Is this a problem?

-

Recently Browsing

- No registered users viewing this page.

-

Topics

-

Posts

-

Alex mentions the coils below the stud should remain the same as you move the regulator block along the terminal curve. Mine do that. What he doesn’t discuss and is used in the other video is how the regulator block is used to adjust rate and positional error. He also doesn’t mention how opening and closing the pins could and in my case does, alter amplitude In Alex’s video once he sets the stud he never adjusts the regulator pins yet every new movement I get have the pins signing closed.

-

The video I linked above does mention the spacing of the hairspring coils, and the importance of the regulator being able to move through its full range without distorting the hairspring - the terminal curve of the hairspring must be concentric with the regulator pins throughout the regulator’s range. If you meticulously follow every step in this video, the regulator system should behave as intended, regardless of the brand of the movement. Best Regards, Mark

-

By coreymsnow · Posted

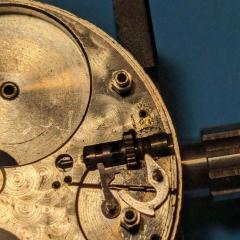

Hi friends! My mother got a bunch of old watches from a horologist who was retiring, and he subsequently passed away. It's been in her studio for years, and she showed it to me today and I just fell in love with it. Sadly, I don't know a darn thing about it yet. It's quite old, or at least seems to be. It has two winding arbors, but the key is missing. The crystal appears to be some kind of yellowed plastic, which is odd- I think it was replaced at some point to possibly protect it or something. If I had to guess, it's from the mid-19th century, given that it has no keyless works and that it says "Anchor Escapement" in French. It looks to be about 18 ligne, and the case fob is positioned in the upper right corner. The face is missing the dial, the hands, and a couple of the wheels that drive the hands- I think. But the movement itself seems to be in excellent shape. The serial number on the movement matches the number on the case- it's stamped on the movement and on the case in two places. I haven't started any disassembly yet, but I'm wondering if anyone can give me some idea of what kind of movement it is, and where I might look to see what parts are missing from the face. i may even have a dial that would fit it. It's in good enough shape that I think I could get it running, assuming I could find the missing parts. Any insights are vastly appreciated and thank you! Addendum: The inside of the case has some *very* tiny scratched numbers and letters in it, but I am having an extremely hard time seeing what they are. Like "N 99" and "No192X", They were clearly done with some kind of sharp stylus and maybe they mean when it was serviced or by who? Addendum the second: At least one of the scratches seems to say "N1921X" or maybe "W1921X". Serviced in 1921? And the inside lid of the case has the letters R H with a star between them, and a very tiny mark that says "ARGENT" in a u-shape. -

I’ve watched every video I can find on YouTube. Some of the info is contradictory and none mention the effect on amplitude or spring coil spacing which I observed. I was hoping someone here is a Seiko expert and knows these inside out.

-

This video explains how to set up and adjust the etachron regulator : I hope that helps, Mark

-

Recommended Posts

Join the conversation

You can post now and register later. If you have an account, sign in now to post with your account.

Note: Your post will require moderator approval before it will be visible.