Search the Community

Showing results for tags 'review'.

-

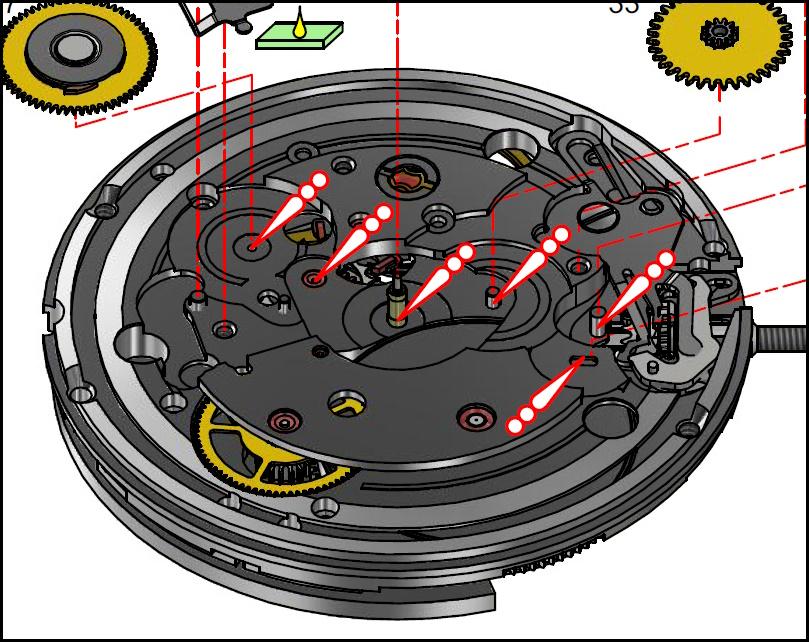

I recently serviced my first Sellita movement, the SW 200-1 calibre. It was my very first Sellita movement, so it was a bit more exciting, especially since I could compare it with my experience of servicing and repairing several ETA movements, including the famous 2824-2. The first time I heard about this movement, it was described—and still is—as an ETA clone. The impression I got back then was that the SW 200-1 was a fairly decent and relatively inexpensive copy, though it didn’t quite reach the same level of quality as the original. After servicing it, however, I’m pleased to say that my overall impression is that Sellita's movement is at least as good and, in some aspects, even better than ETA’s. When I disassembled the movement, the only unexpected thing was that the cap jewels and pallet stones were somewhat overoiled. Whether Sellita or someone else was responsible for this, I don’t know. Regardless, the movement performed well, but after seven years of 24/7 use by the previous owner, it was time for a service. One thing I really appreciate about the Sellita SW 200-1 is how easy it is to pull the crown to its second position to set the date. There’s absolutely no risk of accidentally pulling the crown too far out. This, I believe, is an improvement introduced by Sellita. My memory of the corresponding function in ETA's movements is that it’s far too easy to overshoot, inadvertently stopping the watch when you only intend to set the date. In fact, it works about as well as on the Rolex calibre 3135, which is perfect in this regard. ETA’s 2824-2 has 25 jewels, while Sellita’s SW 200-1 has 26 jewels. I’ve long been curious whether this difference was simply a way for Sellita to outdo ETA in the jewel-counting competition. To my delight, this turned out not to be the case. The extra jewel is placed exactly where, in my opinion, it does the best: as a bearing for the barrel arbor on the barrel bridge. Very nice! It’s also my impression that the click spring is stronger in Sellita’s movements, to the point where it became a bit fiddly to fit the click itself. I think there’s a good reason for this. When the cogs of the winding pinion and sliding pinion begin to wear (which only happens when you manually wind the watch), the pressure from the click on the crown wheel (which can move sideways away from the ratchet wheel) needs to be high enough to prevent the teeth of the crown wheel from slipping over those of the ratchet wheel. This could result in the ratchet wheel losing grip on the mainspring (not good!). This issue only manifests when you wind the watch manually. I’ve written about this issue in this thread/post. In short, I believe Sellita has solved this problem by making the click spring stiffer. Another sign of good manufacturing precision is the wonderful feeling when setting the time. The play you almost always feel in the crown of ETA movements is almost completely eliminated. It’s not at all stiff, just very precise. What unfortunately doesn’t impress me is Sellita’s assembly instructions. However, the documentation, unlike ETA’s, includes several exploded diagrams with part measurements. Personally, I don’t find this particularly useful, although it’s a nice touch. As for the assembly instructions themselves, there’s certainly room for improvement. The documentation is not particularly easy to understand and contain a few outright mistakes, such as showing that the escape wheel bearing on the main plate should first be oiled with 9010 and then with HP-1300. ETA isn’t entirely free from this issue, but their documentation is significantly more useful. And, of course, there’s nothing stopping you from using ETA’s documentation, as both movements are built in exactly the same way. This is something I actually recommend if you’re not experienced enough to not need the documentation. All in all, I would recommend the Sellita SW 200-1 over the ETA 2824-2. Not least because spare parts are readily available for independent watchmakers, meaning owners of watches with Sellita movements can generally expect faster and cheaper service and repairs. This also means they’re not dependent on the Swatch Group, which owns ETA, as well as brands like Hamilton, Tissot, Omega, Longines, Rado, Certina, Mido, and others, and doesn’t sell parts to independent watchmakers. In this respect, it’s better to choose a watch that houses a Sellita movement from brands like Oris, Baume & Mercier, Maurice Lacroix, Christopher Ward, or Stowa, to name a few. Additionally, ETA has started using plastic in some of its movements, which, for me at least, is a red flag and something I struggle to associate with high-quality Swiss movements. Thankfully, as far as I know, Sellita's movements are entirely free of plastic. Thanks for reading!

-

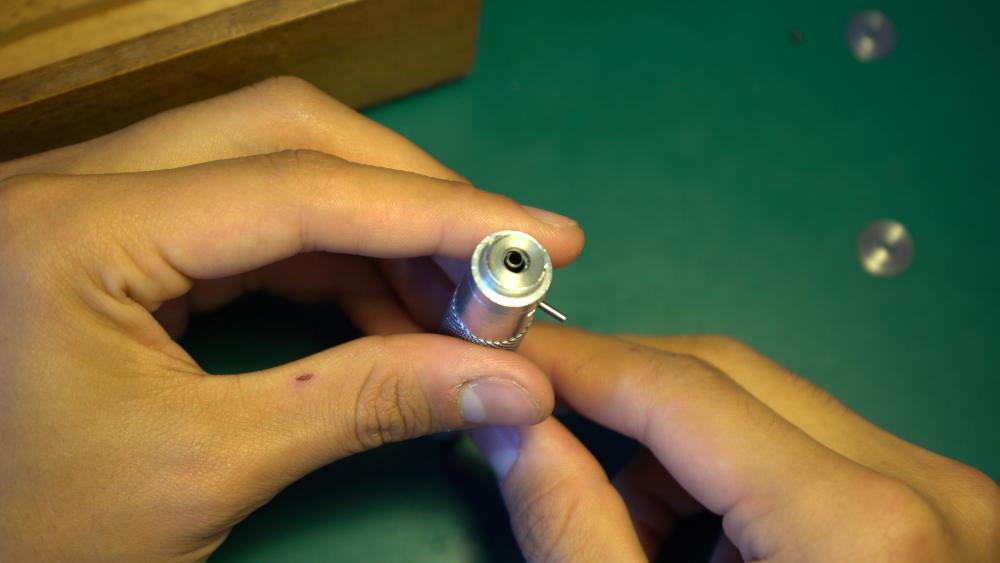

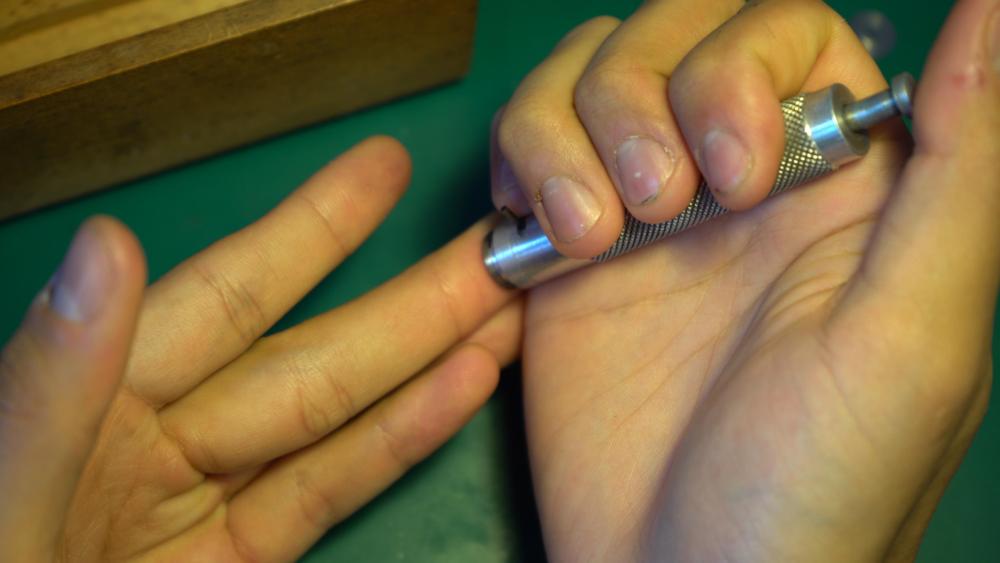

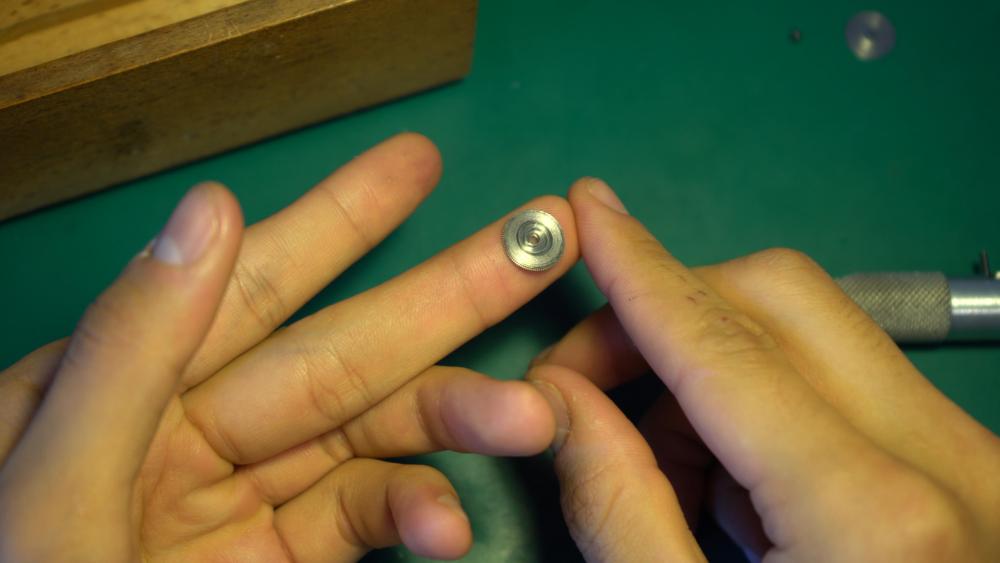

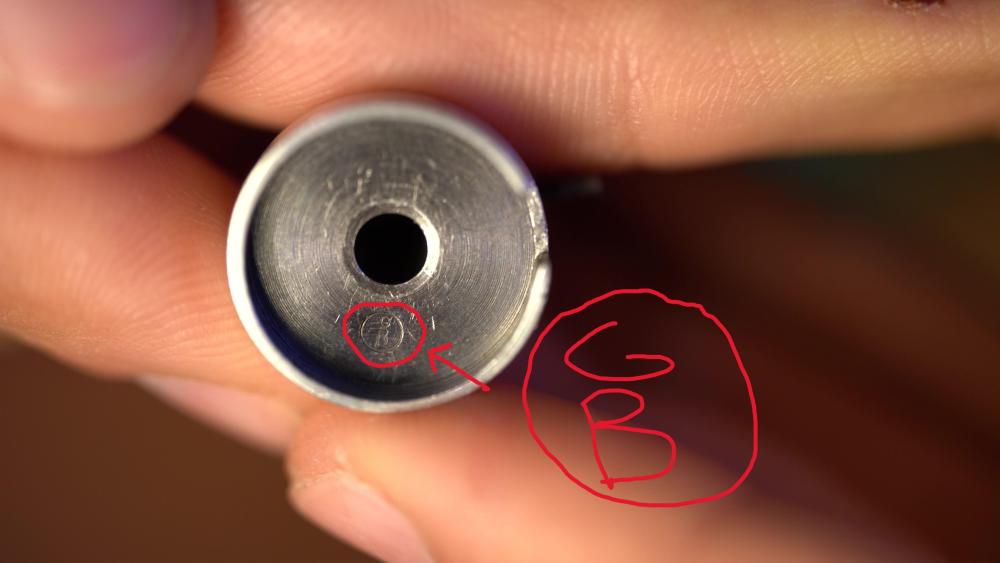

Hello Watchbangers! Today I return with another small post introducing my vintage mainspring winders! For those who prefer watching something rather than reading through the whole post, here is all the contents in form of a video: https://youtu.be/-63Do2Dkikk Now to the written part! While I first started winding mainsprings by hand ( and recommend this method for hobbyists who don't want to break their wallets) it was clear that I couldn't continue this practise due to the wear and damage it left on the mainspring and barrel! Thus I set out on the search for a pair of vintage Winders as the modern alternatives are not financially possible for a student. I was first eying american K&D winders or Watchcraft sets but coincidentally found a unbranded box of winders on Ebay for around 100 Euros: After inspecting and cleaning the set I was delighted to find that they were produced by Boley as they were stamped gB ( Gebrüder Boley) meaning Brothers Boley: The set came with 8 sized drums, their cranks and a holder! While I'm pretty sure that the hooks only point in one direction, I have tried winding left and right turning mainsprings with success, not sure what is going on there haha. Now the process of using these mainspring winders is the same as any other really! 1. You start by pressing the innermost coil of the spring down onto the arbor, making sure that the hook catches the mainspring latch. Be sure that you are attaching the mainspring the right direction/ way otherwise you will wind it wrong! 2. Then you slide the arbor into the drum and start turning the crank to wind the spring! Be careful on manual-wind springs when approaching the part of the spring which hooks into the barrel! If you go too fast these can catch the edge of the drum opening and break off! Just go slow and optionally help out with a tweezer for example! 3. Then carefully lift off the arbor, making sure that the innermost coil of the spring unlatches itself from the arbor hook again. This will make sure that the spring won't be pulled out as you remove the crank. I like using a pair of tweezers here! 4. Finally you just press down on the pusher, pressing the spring out of the winder into the cleaned and lubricated barrel drum underneath. While I am fully satisfied with the performance of my older set, I must say that it is a bit fidgety to use! The spring power often turns the barrel out of the holder slot leaving me no option other than to press against it firmly. Secondly, the lids of the cranks are also a bit bent. Occasionally, when the spring is almost fully wound in, the strong power allows the left over spring to slip between lid and barrel lip, scratching it around for one turn before I can press down firmly on the lid so the spring is wound into where it should be! I hope you guys are also as lucky in finding an affordable set of mainspring winders and if you have any other questions or comments, please put them down below!

- 2 replies

-

- 2

-

-

-

- mainspring winders

- review

-

(and 2 more)

Tagged with:

-

I’m working myself through Mark Lovic’s “Watch Repair Lessons & Courses”. Before enrolling I wasn’t sure the courses would be worthwhile to me, as I had spent a huge amount of time researching the Internet on how to service watches, and had serviced several Vostok 24XX movements (very affordable movements, BTW). Now, in hindsight, the courses have proved to be extremely valuable to me. I’ve learned things that I just haven’t been able to find elsewhere, like how to easily transfer watch oil from the bottles to the oil pots, how the get the right amount of oil onto the escape wheel teeth, how to remove rust from pinion leaves, that I shouldn’t oil the pallet fork jewel bearings (and why!). The list could be made very long. Anyway, yesterday I finished the level 2 section of the course, named “Lubrication and Re-Assembly”, and as I beheld the magic of seeing the movement come to life again I shoot a slow-motion video of its beating heart, i.e. the balance wheel. For anyone interested you can see the video here. Thanks for reading!

- 9 replies

-

- 4

-

-

- mark lovick

- watch repair lessons

-

(and 4 more)

Tagged with:

-

Hi there, I am new to the world of watch repair and ordered my first tools (screwdrivers, tweezers and the lot) to get started from Watchtool.co.uk. I have placed the order on January 23rd and paid by bank transfer (the only selectable option regardless their PayPal logo on the homepage). I haven't received the order and also can't track my parcel with the given track & trace number as it is non-existing with the carrier. Normally I would assume that it could take a while but I tried to contact them both by mail and phone, but they haven't replied. Does anyone have a recent experience with this web shop (part of the TWGC ltd.)? Thanks for sharing your experiences with me.

- 4 replies

-

- experience

- review

-

(and 3 more)

Tagged with: