Leaderboard

Popular Content

Showing content with the highest reputation on 04/20/25 in all areas

-

Hi all, I did ad the Google Adsense program to this site quite some time ago in order to attempt to reduce some of the costs of this site - which it did. I never did enjoy the look of the site clustered with ads and all sorts of tricks Google plays in order to garner clicks. In fact I hated it. Yesterday I decided to ditch Google Adsense and remove all ads from the site with immediate effect. I hope this will help to make the site more enjoyable and, hopefully, even faster loading.13 points

-

In tandem with my last post regarding the removal of Google Adsense on this website - I have also decided to fully self fund this site as a gift to the watch repair community of which I’ve been a member of, and have benefited from since being extremely lucky to gain an apprenticeship back in the late 80s. Well, that means that I have also closed down my Patreon account - or, to be clear, stopped all future transactions on my Patreon account and this is with immediate and permanent effect. not to mention, but I will, I really really do appreciate the contribution all my patreon and PayPal supporters have provided over the years, you guys have been absolutely awesome and helped to keep this forum alive and available for those who might not be able to afford the payments. again, from the bottom of my heart thank you.6 points

-

This is indeed a unique site and members including myself genuinely care about it. All we want is the site to continue.4 points

-

Hello Mark, thank you for the ad removal , like JohnR725 , I appreciate any revenue from such would be helpful. This is the one forum which encourages conversation and social interaction and in that sense it is unique All the others I frequent can be a little intimidating and answers some what terse some quite rude. I think on here we try to do justice to your site in keeping with your principals. In my opinion it is like no other. The contributors behave and act like gentlemen and ladies. And long may it continue to be so.4 points

-

4 points

-

3 points

-

Cheers @mikepilk you are correct. A senior moment iam afraid, will go bang my head on the wall.2 points

-

A pump can be substituted with a plastic syringe making sure you have an air tight seal in order to pressurise the case, remember to screw the back on tight.2 points

-

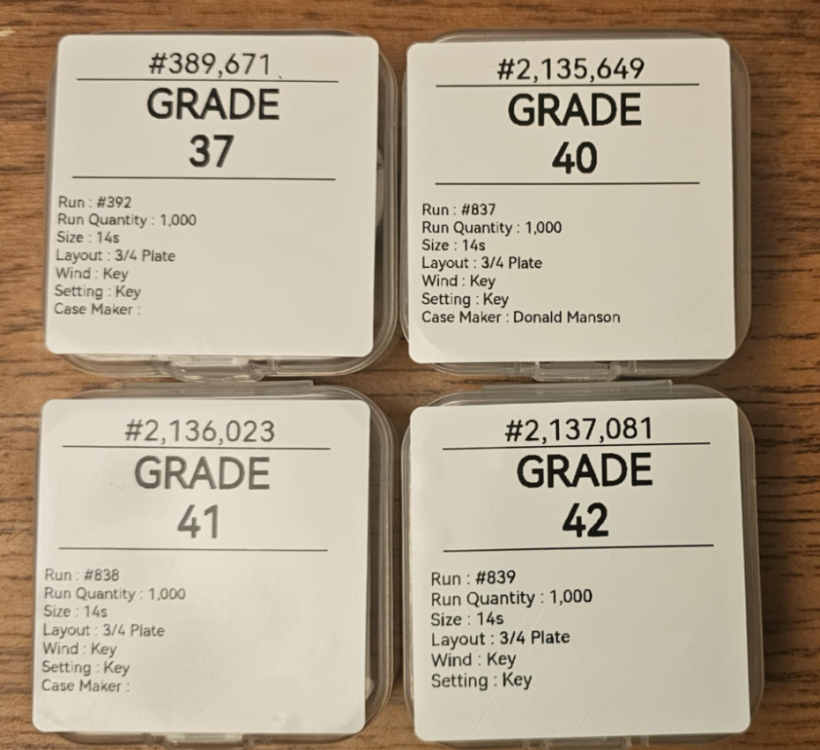

No it's not 52. I had looked at the Pocket Watch lift angles thread, which lists Elgin 6s as something really high like 62° but visually that is not at all what this watch is doing. I think 42° is more correct and that's where my machine is setup. The watch has a million problems but I have made solid progress. Impulse jewel replaced. Hairspring didn't match the balance (which also doesn't match the serial) but I got it down into range this weekend with 8 or 10 huge timing washers. Replaced the mainspring, balance and train are nice and free. At this point it is running consistently and in beat at about 160°, the third wheel has a bend that sends the timegrapher on a little roller coaster every 8 minutes or so. Remaining amplitude problems may be down to the escapement. The banking pins were way out and it didn't run at all before I started. It has one of the old brass escape wheels rather than steel, and I assume the faces its teeth are probably worn or scored in a way I can't yet fix (or see without a microscope). I know this watch is not going to run above 250° but I am going to keep trying to get above 200. But the best part about this watch? Some unscrupulous person stamped "21 JEWELS" on the train bridge sometime in the past, right on top of the Damascening. It's a 15 jewel movement.2 points

-

I'm currently rebuilding one of these and converting it to run off mains AC. The circuit of these battery powered spot welders are not very good and it tends to drain the battery flat and kill it.2 points

-

Just did a quick google, unbelievably there are battery powered micro spot welders on amazon from about 25 pounds up. No knowledge of them, just one of the things that I find fun on this forum, often go off down a new rabbit hole and learn a bit about something I haven’t previously thought about. thanks for the unexpected diversion Tom2 points

-

This is a modern watch, the crown is definitely made from solid 316l steel. You must have heated the crown to some 200C caused the surface colour to change to light yellow. It's similiar to steel tempering. Yes it is the chromium oxide that forms during the heating that gives rise to the colours you see as you know stainless steel contains chromium. The fact the crown is SS lead me to a question, you've never heard of the alum method? Because alum would work perfectly in this case, instead of drilling, which, there is always a risk of damaging the crown, I would just let the crown chilling in some warm alum solution for 1-2 days and the job is done. Sure can but the thing is the crown is not just mirror finishing, the lock symbol is polish while its background is some sand-blasted finishing so it would be hard to replicate that. You can buff it all shiny but losing the sand-blasted finishing means it won't look exactly like before. Gasket is always tricky to me. I would try to use some gasket that look closest to the broken one in term of thickness and diameter, and check if the replacement gasket fit with some friction to the case tube. Lastly you can still use alum at this point.2 points

-

Thanks Mark I have uBlock Origin Lite add-on for my Windows Chrome browser, so I've never seen a single ad on this site ! It also removes all adds from Youtube - I couldn't bear to watch it without uBlock2 points

-

Thank you Mark it definitely makes the site looked much nicer. Although I didn't mind the ads as long as it helped to pay for the messageboard but sometimes when you had the feeling that there were more ads than message board yes it was a little annoying. Thank you2 points

-

I've seen many quartz watches with this kind of foggy crystals. It usually happens when the battery leaks. It's probably the electrolyte vapor. Remove the crystal by sticking a piece of double sided foam tape to the crystal and to the surface of your workbench. Then pull straight up on the watch straps. The crystal should pop off. There is an actual tool on AliExpress for this job, in case you find this method too "rustic". The fog should wash of easily. But I'm more concerned about the rest of the watch, as the electrolyte vapor is all over everything and it's very corrosive. I would do a full disassembly and rinse everything in a diluted acid. I use phosphoric acid but vinegar works fine too. Dry thoroughly, then do a full service. Watch tool is used to open the watch glass and open the watch cover https://a.aliexpress.com/_msI3lhh2 points

-

2 points

-

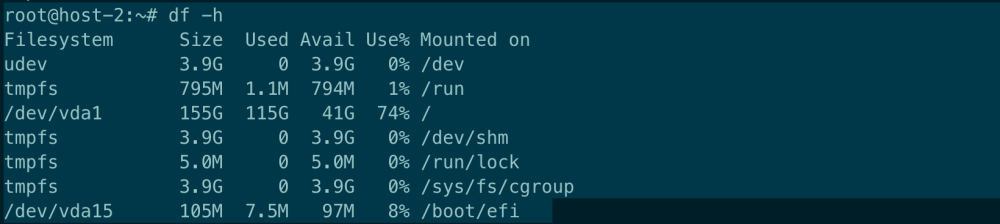

Hi guys. @VWatchie Those images are self hosted (not hosted on this server). Do a look at the page source and you will see this. I’m afraid, I can’t have control or backup images not hosted on this server. ( They seem to be served from here: https://qehvsw.bn.files.1drv.com/) This server is backed up fully every night and the database is backed up and versioned every hour, all stored off site on Amazon S1 platform. It’s hard for us to lose data. Ive got a huge overhead of space on this particular server the site is served from so no worries there Sorry all for lack of response so far, I have been extremely busy and am embarrassed to say that priorities had to be set in place for a while. Be assured that i’ve got constant monitoring and alerts should the site be in an extended problematic state (down etc) and work on these issues if they arise.2 points

-

1 point

-

1 point

-

typically any time people talk about a pocket watch lift angle list I find it's the one that I gave out. Amusingly I've even seen it quoted on another discussion group that they found this list. then if you look carefully at the list you'll notice that it's not just the Elgin six size but also a Illinois six size is 62°. what becomes interesting if you look at the list is there's a lot of variations in lift angles for particular watch sizes. So basically this means if your timing machine does not seem to be giving you whatever you perceive you're supposed to be getting you should verify that the lift angle is indeed correct for your watch as there seems be lots of variations with pocket watches even amongst the same size. Then unfortunately on every single pocket watch you do especially with movable banking pins is you do have to verify that they are where there supposed to be. It seems to be that anything that's movable on a watch will get moved just because it can be moved. It's amazing moving banking pins playing with the pallet jewels how poorly a watch can run..1 point

-

I just went back in & found a speck of pegwood dust in the 3rd wheel pinion so that probably explains it.1 point

-

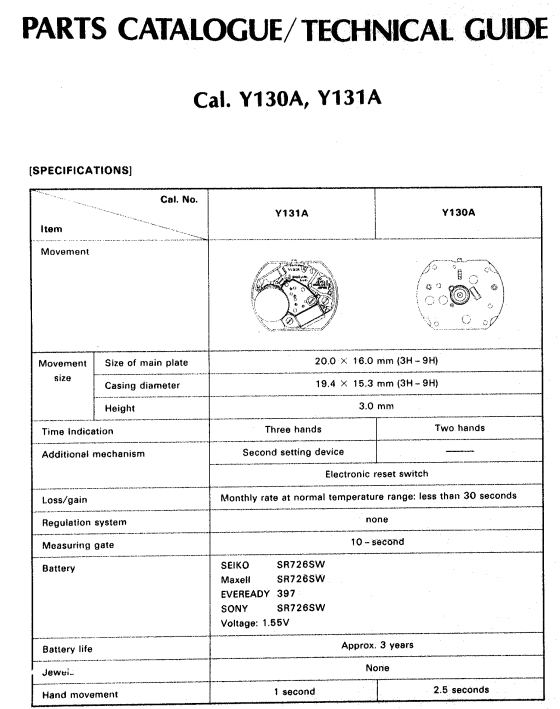

Hi Richard. The movement shiojiri is from the Epson, Hattori TMI, factory the battery is probably a 364 or a 377 which is used a lot in their movements. The Y1305A is not listed on the site I pulled up.1 point

-

there is a seller on Ebay always selling bezels, he lists what they fit by case number too....1 point

-

1 point

-

I think it would rather be the blast of high current drain that would do the damage. But if used occasionally to maybe fix a mainspring or do dial feet it might be worth trying especially if the mainspring or a replacement couldn’t be found. Tom1 point

-

The high voltage will take a toll on the battery but if used occasionally such a the proposed bridle welding I guess if it works it’s worth the price of a battery.1 point

-

No mate. Sorry if that offends you! Also please don’t take threads off-topic. I thank you sir.1 point

-

Thanks Mark, but can we still discuss the other important matter please and not be distracted from it. Thank you.1 point

-

My pleasure. I would rather pay more than have those annoying ads ruin this site. They were a terrible idea and something I never even saw much, but I was on my iPad yesterday testing a security update for the forum software and it was impossible. I decided then - they had to go!!! Also, co-incided with this, for those who are paying for pattern in order to help fund this site - I’ve just disabled patreon. Future monthly payments will not be taken. PayPal is a little more complicated. I will try to work out how to cancel the few subscriptions but if you are a PayPal donator then please feel free to cancel the monthly sub. I will, however thank you all from the bottom of my heart for helping to contribute to this site financially - it means a lot. But going forward, I’m funding it personally from my pocket and that’s the end of it1 point

-

1 point

-

1 point

-

I have been looking for this exact thread for days now! I love watchrepairtalk.com!! Thank you, thank all of you!1 point

-

I’m having a hard time seeing exactly what’s going on, even when I zoom in as much as possible, but it kind of looks like the hairspring has gotten itself tangled up. How does the spring look when you place the balance cock on your balance tack? Tangled?1 point

-

1 point

-

Agreed. There are many different automatic winding mechanisms, each with their own quirks wrt. lubrication. Access to the specific service instructions is the ideal. Otherwise, ask here for advice on the movement you are working on.1 point

-

If at all possible, find a service guide for the automatic movements your work on, because the lubrication procedures may have different requirements or rely on oils you would not use in a manual wind train (in addition to the braking grease you mentioned). Some autos like older Seikos do not have a manual wind option, so the procedure of letting down the mainspring without being able to use the crown may require a screwdriver in the ratchet wheel screw and great care. Do you have an auto movement you were planning to start with?1 point

-

It would help a lot to see a picture of the balance cock removed and on its back with the balance pivot in its jewel hole. From this view we can't even rule out the outer hairspring coil being hooked on or under the stud.1 point

-

1 point

-

Thanks MariusJacob. It's an option I will consider if the screw size prove to be non-standard. Currently, I am planning to first purchase a digital caliper to precisely measure them. Head diameter is 2 mm, length 2mm as well, but my old caliper is too worn for the thread diameter. It may be 0.9 or 1.0 mm. I keep going ...1 point

-

I see a lot of URLs pointing to 1drv.com which appears to be a CDN for OneDrive.1 point

-

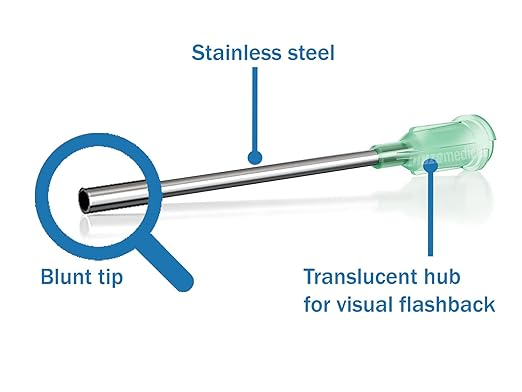

This is the type you need in either 15Gauge or 16Gauge which should be 1.6mm O/D so you can use a 1.5mm Spring Bar. You need to sharpen the tip slightly and I heated with a mini lighter blowtorch. I think there are better options from the strap you're starting with but I'm out most of the day so will see what other people suggest. This was solved as mentioned above by using a spring bar tube to fill the existing hole. Edit Just found you can get 16Gauge Hypodermics which would possibly go through better. And body piercing ones maybe even better.1 point

-

this I would think would actually be the best solution as you wouldn't have to modifying future straps.1 point

-

I don't think there is an easy solution here. If you do manage to make a new hole through the strap, it will be so close to the original hole and tear through eventually. Drilling new holes in the lugs to reduce the gap might be an viable alternative. Why not buy original straps from the manufacturer?1 point

-

The problem is everybody approaches problem solving differently. While it seems crystal clear to you because you're holding the watch in your hand and you can see the problem. Unfortunately everybody in the world is different for some of us one picture's worth 1000 words and Once we look at the picture we can grasp the problem. Actually that's clever marketing because you're forced to purchase their straps. A lot of watch companies do clever things to force you into only purchasing their items.1 point

-

Firstly i think you need calm down, and secondly you need to understand that Andy is trying to help you. A picture tells a thousand words, supplying us with a photo explains more than you can tell and is standard practice. I can't ever remember anyone arguing over it.1 point

-

1 point

-

Just wanted to thank you for this post! I used the plastic sheet approach plenty of times since I saw your video. Primarily for shock springs, but also for the rotor clip on a Rolex 2035. It makes a huge difference. Really a game-changer for these kinds of fiddly tasks.1 point

-

Here is how I installed one of mine. I actually found that I needed to have the jewel in the chaton or else the spring wouldn't stay level and I couldn't get it in. I use the plastic to position it and then an oiler with the force applied the long axis to snap it into place. You can see that when I first tried to apply force with the oiler perpendicular to the direction the spring needed to move, the oiler would flex. Once I came at the spring along the direction of force it snapped right in.1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)