Leaderboard

Popular Content

Showing content with the highest reputation on 04/19/25 in all areas

-

Hi guys. @VWatchie Those images are self hosted (not hosted on this server). Do a look at the page source and you will see this. I’m afraid, I can’t have control or backup images not hosted on this server. ( They seem to be served from here: https://qehvsw.bn.files.1drv.com/) This server is backed up fully every night and the database is backed up and versioned every hour, all stored off site on Amazon S1 platform. It’s hard for us to lose data. Ive got a huge overhead of space on this particular server the site is served from so no worries there Sorry all for lack of response so far, I have been extremely busy and am embarrassed to say that priorities had to be set in place for a while. Be assured that i’ve got constant monitoring and alerts should the site be in an extended problematic state (down etc) and work on these issues if they arise.10 points

-

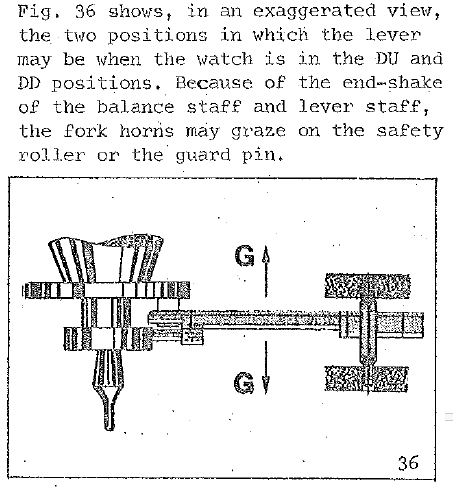

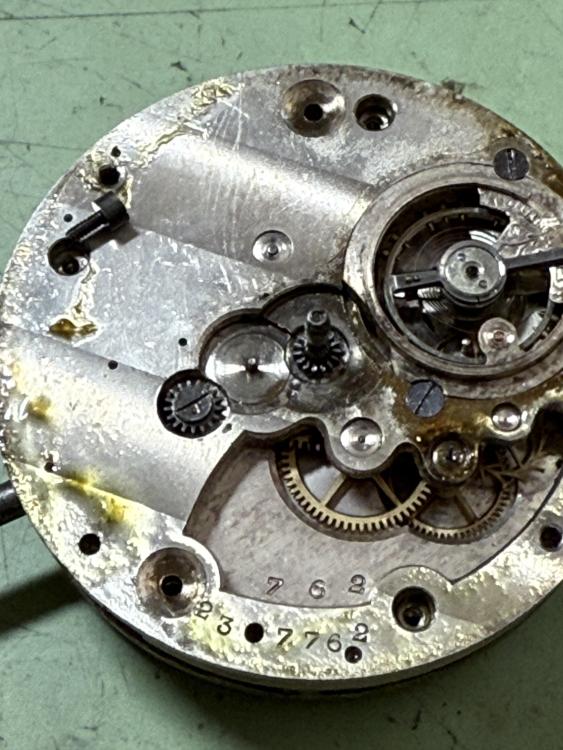

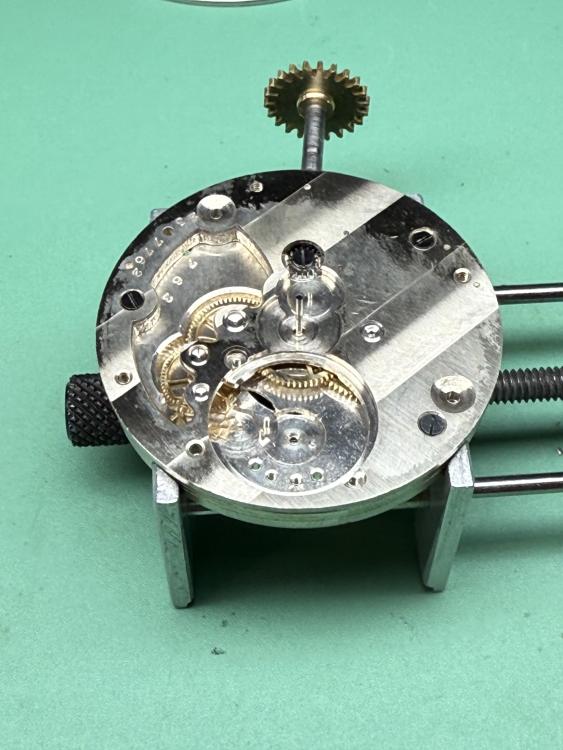

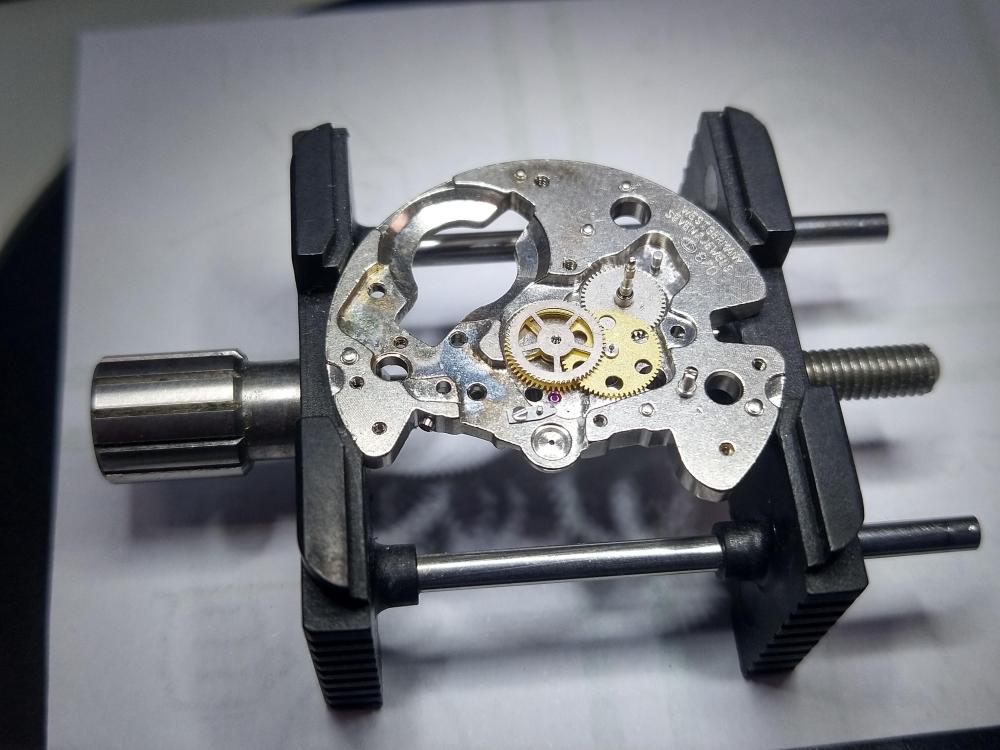

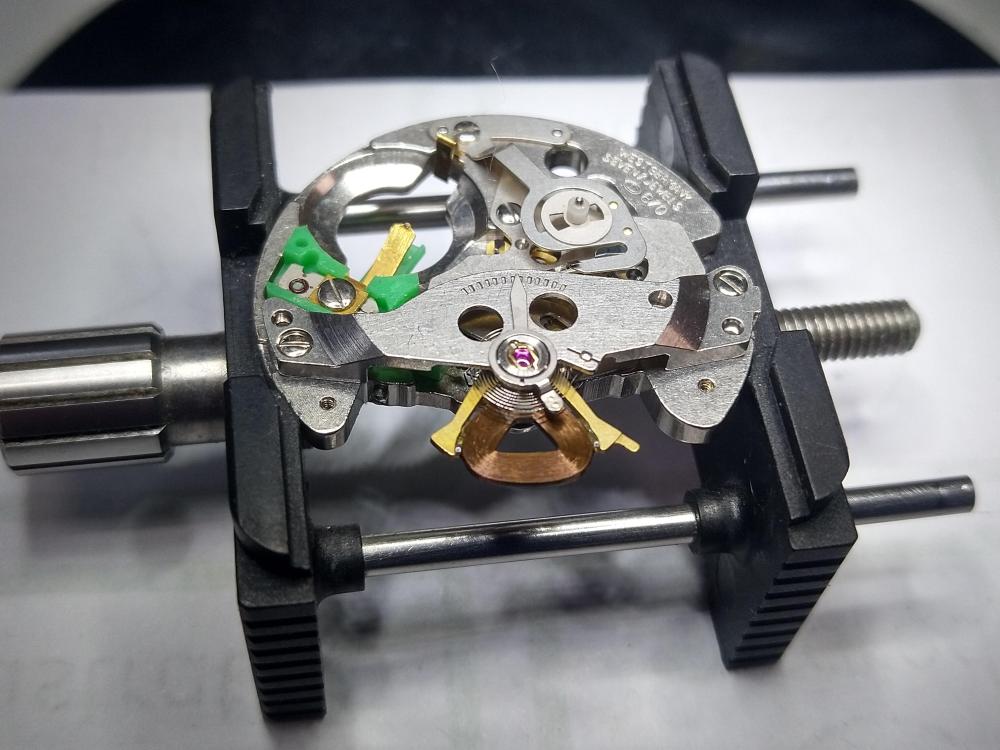

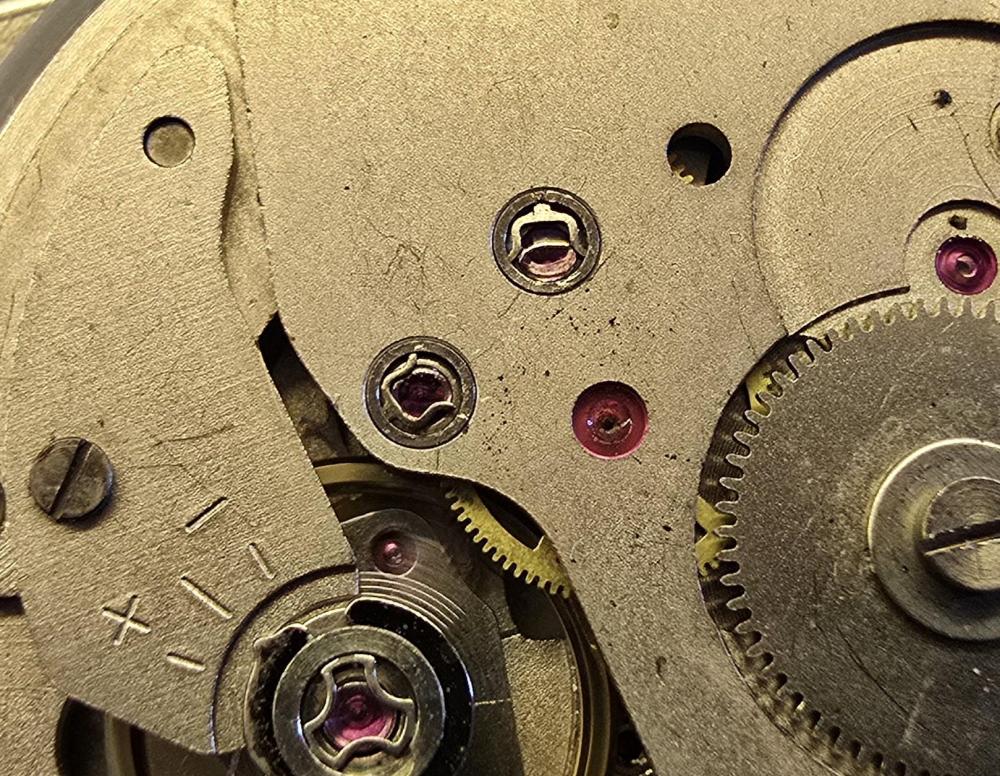

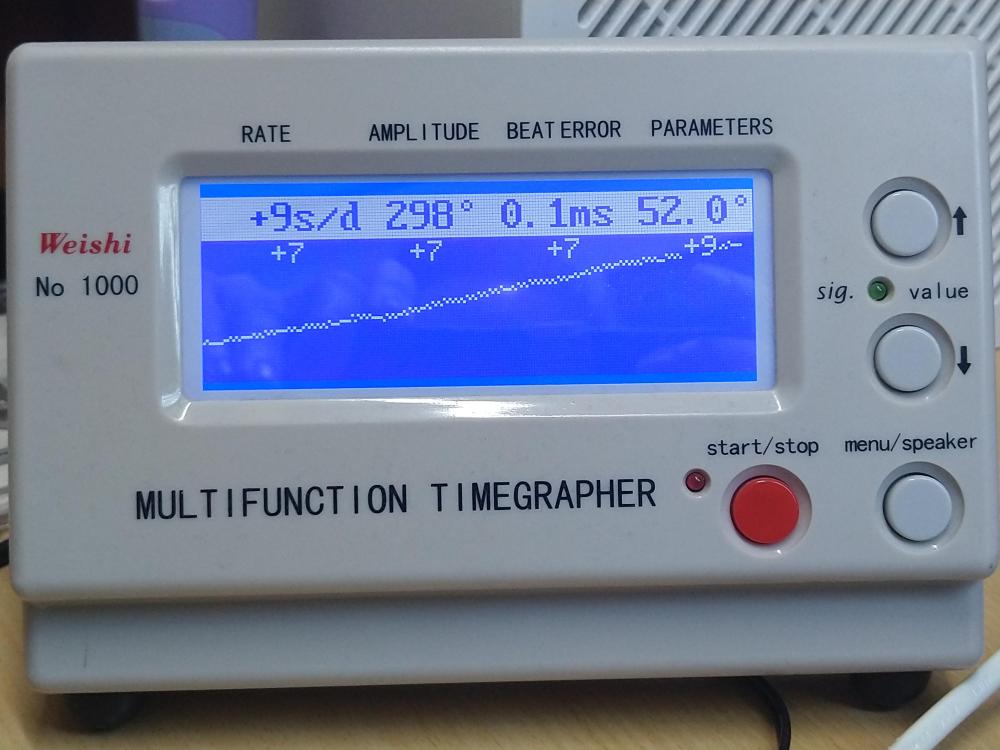

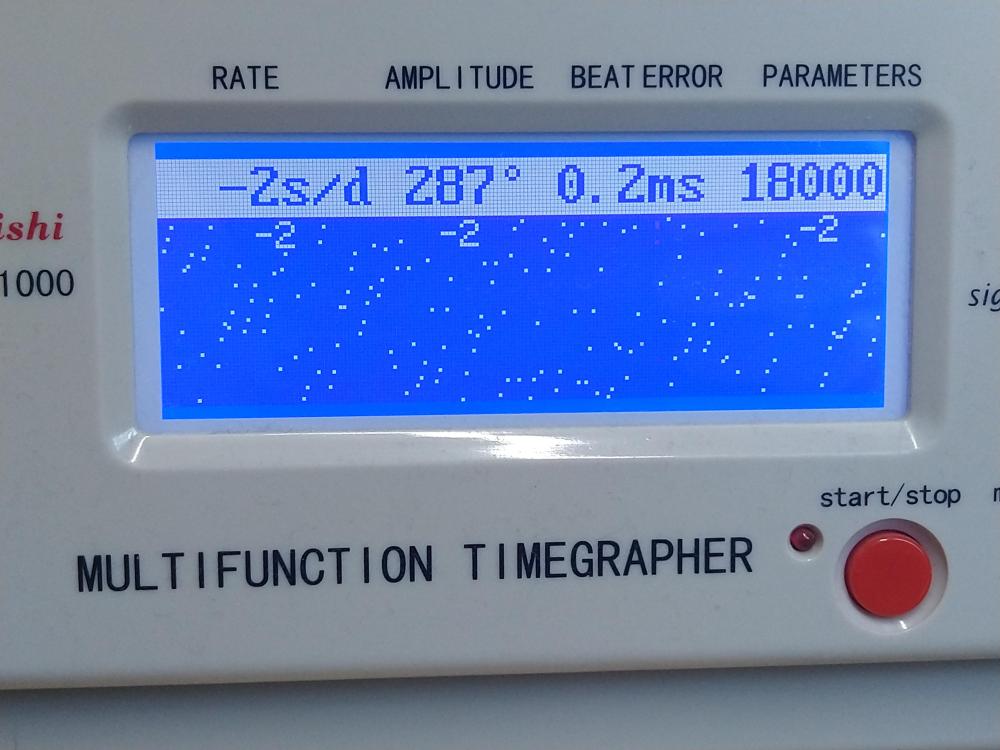

HWGIKE#57 Valex FEF 190 15 jewels Swiss lever full service and repair This one was waiting for a balance staff replacement in my cabinet parts and case cleaned up with a new balance staff and a 4th wheel as the original 4th wheel had a broken pivot for the off center second hand. I never attempted a balance staff replacement before however I received a Bergeon Molfres (i was hunting it for about 2 years) and with the help of it I managed to remove the old staff and riveted the new one in. It also received a new MS, crystal and the hole for the MS arbor was also tightened. With the new MS now it has an acceptable performance meaning that the amplitude goes up to 280 fully wound, has an acceptable beat error and I have the two nice lines but only dial up, dial down is not as nice and I could not figure out as why. I have the two lines but the amplitude is dropping to around 230 and the lines are a bit hairy. Both dial up and dial down the lines just go up and down without seemingly any pattern. I cleaned the movement two times, and then a 3rd time pegged out the main plate and train bridge holes but made no change. Both the HS collet and the roller table was too lose on the new staff... I did not count how many times I took the balance cock off to sort out the HS collet, the roller table and the beat error, somebody before me also shortened the HS by pushing it out a bit and it seems every time somebody is messing with the end of the HS the protruding bit is most of the time twisted bent etc. This one was probably one of the most challenging repair and service. I might take the new MS out and clean it lubricate it as I just pushed the new one in to the barrel from the retaining ring. Plus started to re-read the theory of the escapement and how to analyse the graph on the timing machine: Greiner Chronografic Record manual. I am also thinking to put the watch on a 24 hour long run with the eTimer SW it once helped me to figure out what was wrong with a watch. There is an interesting part of the Greiner record manual talking about the pallets and the end shake of the balance and pallet staff. Maybe this is my issue? Who could that possibly identify? After a few years now I am still without a clue how could watchmakers make parts I can only see with my microscope or how could/can they carry out complicated services impossible to do.. real magic..... .... ..... before I sent this post while the pics were uploading I had an idea, i was browsing the possible outcomes on the timing machine I had one for magnetism..... so I demagnetized the movement and it is not hairy now.... two really nice lines 0.2 ms beat error still a bit wavy, but a lot lot better..... argh....3 points

-

I’m having a hard time seeing exactly what’s going on, even when I zoom in as much as possible, but it kind of looks like the hairspring has gotten itself tangled up. How does the spring look when you place the balance cock on your balance tack? Tangled?2 points

-

Agreed. There are many different automatic winding mechanisms, each with their own quirks wrt. lubrication. Access to the specific service instructions is the ideal. Otherwise, ask here for advice on the movement you are working on.2 points

-

If at all possible, find a service guide for the automatic movements your work on, because the lubrication procedures may have different requirements or rely on oils you would not use in a manual wind train (in addition to the braking grease you mentioned). Some autos like older Seikos do not have a manual wind option, so the procedure of letting down the mainspring without being able to use the crown may require a screwdriver in the ratchet wheel screw and great care. Do you have an auto movement you were planning to start with?2 points

-

Heat from the wearer's wrist is causing internal moisture to settle on the glass. You could try putting it in a dehydrator for an hour with the back off2 points

-

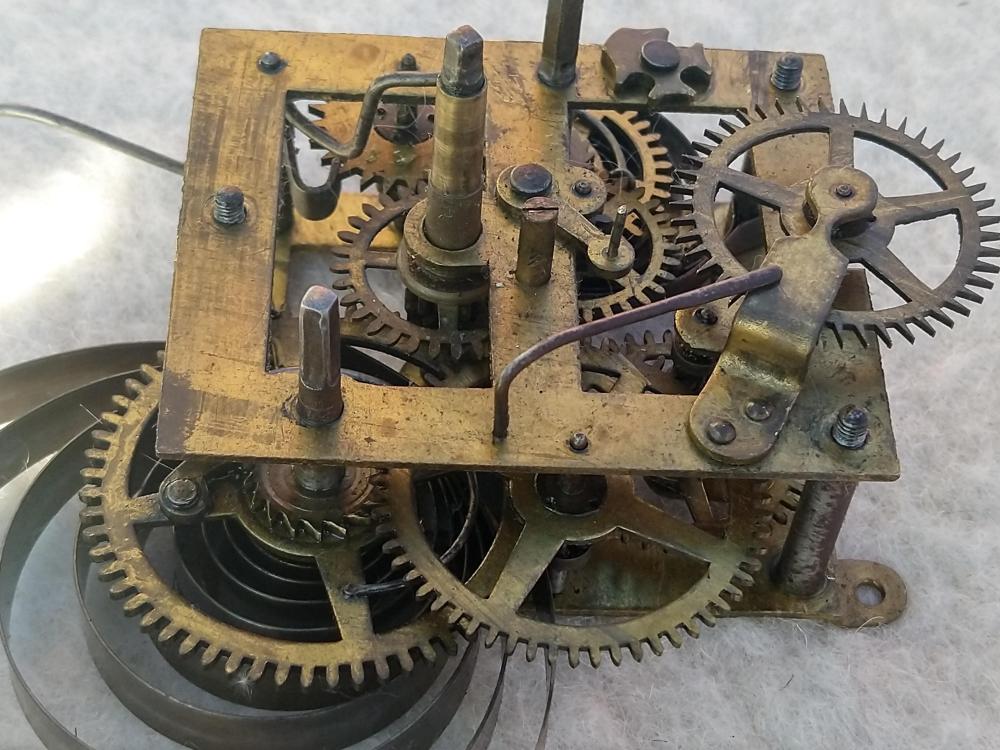

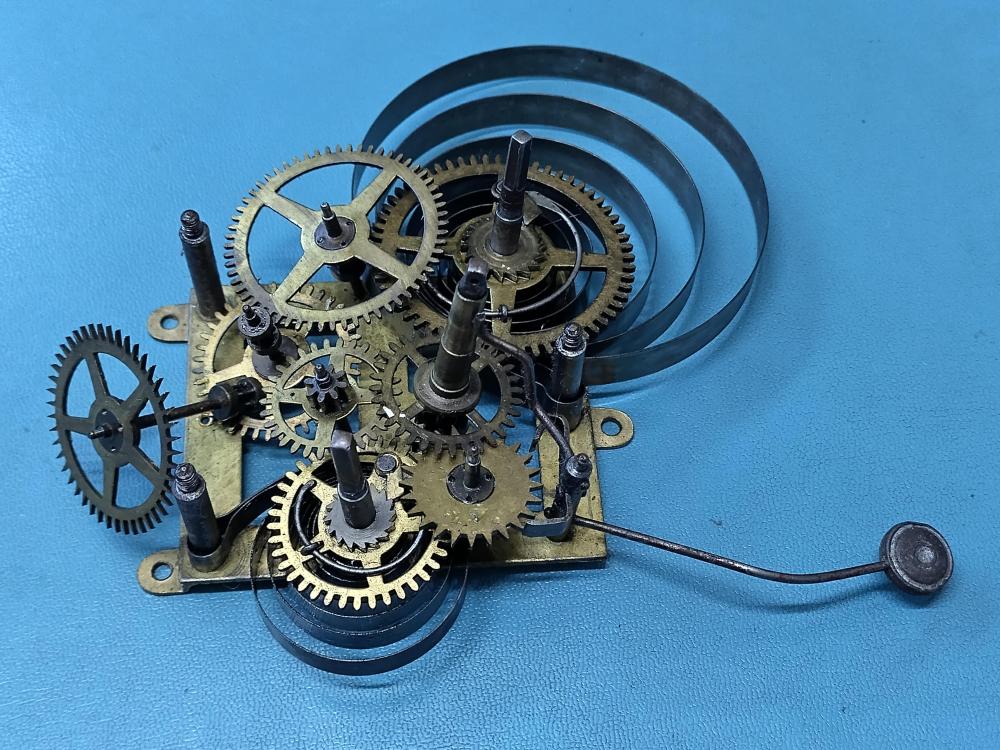

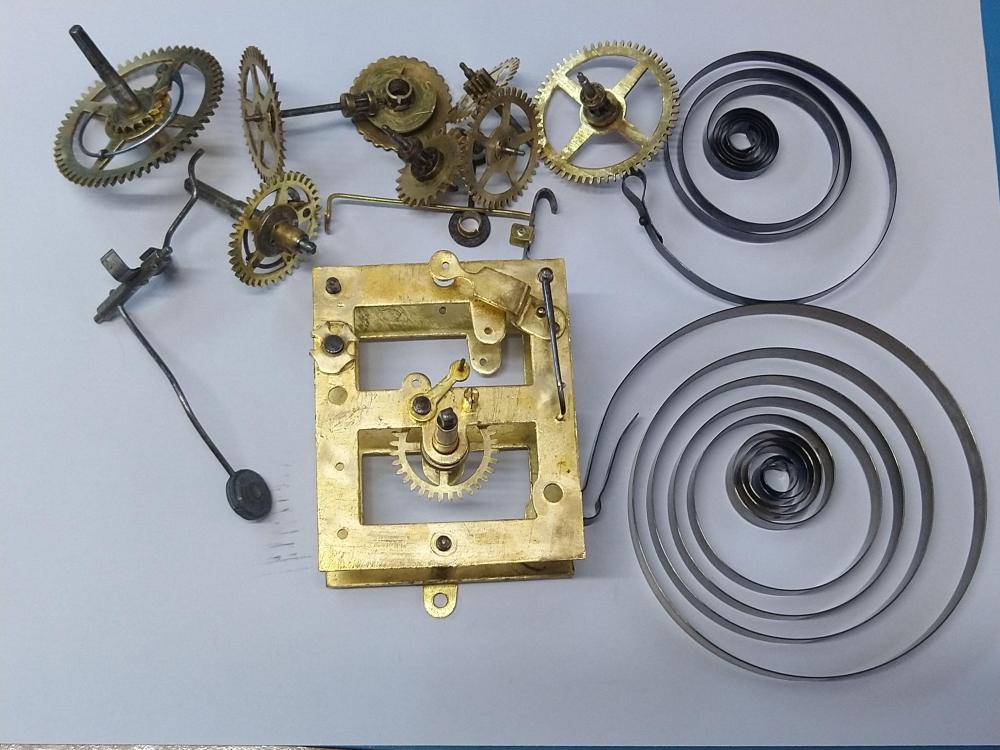

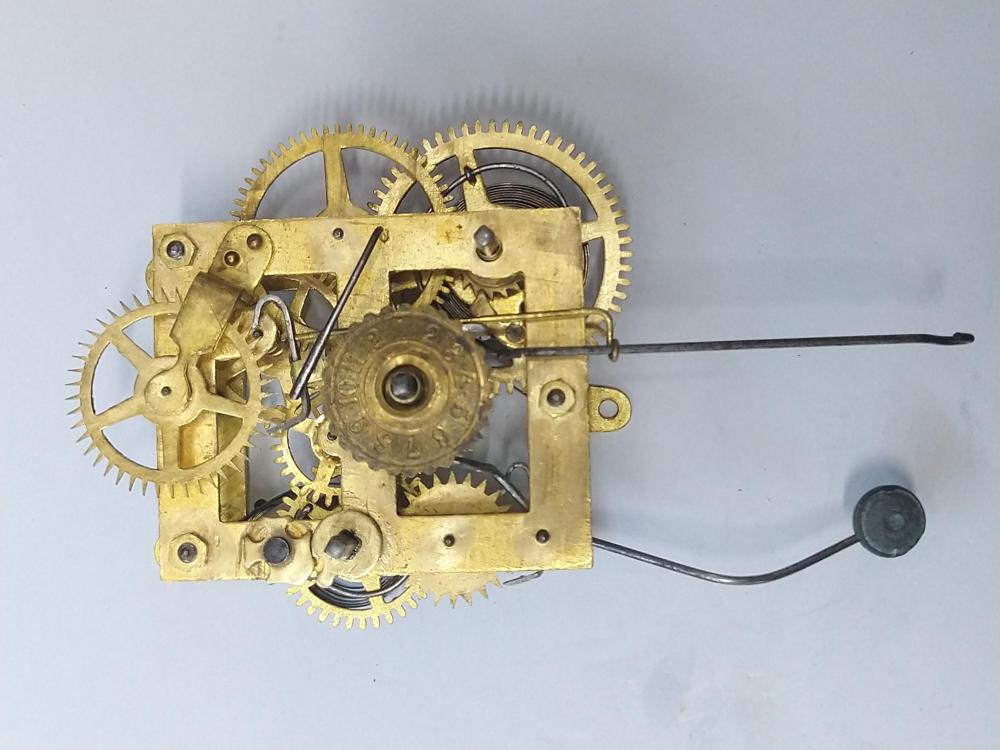

Ok, as per pictures I have a smiths rim set and wind on the bench, swimming in oil but all sorted. The fault I have is the mainspring bridle has lost its tab/notch/hook, like a hebdomas pocket watch the mainspring is fitted to a bridal in the barrel which slides around on full wind onto 4 notches in the barrel wall, thus stopping damage to the mainspring by over enthusiastic winding. So my questiion is this, what is the best way to create another hook in the bridal, my thoughts are along the same lines as making a new hole in the mainspring end, annealing etc, but what and how to make the hook?? I have a pair of barrel hook pliers that work great in soft brass but won’t even scratch the bridal, what I don’t want to do is whack a hole into it and not have a hook. the pictures are of the bridal ( broken) and a hebdomas ( complete ) incase you are wondering what I’m on about. And a few of the serivce. Thanks for any advise.1 point

-

1 point

-

I am an amateur, so there's that. I do not get fixated on amplitude, lift angles, and beat error. However, 4.8ms would bug me if it were my watch. But you must judge your own skills to appreciate the possibility of going backward. I suggest, that you button it up let your friend enjoy the watch for now. As your skills progress, come back to it and correct it. I assume that this watch has a fixed hairspring pin. Some modern watches have an adjustable pin along with adjustable regulator. These are trivial to get in beat. I own a valjoux 726 my dad gave me on my 18th birthday (a looooong time ago). I broke the ratchet wheel with an aggressive wind 4 yrs ago. I have been waiting for my skills to progress before doing a service. I am close. Your advice is well placed and I will apply it.1 point

-

Update! I've dismantled it, cleaned all the glue off, and rebuilt and lubricated the base movement. I'll leave the chrono part for another day. It's running well - great amplitude and keeping time, but it's got a beat error of 4.8ms. How important is it to correct this? I'm worried that the potential for making things worse having to take the hairspring off and on repeatedly to adjust this. Would anyone here accept it at that?1 point

-

It would help a lot to see a picture of the balance cock removed and on its back with the balance pivot in its jewel hole. From this view we can't even rule out the outer hairspring coil being hooked on or under the stud.1 point

-

Update: The demagnetization only helped temporarily, maybe it pulled the wheels into a position where they liked each other. I have to adjust the sub second hand as it is a bit angled upwards and catching the minute hand stopping the whole movement but before this happened there were some wild deviations. HWGIKE#58 Alarm clock, cooked in hot cleaning fluid and oiled gently. This is a movement so I count it. A while ago it tried to fly away one day, it was on my windows sill, we had strong wind the curtain flew like a flag and doing so encouraged my clock to do the same... went out and ended up on the roof above the entrance door, its door in pieces but the clock itself suffered no damage otherwise. The original glass was already broken when I received it I still have the bottom part in two pieces. The new "glass" is acrylic. It also had a paper in the back in the case inside but it disintegrated, I still have a little bit of piece of that too. HWGIKE#59 Durowe 870 / Times M84 This particular instance is a D870, when I saw its worn out contact pin I thought that it must be a design flaw, and here we go: https://17jewels.info/movements/d/durowe/durowe-870/ An incredible movement again where the balance wheel drives the train and has two magnets one for the balance wheel/coil and one for the pallet. The magnet for the pallet is basically the "draw" one direction. The coil is about 1.8kOhm and one end is in contact with the main plate and the other end is soldered to a contact pin which is insulated by the means of putting it into a jewel and this contact pin is rubbing against a wire getting the energy/impulse as it is passing. Behind the contact pin there is an "impulse jewel" not sure why is it there... the wire seems to hit the impulse jewel first then the contact pin but maybe it is there only for insulation purposes? I was almost certain that the screw holding down the battery - (minus) clamp had no insulation washer.. i only noticed the green stuff around it coming from battery leakage... anyway the + and - had a shortcut which took me a while to realize.. had to fabricate one insulating washer on my own. The jewel settings were dirty but not it is all cleaned and oiled. The contact pin might work for a while but I am sure it has a short life. It is a front loader the whole thing is held together by the case so it is not possible to regulate it without putting it all together and taking the movement out of the case again, very inconvenient. A wonderful movement but not made for eternity only for the consumer market.1 point

-

The point I missed to make ! is ; moisture in the movement is the main problem, it can ruin electronic components.1 point

-

I am a very amateur watch maker. After watching Wristwatch Revival, My Retro Watches and Alex's WatchWatch Repair Tutorials, I became fascinated with the hobby. I don't have the best tools yet, but I am having fun. I'm sure my carpet is full of parts that flew away from the several non working movements I have taken apart and attempted to pur together. I know they won't run, but seeing the wheels move freely after reassembly is nice. I am here to hopefully, learn more and have my odd questions answered. Thanks for having me here.1 point

-

Hello and welcome to the forum the attached will help you . catalogueofwalth Watch Parts..pdf TZIllustratedGlossary.pdf1 point

-

Is it water moisture ? If so and you have good sunshine where you are, just put the watch under direct sun light ( Dial facing sun ) a few hours, sun light dries the moisture. Depending on the amount of moisture, lubricants in movement might have been ruined. No other source of heat is safe.1 point

-

With these battery clips , what I do is with a finger cot on cover the coil and release the clip that way if you slip you finger guards the coil, If you use the hole in the clip to hold the tweezers/probe all is ok. I think more coils are damaged by removing the snap backs without due care and clipping the coil, whick always seems to bl located at the pry point.1 point

-

1 point

-

1 point

-

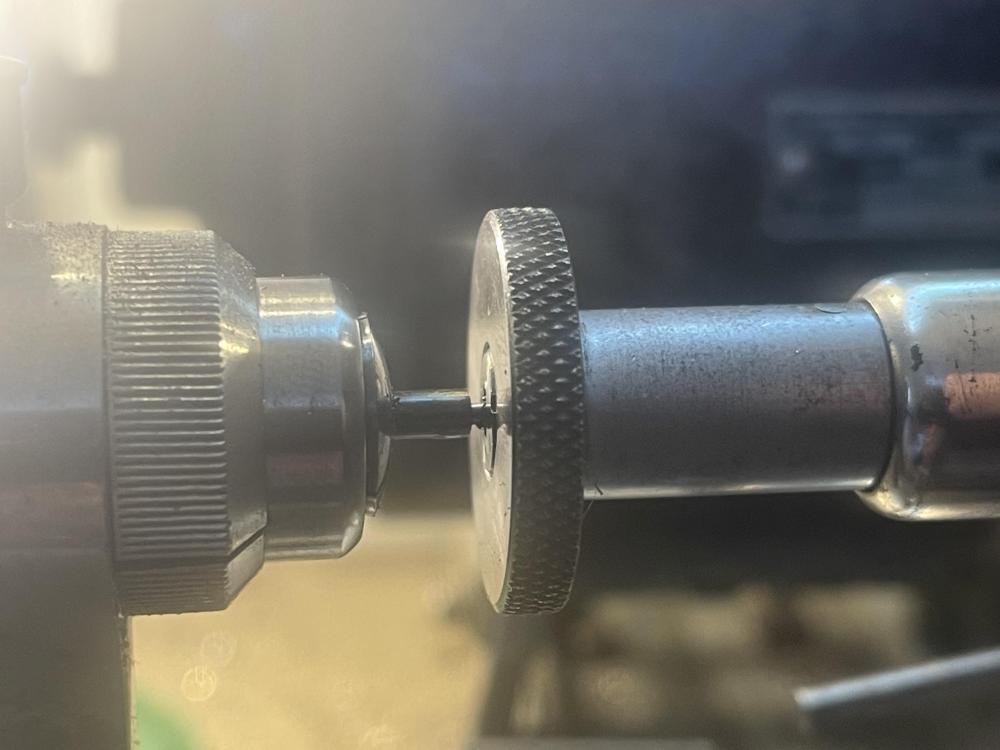

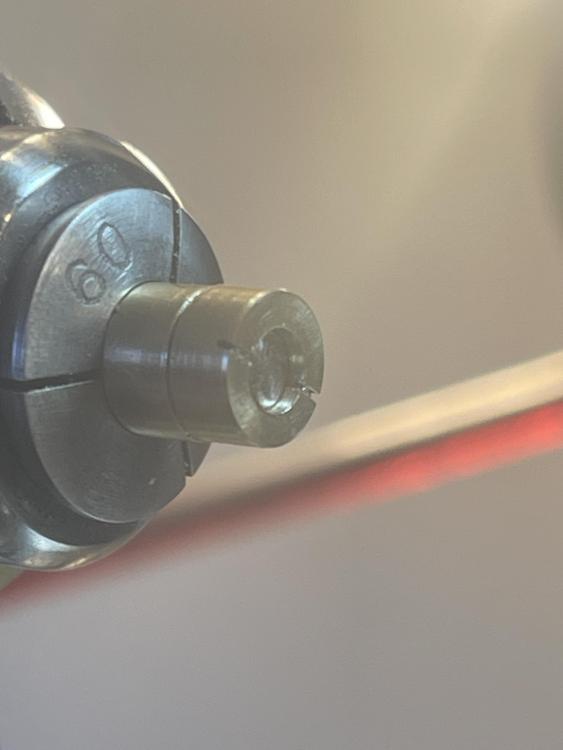

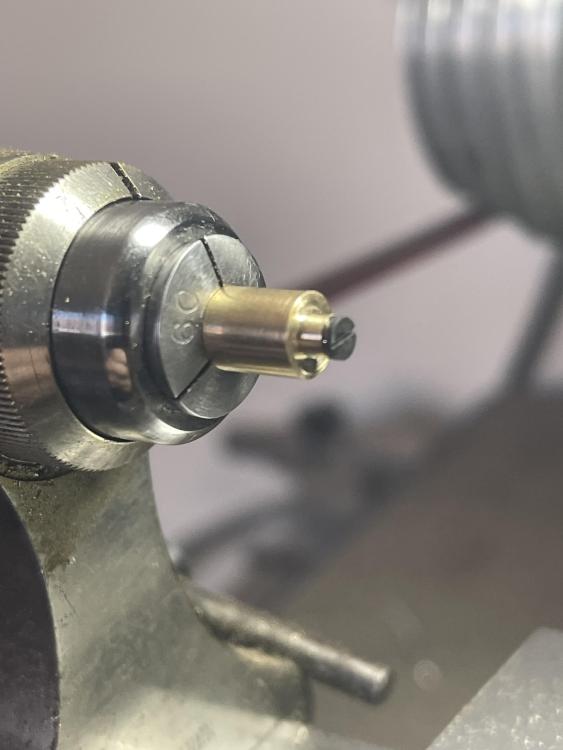

I recently repaired this movement but the screw for the ratchet wheel was the wrong size and it was bugging me (pic 1). I tried to find a replacement but I couldn't match the head width and tap size, so I decided to make one. I wasn't sure of the tap size for the screw, but it looked to be either 1.0 or 1.2 so I made a test screw out of a brass bar, with a matching threaded hole on the other end. I didn't photograph this but you can see the bar in picture 4. I settled on a size and proceeded to cut a steel bar down to length. I softened the bar first to make it easier to work with and the cut it to size, using the chart on my tap and die set for reference Once cut I set up the die in its holder and used my tailstock to hold it straight while I created the thread. Once the thread was cut, I tested it using the brass bar Happy with the diameter and thread I cut the screw off the bar and then twisted it into the bras bar to use it as a holder, for securing it in the lathe to protect the thread I made a face cut to clean the head up Next step was to make the slot. I currently do not have a table saw for the lathe so I was going to have to use a saw. To keep the cut straight and centred, I made a jig out of a piece of brass bar by drilling a hole big enough to slot over the stew, with a slot in it to guide the saw while cutting the slot on the screw head I then cut the slot with a fine saw (I forget what they're called, pin saw?). Once that was done, it was ready for hardening and tempering and then a first polish from 800 grits to 2000 on the lathe. The picture below is just before the first polish. Once I got it to polished with 2000 grit, I removed it from the lathe and then polished it with diamond paste and a Dremel, using the brass bar to hold it. (this turned out to be a really useful tool) Finally, it was ready to go into the movement. I am pleased with the result. I should have made it flatter to match the crown wheel screw better but, overall, it is a vast improvement on the screw that was in there. The main thing I took away from this was how useful the brass bar was, not just for testing the thread but as a holder in the lathe, for cutting the slot and for handling when polishing. No trying to hold it with tweezers or a vice. It was a really simple tool to make and really worth the 10 minuets or so to make it and cut the threads. The slot guide was a huge bonus because it worked much better than expected.1 point

-

I have progressed beyond my practice movements (though I continue to practice) and am in the middle of my first scrap movement from EBay. Advertised as a non runner for restoration. Totally misrepresented, but that has been the fun of it. Crystal glued in. Dial glued on. Glue got into the keyless works and I had to cut the winding stem to remove it. Gasket missing. Case screws missing. Crown tube broken. What could possibly go wrong. But at no time did I feel unprepared thanks to Mark’s courses and my other go-to Alex Hamilton and Marshal Sutclif. So I just wanted to say thanks. Totally disassembled and cleaned. Just waiting for a few parts. And we will take it from there.1 point

-

It can be difficult to keep track of all the different screws on a movement like this, you can save yourself a lot of trouble by putting each screw back on the movement after removing the part it secures. This ensures every screw stays in the position you found it in, but if the watch was serviced by someone willing to glue the dial on, it’s possible that some of the screws are already misplaced. You mentioned that the chronograph functions. That being the case, I suggest you keep all the eccentrics that adjust the depthing and engagement of the chronograph works in the position they’re in, unless you have experience with setting up and adjusting a chronograph. Take plenty of photos, and you should be fine during reassembly. I hope that helps, Mark1 point

-

1 point

-

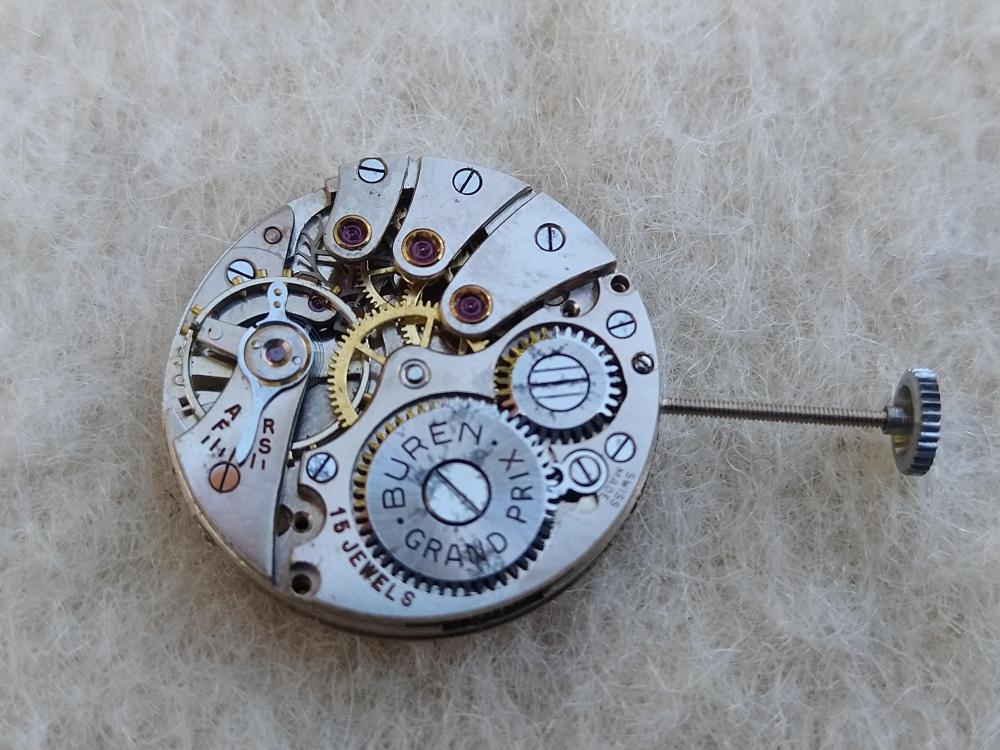

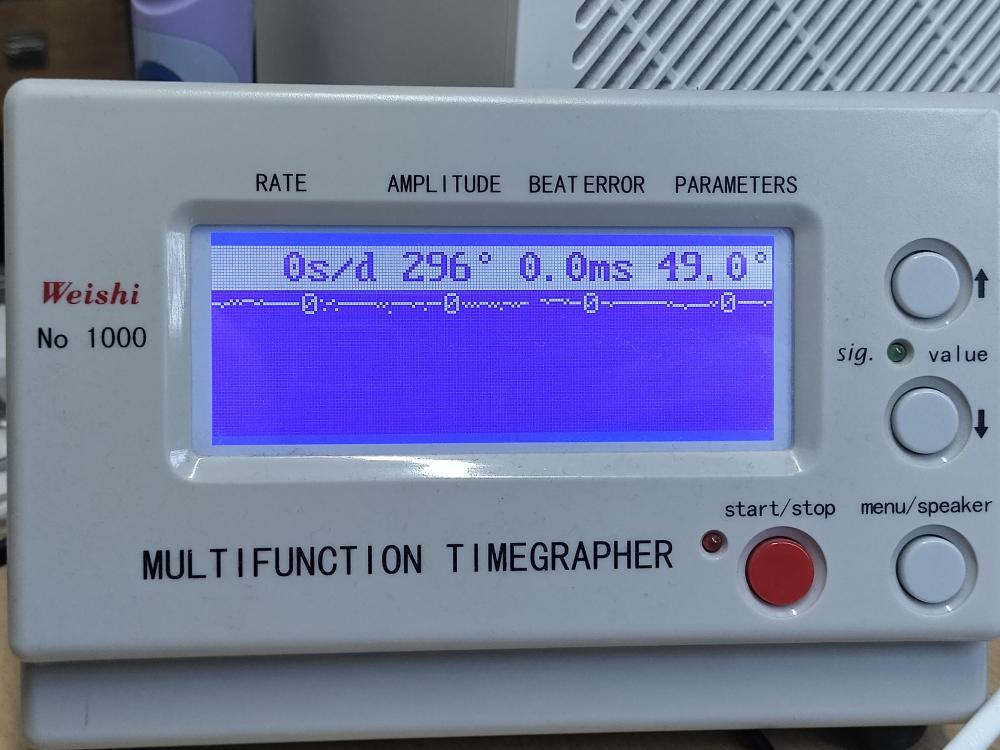

HWGIKE#51 Buren 875, Swiss lever, full service - needs balance staff replacement. Eventless service, but the balance staff pivots are both bent and worn which I have not realized until i cleaned and lubricated the balance jewels. Jacot tool cannot help they are beyond hope. No wonder they are worn there was a lot of dirt in the jewels grinding away the pivots. Unfortunately I cannot replace the balance staffs yet as I am not a master of my watchmakers lathe yet. Hopefully I am going to finish the new platform for my watchmakers lathe soon and I can practice a bit. I had only one job on the lathe so far with a second hand tube which I managed to do with a good result. The criteria to finish the 100 challenge is that I must replace at least one balance staff but not going to do it just now. So even if the time machine shows a nice acceptable performance when you flip over the movement it shows only snowflakes for a minute or two before it is a straight line again I assume the balance wheel cannot drop onto the cap jewel immediately due to the bent pivots. HWGIKE#52 Buren 370 Grand Prix Swiss lever, full service, major mistake! Cleaned the case, replaced one dial foot, sourced a new setting lever and stem, replaced the glass, but when I was about to case it and put the cannon pinion back I broke the 4th wheel pivot accidentally as my tweezers slipped. A movement I like a lot and has a very nice performance... i was devastated... this one was one of the first movements I put into the 100 challenge about 8 months ago and the reason why I am posting it now because i book it as a failure and closing the fist half of the 100, not just that, but I tried to source a 4th wheel... from Cousins UK, from eBay and from a watchmaker who has actually started my watchmaker carrier.... all of them were wrong/long as my movement is thin and all of the 4th wheels I received were made for a thicker Buren 370... maybe I am going to find one in the future but for now I book this as a failure. Recording a failure is a very important part of this series.1 point

-

Discord link if anyone is interested, you will of course need have a discord login. Free, no adds or similar https://discord.gg/xaJES6Wq6H Tom1 point

-

1 point

-

Oh wow! I have a balance assembly coming to me from the US already. If that doesn’t work out for whatever reason I’ll definitely get in touch with you. Thanks for letting me know!1 point