec. Do you have this? Ive attached it for you and any others who might need it.Omega 1140.pdf1 point

-

@VWatchie does make available a lot of stuff previously using one drive so maybe he can have a look. It could easily be something as simple as default permissions have changed with a routine update. Tom1 point

-

1 point

-

so let's break this down the words restaffed balance wheel correctly would mean no distortion at all on the balance wheel. Which can be done but often isn't. Oftentimes balance wheels end up and times particularly discussing a bimetallic all bent up like the one in this discussion. If the balance wheel is out of round you definitely get a poise issue. You also get an issue if somebody pleases and out around balance wheel and then you fix the out of round now the wheel is poised incorrectly because somebody didn't physically make sure the balance wheel was correct in the first place. Yes people really do poise balance wheels that are neither flat or round it's quite annoying and then it typically with anything vintage there's an extreme likelihood of timing issues. Like the fun I had yesterday the wall thumb was 400 seconds fast and had a 202nd positional problem. So yes it's extremely common on vintage watches you're going to have things to fix from prior inappropriate repairs typically and it depends upon how it nitpicky you want to be here. In other words if you are statically poising the definition of poised would be if you give the balance wheel of push it will rotate eventually come to a stop and it will not rock back and forth at all is considered perfectly poised. Typically when I poise I don't worry about that I will let it rock back and forth because it still going to be within 15 seconds typically. Now the problem with statically poising absolutely perfectly is that it does not take into account the hairspring. This is why ideally if you are really obsessed you statically poise until your close and then finish with dynamic poising. This will take into account the hairspring collet that's probably not a poised collet. Yes Hamilton had another companies had poised collet's they hairspring itself affects the poise so for absolute perfect you have to dynamic poise. So the suggestion has been that it absolutely poised dynamically done balance wheel will not be statically poise absolutely perfectly. this is an interesting one? In the United States of America over a time span and I don't remember the exact but it ended in the 60s there was a tear off on watches to protect the American watch industry. I've read the books on the tariffs specifications it would bump up the cost of better watches to making them expensive. This is why you will often see a nice Omega watch for instance that was regulated was adjusted and was still keeping really good time will be marked not adjusted. Because the quantity of jewels each jewel bumped up the cost adjustment adjustment and variety of positions bumped up the cost so a huge percentage of watches imported into this country will be not adjusted but they were adjusted at the factory it's just a terra thing then I suspect that even the cheapest of watches probably were somewhat adjusted because if they had zero adjustments I have no idea how bad the timekeeping would be? It's one of the problems of we don't actually have numbers of what the watches really should be doing we only have numbers of timekeeping basically when timing machines exist or for things like railroad grade watches where they absolutely had to know what the timekeeping is doing. So railroad timekeeping specification in this country is of watch Dependent up has to be within plus or -30/2 per week. Which if you compare it to the specifications of chronometer grade will ask which I think could be up to six seconds a day is better than a Rolex. this is one of my amusements at work. There we have that really nice which he timing machine full automatic microphone we look at every single watch and six positions and my boss once the watches all the keep really good time. So basically the watchmakers have learned to let the boss adjust the watches it seems to make him happy and we can do other things like service watches. So yesterday's fun on the 18 size Waltham to get the 400 timing down to think he got it down to 15 seconds it might've been better than that the Delta was still might've been within a minute much better than what it was before but still took more than an hour of time. When we don't specifically charge for this we charge for servicing of the watch we do not typically charge to make your watch keep time in multiple positions so yes it wastes a lot of time unless you're getting paid for it where it can definitely eat up a lot of time to fix vintage watches that I've had interesting repair histories. sorry I don't remember the brand name we once had a watch that was one of I take 1000 it actually was engraved number or something of something in other words it was a very expensive Swiss watch and I believe there was at least one shim under something. I always think of at the factory level if you have to place a shim to me it's a sign of poor manufacturing but there was a Swiss watch a nice watch that had it done. Of course what it may also be a sign of limited quantity of watches where things or adjusted at the factory we end up with interesting problems and I will pick on American pocket watches again with interesting repairs that can happen? For instance pocket watches dropped balance staff is broken possibly the whole jewels are broken and sometimes cap stones get broken. or worst-case I had a Hamilton 992 it actually had little notches taken out of the main plate I always wonder if it got hit by a train and things were dramatically bent in this watch somebody had ground the pallet fork bridge down to accommodate the balance wheel because the balance bridge had been bent to insane proportions it was bent so much it was no longer up and down in alignment so I always wondered if this particular watch got hit by a train. With its ultimate repair it would've been better to just replace the whole movement but instead we cannibalized another movements to replace all of the horribly mutilated parts. Now back to not watches hit by a train while somebody was crossing the railroad track. If the balance jewels are broken they are replaced but the same problem like we have on this group where do you get replacements? This means people in the field will get creative if they replace things with size differently than the original things will change. In other words the total length of the balance staff conceivably will change because they've changed the jewels and they're not properly sized. Then there's a problem of replacement balance staffs I personally have often theorized in the case of bestfit that they deliberately made the staffs oversize so the watchmaker can reduce the size. But what if you don't have a lay then what happens? A for instance the Hamilton 992B only has one balance staff as it's of friction staff but often times the friction staff doesn't fit because the replacement staff is slightly oversize which should be impossible but it happens. Often times I have to go through an assortment of staffs to find one that fits because I don't feel like reducing at the size to fit. More common though would be staffs with pivots that are too long and if the watchmaker does not have a lathe again how do they fix that problem well undesirable for us that have to deal with it down the road so an ideal perfect world the adjusted by the factory to whatever the specification was at the time and on a seven jewel American pocket watch it's not going to be railroad timekeeping. If we replace the staff in a proper fashion without bending or distorting anything the watch should keep time within the specification when it was originally made except of course we don't know what the specification was and they definitely did not have timing machines when this watch was made. If we replace the balanced staff with a factory original factory staff and everything should fit perfectly if the jewels were broken and we used factory jewels everything once again would be perfect. Although if you look in the parts book typically for American pocket watches for certain parts they recommend sending the entire watch or parts of the watch back because American watch manufacturing at least until the not sure exact date but sometime past the 20s definitely by the 50s watches were made in batches which is why everything has a serial number and the tools over the course of the batch tend to wear a little bit. So conceivably something made at the beginning and the end of the batch may not fit without adjustments. Plus of course there's variations in parts I like the pic on Elgin because they have one balance staff that comes in four different size variations and then a whole bunch of pivot variations all with the same part number so yes and an absolute perfect world which doesn't exist changing a balance staff with everything factory new would not require poising or truing the balance wheel because everything should still be perfect. But unfortunately in the 100+ year life of your watch things have happened. If you want to grasp that go back and start on page 1 of this discussion as the balance wheels in this discussion have had issues they're not flat the probably out of round there were issues with the jewels there is issues possibly with the staffs. Oh and yes apparently there's a donor watch and if the donor watch is not within a very close serial number range of the original watch it will have very likely sizing differences especially for anything related to the balance wheel because all the vintage watches were adjusted individually in the factory. If you look at a video on I can find it if you want to watch it on YouTube from I believe the 30s where you will see on escapement related stuff every single watch is adjusted which is why you can't just grab the balance wheel from one watch shove it into another one as they were adjusted at the factory1 point

-

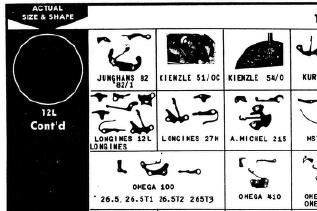

for future reference I'm attaching a PDF. in the PDF various measurements are converted to Ligne size which is a standard measurement for watches the problem with a watch photograph is we can't tell how big it is and when you're looking up what's called the fingerprint system the listing is by size. so this presents a challenge if you're looking because it means you have to look at a heck of a lot of watches if you don't actually know the size and you can't tell by the picture so it looks like it's about a 16 L size. now for the identification we run into several problems. First the watch has to been manufactured in sufficient quantities and spare parts had to be available so that the books like in this particular case I'm looking at the bestfit book it would have to actually list this watch which it does not appear to have listed at all. But your watch is also older than the current book I'm looking at so it might be in a prior edition or other reference books I'm just doing a quick look at this one. then we do run into the problem of people on the group wanting to look for identified their watch in the hopes a getting parts that probably don't exist anymore at all with literally hundreds of thousands of watches having been made and identifying exact watches can be a challenge or basically impossible so the fingerprint system existed to identify watches it's basically a thing of the past. So yeah various reference books of various years and they will typically show you with setting parts look like the physical printed books are in the exact size. This way a billable lay the parts right on the book in a PDF you just have to look through the images. What I did I started past 16 has there aren't that many and was heading down to the smaller sizes where there were way more watches here is an image showing what I was looking at and why it's really important to have the size because of yet the start with a much smaller size there be a heck of a lot to look at hoping to find what you're looking for. So basically it says I have to go find an older book and then were going to have to be really lucky. watch-ligne-size-chart.pdf1 point

-

Hi Old Hippy....I found a chain. After a bit of searching and research into how to measure and determine what size chain was required I bought one from HS Walsh. I also 'sharpened' the spikes and ran the new chain through. I then attached the weight and boom. Tick tock. After a bit of adjustment getting it into beat and regulating, the clock has been keeping good time for about two weeks. The weight hasn't 'dropped' either. The bad news is that I can't get the strike to work. It looks like the wooden 'cam' that locks the train has broken in two....and one half is lost. I was thinking of making a new one but I'm unsure if it's symmetrical, as I have half of what is left to make a pattern...thoughts?? Cheers Al1 point

-

Due to the age of this post it would appear the server where they're stored has started dumping photos to make space.1 point

-

1 point

-

Hello and welcome to the fotum added a collection of reading for you a_practical_course_in_horology_1944.pdf 1941670032_WatchAdjustment.pdf dictionary_ebauches_sa.pdf TZIllustratedGlossary.pdf1 point

-

1 point

-

As I recall, you have a sherline lathe, so that should be a pretty easy thing for you to make!1 point

-

We could give them a Super Diamond Platinum Crown WRT Patron badge if they offered to pay the web hosting fees though...1 point

-

1 point

-

1 point

-

The end of the month is our 5 year anniversary so the wife surprised me with a new watch with a wood inlay (wood is the traditional 5 year gift) Ive become a fan of the affordability of Sea Gulls automatic movements, and always loved the skeleton design (this will be my 3rd skeleton automatic). This has the Sea Gull ST1701 20 jewel automatic movement, which apparently is a Venus 175 clone.1 point

-

As of a couple of months ago, selling on ebay is free (at least for UK sellers). Which is great, BUT a recently they added "Buyer Protection" - a fee added on to the selling price (of 75p and 4% up to £300, 2% over £300). So the buyer pays a bit more. If you sell using the "Global Shipping Programme" on ebay, then you pay local postage to a shipping address, and all customs forms, taxes, postage, and tracking are taken care of by ebay. Couldn't be easier.1 point

-

It exists to make the owners money by advertising - and by selling users data, if you don't spend enough time going through all the privacy settings that allow them to do what they like, by default. My biggest objection is that the have zero interest in maintaining groups, that the users put massive effort in to. Someone I know runs a town/region group, which has more than 100,000 users at peak and so many views than the facebook vie counter limits. Then someone reports something and facebook just delete the whole thing & all the content, so it has to start from scratch again and take another year or to to build back up to similar levels. Repeat ad nauseum. (Apparently any phishing / scamming mob can pick any high usage facebook group, clone the heading artwork etc., and use a couple of fake accounts to post something obnoxious from one and immediately report it from another - instant nuke, then they use the same group name & stolen artwork etc. to post their garbage, which is initially seen by all the real group users looking for it by name). I want nothing to do with Facebook.1 point

-

The Bergeons above are specifically for checking balances for flatness, and in the case of split balances for trueness in the round (a solid balance that isn't round or is eccentric is a bigger problem than what these can handle). The pivots are held by the conical portion, and quite a bit of force can be exerted on the rim to bring it true. The adjustable "finger" is for a visual reference while truing. The truing itself is done simply by finger or with non marking stout tweezers. The one below is a typical caliper for checking and truing train wheels. It holds by the end of the pivot, in V shaped cups. The little tool with the dovetail filed in is the traditional visual reference, it is simply slid around until a point is near the wheel rim, the wheel turned by hand, and checked for flatness. That little dovetail tool is usually one of the first projects a student makes in school, I don't think they sell them (I think my daughter made this one a couple of years ago as a project, hahah). Adjustment is carried out with stout tweezers, with one tip pressing in the center by the pinion, the other side of the tweezer is lifting on the rim at an arm. If a bend is discovered between two arms then the correction is at both arms. Bending between arms is a good way to kill the wheel. Obviously a bit of feel is developed to not strain the pivots. To check pivots for straightness the best is to run them in a lantern in either a Jacot tool or in the turns. If you have a good lathe with good collets that can be used too, I regularly check and straighten balance pivots in my lathe.1 point

.thumb.jpg.e55eb6bf9fe359105c29e888446029bb.jpg)

.thumb.jpg.b34cd9c92d7e24db70cdea9c20fba12d.jpg)

.thumb.jpg.ecdb61f8b7c244fe5dbe9311d763795d.jpg)